文章编号:1004-0609(2009)06-1012-07

铝合金盘类锻件成形过程的变形耦合

李 峰1,苑世剑2,刘 钢2

(1. 哈尔滨理工大学 材料科学与工程学院,哈尔滨 150040;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

摘 要:采用有限元模拟和实验研究相结合的方法,分析了模具结构对航空轮毂件模锻成形过程中金属变形流动行为的影响机理,揭示成形过程中金属变形及流动的规律。结果表明:利用锥角凹模更利于金属向模腔内充填成形;并从塑性加工力学角度,将其成形过程的不同阶段和区域抽象地分解为3个基本变形模式耦合而成的形式,使复杂模锻问题的分析模块化,进而为复杂盘类锻件精确塑性成形的变形流动控制提供理论依据。

关键词:盘类锻件;变形耦合;金属流动;变形模式;模块化

中图分类号:TG 306 文献标识码: A

Coupling deformation of aluminum alloy disk components during forging process

LI Feng1, YUAN Shi-jian2, LIU Gang2

(1. College of Materials Science and Engineering, Harbin University of Science and Technology,

Harbin 150040, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: The effects of the wheel hub part structure on the metallic deformation flow actions during die forging process were analyzed by using the methods of combining the finite element numerical simulation with the experimental study, and the metalic deformation flow rule during die forging process was revealed. The results show that the female die with the cone angel makes the metal flow into the die cavity more easily during forming. From the view of plastic processing mechanics, the different stages and regions of the deforming process are abstractly divided into three basic deformation modes coupled in a form, which makes the analysis of complicated forging modularization, and then supplies with theoretical references for the investigation on the deformation flow control of precise plastic forming of complicated disk components.

Key words: disk components; coupling deformation; metal flow; deformation mode; modularization

模锻成形是一个受多因素影响、非稳态不可逆的变形过程,其变形机理和内部组织的变化都很复杂[1]。由于金属多是在密闭的模腔内成形,因此,难以对其成形过程进行精确控制。传统研究主要是依赖于经验与试错的工艺设计方法,但多限于对典型锻件成形过程的定性分析。随着计算机技术的飞速发展,通过有限元模拟可对模锻成形过程进行预测[2?5],了解金属 在模腔内的流动状况[6?8],从而对工艺参数进行优 化[9?11],避免缺陷的发生[12]。但由于锻件种类繁多,工艺条件差异较大,即使对同类锻件的成形过程,也难以给出统一的规律性认识,更不易于其在解决实际模锻问题中的应用。

针对以上不足,本文作者从塑性加工力学角度,将盘类件模锻成形过程的不同阶段和区域抽象分解为圆柱压缩变形、圆环压缩变形和类挤压变形3个基本塑性变形模式,不仅可以抓住它们的内在联系,又可以找出其本质区别。对于任意形状此类构件的模锻成形过程,都可将其抽象看作是这3种基本变形模式耦合而成的,进而可使复杂的模锻问题简化且易于研究,并以铝合金轮毂件的模锻过程为例进行了论证分析。

1 工艺研究方案

1.1 模具结构设计

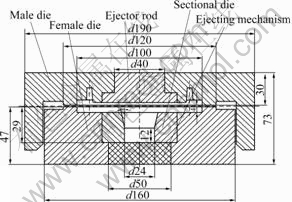

航空轮毂是传动系统中重要的结构部件之一,该件不仅要满足承重的需求和较高安全系数的要求,其在工作中要承受较大的扭矩载荷,因此,对该件成形精度的要求也较高,本文作者采用等温模锻技术进行成形。为便于分析,采用等比例缩小建模的方式,选取与实际工艺比例为1?12的实验模型,实验模具结构示意图如图1所示。

图1 实验模具结构示意图

Fig.1 Schematic diagram of structure of experiment die (mm)

为了使成形后锻件脱模方便,根据该件的结构特点,芯模采用两块对称的组合结构。芯模及凹模套的配合面都设计成锥形,既利于从凹模套中取出可分式芯模,又便于保证凹模套与可分式芯模的紧密配合。

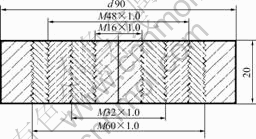

1.2 实验材料及方案

实验材料为超硬铝合金7050,成形时所需坯料为原始外径和高分别为90 mm和23 mm的圆柱体。为了能对模锻成形过程中金属的变形及应变分布进行测量研究,利用套环螺纹法[13]制备成形所需的坯料。综合考虑加工难易及测量部位等各因素的影响,实验坯料的制备选用三层套环的结构形式,其原始螺距为1.0 mm,坯料结构示意图如图2所示。为防止在复杂变形条件下螺纹界面间的焊合问题,对各套环螺纹的表面进行阳极化处理[14]。

图2 带螺纹线坯料的结构示意图

Fig.2 Schematic diagram of structure of billet with screw lines (mm)

成形过程中上模的下压速度2 mm/s,实验温度435 ℃,保温时间1 h,润滑剂为水基石墨。为了减少成形过程中的热量损失,实验中采用整体加热的方式。

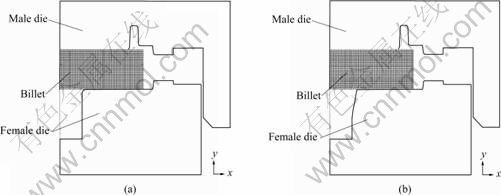

1.3 有限元模型建立

考虑到实际中轮毂件的对称性,采用有限元软件为DEFORMTM-2D。同时,为了减少单元划分数量、提高计算速度和时间,可简化为轴对称模型,并采用四面体单元对坯料进行离散。为了便于对比,本文作者采用两种不同模具结构形式分别进行研究,有限元模型如图3所示。

图3 有限元模型

Fig.3 Finite element model: (a) Model 1; (b) Model 2

在计算过程中,根据网格畸变的情况随时进行自适应重划分,网格形状也发生相应变化,以保证计算精度和收敛性。通过圆环热压缩试验测得相应摩擦因子为0.3,其它模拟条件均与实验相同。

2 变形模式耦合变化规律的分析

2.1 速度场的耦合变化规律

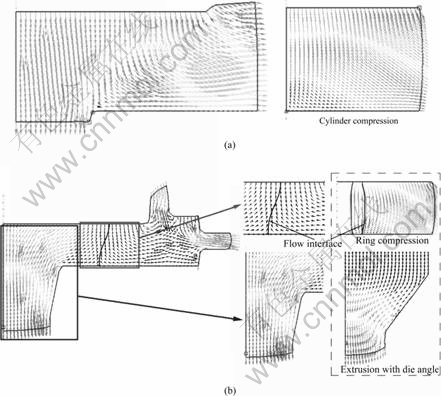

模型1成形过程中不同阶段及部位的速度场分布与所对应的变形模式成形规律的对比如图4所示。

根据模锻成形初期金属的变形流动特征(见图4(a)),可将其抽象为圆柱压缩变形模式。模腔内金属整体沿轴向向下流动的同时,沿径向外流的趋势也比较显著。由于轴颈处型腔的存在,其上部区域金属瞬时流动方向为平行于轴线方向,因此,该部位金属以轴向流动为主。随着成形过程的进行,金属沿径向外流的同时,不断向轴颈及轮辐筋部型腔同时充填流动。由于坯料为一连续整体,因此,在模腔中部形成了流动方向相反的分界面,其余金属逐渐外流进而形成飞边。可将此时模腔内金属变形流动的特征抽象看成是圆环压缩变形和类挤压模式耦合而成的(见图4(b))。在分流面的附近,靠近下模的金属向轴颈型腔内大量流动,靠近上模部位的金属向筋部型腔流动的趋势则较为显著,与圆环压缩过程相比,型腔中部流动分界面的形状是反S形而非上下对称的分布形式。轴颈部位金属的变形流动行为可抽象为积极摩擦类挤压变形模式,因此,该部位金属为整体上呈辐射状均匀向型腔方向充填流动。由前述分析可知,成形过程可看成是圆环压缩变形和类挤压变形模式的耦合作用,因此,当金属向轴颈部位充填速率较大时,型腔中部流动分界面下左上右的分布趋势越明显。

图4 模型1成形过程中速度场分布的对比

Fig.4 Comparison of velocity field distribution during forming process of model 1: (a) Initial stage during forming process; (b) Forming process

图5所示为模型2成形过程中不同阶段及部位与对应变形模式成形过程的速度场分布对比。从图5可以看出,成形初期金属的变形流动特征与模型1的成形过程较相似,因此,可抽象为圆柱压缩变形模式,即轴颈处型腔上部的金属有大致沿着轴线方向向下充填流动的趋势。随着成形过程的进行,金属不断向轴颈及轮辐筋部型腔同时充填流动。根据其成形特点,可将模腔内金属的变形流动特征抽象看成是圆环压缩变形和类锥模挤压变形模式耦合而成的形式(见图5(b))。型腔中部金属流动分界面的形状仍为反S形,与模型1成形过程相比,由于轴颈型腔处金属为锥模挤压变形模式,由前述分析可知,金属较易向型腔充填流动,因此,流动分界面下部向左发生了较明显地弯曲变化趋势。

图5 模型2成形过程中速度场分布的对比

Fig.5 Comparison of velocity field distribution during forming process of model 2: (a) Initial stage during forming process; (b) Forming process

2.2 变形分区的耦合变化规律

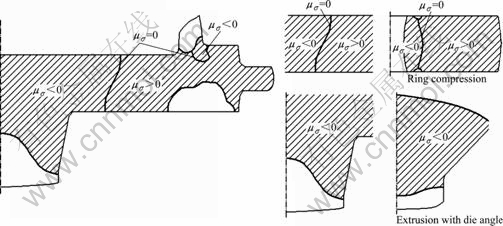

利用应力偏张量J2不变量、罗德系数μσ等特征量对成形过程进行变形分区,可对成形机理进行深入分析[15]。图6所示为模型1模锻成形过程中典型部位与基本变形模式变形分区结果的对比。

由图6可以看出,位于型腔中部区域内金属的变形特征可抽象为圆环压缩变形模式,即内侧呈伸长类趋势变化,外侧为压缩类变化。由于变形条件的差异,罗德系数零值线处靠近上下模端面部位的金属也发生了塑性变形。因成形过程中圆环压缩变形和类挤压变形模式的耦合作用,型腔中部罗德系数零值线的形状同样近似为反S形而非对称分布,由形状和作用部位可知,与此处流动分界面的分布相一致。轴颈处材料的流动行为可抽象为类挤压变形模式,因变形条件的改变,靠近上模区域内的材料也能发生塑性变形且处于伸长类变化。

图6 模型1成形过程变形分区的对比

Fig.6 Comparison of deformation division during forming process of model 1

同理可以得到,模型2成形过程中典型部位与基本变形模式的变形分区对比如图7所示。

图7 模型2成形过程变形分区的对比

Fig.7 Comparison of deformation division during forming process of model 2

从图7可以看出,成形时型腔中部金属的变形流动行为仍为圆环压缩变形模式。与模型1成形过程的变形分区及应变分布规律较一致,即该区内金属均发生了塑性变形,此处罗德系数的零值线与金属的流动分界面呈重合分布。由于模型2轴颈处型的腔结构不同,该部位可抽象为锥模挤压变形模式,且位于圆环压缩变形模式的内侧。由于变形模式的耦合作用,轴颈型腔内塑性区的范围发生了显著地改变,即随着离轴心距离的增加,发生塑性变形区域的范围逐渐向型腔内扩大,材料所处应变类型仍为伸长类。与模型1相比,利用模型2较有利于金属向轴颈处型腔流动充填成形。

由此可知,可将不同模型成形过程不同区域及部位抽象为圆柱压缩、圆环压缩和挤压变形3个基本变形模式或其耦合而成的形式。由于不同变形模式的耦合作用,金属处于塑性变形区域的范围及流动分界面的分布形式都发生了显著变化,进而引起成形过程中相应部位金属流动行为的改变。

3 工艺实验验证

图8所示为成形后样件的俯视图和螺纹线位置分布。经检测可知,成形后叶轮件的筋部充填良好,且尺寸精度和组织性能均符合设计要求。

图8 成形后样件的俯视图及螺纹线位置分布

Fig.8 Planforms and position distributions of screw lines of models 1 (a) and 2 (b) after deformation

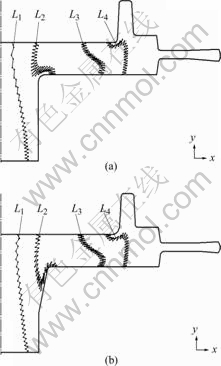

由螺纹线位置的变化可以看出,成形后锻件表面处金属的变形流动趋势。利用显微镜可观察并测量剖面上螺纹线各顶点的坐标。由于螺距较小且变形条件复杂,因此,可假设相邻螺纹顶点间的螺纹线在变形前后均为直线,将测量得到的螺齿顶点按顺序连接起来,可得到变形前后断面上螺纹线的分布情况如图9所示。

图9 显微镜测得的螺纹线分布

Fig.9 Distribution of screw thread lines tested by microscope: (a) Model 1; (b) Model 2

图9所示为通过显微镜测得的螺纹线分布。由螺纹线的分布可以看出,成形时坯料在复杂的模腔内逐渐发生了变形流动。随着成形过程的进行,螺纹线的分布形式也发生了显著地变化。从图9(a)可以看出,模型1成形过程中螺纹线L1和L2处金属都向内产生了变形流动。特别是螺纹线L1处靠近上模及螺纹线L2处靠近下模部位的金属,沿径向内流的趋势更为明显。螺纹线L3和L4处金属继续沿径向向外流动,随着成形过程的进行,金属向外流动的趋势更为显著。同时,不同螺纹线处金属沿轴向也发生了显著的变形流动。从螺纹线的分布来看,螺纹线L1处金属沿轴向流动趋势较为明显,直至完全充填模腔。从螺纹线L4的分布形貌可知,金属沿轴向外流的同时,有明显地沿轴向流动进而向筋部充填的趋势。

成形过程中模型2的各条螺纹线的变化趋势与模型1的大致接近。不过由于模具结构形式的差异,从螺纹线L1间距的分布趋势看,此处模型2金属沿轴向模腔的充填流动比较均匀、平稳,螺纹线L2处靠近下模的金属向型腔充填的趋势较为显著。由此可知,利用如模型2所示的模具结构进行成形时,金属更容易充填模腔。

4 结论

1) 从塑性加工力学角度,可将轮毂件模锻成形过程的不同阶段和区域抽象分解为3个基本变形模式,进而使模锻成形分析模块化。

2) 与普通凹模相比,锥角凹模成形时塑性区的范围显著地向型腔内扩大,所处应变类型为均一的伸长类,因此,金属更易于向轴颈处型腔充填流动。

3) 通过对分流面的部位(区域)和应变分布的对比可知,利用锥角凹模更利于轮毂件的成形。

REFERENCES

[1] REINSCH S, MUSSIG B, SCHMIDT B, TRACHT R. Advanced manufacturing system for forging products[J]. J Mater Process Technol, 2003, 138(1/3): 16?21.

[2] ZHOU Y G, ZENG W D, YU H Q. An investigation of a new near-beta forging process for titanium alloys and its application in aviation components[J]. Mater Sci Eng A, 2005, 393(1): 204?212.

[3] SHAN De-bin, XU Wen-chen, SI Chang-hao, LV Yan. Research on local loading method for an aluminium-alloy hatch with cross ribs and thin webs[J]. J Mater Process Technol, 2007, 187/188: 480?485.

[4] LI C S, LIU X H, WANG G D. Ring upsetting simulation by the meshless method of corrected smooth particle hydrodynamics[J]. J Mater Process Technol, 2007, 183(2/3): 425?431.

[5] BEWLAY B P, GIGLIOTTI M F X. Net-shape manufacturing of aircraft engine disks by roll forming and hot die forging[J]. J Mater Process Technol, 2003, 135(2): 324?329.

[6] BOYER R R. An overview on the use of titanium in the aerospace industry[J]. Mater Sci Eng A, 1996, 213(1/2): 103?114.

[7] SHEN G S, FURRER D. Manufacturing of aerospace forgings[J]. J Mater Process Technol, 2000, 98(1): 189?195.

[8] SRINIVASAN N, RAMAKRISHNAN N, RAO A V, SWARMY N. CAE for forging of titanium alloy aero-engine disc and integration with CAD-CAM for fabrication of the dies[J]. J Mater Process Technol, 2002, 124(3): 353?359.

[9] CHOI S K, CHUN M S, VAN TYNE C J, MOON Y H. Optimization of open die forging of round shapes using FEM analysis[J]. J Mater Process Technol, 2006, 172(1): 88?95.

[10] HE Yang, ZHAN Mei, LIU Yu-li, XIAN Feng-jun, SUN Zhi-chao, LIN Yan, ZHANG Xu-gang. Some advanced plastic processing technologies and their numerical simulation[J]. J Mater Process Technol, 2004, 151(1/3): 63?69.

[11] PARK J J, HWANG H S. Preform design for precision forging of an asymmetric rib-web type component[J]. J Mater Process Technol, 2007, 187/188: 595?599.

[12] WALTERS J, WU W T, ARVIND A, LI G L, LAMBERT D, TANG J P. Recent development of process simulation for industrial applications[J]. J Mater Process Technol, 2000, 98(2): 205?211.

[13] 李 峰, 何祝斌, 苑世剑. 模锻成形过程中金属变形流动的测试方法[J]. 中国有色金属学报, 2007, 17(6): 885?889.

LI Feng, HE Zhu-bin, YUAN Shi-jian. A new method to measure metal flow during die forging[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(6): 885?889.

[14] YUAN S J, ZHANG J, HE Z B. Validation and application of a screw method for strain measurement in bulk metal forming source[J]. J Strain Analysis, 2007, 42(7): 519?527.

[15] LI F, YUAN S J, LIU G, HE Z B. Effect of friction on metal flow behavior during extrusion process[J]. J Mater Eng Per, 2008, 17(1): 7?14.

基金项目:国家重点基础研究发展计划资助项目(5131903ZT2)

收稿日期:2008-05-13;修订日期:2009-02-13

通讯作者:李 峰,讲师,博士; 电话:0451-86393466;E-mail: hitlif@126.com

(编辑 李艳红)