单靶磁控溅射Cu1-xCrx(x=1.19~2.37)薄膜的制备

王新建, 姜传海, 王家敏, 洪 波

(上海交通大学 材料科学与工程学院 高温材料及测试教育部重点实验室, 上海 200030)

摘 要: 利用简易合金靶材在Si(100)基底上单靶磁控溅射制备Cu1-xCrx(x=1.19~2.37, 摩尔分数, %)薄膜。 研究不同名义成分的合金靶材得到的溅射态薄膜的成分、 电学性能、 组织结构及表面状态。 研究结果表明: 利用简易合金靶材制备的Cu1-xCrx薄膜成分可控。 Cr的加入增强了溅射态薄膜的(111)织构, 且随着薄膜厚度的增加, (111)织构增强; 855nm厚的Cu-2.37%Cr薄膜的(111)与(200)的峰强比高达8.48; 合金元素Cr显著影响溅射态薄膜的表面状态(平整性和致密度)和电阻率; 随着Cr含量的增加, 前者呈现先升高后下降的趋势, 而薄膜电阻增加; Cu-2.18%Cr薄膜由于应力增加局部产生微裂纹, 薄膜连续性下降。 并从薄膜生长动力学以及自由能的角度对上述结果进行了初步的阐述。

关键词: Cu1-xCrx薄膜; 磁控溅射; 溅射态; 织构 中图分类号: TM241.1

文献标识码: A

Preparation of Cu1-xCrx(x=1.19-2.37) films by magnetron sputtering single target

WANG Xin-jian, JIANG Chuan-hai, WANG Jia-min, HONG Bo

(Key Laboratory of Ministry of Education for High Temperature Materials and Testing,School of Materials Science and Engineering, Shanghai Jiao Tong University,Shanghai 200030, China)

Abstract: Cu1-xCrx films(x=1.19-2.37, mole fraction, %) were deposited on the Si (100) substrate by magnetron sputtering using a single alloy target. The concentration, electrical resistivity, microstructure and morphology of films deposited by targets with different nominal Cr concentration were investigated. The results show that the concentrations of films are predictably. Cr intensifies the (111) texture which increases with increasing thickness of films. The peak strength ratio of (111) to (200) of Cu-2.37%Cr film with thickness of 855nm is 8.48. As the concentration of Cr increases, the smoothness and compactness of films increase firstly whereas then decrease subsequently, while the electrical resistivity keeps on increasing. The continuity of Cu-2.18%Cr film decreases due to the formation of micro-crack.. These results are explained in the view of the dynamics of film growth and energy.

Key words: Cu1-xCrx films; magnetron sputtering; as-deposited; texture

近年来, 人们提出通过铜的非化合物形成元素的合金化来控制铜薄膜的微结构[1-4], 这样具有正混和热(ΔH>0)并且不形成中间化合物的两相CuCr合金系统引起了人们的注意[5-6]。 但是由于Cu与Cr不互溶, 特别当Cr含量(摩尔分数)在1.5%~40%之间时, 合金由高温单相区冷却进入液固两相区时, 液相中将析出过饱和的Cr。 在重力场作用下, 密度较小的固态Cr将迅速上浮, 导致Cu/Cr两相宏观分离。 本文作者采用真空电弧熔炼对Cr含量为3.5%的CuCr合金靶的熔炼制备结果也证明了这一点。 磁控溅射合金薄膜的制备一般都是采用单合金靶溅射或者双靶溅射的方式。 因此通过铜铬合金靶来溅射制备不同Cr含量的Cu1-xCrx显然是很困难的。 而双靶磁控溅射虽然可以灵活地设计薄膜成分, 但是靶材费用较大, 溅射工艺比较复杂, 设备要求较高。

Barmak等[3]曾提出利用双靶的电子束共沉积法在热生长SiO2的硅衬底上制备CuCr合金薄膜, 并且对薄膜的电阻和组织结构进行了研究。 然而此方法制备的合金薄膜的成分不均匀, 并且工艺复杂, 对设备要求较高。

本文作者利用简易合金靶材单靶磁控溅射不同Cr含量的Cu1-xCrx(x=1.19~2.37, 摩尔分数, %)合金薄膜, 提出了一种具有良好导电性能的电子材料用铜铬合金薄膜的制备方法。 与其它方法相比, 该方法具有薄膜纯度高、 制备工艺简单的特点, 能够随时调节合金含量, 提高生产效率。

1 实验

1.1 单靶磁控溅射Cu1-xCrx薄膜靶材的制备

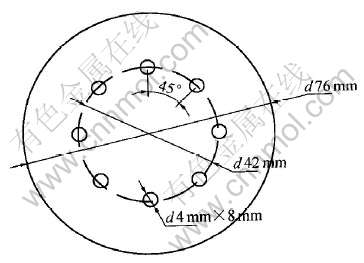

用铜板(99.99%)加工出如图1所示的靶材(靶材厚度为5mm)及一个铜挡片(厚度为1.5mm)。 小孔的分布按照溅射仪的溅射参数而定。 将纯度为99.9%的铬加工成相应尺寸的圆形小棒(小棒尺寸以与孔径达到紧密配合为准)。 靶材经过清洗后, 吹干待用。

图1 单靶磁控溅射用Cu1-xCrx靶材示意图

Fig.1 Sketch of magnetron sputtering Cu1-xCrx target

1.2 薄膜的制备

利用CEVP Gamma 1000c 型多靶磁控溅射仪, 采用射频磁控溅射的方式在(100)硅单晶片基底上制备CuCr合金薄膜。 硅单晶片在经过清洗后, 与铜挡片, 铜靶材依次装入溅射仪中。 铜挡片的作用就是防止溅射离子透过溅射铜靶与铬小棒之间的间隙而溅射到靶座上。 溅射靶与基底底座倾斜成15°。 基底底座在溅射过程中旋转速度为10r/min。 溅射仪的背底真空度为0.439~0.598mPa, 工作气体为Ar, 工作气压为0.665Pa, 镀距为27cm, 溅射温度为室温。

本实验采用两种成分的靶材, 其名义成分分别为Cu-2.06%Cr和Cu-4.04%Cr。 射频磁控溅射的溅射功率为100W, 溅射时间分别为50、 30和120min。

为进行对比, 实验还在同样的溅射条件下制备了纯铜薄膜, 溅射功率为100W, 溅射时间为50min。

经Dektak 6M型台阶仪的测定, 3种溅射时间下对应的溅射态薄膜厚度分别为234、 326和855nm。

1.3 薄膜性能的测定

采用能量分散X射线谱分析(EDX), SDY-5型双电测四探针电阻仪对溅射态Cu-Cr薄膜的成分、 电阻进行了测试。 并用X射线衍射分析(XRD)、 Sirion 200型场发射扫描电子显微镜(FESEM)、 原子力显微镜(AFM)对溅射态薄膜的初始结构、 表面形貌进行了分析。

2 结果与讨论

2.1 薄膜成分鉴定

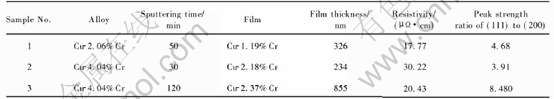

采用能量分散X射线谱分析(EDX)对合金薄膜的成分进行测定。 结果表明, Cu-2.06%Cr合金靶在溅射时间为50min制备的合金薄膜的实际成分为Cu-1.19%Cr; Cu-4.04%Cr合金靶在溅射时间为30min和120min制备的合金薄膜的实际成分分别为Cu-2.18%Cr和Cu-2.37%Cr。 即在100W溅射功率下, 3种条件下的铬、 铜元素的溅射产额之比率分别为0.55、 0.53和0.57, 溅射产额基本保持不变。 即薄膜的成分是可以控制的。 各溅射态薄膜性能参数如表1所示。

表1 单靶磁控溅射Cu1-xCrx(x=1.19~2.37, 摩尔分数, %) 溅射态薄膜性能

Table 1 Properties of as-deposited Cu1-xCrx(x=1.19~2.37, mole fraction, %) deposited by magnetron sputtering single target

2.2 薄膜电阻的测定

四探针电阻仪的测试结果表明, 本实验条件下制备的溅射态的Cu-1.19%Cr、 Cu-2.18%Cr和Cu-2.37%Cr薄膜电阻率分别为17.77、 30.22和20.43μΩ·cm。 这也与文献[3, 5]的报道一致。 溅射态薄膜电阻率较高, 除了与薄膜本身的成分有关之外, 与薄膜的微观组织状态(如晶化不完全, 致密度以及厚度的不均匀性等)、 溅射沉积速率也有关。 溅射态薄膜在经过适当的退火处理工艺后, 电阻率显著下降。 实验表明, 326nm厚的Cu-1.19%Cr薄膜在经过400℃退火30min后, 其电阻率为3.72μΩ·cm。 因此, Cu-Cr合金薄膜在经过合适的退火工艺后基本上能够满足在铜互连线中的应用。

2.3 溅射态薄膜的初始结构分析

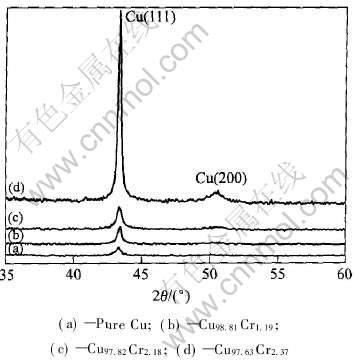

图2所示为纯铜膜、 Cu-1.19%Cr、 Cu-2.18%Cr和Cu-2.37%Cr溅射态薄膜的XRD谱。 从图中可以看到各溅射态薄膜的初始结构主要为Cu(111)和Cu(200)峰。 本实验制备的溅射态纯铜膜的Cu(111)与Cu(200)的峰强比约为2, 表明此时薄膜为晶态的多晶膜。 室温下铜薄膜的晶化可能与薄膜中的杂质含量, 各种应变能和界面能有关[4]。 而Detavernier等[7]的研究表明, 杂质、 应变能以及界面能的影响并不是导致溅射态铜薄膜室温晶化的主要原因, 薄膜中各种高密度的缺陷(空位、 位错等)才是促使薄膜晶粒长大的主要驱动力。 溅射态Cu-1.19%Cr、 Cu-2.18%Cr和Cu-2.37%Cr薄膜的(111)与(200)的峰强比分别为4.68、 3.91以及8.48, 与溅射态的纯铜膜相比明显增大, 且峰位和峰宽发生明显的变化。 表明合金薄膜具有较强的(111)取向织构且Cr元素混溶于Cu薄膜中。 并且随着薄膜厚度的增加, 薄膜(111)织构增强。 这是由于在薄膜的生长过程中, (111)晶面由于具有最低的能量而优于其它晶面的生长。 表2列出了面心立方结构主要晶面表面能相对比值[8]。 溅射态Cu1-xCrx(x=1.19~2.37)薄膜室温下为面心立方

图2 各溅射态薄膜的XRD谱

Fig.2 XRD patterns of as-deposited films

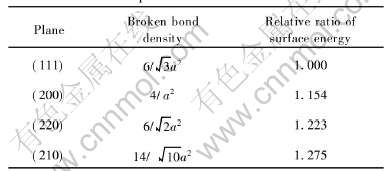

表2 面心立方结构主要晶面表面能相对比值

Table 2 Ratio of surface energy of main planes in FCC lattice

结构[9-10], Cr的添加增大了系统的自由能(包括界面能、 表面能以及应变能等)。 在薄膜成长的过程中, 晶体表面能的各向异性以及应变能的各向异性成为具有(111)织构的二次晶粒长大的驱动力。 且随着薄膜厚度的增加, 薄膜中的界面能、 应变能随之增加, 从而导致(111)织构转变的驱动力增加。 二次晶粒的尺寸增大, (111)织构进一步增强[11-12]。 因此, 可以说溅射态薄膜的室温晶化以及晶粒长大现象与薄膜中的杂质以及由此而产生的界面能、 应变能的增加有关。 同时由于在573K时Cr在Cu中的体扩散系数为4.31×10-22cm2/s[13-14](尽管用体扩散系数来描述薄膜中的Cu、 Cr互扩散是不现实的)。 基于这个数据可知, 在室温沉积的过程中, 由于Cr的扩散距离短, Cr在Cu中“冻结”, 形成过饱和亚稳态, 促进了铜铬合金薄膜织构的形成。 (111)织构的形成有利于提高薄膜的力学性能, 改善薄膜的耐腐蚀性以及抗电迁移的能力[15-16]等。

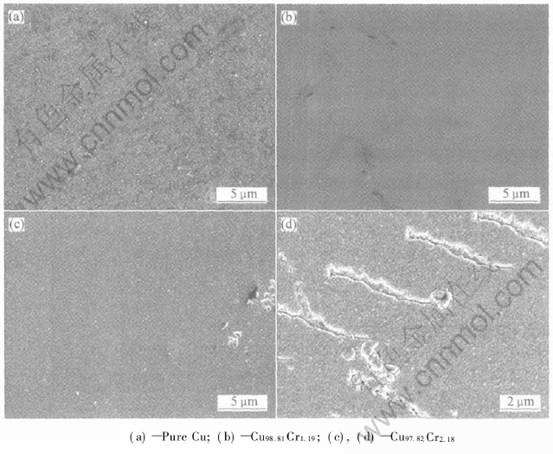

2.4 薄膜表面形貌观察

图3和4所示分别为溅射态纯铜薄膜以及Cu-1.19%Cr、 Cu-2.18%Cr薄膜的AFM表面形貌及FESEM表面形貌分析图。 由图3(a)中可以看出, 溅射态的纯铜薄膜厚度不均匀, 表面平整性较差, 表面粗糙度Ra约5.828nm, 与FESEM表面形貌结果相吻合(图4(a))。 当加入合金元素Cr之后, Cu-1.19%Cr薄膜的表面致密度显著提高, 表面粗[CM(22]糙度约为2.140nm。 当Cr含量增加到2.18%时, 与纯铜膜相比较, Cu-2.18%Cr合金薄膜整体上的表面平整性有所提高(图4(c)), 表面粗糙度约为4.375nm, 薄膜的整体致密度显著增加。 但是相对于Cu-1.19%Cr溅射态薄膜, 薄膜表面的致密性下降。 这与元素溅射产额以及原子的表面扩散迁移的能力, 即原子的沉积速率和铜原子在薄膜表面的扩散速率有关。 根据薄膜的生长动力学, 薄膜生长临界核形成后, 对于纯铜膜来说, 由于铜的溅射产额高, 单位时间内到达基底表面的原子数量多, 临界核原子团长大, 形成尺寸较大的粒子。 由于铜原子沿薄膜表面的扩散这些岛状粒子不断扩大, 连接形成连续膜。 但薄膜表面高低不平, 起伏较大, 具有较大的粗糙度。 当加入Cr之后, 由于Cr的溅射产额小, 原子沉积速率下降, 基底上形成的粒子尺寸小, 这样形成的连续膜表面起伏减小, 粗糙度也明显减小。 并且铜、 铬原子因尺寸不同, 在溅射过程中原子相互堆积填充, 提高了溅射态薄膜的致密度。 而当Cr含量增大到2.18%时, 过量的“冻结”态Cr对铜原子沿表面扩散的阻碍作用明显增大, 降低了铜的扩散速率, 造成薄膜的表面起伏有所增加。 并且, Cu-2.18%Cr薄膜的局部区域出现了鳞形裂纹(图4(d))。 这些裂纹成一定角度均匀地出现在薄膜中, 并且在裂纹的尖端有明显的应力坑。 这主要是由于添加2.18%的Cr后薄膜中的应力增大, 在溅射之后时效的过程中, 应力释放, 导致裂纹和应力坑的形成, 致使溅射态薄膜的连续性有所下降。

图3 溅射态薄膜的AFM照片

Fig.3 AFM images of as-deposited films

图4 溅射态薄膜的FESEM形貌

Fig.4 FESEM images of as-deposited films

3 结论

1) 单靶磁控溅射法制备Cu1-xCrx(x=1.19~2.37)合金薄膜。 薄膜成分可以合理控制。 溅射态薄膜的初始电阻率较高。 经过合理的退火工艺后, 薄膜电阻率减小。 Cu-1.19%Cr薄膜在经过400℃退火30min后电阻率由17.77μΩ·cm 减小为3.72μΩ·cm。 因此, 选择合理的合金元素含量和退火温度能够使得Cu1-xCrx薄膜满足铜互连的要求。

2) 室温下的溅射态纯铜薄膜为晶态膜。 与溅射态纯铜膜相比, 溅射态Cu-1.19%Cr、 Cu-2.18%Cr和Cu-2.37%Cr薄膜具有较强的(111)织构。 且随着薄膜厚度的增加, (111)织构逐渐增强。 855nm厚的Cu-2.18%Cr薄膜的(111)与(200)的峰强比高达8.48。 溅射态合金薄膜织构的变化和薄膜系统自由能(界面能、 表面能、 应变能等)的增加有关。

3) 添加Cr明显改善溅射态薄膜的表面平整性和致密度。 与溅射态纯铜膜相比, 溅射态Cu-1.19%Cr以及Cu-2.18%Cr薄膜的致密度显著增加, 表面平整性提高, 粗糙度分别由纯铜膜的5.828nm降低到2.140nm和4.375nm。 然而溅射态Cu-2.18%Cr薄膜局部产生微裂纹, 薄膜连续性下降。

REFERENCES

[1]Chu J P, Lin T N. Deposition, microstructure and properties of sputtered copper films containing insoluble molybdenum[J]. Journal of Applied Physics, 1999, 85(9): 6462-6469.

[2]Gungor A, Barmak K, Rollett A D. Texture and resistivity of dilute binary Cu(Al), Cu(In), Cu(Ti), Cu(Nb), Cu(Ir), and Cu(W) allow thin films[J]. J Vac Sci Technol, 2002, B20(6): 2314-2319.

[3]Barmak K, Lucadamo G A, Cabral C, et al. Dissociation of dilute immiscible copper alloy thin films[J]. Journal of Applied Physics, 2000, 87(5): 2204-2214.

[4]Cabral C, Harper J M E Jr, Holloway K, et al. Preparation of low resistivity Cu-1at.%Cr thin films by magnetron sputtering[J]. J Vac Sci Technol, 1992, A10(4): 1706-1722.

[5]Harper J M E, Rodbell K P. Microstructure control in semiconductor metallization[J]. J Vac Sci Technol, 1997, B15: 763-779.

[6]Kamijo T, Furukawa T, Watanabe M. Homogeneous nucleation of coherent precipitation in copper-chromium alloys[J]. Acta Metall, 1987, 36: 1763-1769.

[7]Detavernier C, Deduytsche D, Van Meirhaeghe R L, et al. Room-temperature grain growth in sputter-deposited Cu films[J]. Applied Physics Letters, 2003, 82(12): 1863-1865.

[8]王春青, 田艳红, 孔令超, 等. 电子封装和组装中的微连接技术[EB/OL]. http://mwjl.hit.edu.cn/micro/pdf_files/conclusion/microjoining-9.pdf. 2005

WANG Chun-qing, TIAN Yan-hong, KONG Ling-chao, et al. Microjoining Technology in Electronics Packaging and Assembly[EB/OL]. http://mwjl.hit.edu.cn/micro/pdf_files/conclusion/microjoining-9.pdf, 2005.

[9]Kim J, Wen S H, Yee D. Coevaporation of Cr-Cu and Mo-Ag[J]. J Vac Sci Technol, 1988, A6(4): 2366-2370.

[10]Machlin E S. Lattice energy functions for prediction of structural properties OF alloys phases[J]. Proc Mater Res Soc Symp, 1983, 19: 67-80.

[11]Hoshino K, Iijima Y, Hirano K I. Diffusion of vanadium, chromium, and manganese in copper[J]. Metall Trans A, 1977, A8: 469-472.

[12]Wong C C, Smith H I, Thompson C V. Surface-energy-driven secondary grain growth in thin Au films[J]. Appl Phys Lett, 1986, 48(5): 335-337.

[13]Thompson C V, Carel R. Texture development in polycrystalline thin films[J]. Mater Sci Eng B, 1995, 32: 211-219.

[14]周浪, 周耐根, 朱圣龙. 内应力对金属薄膜生长织构的影响[J]. 金属学报, 2002, 38: 795-798.

ZHOU Lang, ZHOU Nai-gen, ZHU Sheng-long. Effect of internal stress on growth texture of metallic thin films[J]. Acta Metallurgica Sinica, 2002, 38: 795-798.

[15]Kusche W M, Kreschman A, Keller R M. Texture of thin films[J]. J Mater Res, 1998, 13(10): 2962-2968.

[16]Tracy D P, Knorr D B. Texture and microstructure of thin copper films[J]. Journal of Electronic Materials, 1993, 22(6): 611-616.

(编辑何学锋)

基金项目: 上海应用材料研究发展基金资助项目(0412)

收稿日期: 2006-06-27; 修订日期: 2006-09-11

通讯作者: 王新建, 博士研究生; 电话: 021-62932440; E-mail: xinjian_wang@sjtu.edu.cn