纳米晶WC-6Co复合粉的制备

张武装,高海燕,曹顺华

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:采用W,C和Co粉为原料,经机械活化—反应热处理工艺制备纳米晶WC-6Co(质量分数)复合粉末。研究结果表明:机械活化可使混合粉末化学反应活性增大,扩散能力增强,体系能量增高;反应热处理阶段活化粉末的反应具有反应温度低,反应速度快的特点;在900 ℃热处理保温35 min制备出粒度为33.3 nm的纳米晶WC-6Co复合粉末。复合粉末晶粒粒度随热处理温度的升高和保温时间的延长而缓慢增大,所制得复合粉末的热稳定性较好。

关键词:机械活化;反应热处理;纳米晶;WC-Co复合粉末

中图分类号:TF125.3 文献标识码:A 文章编号:1672-7207(2007)05-0837-06

Fabrication of nanocrytalline WC-6Co composite powder

ZHANG Wu-zhuang, GAO Hai-yan, CAO Shun-hua

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The nanocrystalline WC-6Co(mass fraction) composite powders were prepared by mechanical activation- reaction heat treatment using W, C and Co powders as raw materials. The results show that after mechanical activation the active ability, diffusion coefficient and energy of mixed powder can be improved. The activation powder represents the feature of low reaction temperature and fast reaction speed in the heat-treatment process. At 900 ℃ heat-treatment for 35 min, WC-6Co composite powder of 33.3 nm grain size is obtained. The grain size of composite powder is increased marginally with the increase of heat treatment temperature and holding time. The grain size of nanocrystalline WC-6Co composite powder is stable with the increase of temperature.

Key words: mechanical activation; reaction heat treatment; nanocrystalline; WC-Co composite powder

硬质合金是一种本征脆性材料,其强度和硬度之间的矛盾一直阻碍其进一步发展和应用。减小WC的晶粒粒度,将增大碳化物的接触数量,而以分布高度均匀的钴作粘结相,可以得到强度和硬度高、韧性强的合金[1-4]。尤其当WC的晶粒粒度减小到纳米级时,它的各项性能指标将得到进一步的提高,这成为解决该材料强度和硬度间矛盾的一种重要方法。另外,纳米结构合金具有均匀的显微结构,无异常长大的晶粒,而且碳化物晶粒之间钴相的分布均匀,纳米结构复合粉末在分子尺度上混合保证了其化学均匀性高,从而使纳米结构硬质合金具有很强的抗裂性和耐磨性[5-7]。

目前,制备纳米晶硬质合金粉的方法可分为化学法和机械法。化学法产品往往易受到介质或反应副产物的污染,因而有一定的局限性。采用机械法虽然工艺简单,成本低廉,便于实现工业化生产,但该方法要达到合金化效果主要靠细化晶粒来实现,且研磨使温度升高对固态合成反应能否完全影响很大[8]。R. M. Davis等[9]通过计算并结合机械合金化过程的动力学研究,认为研磨引起的温度升高不超过350 K。因此该方法在较短的时间内很难得到合金化的纳米晶粉末。另外,长时间球磨会使杂质含量增多,对产品性能不利。

在此,本文作者提出一种新型的纳米晶WC-Co复合粉末的制备方法,该方法能克服化学法和机械法的不足,可用于制备优质的纳米晶WC-Co复合粉末。此外,对制备工艺参数进行研究,以期为纳米晶硬质合金的制备打下基础。

1 实 验

本实验采用工业用的钨粉、碳黑和钴粉,其中钨粉粒度为2.03 μm,钴粉粒度约3.0 μm。将混合好的原料粉末装入球磨筒内球磨,球料比为25?1,搅拌杆的转速为240 r/min,充入适量的氩气作为保护气氛以防止粉末氧化,球磨一定时间,使粉末充分活化。将活化后的粉末取出少许装入坩埚内,放入真空电阻炉进行反应热处理。反应热处理温度分别为800,850和900 ℃,每个温度点分别保温15,20,25,30和35 min。对所得粉末进行X射线衍射(XRD)相分析和晶粒度计算,本实验晶粒度的计算是通过X射线衍射宽化法测定的,晶粒的细化可引起衍射线显著的宽化,采用Cauchy-Gauss近似函数法,同时考虑晶粒细化加宽和晶格畸变加宽,用Scherrer公式:d=kλ/(Bcos θ) 计算晶粒粒度(式中:k为常数,k=1;B为晶格细化引起的衍射峰宽化度;λ为X射线衍射波长,λ= 0.154 06 mm)。

2 结果讨论与分析

2.1 元素粉末机械活化后物相分析

W,C和Co粉经过一定时间的机械活化后,其原料混合粉末与活化粉末的XRD谱如图1所示。可见,机械活化后的X射线衍射峰明显宽化;衍射峰主要为W峰,C和Co峰基本检测不到,没有发现其他相。衍射峰宽化是由于机械活化过程中在机械力的作用下元素粉末颗粒被细化,晶格产生了畸变。没有Co峰可能是Co固溶或亚固溶于W中,而C则包覆在W的表层。

1—原料混合粉末;2—活化粉末

图1 原料混合粉末与活化粉末的XRD谱

Fig.1 XRD patterns of mixed powder and active powder

2.2 800 ℃反应热处理后粉末的物相分析

2.2.1 XRD物相分析

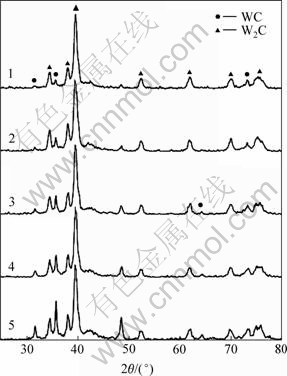

将活化粉末在真空电阻炉中于800 ℃分别保温15,20,25,30和35 min后进行XRD分析,其XRD谱如图2所示。

热处理时间/min: 1—15; 2—20; 3—25; 4—30; 5—35

图2 活化粉末于800 ℃反应热处理不同时间的XRD谱

Fig.2 XRD patterns of active powder with heat-treatment at 800 ℃ for different time

由图2可知,W峰消失,出现了新相W2C和WC;W2C为主要物相,WC衍射峰随保温时间的延长有增强的趋势;与活化粉末衍射峰相比,热处理后的衍射峰变高、变窄;XRD谱中没有发现Co峰。

W峰消失是由于在该温度下发生了W+ C→W2C和W+C→WC的反应,生成了新相W2C和WC。而这2个反应原本在1 200 ℃左右才能开始。本实验中这2个反应在800 ℃能进行,是由于粉末在机械力的作用下,反复破碎、焊合、断裂、缺陷密度增加,很快使晶粒粒度减小,考虑晶粒细化作用,当晶界扩散系数为D1,晶格扩散系数为Db时,有效扩散系数Deff可用下式进行估算[10]:

式中:F为与扩散方向相垂直的短路扩散途径(晶界)的面积分数,F=2δ/d(δ为晶界宽度,d为晶粒粒度)表明有效扩散系数可通过增加晶界,也即减小晶粒粒度来提高。所以,机械活化后晶粒的细化导致扩散系数提高,使元素的扩散能力显著增强,降低了反应激活能,提高了元素的化学反应活性,从而降低了固态反应时要求外界输入的能量和反应发生的温度。

因为活化粉末的XRD谱中没有出现W2C相,所以,W2C相主要是在热处理时生成的。随着保温时间的延长,WC衍射峰增强,这是因为保温时间越长,W和C反应生成WC越充分,另外,少量活性大的W2C发生分解转化成WC。衍射峰变高变窄是因为热处理时晶粒在较高温度作用下发生了长大,晶格畸变有所消失。没有Co相衍射峰,可能是Co固溶或亚固溶于WC和W2C或分布于纳米级WC或W2C的晶 界上[11-14]。

2.2.2 物相含量分析

WC-6Co活化粉末于800 ℃热处理不同保温时间的各物相含量随保温时间的变化关系如图3所示。

图3 800 ℃热处理时WC和W2C物相含量随保温时间的变化关系

Fig.3 Relationship between WC, W2C contents and heat-treatment time at 800 ℃

由图3可知,WC-6Co活化粉末于800 ℃热处理后的主要物相是W2C,其含量随保温时间的延长而降低,由87.3%降到68.7%;WC相含量随保温时间的延长而升高,由12.7%上升到31.3%。没有出现脆性相。

WC-6Co原料粉末经机械活化后在800 ℃热处理条件下生成了大量的W2C相,只有少量的W和C发生反应生成WC。但随着保温时间的延长,反应越来越充分,WC含量逐渐升高,W2C相含量则相对降低。相对于普通的未经机械活化的粉末,本实验所制备的WC-6Co活化粉已经使W2C和WC的生成温度降低了几百度,因此,机械活化的效果还是较好的。没有脆性相可能是因为在此热处理条件下不能为该活化粉提供足够的能量来生成此相。而其他原因引起的脱碳生成了脆性相,因为其数量较少X射线衍射没有检测到或被背底所掩盖。

2.3 850 ℃反应热处理后粉末的物相分析

2.3.1 XRD物相分析

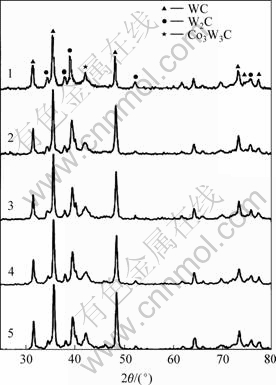

WC-6Co活化粉末于850 ℃热处理不同保温时间的XRD谱如图4所示。可见,此时主要物相为WC相,而W2C衍射峰强度明显减弱,还出现了Co3W3C相。

热处理时间/min: 1—15; 2—20; 3—25; 4—30; 5—35

图4 活化粉末于850 ℃反应热处理不同时间的XRD谱

Fig.4 XRD patterns of active powder with heat-treatment at 850 ℃ for different time

由于提高了反应温度,为W+C→WC和W2C→WC反应提供了较800 ℃热处理时较多的能量,使反应进行更完全。从而WC相的衍射峰强度增强,而W2C相衍射峰强度减弱。在此热处理条件下发生了脱碳生成了脆性相。

2.3.2 物相含量分析

WC-6Co活化粉末于850 ℃热处理后各物相含量随保温时间的变化关系如图5所示。可见,WC的含量随保温时间的延长由48.5%升高到63.3%,而W2C相的含量随保温时间的延长由36.0%降低到17.3%,这是反应越来越完全所致。而Co3W3C相的含量随保温时间的延长变化不大,该相主要是因脱碳而生成的,由于导致脱碳的因素没变,总脱碳量变化不大,所以,Co3W3C相的含量较稳定。

图5 850 ℃热处理时各物相随保温时间的变化关系

Fig.5 Relationship between phase contents and heat-treatment time at 850 ℃

2.4 900 ℃反应热处理后粉末的物相分析

2.4.1 XRD物相分析

图6所示为活化粉末于900 ℃热处理不同保温时间后的XRD谱。可见,WC衍射峰不断增强,W2C衍射峰有所减弱,在保温35 min时W2C衍射峰基本消失,此时Co3W3C衍射峰较850 ℃热处理时的衍射峰有所加强。

热处理时间/min: 1—15; 2—20; 3—25; 4—30; 5—35

图6 活化粉末于900 ℃反应热处理不同时间的XRD谱

Fig.6 XRD patterns of active powder with heat-treatment at 900 ℃ for different time

随着温度的升高,W2C向WC转化更完全,另外,在热处理过程中会有极少量的未反应W得到了充足的能量参加了反应生成WC,使WC相增多,W2C相减少。而Co3W3C相衍射峰有所增强是由于该粉末样品在空气中放置了一段时间,导致其含氧量有所增加,导致脱碳较严重。另外,一些W2C与Co反应生成了Co3W3C脆性相。

2.4.2 物相含量分析

活化粉末于900 ℃热处理后各物相含量随保温时间的变化关系如图7所示。由图7可见,WC相为主要相,且其含量随保温时间的延长而有所增加。W2C相含量在保温35 min时基本为零。于900 ℃热处理后的Co3W3C相含量波动不大,但已经达到了20%~30%,说明脱碳很严重。用该活化粉末在950, 1 000和1 050 ℃保温30 min进行热处理,结果发现Co3W3C相含量没有减少,反而有所增加。由此可知,因为机械活化粉的粉末粒度极细,晶格畸变大,缺陷及晶界浓度高,与空气接触时极易吸附空气中的O2和H2O,O2和H2O的含量随粉末放置时间的延长而迅速增加。反应热处理时O和C结合造成脱碳生成大量的脆性相,这些脆性相对制品的性能产生不利影响,因此,要采取措施防止活化粉末的氧化[10, 15-16]。

图7 900 ℃热处理时各物相含量随保温时间的变化关系

Fig.7 Relationship between phase contents and heat-treatment time at 900 ℃

2.5 反应热处理粉末的晶粒粒度分析

2.5.1 保温时间对粉末晶粒粒度的影响

本实验中用来测晶粒粒度的方法是计算复合粉末中主要物相晶粒尺寸。800 ℃热处理后粉末的主要物相是W2C相,所以用K值法计算的是W2C的晶粒粒度。图8所示为800 ℃热处理后W2C晶粒粒度随保温时间的变化关系。

图8 800 ℃热处理后W2C晶粒粒度随保温时间的变化关系

Fig.8 Relationship between crystalline grain size of W2C and heat-treatment time at 800 ℃

由图8可见,W2C的晶粒粒度随保温时间的延长而逐渐增大,由保温15 min的11.3 nm增大到保温35 min的13.7 nm,在此期间内晶粒粒度只增大了2.4 nm。从而可推断粉末在该热处理温度及保温时间范围内只是处于回复阶段,即点缺陷的运动以及位错的运动与重新组合阶段。

活化粉末于850和900 ℃热处理后的主要物相为WC相,所以,用K值法计算的晶粒粒度为WC的晶粒粒度。图9所示为850和900 ℃热处理不同保温时间与WC晶粒粒度的变化关系。

图9 WC晶粒粒度随保温时间的变化关系

Fig.9 Relationship between crystalline grain size of WC and heat-treatment time

由图9可见,WC晶粒粒度随保温时间的延长而不断增大,850 ℃热处理时粒度由保温15 min的22.6 nm增大到保温35 min的32.2 nm;900 ℃热处理时由保温15 min的26.8 nm增大到保温35 min的33.3 nm。WC晶粒粒度的增大都小于10 nm,增大幅度不大。这说明在同一热处理温度下晶粒粒度受保温时间的影响不大。

2.5.2 热处理温度对晶粒粒度的影响

在本实验中,还进行了950,1 000和1 050 ℃保温20 min的热处理,并计算了主要相WC的晶粒粒度。结果如图10所示。

图10 WC晶粒粒度随热处理温度的变化关系

Fig.10 Relationship between crystalline grain size of WC and heat-treatment temperature

由图10可见,WC晶粒粒度随热处理温度的升高而增大,在900~1 000 ℃之间晶粒增大较快,可能是因为在该阶段发生了再结晶。但总的来说,由850 ℃时的30.2 nm增大到1 050 ℃时的38.6 nm,共增大了8.4 nm。晶粒粒度增加幅度不大,说明在此温度范围内,晶粒粒度对温度不是很敏感,热稳定性较好。

3 结 论

a. WC-6Co系列的原料粉末经一定时间的机械活化后,粉末体系能量升高,晶粒变细,晶格畸变增加,出现了高浓度的位错、空位等缺陷。

b. 机械活化后的粉末由于化学反应活性大,扩散能力强,体系能量高,在900 ℃热处理保温35 min制备出粒度为33.3 nm的纳米晶WC-6Co复合粉末。

c. 晶粒粒度随热处理温度的升高和保温时间的延长而增大,但增加幅度不大,所制粉末的热稳定性较好。

d. 粉末在本工艺保存条件下脱碳严重,导致反应热处理后形成了脆性相Co3W3C,应根据各诱发脱碳的因素设法消除。

参考文献:

[1] WANG Xing-qing, CHEN Li-dong, LI Xiao-dong, et al. Research on preparation of nano-grained cemented carbide by spark plasma sintering[J]. Materials Research Innovations, 2005, 9(3): 82-83.

[2] Lisovsky A F. Some speculation on an increase of WC-Co cemented carbides service life under under dynamic loads[J]. International Journal of Refractory Metals and Hard Materials, 2003, 21(1/2): 63-67.

[3] Engqvist H, Uhrenius B. Determination of the average grain size of cemented carbides[J]. International Journal of Refractory Metals and Hard Materials, 2003, 21(1/2): 31-35.

[4] Engqvist H, Jacobson S, Axen N. A model for the hardness of cemented carbides[J]. Wear, 2002, 252(5/6): 384-393.

[5] Tepper F. Nanosized powders produced by electro-expolosion of wire and their potential applications[J]. Powder Metallurgy, 2000, 43(4): 320-322.

[6] 王辉平. 纳米技术与硬质合金[J]. 中国钨业, 2001, 16(2): 30-32.

WANG Hui-ping. Nanosized technology and cemented carbides[J]. China Tungsten Industry, 2001, 16(2): 30-32.

[7] Andren H O. Microstructure of cemented carbides[J]. Materials and Design, 2001, 22(6): 491-498.

[8] 席生岐, 屈晓燕, 刘心宽, 等. 高能球磨固态扩散反应研究[J]. 材料科学与工程, 2000, 8(3): 88-91.

XI Sheng-qi, QU Xiao-yan, LIU Xin-kuan, et al. Diffusion reaction during high-energy ball milling[J]. Material Science & Technology, 2000, 8(3): 88-91.

[9] Davis R M, McDermott B, Koch C C. Mechanical alloying of brittle materials[J]. Metallurgical Transactions, 1988, 19A: 2867-2870.

[10] Cha S I, Kim B K, Hong S H. Microstructure and mechanical properties of WC-10Co cemented carbides sintered from nanocrystalline spray conversion processed powders[J]. Rare Metals, 2002, 21: 130-135.

[11] Cha S I, Hong S H, Kim B K. Spark plasma sintering behavior of nanocrystalline WC-10Co cemented carbide powders[J]. Materials Science and Engineering A, 2003, 351(1/2): 31-38.

[12] Frykholm R, Andren H O. Development of the microstructure during gradient sintering of a cemented carbide[J]. Materials Chemistry and Physics, 2001, 67(1/3): 203-208.

[13] Andren H O. Microstructure development during sintering and heat- treatment of cemented carbides and cermets[J]. Materials Chemistry and Physics, 2001, 67(1/3): 209-213.

[14] Leev G H, Kang S. Synthesis of nano-sized WC-Co powders by reduction-carburization process[J]. Materials Transactions, 2001, 42(8): 1575-1581.

[15] 刘寿荣. WC-Co硬质合金中的η相[J]. 硬质合金, 1997, 14(4): 198-203.

LIU Shou-rong. Composition of η phase in WC-Co cemented carbides[J]. Cemented Carbide, 1997, 14(4): 198-203.

[16] Allibert C H. Sintering features of cemented carbides WC-Co processed form fine powders[J]. International Journal of Refractory Metals and Hard Materials, 2001, 19(1): 53-61.

收稿日期:2006-12-18;修回日期:2007-01-19

作者简介:张武装(1974-),男,湖南浏阳人,博士研究生,讲师,从事硬质合金材料研究

通信作者:高海燕,女,博士研究生;电话:0731-8876630;E-mail: gaohy@mail.csu.edu.cn