文章编号:1004-0609(2010)06-1110-06

轨道交通车辆大型材用7005铝合金的热处理特性

王正安1, 2,汪明朴2,李 周2,杨文超1,肖从文2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 教育部有色金属材料科学与工程实验室,长沙 410083)

摘 要:利用力学性能测量和透射电镜观察等手段对轨道交通车辆大型材用7005 铝合金热处理特性进行研究。结果表明:该合金在线挤压淬火后于105 ℃时效时,随着时效的进行,开始阶段硬度上升很快,时效8 h后,硬度(HB)达100 HB;时效50 h后,硬度(HB)可达125 HB以上;此后随着时效时间的延长硬度上升缓慢,时效200 h后,硬度仍未达到峰值;经(105 ℃,8 h)+(155 ℃,8 h)双级时效后,σb=395 MPa,σ0.2=330 MPa,δ=12%,硬度为117 HB。合金在较高温度(155 ℃和180 ℃)单级时效及双级时效时间过长,均引起析出相粒子明显长大、粗化,导致合金强度降低。

关键词:7005铝合金;热处理特性;淬火;时效;力学性能

中图分类号:TG 113.12 文献标志码:A

Heat treatment characteristic of

7005 Al alloy employed in railway trains

WANG Zheng-an 1, 2, WANG Ming-pu2, LI Zhou2, YANG Wen-chao1, XIAO Cong-wen1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: The heat treatment characteristic of the 7005 aluminum alloys was studied by mechanical properties measurement and TEM. The results show that, during the process of aging at 105 ℃ after on-line quenching, the hardness(HB) of alloy increases quickly at first and reach about 100 HB after aging for 8h and 125 HB after 50 h, then the hardness increases slowly with increasing aging time, and the hardness does not reach the peak value even the alloy is aged for 200 h. After aging at (105 ℃, 8 h)+(155 ℃, 8 h), the mechanical properties of 7005 aluminum alloy are σb=395 MPa, σ0.2=330 MPa, δ=12%, 117 HB. If the aging of alloy at high temperature (155 ℃, 180 ℃) or the two-stage aging is too long, the precipitated phases of the alloy will grow and coarsen, and then the alloy strength decreases.

Key words: 7005 Al alloy; heat treatment characteristic; quenching; aging; mechanical properties

高速、节能、安全、舒适、环保是现代化交通运输业面临的重要课题,而轻量化是实现上述目标的重要途径,铝合金因其具有密度小、强度高、挤压性能好和焊接性能好等较优异的特点而作为高速列车、地铁列车、轻轨列车、双层列车和豪华大巴等现代化交通运输工具的关键材料 [1-2]。为了加速我国交通运输工具向现代化、高速化和轻量化方向发展,国家将车辆用大型铝合金型材的国产化与产业化列为重点科技攻关项目。7005铝合金是属于Al-Zn-Mg-Cu系可热处理强化的中高强铝合金,它不仅具有较好的力学性能、抗腐蚀性能、热稳定性和较好的焊接性能,而且还具有较好的挤压性能和在线淬火性能[3-4]。7005铝合金已逐步成为车辆用大型铝合金型材的主要用材之一。而在Al-Zn-Mg-Cu合金中加入适量Mn、 Cr 和Zr 等微量元素可以有效提高合金的再结晶温度和可焊性,其在要求具有承载和减重要求的结构件中得到广泛的应用[5-7]。对该系中高强铝合金的热处理组织与性能研究,主要集中在时效组织与性能之间的关系方面,合理的热处理制度是7005铝合金能够取得优异综合性能的关键因素之一[8-10],但目前对于该合金具体热处理制度的研究尚不深入。本文作者详细研究不同热处理制度下合金力学性能的变化规律,并从微观角度分析合金强化机制,以便为实际生产工艺的制定提供理论依据。

1 实验

实验合金为添加适量Mn、Cr和Zr的7005 铝合金, 经熔炼后半连续铸造成d160 mm 的锭坯。对锭坯进行锯切、均匀化退火和铣面, 并在2 500 t 挤压机上挤压成壁厚6 mm 的空心型材。挤压温度为440 ℃, 挤压速度为5 m/min,在线风淬[5],接着进行时效处理, 时效处理工艺分为单级时效和双级时效两种,单级时效制度为分别在105、135、155、180 ℃时效不同时间,双级时效制度为105 ℃时效8 h,然后在155 ℃时效不同时间。拉伸实验和硬度实验分别在CSS-44100电子拉伸试验机和HBE-3000硬度计上进行。电子显微观察在H-800透射电镜上进行。

2 结果与分析

2.1 7005铝合金单级时效后的硬度变化

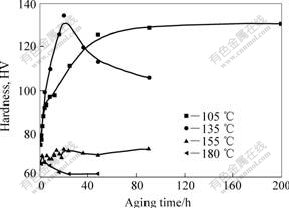

图1所示为7005铝合金在105 ℃、135 ℃、155 ℃和180 ℃时效不同时间后硬度变化曲线。由图1中可看出,7005铝合金经105 ℃时效时,随着时效的进行,开始阶段硬度上升很快,时效8 h后,硬度达100 HB左右;时效50 h后,硬度可达125以上;此后随着时效时间的延长硬度上升缓慢,时效至200 h后,硬度仍未达到峰值。经135 ℃时效20 h后,达到峰时效。而155 ℃和180 ℃时效并未引起硬度明显变化,合金的硬度一直停留在固溶态的水平上。

图1 7005铝合金单级时效硬化曲线

Fig. 1 Single-stage age hardening curves of 7005 Al alloy

2.2 7005铝合金单级时效后的显微组织

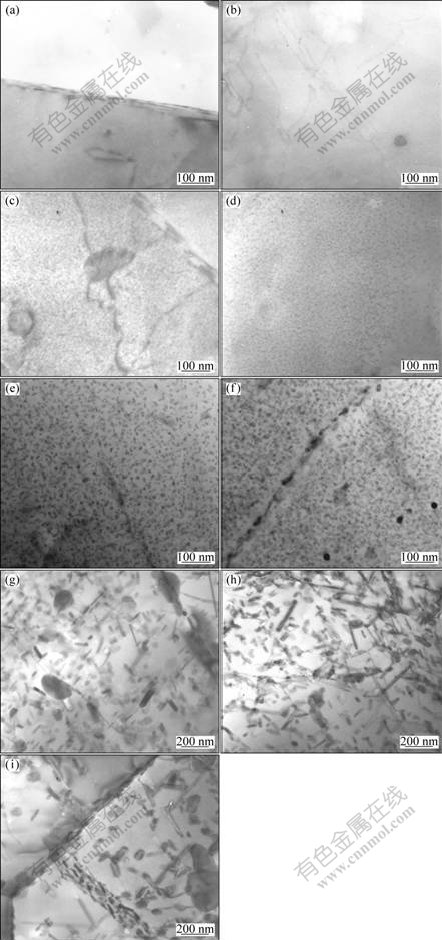

图2所示为7005铝合金在不同温度单级时效后的典型TEM像。由图2可看出,除了位错(制样过程中形成的) 和少量第二相粒子外,晶界及晶内均未发现弥散分布的强化相(见图2(a)和(b));沉淀相η′呈颗粒状高度弥散分布, η′相粒子大小约为5~10 nm,在晶界和晶内还存在少量粗大析出物,可能只添加微量元素Mn、Cr和Zr生成的MnAl6、CrAl7和Al3Zr等粒子(见图2(c)和(d));晶内球状GP区进一步长大,并出现少量与基体半共格的针状η′相(见图2 (e) );晶界上η平衡相呈连续链状分布,晶界无沉淀析出带宽度约为10~20 nm(见图2(f));晶界与晶内均析出了大量粗大的杆状析出相(见图2(g)和(h));经180 ℃时效1 h后,杆状析出相更为粗大(见图2(i))。

图2 7005铝合金单级时效后的典型TEM像

Fig.2 Typical TEM images of 7005 Al alloy after single-stage aging: (a) As-quenched, intergranular; (b) As-quenched, transgranular; (c) 105 ℃, 50 h; (d) 105 ℃, 200 h; (e) 135 ℃, 20 h, transgranular; (f) 135 ℃, 20 h, intergranular; (g) 155 ℃, 1 h; (h) 155 ℃, 20 h; (i) 180 ℃, 1 h

2.3 7005铝合金双级时效后的硬度变化

从图1可以发现,该合金经105 ℃时效8 h后,合金硬度可达100左右,延长时效时间,硬度增加幅度较小,为此选用双级时效制度为(105 ℃,8 h)+(155 ℃,不同时间)。试验结果如图3所示。由图3可看出,合金硬度在155 ℃随着双级时效时间的延长而明显上升,时效8 h后,硬度达到峰值,约为117 HB;随后硬度缓慢下降,时效100 h后,硬度仍在95 HB左右。

图3 7005铝合金的双级时效硬化曲线

Fig.3 Hardness curves of 7005 Al alloy after two-staged aging

2.4 7005铝合金双级时效显微组织

图4(a) 和(b)所示为 7005铝合金经(105 ℃,8 h)+(155 ℃,8 h)双级时效后的典型微观组织。由图4(a)和(b)可见,沉淀相η′呈颗粒状高度弥散分布, η′相粒子大小约为10 nm,较(105 ℃,200 h)单级时效沉淀析出相略有长大。图4(c)和(d)所示为合金经(105 ℃,8 h)+(155 ℃,100 h)时效后的TEM像。由图4(c)和(d)可以明显看到晶内存在大量析出相,析出相比较粗大,呈棒状或盘片状,平均尺寸约50~150 nm,呈过时效特征。

图4 7005铝合金双级时效后的典型TEM像

Fig.4 Typical TEM images of 7005 Al alloys after two-stage aging: (a), (b) (105 ℃, 8 h)+(155 ℃, 8 h); (c), (d) (105 ℃, 8 h)+(155 ℃, 100 h)

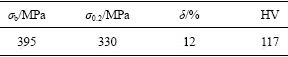

2.5 7005铝合金双级峰时效后的力学性能

表1所列为7005铝合金经(105 ℃,8 h)+(155 ℃,8 h)双级时效后的力学性能。由表1可看出,这一性能指标已经能够满足高速列车、地铁列车的使用要求。

表1 7005铝合金经(105 ℃, 8 h)+(155 ℃, 8 h)时效后的力学性能

Table 1 Mechanical properties of 7005 Al alloy under (105 ℃, 8 h)+(155 ℃, 8 h)

3 讨论

时效是过饱和固溶体分解和强化相沉淀析出的过程。第二相的粒度与基体的界面关系以及晶界特性决定合金的最终力学性能。合金沉淀相的析出序列如下:α(过饱和固溶体)—GP区—η′过渡相(MgZn2)—η平衡相(MgZn2)。其中,GP区是Mg和Zn原子在Al基体某一晶面上偏聚而形成的球状溶质原子偏聚区,与基体保持完全共格,形状为球形,其强度较低,容易被位错切割;η′相为MgZn2的过渡相,呈针状,具有六方结构,晶格常数a=0.507 8 nm,c=1.395 nm,与基体保持半共格关系,其强度较高,不容易被位错剪切;η相为平衡相,与基体非共格,六方结构,呈片状或块状。上述3种相中,GP区和η′过渡相在合金中起主要的强化作用,η相的强化作用较小。合金在时效过程中的强度(硬度)的变化主要由GP区、η′和η等沉淀相的大小、数量和分布所决定。

沉淀强化理论认为,合金变形时,位错与粒子之间的交互作用方式有切割和绕过两种机制,取决于不同时效态析出物的性质和粒度。根据位错理论,对位错绕过和切过两种机制进行分析,可以得出以下关系

式:

由式(1)和(2)可知,切割机制的强化效应随质点体积分数和尺寸的增大而增大,而绕过机制的强化效果则随质点体积分数的减小和尺寸的增大而减小。在欠时效状态下,合金中的沉淀相主要为GP区,变形时为位错切割GP区,而过时效状态下合金中的沉淀相主要为η′相和η相,变形时位错绕过析出物质点,峰时效状态下沉淀相主要为GP区和部分η′相,位错由切割向绕过机制转变,合金强度最高。此外,时效过程动力学由溶质原子扩散所控制,温度是影响原子扩散系数的最主要因素。根据阿累尼乌斯公式:D=D0exp[-Q/(RT)]。时效温度T越高,溶质原子的扩散系数越大,过饱和固溶体的分解速度越快,则达到时效峰值的时间越短,进入过时效的速度越快。过饱和固溶体的分解过程强烈地依赖于时效温度、时间以及过剩空位浓度。在本实验中,当时效温度过低(为105 ℃)时,随着时效的进行,开始阶段硬度上升很快,时效8 h硬度达100 HB左右,50 h后硬度可达125 HB以上,此后随着时效时间的延长硬度上升缓慢,时效至200 h后,硬度仍未达到峰值,强化相析出不充分;时效温度过高(为155 ℃),高于GP区溶解温度(150 ℃)时,时效脱溶会跳过溶质原子偏聚阶段,直接析出过渡相,过渡相迅速转变为粗大的平衡相而与基体完全脱离共格关系,合金的强度和硬度明显下降。

在单级时效条件下,高强铝合金具有很强的应力腐蚀敏感性,限制其在高速列车中的应用和进一步发展。研究表明[11-13],采用合适的双级时效(预时效-终时效)工艺,可以提高超高强铝合金的抗应力腐蚀性能和断裂韧性,是改善高强铝合金综合性能的有效途径。同时,双级时效可以加快时效进程,通常在工业生产中选择双级时效制度。对于双级时效制度的选择,要遵循一条基本原则:在低温时效要尽量析出大量弥散质点作为后续时效中强化相的形核核心。

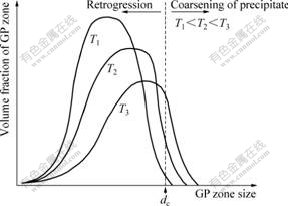

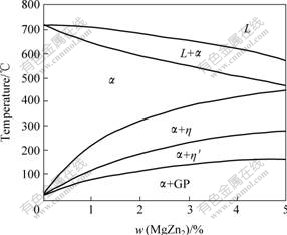

LORIMER和NICHOLSON[14]根据一系列的电镜研究工作,提出析出相成核动力学模型(见图5)。该模型指出,淬火合金中的空位浓度和分布状态对析出物的匀质形核起着很重要的作用,在淬火冷却过程中和时效初期形成的“溶质原子-空位集团”或GP区是后续析出相的核心。根据这个经典的形核模型,析出相的弥散度对淬火冷却过程和时效初期非常敏感。他们认为,合金中存在某一温度(TGP),当时效温度高于这一温度时,GP区不稳定而被溶解;当时效温度低于这一温度时,若所形成GP区的尺寸大于某一临界尺寸(dc),它就成为过渡相析出的核心。在GP区溶解温度(TGP)以下时效时,时效温度越高,则达到临界尺寸并能在高于TGP的时效温度条件下成为晶核的GP区数目越多。

图5 GP区尺寸随时效温度变化

Fig.5 Change of GP zone size with aging temperature

基于LORIMER和NICHOLSON的研究,Al-Mg-Zn系合金GP区和过渡相的亚稳相图[15](见图6),针对本研究合金的实验结果,可以认为:试验合金经过105 ℃,8 h预时效后,合金基体析出组织主要为较稳定的GP区,在155 ℃时效过程中,只有部分小于临界尺寸的GP区溶解,而大于临界尺寸的GP区逐渐长大或转变成η′相,形成细小弥散的多相析出组织(见图4(a)和(b)), 超过8 h后,析出相粒子逐渐长大。

图6 Al-Zn-Mg系合金亚稳相图

Fig.6 Metastable phase diagram of Al-Zn-Mg alloy

经过105 ℃,8 h预时效后,合金基体析出组织主要为较稳定的GP区。在155 ℃时效过程中,只有部分小于临界尺寸的GP区溶解,而大于临界尺寸的GP区逐渐长大或转变成η′相,形成细小弥散的多相析出组织,这种组织对位错运动构成较强的阻碍作用,合金强度较高。

4 结论

1) 7005铝合金不同温度下单级时效时,硬度变化规律不同。合金分别在155 ℃和180 ℃进行单级时效,合金的硬度变化不大,停留在固溶态的水平上。经105 ℃时效时,随着时效的进行,开始阶段硬度上升很快,时效8 h硬度达100 HB左右,50 h后硬度可达125 HB以上,此后随着时效时间的延长,硬度上升缓慢,时效至200 h后硬度仍未达到峰值,经135 ℃时效20 h,硬度达到峰值,为135 HB左右。

2) 7005铝合金经440 ℃在线挤压风淬后,经 (105 ℃,8 h)+(155 ℃,8 h)双级时效后,σb=395 MPa,σ0.2=330 MPa,δ=12%,117 HB。

3) 7005铝合金分别在155 ℃和180 ℃进行单级时效以及双级时效过程中,时效时间过长均引起析出相粒子明显长大、粗化,导致合金强度降低。

REFERENCES

[1] 王志伟, 汪明朴, 王正安, 等. 在线挤压淬火对地铁列车用6005A 合金力学性能及微观组织的影响[J]. 中国有色金属学报, 2001, 11(4): 603-606.

WANG Zhi-wei, WANG Ming-pu, WANG Zheng-an, et al. Effects of on-line extrusion quenching technique on mechanical properties and microscopic structure of 6005A alloys employed in underground railway trains[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 603-606.

[2] 林学丰, 宋传玉, 秦朝霞. 铝材在交通运输工具中的应用前景[J]. 铝加工, 1999, 22(1): 1-10.

LIN Xue-feng, SONG Chuan-yu, QIN Zhao-xia. The future of aluminum in transport[J]. Aluminium Fabrication, 1999, 22(1): 1-10.

[3] 冯展鹰, 赵仁祥. 7005铝合金热处理工艺研究[J]. 电子机械工程, 2006, 22(5): 46-48.

FENG Zhan-ying, ZHAO Ren-xiang. A study on heat treatment process of the 7005 alloy[J]. Electro- Mechanical Engineering, 2006, 22(5): 46-48.

[4] 汪明朴, 王志伟, 王正安. 地铁列车用7005铝合金力学性能及微观结构分析[J]. 中国有色金属学报, 2001, 11(6): 1069-1073.

WANG Ming-pu, WANG Zhi-wei, WANG Zheng-an. Mechanical properties and microscopic structure analysis of 7005 alloys employed in underground raiway trains[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(6): 1069-1073.

[5] 张新明, 朱航飞, 李国锋, 李鹏辉. 微量Zr, Er和Y对Al-Zn-Mg-Cu 合金铸态组织的影响[J]. 中南大学学报: 自然科学版, 2008, 39(6): 1196-1200.

ZHANG Xin-ming, ZHU Hang-fei, LI Guo-feng, LI Peng-hui. Effects of mini Zr, Er, Y on microstructures of cast Al-Zn-Mg-Cu alloy[J]. Journal of Central South University: Science and Technology, 2008, 39(6): 1196-1200.

[6] 张 茁, 陈康华, 方华婵. 微量 Cr 和Nb对Al-Zn-Mg-Cu-Zr 合金力学性能和应力腐蚀性能的影响[J]. 中国有色金属学报, 2008, 18(6): 985-990.

ZHANG Zhuo, CHEN Kang-hua, FANG Hua-chan. Effects of trace Cr and Nb additions on mechanical properties and stress corroded cracking of Al-Zn-Mg-Cu-Zr aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 985-990.

[7] ZHAO P Z, TSUCHIDA T. Effect of fabrication conditions and Cr, Zr contents on the grain structure of 7075 and 6061 aluminum alloys[J]. Mater Sci Eng A, 2009, 499: 78-82.

[8] BUHA J, LUMLEY R N, CROSKY A G. Secondary ageing in an aluminium alloy 7050[J]. Mater Sci Eng A, 2008, 492: 1-10

[9] LI Zhi-hui, XIONG Bai-qing, ZHANG Yong-an. Investigation of microstructural evolution and mechanical properties during two-step ageing treatment at 115 and 160 ℃ in an Al-Zn-Mg-Cu alloy pre-stretched thick plate[J]. Materials Characterization, 2008, 59: 278-282.

[10] BOBBY M, RAJA K V S. Role of coarse intermetallic particles on the environmentally assisted cracking behavior of peak aged and over aged Al-Zn-Mg-Cu-Zr alloy during slow strain rate testing[J]. J Mater Sci, 2007, 42: 5458-5464.

[11] 梵喜刚, 蒋大鸣, 孟庆昌, 李念奎, 孙兆霞. 时效制度对7150铝合金组织和性能的影响[J]. 材料热处理, 2006, 35(16): 22-25.

FAN Xi-gang, JIANG Da-ming, MENG Qing-chang, LI Nian-kui, SUN Zhao-xia. Effect of aging on microstructure and properties of 7150 aluminum alloy[J]. Material & Heat Treatment, 2006, 35(16): 22-25.

[12] 王 锋, 熊柏青, 张永安, 朱宝宏, 刘红伟, 何小青. 双级时效处理对喷射沉积Al-Zn-Mg-Cu 合金微观组织和力学性能的影响[J]. 中国有色金属学报, 2007, 17(7): 1058-1062.

WANG Feng, XIONG Bai-qing, ZHANG Yong-an, ZHU Bao-hong, LIU Hong-wei, HE Xiao-qing. Effect of two-step aging treatment on microstructure and mechanical properties of spray-deposited Al-10.8Zn-2.8Mg-1.9Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1058-1062.

[13] LI Zhi-hui, XIONG Bai-qing, ZHANG Yong-an. Effects of the two-step ageing treatment on the microstructure and properties of 7B04 alloy pre-stretched thick plates[J]. Rare Metals, 2007, 26(3): 193-199.

[14] LORIMER G W, NICHOLSON R B. The mechanism of phase transformations in crystalline solids[J]. Inst Metals, 1968: 36.

[15] BER L B. Accelerated artificial ageing regimes of commercial aluminum alloys[J]. Mater Sci Eng A, 2000, 280: 91-96.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2006AA03Z517)

收稿日期:2009-11-14;修订日期:2010-03-08

通信作者:汪明朴,教授,博士;电话:0731-88830264;E-mail: mpwang@mail.csu.edu.cn