DOI: 10.11817/j.issn.1672-7207.2015.01.012

NiAl-2.5Ta-7.5Cr合金的室温摩擦磨损性能

张孟恩1,王振生1, 2,郭源君1,郭建亭3,周兰章3,杨双双1

(1. 湖南科技大学 机械设备健康维护湖南省重点实验室,湖南 湘潭,411201;

2. 湖南科技大学 高温耐磨材料及制备技术湖南省国防科技重点实验室,湖南 湘潭,411201;

3. 中国科学院金属研究所,辽宁 沈阳,110016)

摘要:采用SEM和XRD分析NiAl-2.5Ta-7.5Cr合金的微观组织,用万能力学试验机测试合金的力学性能,用高速往复摩擦磨损试验机研究合金的室温摩擦磨损特性。研究结果表明:NiAl-2.5Ta-7.5Cr合金由NiAl相、NiAl-Cr共晶和Cr2Ta相组成,其强度和塑性良好。在低P1/2·v (P为载荷,v为速度)下,合金的磨损机制为磨粒磨损,随着P1/2·v的增加,摩擦热效应增强,合金的磨损机制逐渐转变为黏着磨损,摩擦因数和磨损率增加;当P1/2·v>0.54 N1/2·m/s时,摩擦热效应逐渐导致摩擦表面形成了无定形层,无定形层具有自修复特性,部分或全部隔离了摩擦副的直接接触,磨损机制逐渐转变为氧化磨损,磨损率快速降低后保持稳定,摩擦因数逐渐降低;当P1/2·v≥4.02 N1/2·m/s时,合金磨损表面开始出现疲劳磨损特征,表面剥落导致合金的磨损率升高。

关键词:NiAl-2.5Ta-7.5Cr合金;摩擦磨损性能;磨损机制;无定形层

中图分类号:TH117;TG146 文献标志码:A 文章编号:1672-7207(2015)01-0088-06

Friction and wear behavior of NiAl-2.5Ta-7.5Cr alloy at room temperature

ZHANG Mengen1, WANG Zhensheng1, 2, GUO Yuanjun1, GUO Jianting3,

ZHOU Lanzhang3, YANG Shuangshuang1

(1. Hunan Provincial Key Laboratory for Health Maintaining of Mechanical Equipment,

Hunan University of Science and Technology, Xiangtan 411201, China;

2. Hunan Provincial Key Defense Laboratory of High Temperature Wear-resisting Materials and Preparation Technology, Hunan University of Science and Technology, Xiangtan 411201, China;

3. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The microstructure and properties of NiAl-2.5Ta-7.5Cr alloy were investigated. The microstructure was analyzed by SEM and XRD, the mechanical properties were conducted by a universal mechanical testing machine, and the friction and wear features at room temperature were studied using a friction and wear tester of high speed reciprocating. The results show that the NiAl-2.5Ta-7.5Cr alloy consists of NiAl, NiAl-Cr eutectic and Cr2Ta, and that makes the alloy have good strength and plasticity. The wear mechanism of alloy is abrasive wear in low P1/2·v. With the increase of P1/2·v, the wear mechanism of NiAl-2.5Ta-7.5Cr alloy gradually transforms itself into the adhesive wear, and at the same time both the wear rate and friction coefficient increase. When P1/2·v is greater than 0.54 N1/2·m/s, the wear mechanism gradually turns into the oxidation wear mechanism. The friction pairs are divided with the amorphous layer formed on the wearing surface. The wear rate keeps stable after decreasing rapidly, and the friction coefficient gradually decreases under the condition. Fatigue wear characteristics appear when P1/2·v is greater than 4.02 N1/2·m/s, and the surface spalling leads to high wear rate.

Key words: NiAl-2.5Ta-7.5Cr alloy; friction and wear properties; wear mechanism; amorphous layer

金属间化合物NiAl具有熔点高(1 640 ℃)、密度低(5.86 g/cm3)、弹性模量高(184 GPa)、导热性好(70~80 W/(m·K))、抗氧化性能优异等一系列优点,是极具潜力的新一代高温结构材料[1-3]。然而除用作发动机的结构材料外,NiAl金属间化合物及其合金具有作为苛刻环境下的抗磨材料的潜在应用前景[4-5]。有研究表明:在与SiC配副的条件下,NiAl的抗磨性能优于Fe3Al,TiAl 和MoSi2等金属间化合物以及Al2O3和PS-ZrO2陶瓷材料的抗磨性能[6],TiB2硬质陶瓷颗粒的加入可进一步提高NiAl的耐磨性能[7]。王振生等[8-9]在700~900 ℃的高温摩擦磨损中发现:NiAl基合金(合金含有W,Mo和Co)具有良好的持久自润滑性能和较好的耐磨损性能,摩擦因数和磨损率低于Ni基高温合金。进一步添加S元素[10-11],NiAl基合金在200~ 400 ℃也可以产生良好的持久自润滑特性。鉴于NiAl合金的应用前景,多年来,人们通过多种强化方法提高合金的蠕变强度和室温韧性[12]。其中,Ta可以提高NiAl基合金[13-15]的蠕变强度,Cr有利于提高NiAl-Ta-X(X代表Cr,Mo,V)系合金[16]的室温韧性。故NiAl-2.5Ta-7.5Cr[17]合金具有优异的高温性能和可容忍的室温韧性,应用前景较好。为此,本文作者对NiAl-2.5Ta-7.5Cr合金的摩擦磨损性能进行研究。

1 实验

实验采用高纯金属Ni,Al,Ta和Cr(>99.9%,质量分数),用高真空电弧炉,按名义成分NiAl-2.5Ta-7.5Cr(摩尔分数,%) 熔炼合金。采用HRS-2M高速往复摩擦磨损试验机测试合金的摩擦磨损性能。用线切割方法切取厚度为4 mm的NiAl-2.5Ta-7.5Cr合金试样,表面磨至1200号砂纸,经丙酮+酒精超声波清洗,烘干。配副试样为直径4 mm的Si3N4陶瓷球。载荷施加于球,试样在夹具带动下往复运动,形成球和试样接触表面的滑动磨损。实验在大气和干摩擦条件下进行,空气相对湿度为30%。往复滑行频率为5,10,20,30和45 Hz,载荷为10,45,80和118 N,单次往复滑动距离为10 mm,磨损时间为20 min。摩擦因数由设备监控记录,取稳定后摩擦因数的平均值。磨损体积量用NanoMap-500LS三维接触式表面轮廓仪测得。磨损率计算公式为W=V/(F·L)(其中W为磨损率,V为磨损体积损失,F为载荷,L为滑行距离)。利用万能力学试验机测试合金室温压缩强度,压缩应变速率为2.8×10-3 s-1,压缩样品的长×宽×高为4 mm×4 mm×6 mm,表面磨至800号砂纸。采用D/Max-2550型 X线衍射仪分析合金的相组成。采用HV-50维氏硬度计测试合金的维氏硬度。利用配置了能谱仪(EDS)的S-3400N型扫描电镜(SEM)和光学显微镜(OM)观察合金组织形貌和摩擦表面形貌。

2 实验结果与讨论

2.1 NiAl-2.5Ta-7.5Cr合金的组织与力学性能

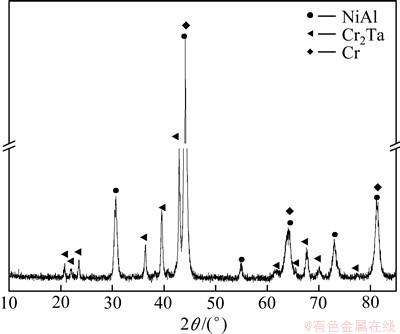

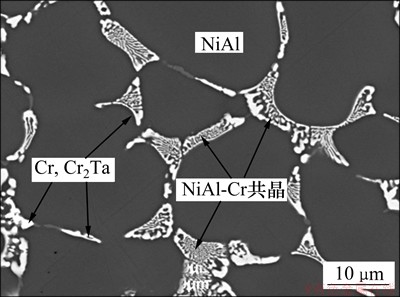

图1所示为NiAl-2.5Ta-7.5Cr合金的X线衍射图谱,图2所示为NiAl-2.5Ta-7.5Cr合金的背散射(BSE)照片。结合EDS图谱,可见合金的组织由黑色NiAl相、灰白色NiAl-Cr共晶相以及白色的Cr2Ta相组成。

NiAl-2.5Ta-7.5Cr合金室温抗压强度为1 411 MPa,弹性模量为138 GPa,维氏硬度为549 HV,压缩率为25.9 %。NiAl-2.5Ta-7.5Cr合金良好的室温强度和塑性对于其作为室温下应用的耐磨材料非常有利。

图1 NiAl-2.5Ta-7.5Cr合金的XRD谱

Fig. 1 XRD pattern of NiAl-2.5Ta-7.5Cr alloy

图2 NiAl-2.5Ta-7.5Cr合金的背散射组织形貌

Fig. 2 SEM-BSE image of NiAl-2.5Ta-7.5Cr alloy

2.2 NiAl-2.5Ta-7.5Cr合金的摩擦磨损性能与机理

2.2.1 摩擦磨损性能

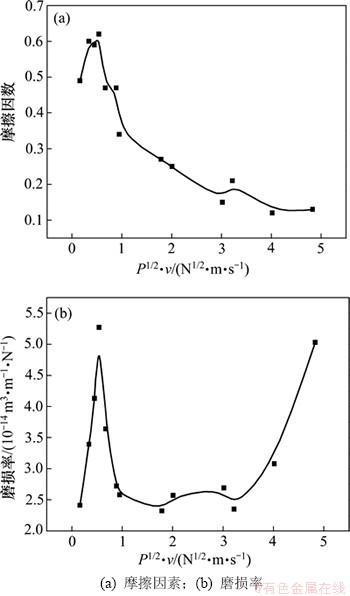

图3所示为NiAl-2.5Ta-7.5Cr合金的摩擦磨损性能曲线。从图3可以看出:P1/2·v为0.16 N1/2·m/s时,合金的摩擦因数为0.49,磨损率为2.41×10-14m3/(m·N)。随着P1/2·v的增加,合金的摩擦因数和磨损率增加。当P1/2·v增大至0.54 N1/2·m/s时,合金的摩擦因数和磨损率均达到最高值,此后,随着P1/2·v的增加,合金的摩擦因数逐渐降低,磨损率快速降低后基本保持稳定。当P1/2·v>3.22 N1/2·m/s时,合金的摩擦因数继续降低,磨损率开始升高。

图3 不同P1/2·v下NiAl-2.5Ta-7.5Cr合金的摩擦磨损性能

Fig. 3 Friction and wear properties of NiAl-2.5Ta-7.5Cr alloy at different P1/2·v

2.2.2 磨损机理

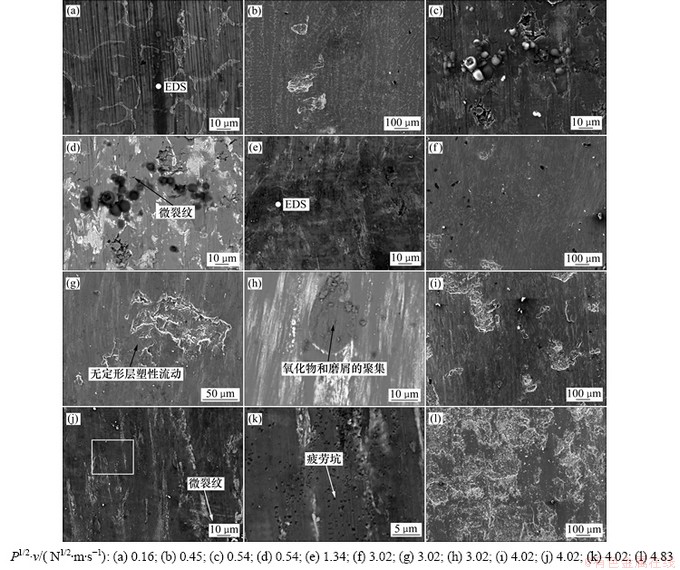

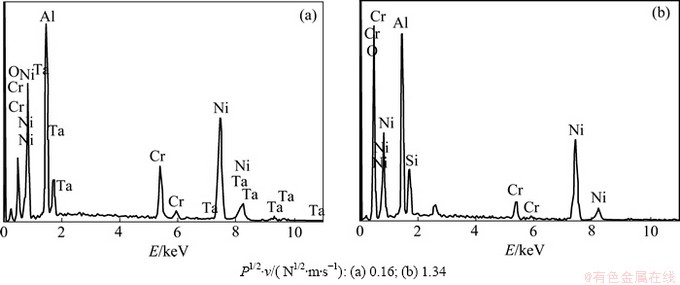

当P1/2·v为0.16 N1/2·m/s时,高倍SEM下可以看到:合金磨损表面存在大量的犁沟及少量的黑色膜特征(图4(a)),黑色膜的EDS分析发现主要含有镍、铝、铬和钽元素,并含有少量的氧元素(图5(a)),可能存在少量的氧化物。随着P1/2·v的增加,合金磨损表面开始出现剥落特征(图4(b)),并逐渐开始出现黏着、裂纹和塑性变形特征(图4(c)和4(d)),磨粒磨损特征减弱。

对于一个固定配对的摩擦副来说,当P1/2·v为常数时,温升也应当是常数[18],随着P1/2·v增大,摩擦热效应增强。低P1/2·v时,磨损表面的温度低,合金的强度和硬度较高,塑性较低,由于NiAl合金的脆性强[12],合金表面微凸体在硬的Si3N4陶瓷球滑动作用下会发生脱落,Si3N4陶瓷球表面微凸体对合金表面产生犁削作用,脱落的磨屑在往复滑动过程中发生加工硬化,硬化的颗粒也犁削合金表面。故P1/2·v为0.16 N1/2·m/s时,合金的磨损机制为磨粒磨损,犁削导致合金的摩擦因数较高。随着P1/2·v增大,摩擦表面温度升高导致合金强度和硬度降低,塑性增加[19],由于合金中不同相的力学特征不同,合金磨损表面中各相的塑性变形不协调将产生裂纹(图4(c)和4(d)),裂纹导致磨损表面合金的剥落,故合金的磨损率逐渐升高;局部接触峰顶可能发生焊合和转移,磨损机制逐渐由磨粒磨损转变为黏着磨损,黏着磨损的增强导致合金的摩擦因数逐渐升高。

随着P1/2·v的进一步增加,由图4(e)可以看出:摩擦表面逐渐变得较为平整,塑性变形特征增强,剥落特征减弱,摩擦表面存在大量的黑色膜。EDS分析发现:黑色膜中存在氧、镍、铝、铬和硅元素(图5(b)),硅元素是从对磨件Si3N4陶瓷球上转移过来的。对比图5(a),黑色膜中的氧元素含量大幅度增加,其中含有较多氧化物。黑色膜随P1/2·v的增加而增加,最后,基本覆盖了全部磨损表面(图4(f))。

这是由于随着P1/2·v的增大,表面温度升高,生成的氧化物增多,摩擦热又致使表面合金流动现象增强,表面层在类似抛光过程中被熔化,由于底材金属的高热导率,熔化的表面层可能迅速凝固生成一层无定形层[18]。结合EDS分析结果,这层无定形层为氧化物与基体材料的混合层,这层膜部分或全部隔离了摩擦副的直接接触,形成无定形层/Si3N4的磨损状态,由于无定形层具有良好的减摩和耐磨效果[8~11],故合金的摩擦因数逐渐降低,磨损率快速降低后保持稳定。另外,SEM还发现磨损表面无定形层剥落区域存在自修复的特征,修复方式有2种:一是剥落区域周围的无定形层在摩擦力和压力的作用下发生塑性流动填补剥落处(图4(g)),二是氧化物和磨屑颗粒在摩擦过程中在剥落处聚集,在摩擦热和摩擦功的共同作用下发生微区热压烧结[20-21]和摩擦化学反应[22],生成无定形层(图4(h))。摩擦表面无定形层的自修复特性有利于合金产生持久的低摩擦因数和低磨损率。

当P1/2·v增加到4.02 N1/2·m/s时,摩擦表面剥落特征增强(图4(i));高倍SEM下发现,摩擦表面有少量的裂纹特征(图4(j)),并有显著的疲劳剥落凹坑存在(图4(k))。这可能是由于,此工况下,滑动速度过高,在高速往复应力作用下,磨损表面合金经受反复的弹性变形,致使表面材料发生疲劳磨损,故磨损率升高。

另外,高的P1/2·v致使摩擦热效应进一步加强,易于表面无定形层的形成,温度的升高又降低了无定形层的剪切强度,进一步降低摩擦因数。因而,当P1/2·v增加到4.83 N1/2·m/s时,虽然磨损表面无定形层遭到严重破坏(图4(l)),但其摩擦因数仍很低。

图4 不同P1/2·v下NiAl-2.5Ta-7.5Cr合金的摩擦磨损表面形貌

Fig. 4 Wear morphology of NiAl-2.5Ta-7.5Cr alloy at different P1/2·v

图5 NiAl-2.5Ta-7.5Cr合金的摩损表面黑色膜EDS图

Fig. 5 EDS spectra of NiAl-2.5Ta-7.5Cr alloy’s black wear surfaces

3 结论

1) NiAl-2.5Ta-7.5Cr合金由NiAl相、Cr2Ta相和NiAl-Cr共晶相组成,其强度和塑性良好。

2) 当P1/2·v为0.16 N1/2·m/s时,合金的磨损机制为磨粒磨损;随着P1/2·v的增加,合金的磨损机制逐渐转变为黏着磨损,摩擦因数和磨损率增加。P1/2·v>0.54 N1/2·m/s时,摩擦热效应导致磨损表面氧化物增多,磨损机制逐渐转变为氧化磨损,摩擦表面形成的无定形层部分或全部隔离了摩擦副的直接接触,磨损率快速降低后保持稳定,摩擦因数逐渐降低。P1/2·v增加至4.02 N1/2·m/s时,合金磨损表面出现疲劳磨损特征,摩擦表面剥落特征增加,磨损率快速升高。

3) 无定形层通过2种方式产生自修复特性。一是无定形层塑性流动填平摩擦表面剥落处,二是氧化物和磨屑颗粒在摩擦过程中在较低处聚集,在摩擦热和摩擦功的共同作用下发生微区热压烧结和摩擦化学反应,生成无定形层。

参考文献:

[1] 郭建亭. 有序金属间化合物镍铝合金[M]. 北京: 科学出版社, 2003: 58.

GUO Jianting. Ordered intermetallic compound NiAl alloy[M]. Beijing: Science Press, 2003: 58.

[2] Noebe R D, Bowman R R, Nathal M V. Physical and mechanical properties of the B2 compound NiAl[J]. Inter Mater Rev, 1993, 38(4): 193-232.

[3] Miracle D B. The physical and mechanical properties of NiAl[J]. Acta Metall Mater, 1993, 41(3): 649-684.

[4] 周文龙, 郭建亭, 张士宏. 镍铝金属间化合物磨损研究进展[J]. 铸造, 2003, 52(S): 836-838.

ZHOU Wenlong, GUO Jianting, ZHANG Shihong. Progress inwear research on NiAl intermetallic alloys[J]. Foundry, 2003, 52(S): 836-838.

[5] Mishra S C, Satapathy A, Chhaithanya M. Wear characteristics of plasma sprayed nickel-aluminum compositecoatings[J]. Journal of Reinforced Plastics and Composites, 2009, 28(23): 2931-2940.

[6] Hawk J A, Alman D E. Abrasive wear of intermetallic-based alloys and composites[J]. Journal of Materials Science and Engineering, 1997, 239/240: 899-906.

[7] Hawk J A, Alman D E. Abrasive wear behavior of NiAl and NiAl-TiB2composites[J]. Wear, 1999, 225/226/227/228/229: 544-556.

[8] 王振生, 郭建亭, 周兰章, 等. NiAl-Cr(Mo)-Ho-Hf共晶合金的高温磨损特性[J]. 金属学报, 2009, 45(3): 297-301.

WANG Zhensheng, GUO Jianting, ZHOU Lanzhang, et all. High temperature wear behavior of a NiAl-Cr(Mo)-Ho-Hf eutectic alloy[J]. Acta Metallurgica Sinica, 2009, 45(3): 297-301.

[9] 王振生, 周兰章, 郭建亭, 等. 原位内生NiAl-Al2O3-TiC的高温磨损特性[J]. 摩擦学学报, 2008, 28(6): 497-502.

WANG Zhensheng, ZHOU Lanzhang, GUO Jianting, et al. High temperature wear behavior of in situ composite NiAl-Al2O3- TiC[J]. Tribology, 2008, 28(6): 497-502.

[10] GUO Jianting, WANG Zhensheng, SHENG Liyuan, et al. Wear properties of NiAl based materials[J]. Progress in Nature Science: Materials International, 2012, 22(5): 414-425.

[11] 王振生, 周兰章, 郭建亭, 等. NiAl-Cr(Mo)-CrxSy自润滑复合材料的摩擦磨损特性[J]. 摩擦学学报, 2010, 30(6): 589-595.

WANG Zhensheng, ZHOU Lanzhang, GUO Jianting, et al. Friction and wear behavior of NiAl-Cr(Mo)-CrxSy self- lubricating composite[J]. Tribology, 2010, 30(6): 589-595.

[12] 郭建亭. 金属间化合物 NiAl的研究进展[J]. 中南大学学报(自然科学版), 2007, 38(6): 1013-1027.

GUO Jianting. Research progress of intermetallic NiAl alloys[J]. J Cent South Univ (Science and Technology), 2007, 38(6): 1013-1027.

[13] Zeumer B, Sauthoff G. Intermetallic NiAl-Ta alloys with strengthening Laves phase for high temperature applications. I. Basic properties[J]. Intermetallics, 1997, 5(7): 563-577.

[14] Zeumer B, Sauthoff G. Deformation behavior of intermetallic NiAl-Ta alloys with strengthening Laves phase for high- temperature applications. Ⅱ. Effects of alloying with Nb and other elements[J]. Intermetallics, 1997, 5(8): 641-649.

[15] Zeumer B, Sauthoff G. Deformation behavior of intermetallic NiAl-Ta alloys with strengthening Laves phase for high-temperature applications. Ⅲ. Effects of alloying with Cr[J]. Intermetallics, 1998, 6(5): 451-460.

[16] Johnson D R, Oliver B F, Noebe R D, et al. NiAl-based polyphase in situ composites in the NiAl-Ta-X(X=Cr,Mo,V) systems[J]. Intermetallics, 1995, 3(6): 493-503.

[17] Palma M, Preuhsb J, Sauthoff G. Production-scale processing of a new intermetallic NiAl-Ta-Cr alloy for high temperature application: PartⅠ. Production of master alloy remelt ingots and investment casting of combustor Liner model panels[J]. Journal of Materials Processing Technology, 2003, 136: 105-113.

[18] Bowden F P, Tabor D. 固体的摩擦与润滑[M]. 陈绍澧, 袁汉昌, 丁雪加, 译. 北京: 机械工业出版社, 1982: 74.

Bowden F P, Tabor D. The friction and lubrication of solids[M]. CHEN Shaoli, YUAN Hanchang, DING Xuejia, transl. Beijing: China Machine Press, 1982: 74.

[19] 温诗铸, 黄平. 摩擦学原理[M]. 3版. 北京: 清华大学出版社, 2008: 223-262.

WEN Shitao, HUANG Ping. Principles of tribology[M]. 3rd ed. Beijing: Tsinghua University Press, 2008: 223-257.

[20] Stott F H, Glascott J, Wood G C. The sliding wear of commercial Fe-12%Cr alloys at high temperature[J]. Wear, 1985, 101(4): 311-324.

[21] Jiang J R, Stott F H, Stack M M. Some frictional features associated with the sliding wear of the nickel-base alloy N80A at temperatures to 250 °C[J]. Wear, 1994, 176(2): 185-194.

[22] Quyang J H, Sasaki S, Murakami T, et al. Spark-plasma-sintered ZrO2(Y2O3)-BaCrO4 self-lubricating composites for high temperature tribological applications[J]. Ceramics International, 2005, 31(4): 543-553.

(编辑 杨幼平)

收稿日期:2014-02-10;修回日期:2014-04-06

基金项目(Foundation item):国家自然科学基金资助项目(51101055,51275167);湖南省自然科学基金资助项目(13JJ8015) (Projects(51101055, 51275167) supported by the National Natural Science Foundation of China; Project(13JJ8015) supported by the Natural Science Foundation of Hunan Province)

通信作者:王振生,博士,副教授,硕士生导师,从事摩擦学与模具强化方面的研究;E-mail: zswang@imr.ac.cn