同步辐射X射线成像法原位研究Al-15%Cu合金柱状晶-等轴晶转变以及无轴柱状枝晶生长

来源期刊:中国有色金属学报(英文版)2014年第7期

论文作者:李发国 东青 张佼 戴永兵 付亚楠 谢红兰 尹付成 孙宝德

文章页码:2112 - 2116

关键词:Al-15%Cu合金;定向凝固;柱状晶-等轴晶转变;同步辐射X射线成像

Key words:Al-15%Cu alloy; directional solidification; columnar to equiaxed transition; synchrotron X-ray radiography

摘 要:利用上海光源同步辐射装置(SSRF),通过原位及实时探测研究Al-15%Cu合金定向凝固。结果表明:外部热扰动激发柱状晶-等轴晶转变(CET)。当固-液界面前沿的溶质边界层较薄时,枝晶尖端碎片的分离和漂浮是转变的前奏。而枝晶的三角尖端是断裂敏感区域。只要条件合适,一种新的枝晶形貌将孕育和长大。这种枝晶没有明显的主枝臂,称为无轴柱状枝晶。

Abstract: Directional solidification of Al-15% (mass fraction) Cu alloy was investigated by in situ and real time radiography which was performed by Shanghai synchrotron radiation facility (SSRF). The imaging results reveal that columnar to equiaxed transition (CET) is provoked by external thermal disturbance. The detaching and floating of fragments of dendrite arms are the prelude of the transition when the solute boundary layer in front of the solid-liquid interface is thin. And the dendrite triangular tip is the fracture sensitive zone. When the conditions are suitable, new dendrites can sprout and grow up. This kind of dendrite has no obvious stem and is named anaxial columnar dendrites.

Trans. Nonferrous Met. Soc. China 24(2014) 2112-2116

Fa-guo LI1, Qing DONG1, Jiao ZHANG1, Yong-bing DAI1, Ya-nan FU2, Hong-lan XIE2, Fu-cheng YIN3, Bao-de SUN1,4

1. Shanghai Key Lab of Advanced High-temperature Materials and Precision Forming, Shanghai Jiao Tong University, Shanghai 200240, China;

2. Shanghai Institute of Applied Physics, Chinese Academy of Sciences, Shanghai 201800, China;

3. School of Mechanical Engineering, Xiangtan University, Xiangtan 411105, China;

4. State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University, Shanghai 200240, China

Received 17 October 2013; accepted 23 April 2014

Abstract: Directional solidification of Al-15% (mass fraction) Cu alloy was investigated by in situ and real time radiography which was performed by Shanghai synchrotron radiation facility (SSRF). The imaging results reveal that columnar to equiaxed transition (CET) is provoked by external thermal disturbance. The detaching and floating of fragments of dendrite arms are the prelude of the transition when the solute boundary layer in front of the solid-liquid interface is thin. And the dendrite triangular tip is the fracture sensitive zone. When the conditions are suitable, new dendrites can sprout and grow up. This kind of dendrite has no obvious stem and is named anaxial columnar dendrites.

Key words: Al-15%Cu alloy; directional solidification; columnar to equiaxed transition; synchrotron X-ray radiography

1 Introduction

The grain structure and morphology can strongly affect the properties of the alloy, such as hardness [1], tensile property [2-4], and weld ability [5]. In general, as-cast alloys exhibit columnar grain structures ended with an equiaxed zone, which indicates that columnar-to- equiaxed grain transition (CET) has taken place. Two mechanisms of CET are well known, one is due to spontaneous nucleation of equiaxed grains in the adjacent area ahead of growing interface, the other is subject to the growing of the fragments of dendrite arms during solidification [6]. However, the formation of fragments still keeps vague at some points including microflow in the interdendritic space and solute redistribution during complex solidification [7]. Transparent organic alloys, rapid quenching technique, mathematical and physical models and simulations based on modern computing techniques were commonly used to clarify the hazes during a long period [8-14]. Until the development of synchrotron radiation, the X-ray imaging became the powerful tool for metallurgists to unveil the indistinct solidification process [15]. Although some researchers focused their interests on CET for refinement of alloys by radiography [16-18], the internal mechanism behind CET phenomena was still the basic to clarify solidification process.

The preferred crystallographic direction of hypoeutectic Al-Cu alloy is <100>, however, it may grow into twined dendrite along [110] direction under conditions with high temperature gradient and high cooling rate [19-24]. In our previous work [25], a new directional solidification dendritic morphology was been observed in Al-15%Cu alloy, which was 2D-shape dendrite, i.e. so called anaxial dendrite, split by a narrow liquid gap at the center. In the present work, the morphology of solidification structure of Al-Cu alloys was studied by synchrotron radiography using Shanghai synchrotron radiation facility (SSRF, China). Based on the imaging observations, the behaviors of fragment in front of S/L interface and the tip growth model of anaxial dendrite were discussed.

2 Experimental

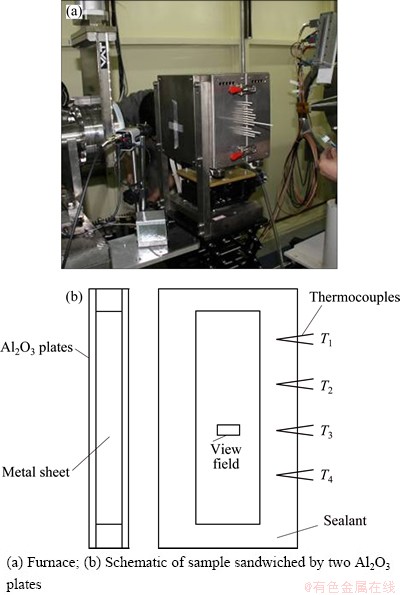

The experiments were carried out with a resistance furnace with two opposite windows (Fig. 1). Al-15%Cu alloy was prepared by Al and Cu (purity of 99.999%) in a graphite crucible. Rectangular slices with 60 mm × 15 mm × 0.7 mm in size were cut and sandwiched between two 120 μm thick Al2O3 sheets. The edge of the samples was sealed by high temperature adhesive. Four thermocouples were embedded into the sample with an interval of 8 mm along the side of the sample to control and measure the temperature. The solidification rig was set at beam line BL13W1 of SSRF for radiographic experiments.

Fig. 1 Synchrotron radiation imaging experiment device

The sample was fixed upright in the holder and heated to the temperature about 60 K higher than the melting point of the alloy. Holding at that point for 60 min to homogenize the melt, the sample was cooled by a gas cooler set at the bottom of the sample. The cooling rate was kept at 0.146 K/s with a thermal gradient G=4.0 K/mm. A sudden increase of argon flow was induced to trigger CET and the instantaneous cooling rate reached 0.250 K/s. The sequence images of solidification were captured by X-ray phase contrast imaging method [26]. In the image, grey scale corresponded to the Cu composition in both liquid and solid zones. An incident monochromatic X-ray energy of 20 keV was employed. A detector dead time was 0.2 s between each frames, and the exposure time was 3.5 s.

3 Results and discussion

3.1 Fracture location

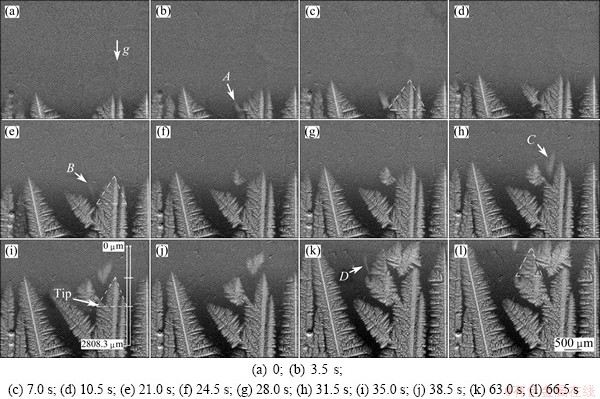

Figure 2 presents the dendrite arms successively fragmenting from the tip of the columnar dendrite. The fracture of fragments occurred at the similar location for the dendrite, where was a triangle profile of the dendrite tip. The height of the dendrite tips triangle profile (d) was measured according to the scale of the image, and the values of d for different fragments were 850, 950, 700 and 900 μm, respectively.

3.2 Solute distribution of liquid at mash zone

Figure 2(a) shows that the brightness of the large area melt zone far away from the growth interface is relatively light and uniform. It indicates that the solute concentration almost keeps uniform along growth direction. However, the brightness of the residual melt in the interdendritic space is darker than that of melt far from growth interface due to the Cu element segregation during solidification, as well as the brightness of the melt ahead of the growth interface.

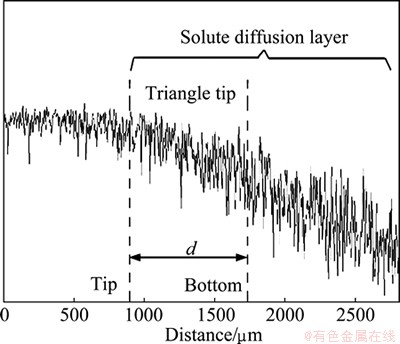

In order to better present the solute distribution in the solute diffusion layer, a relative comparison for the brightness along the vertical direction was carried out (Fig. 3). The variation curve of brightness in Fig. 3 corresponds to the change of the melt concentration, which is between the two columnar dendrites. From the dendrite tip to the mushy zone, the brightness decreases with the increasing of the distance, showing that Cu concentration increases with the increasing of the distance.

Dendrite tip triangle zone is in the solute intensive increase area, which will stimulate greater thermal disturbance easily and results in the high order dendrite root re-melting and fracture. The equilibration time for thermal diffusion (tTeq) or solute diffusion (tCeq) can be estimated from tTeq≈d2/α and tCeq≈d2/DL, respectively, where α is the thermal diffusivity (5.69×10-5 m2/s) and DL is the diffusivity of copper in molten aluminum (3.5×10-9 m2/s) [27]. For the tip triangle zone, the tTeq and tCeq are about 14 ms and 231.4 s, respectively. Therefore, when the triangle zone liquid is forced to flow between the dendrites arms, the temperature rapidly equilibrates to the new microenvironment, but the liquid solute concentration is unable to adjust quickly, and persists for longer times in a metastable state.

Fig. 2 Columnar-to-equiaxed transition during directional solidification of Al-15%Cu sample at different time

Fig. 3 Changes of brightness along straight line direction in Fig. 2(i)

Under a quasi-static condition that growth (or coarsening) is comparatively slow, the temperature of the interface T* at any point on the surface of the solid is given by

T*=Tf+mLC*L-ΓK* (1)

ΔC*L=C*L1-C*L0 (2)

ΔK*=K*1-K*0 (3)

where Tf is the equilibrium freezing temperature of the alloy; mL is the slope of the liquidus; C*L is the liquid composition at the interfacel; Γ is the Gibbs–Thomson coefficient; K* is the local curvature of the interface at the dendrite root, K*=1/r, and the r is the radius of necking at the root. As previously described, there will be only a negligible change in the interface temperature due to the much faster equilibration of temperature (ΔT*→0). Therefore, Eq. (1) can be expressed as

mLΔC*L=ΓΔK*=Γ(1/r1-1/r0) (4)

Equation (4) shows that, under otherwise constant conditions, changes in the local liquid concentration in the dendrite root will induce changes in the local curvature. If induced movement of the liquid causes an enrichment at the interface (mLΔC*L is positive), then a driving force exists for an increase in r1, which will promote dendrite root remelting.

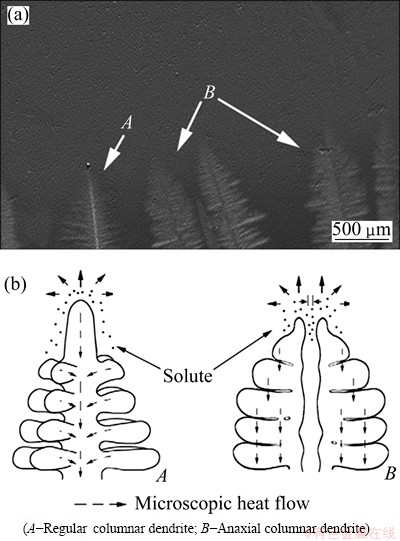

3.3 Growth of anaxial columnar dendrites

Anaxial columnar dendrites have special growth characteristics that are far different from regular dendrites. There is no axis (primary arm) as the trunk of a dendrite. It is composed of a pair of laterally growing dendrites which are split by a linear liquid zone. In this synchrotron imaging work, it is very coincidental to capture the images of the anaxial columnar dendrites at the time of early, as shown in Fig. 4(a). The four branches (named B) on the right side of Branch A have no obvious primary arm. These so-called anaxial columnar dendrites are much darker in the center of the branches, indicating that there is a liquid phase with a relatively high solute composition in the central areas of those dendrites. It should be noted that this kind of columnar dendrites may have aborted primary arms. Their secondary arms are symmetric with respect to the central liquid zone and arranged much more closely.

Fig. 4 Two kinds of columnar dendrites (a) and schematic diagrams of tips of columnar dendrites (b)

Velocity estimates for the dendrite tips are found straight forward as

Vtip(t)=(Ltip(t+Δt)-Ltip(t-Δt))/2Δt (5)

where Ltip is the tip positions related to a fixed origin. The Vtip(t) of the anaxial dendrite versus that of the regular dendrite is about 1.35. The solidification speed is proportional to the heat transfer speed. It indicates that the growth models of split tip and needle tip are different. Heat conduction and solute diffusion decide the solidification model, so in this work, tip growth model from the heat conduction point of view will be established. For the regular columnar dendrite, its secondary arms are not joined to each other. The gaps between the secondary arms are filled with melt with lower thermal conductivity. So the primary arm is the main path for heat transfer. The directions of the microscopic heat flows are shown in the left part of Fig. 4(b). For the anaxial columnar dendrite, because the secondary arms adhere with each other, the latent heat can be transferred directly through the closely arranged secondary arms, as shown in the right part of Fig. 4(b). So the secondary arms show an obvious growth preference. It is obvious that the dissipation area of anaxial dendrite is much larger than that of regular dendrite, so the anaxial dendrite grows faster.

4 Conclusions

1) The natural convection caused by external thermal disturbance leads to growth interface instability and then CET.

2) During directional solidification, the well- developed dendrites of hypoeutectic alloy can form open solute enriched zones. The zones are the only area in which the high order arms of dendrite can detach from matrix.

3) New anaxial columnar dendrite was found during directional solidification of the Al-15%Cu alloy. The anaxial columnar dendrite is composed of a pair of stems, which are divided by a narrow liquid zone located in its center, with the different heat transfer model other than normal columnar dendrite.

References

[1] SHUVARIKOVA E P. Influence of fan structure on the quality of heavy extruded shapes of AMg6 alloy [J]. Metal Science and Heat Treatment, 1986, 28(8): 613-617.

[2] HE K Z, YU F X, ZHAO D Z, ZUO L. Effects of phosphorus modification on morphology of primary silicon particles and mechanical properties of wrought Al-17.5Si-4.5Cu-1Zn-0.7Mg- 0.5Ni alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2081-2087. (in Chinese)

[3] WANG J F, WEI W W, LI L, LIANG H, PAN F S. Effects of Y and Zn on mechanical properties and damping capacity of Mg-Cu-Mn alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(10): 1846-1850.

[4] JIANG W J, LI F, YU G S, TAN C G, LIN J G. Microstructure and mechanic properties of multi-phase Ti based composite [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(6): 1041-1045. (in Chinese)

[5] ZHAO G J, SHENG G M, LUO J. Influence of rapid solidification on characteristics of Sn-6.5Zn solder alloy and mechanical properties of solder/Cu joints [J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2805-2810. (in Chinese)

[6] MARTORANO M A, BECKERMANN C, GANDIN C A. A solutal interaction mechanism for the columnar-to-equiaxed transition in alloy solidification [J]. Metallurgical and Materials Transactions A, 2003, 34(8): 1657-1674.

[7] RUVALCABA D,MATHIESEN R H, ESKIN D G, ARNBERG L, KATGERMAN L. In situ observations of dendritic fragmentation due to local solute-enrichment during directional solidification of an aluminum alloy [J]. Acta Materialia, 2007, 55(13): 4287-4292.

[8] AKAMATSU S,BOTTIN-ROUSSEAU S, PERRUT M, FAIVRE G, WITUSIEWICZ V T, STURZ L. Real-time study of thin and bulk eutectic growth in succinonitrile–(D) camphor alloys [J]. Journal of Crystal Growth, 2007, 299(2): 418-428.

[9] LIU S, MAZUMDER P, TRIVEDI R. A new thermal assembly design for the directional solidification of transparent alloys [J]. Journal of Crystal Growth, 2002, 240(3-4): 560-568.

[10] CHARPENTIER M, DALOZ D, GAUTIER E, LESOULLT G, HAZOTTE A, GRANGE M. Study of microstructure and solute partitioning in a cast Ti-48Al-2Cr-2Nb alloy by quenching during directional solidification technique [J]. Metallurgical and Materials Transactions A, 2003, 34(10): 2139-2148.

[11] LI X, GAGNOUD A, FAUTRELLE Y, REN Z M, MOREAU R, ZHANG Y D, ESLING C. Dendrite fragmentation and columnar-to- equiaxed transition during directional solidification at lower growth speed under a strong magnetic field [J]. Acta Materialia, 2012, 60(8): 3321-3332.

[12] ARES A E, GUEIJMAN S F, SCHVEZOV C E. An experimental investigation of the columnar-to-equiaxed grain transition in aluminum-copper hypoeutectic and eutectic alloys [J]. Journal of Crystal Growth, 2010, 312(14): 2154-2170.

[13] DONG H B, LEE P D. Simulation of the columnar-to-equiaxed transition in directionally solidified Al-Cu alloys [J]. Acta Materialia, 2005, 53(3): 659-668.

[14] HE B L, LI Q P, QI Q Y, YAO X D. Numerical simulation of microstructure formation of AZ91 using mCA method [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(3): 1681-1684.

[15] ARNBERG L, MATHIESEN R H. The real-time, high-resolution X-ray video microscopy of solidification in aluminum alloys [J]. JOM, 2007, 59(8): 20-26.

[16] REINHART G,  N, NGUYEN-THI H, SCHENK T, GASTALDI J, BILLIA B, PINO P,

N, NGUYEN-THI H, SCHENK T, GASTALDI J, BILLIA B, PINO P,  J, BARUCHEL J. Investigation of columnar-equiaxed transition and equiaxed growth of aluminium based alloys by X-ray radiography [J]. Materials Science and Engineering A, 2005, 413-414: 384-388.

J, BARUCHEL J. Investigation of columnar-equiaxed transition and equiaxed growth of aluminium based alloys by X-ray radiography [J]. Materials Science and Engineering A, 2005, 413-414: 384-388.

[17] SCHENK T, NGUYEN THI H, GASTALDI J, REINHART G, CRISTIGLIO V,  N, KLEIN H,

N, KLEIN H,  J, GRUSHKO B, BILLIA B, BARUCHEL J. Application of synchrotron X-ray imaging to the study of directional solidification of aluminium-based alloys [J]. Journal of Crystal Growth, 2005, 275(1-2): 201-208.

J, GRUSHKO B, BILLIA B, BARUCHEL J. Application of synchrotron X-ray imaging to the study of directional solidification of aluminium-based alloys [J]. Journal of Crystal Growth, 2005, 275(1-2): 201-208.

[18] DONG Q, ZHANG J, DONG J F, XIE H L, LI Z J, DAI Y B, LIU Y, SUN B D. In situ observation of columnar-to-equiaxed transition in directional solidification using synchrotron X-radiation imaging technique [J]. Materials Science and Engineering A, 2011, 530: 271-276.

[19] HENRY S, JARRY P, RAPPAZ M. <110> dendrite growth in aluminum feathery grains [J]. Metallurgical and Materials Transactions A, 1998, 29(11): 2807-2817.

[20] HENRY S, MINGHETTI T, RAPPAZ M. Dendrite growth morphologies in aluminium alloys [J]. Acta Materialia, 1998, 46(18): 6431-6443.

[21] SALGADO-ORDORICA M A, RAPPAZ M. Twinned dendrite growth in binary aluminum alloys [J]. Acta Materialia, 2008, 56(19): 5708-5718.

[22] SALGADO-ORDORICA M A, VALLOTON J, RAPPAZ M. Study of twinned dendrite growth stability [J]. Scripta Materialia, 2009, 61(4): 367-370.

[23] SALGADO-ORDORICA M A, DESBIOLLES J L, RAPPAZ M. Study of the twinned dendrite tip shape I: Phase-field modeling [J]. Acta Materialia, 2011, 59(13): 5074-5084.

[24] SALGADO-ORDORICA M A, BURDET P, CANTONI M, RAPPAZ M. Study of the twinned dendrite tip shape II: Experimental assessment [J]. Acta Materialia, 2011, 59(13): 5085-5091.

[25] DONG Q, ZHANG J, DONG J F, DAI Y B, BIAN F G, XIE H L, LU Y L, SUN B D. Anaxial columnar dendrites in directional solidification of an Al-15wt.% Cu alloy [J]. Materials Letters, 2011, 65(21-22): 3295-3297.

[26] MATHIESEN R H, ARNBERG L,  K, WEITKAMP T, RAU C, SNIGIREV A. Time-resolved X-ray imaging of aluminum alloy solidification processes [J]. Metallurgical and Materials Transactions B, 2002, 33(4): 613-623.

K, WEITKAMP T, RAU C, SNIGIREV A. Time-resolved X-ray imaging of aluminum alloy solidification processes [J]. Metallurgical and Materials Transactions B, 2002, 33(4): 613-623.

[27] QUARESMA J M V, SANTOS C A, GARCIA A. Correlation between unsteady-state solidification conditions, dendrite spacings, and mechanical properties of Al-Cu alloys [J]. Metallurgical and Materials Transactions A, 2000, 31(12): 3167-3178.

李发国1,东 青1,张 佼1,戴永兵1,付亚楠2,谢红兰2,尹付成3,孙宝德1,4

1. 上海交通大学 上海先进高温材料及精密成型重点实验室,上海 200240;

2. 中国科学院 上海应用物理所,上海 201800;

3. 湘潭大学 机械工程学院,湘潭 411105;

4. 上海交通大学 金属基复合材料国家重点实验室,上海 200240

摘 要:利用上海光源同步辐射装置(SSRF),通过原位及实时探测研究Al-15%Cu合金定向凝固。结果表明:外部热扰动激发柱状晶-等轴晶转变(CET)。当固-液界面前沿的溶质边界层较薄时,枝晶尖端碎片的分离和漂浮是转变的前奏。而枝晶的三角尖端是断裂敏感区域。只要条件合适,一种新的枝晶形貌将孕育和长大。这种枝晶没有明显的主枝臂,称为无轴柱状枝晶。

关键词:Al-15%Cu合金;定向凝固;柱状晶-等轴晶转变;同步辐射X射线成像

(Edited by Chao WANG)

Foundation item: Project (51001074) supported by the National Natural Science Foundation of China; Project (12ZR1414500) supported by Shanghai Municipal Natural Science Fund of China; Project (2012CB619505) supported by the National Basic Research Program of China

Corresponding author: Jiao ZHANG; Tel: +86-21-54747387; Fax: +86-21-34202951; E-mail: zj119@sjtu.edu.cn

DOI: 10.1016/S1003-6326(14)63320-3