文章编号:1004-0609(2015)-09-2484-08

液相还原法制备微米级球形银粉及其分散机理

郭学益1, 2,邓 多1, 2,李 宇1, 2,田庆华1, 2

(1. 中南大学 冶金与环境学院,长沙 410083;

2. 中南大学 中国有色金属工业清洁冶金工程研究中心,长沙 410083)

摘 要:采用液相还原法,以硝酸银为原料、抗坏血酸为还原剂制备银粉。系统探索加料方式、分散剂、反应温度、分散剂用量和AgNO3溶液浓度等工艺参数对银粉形貌、粒径的影响,并对分散机理进行研究。结果表明:聚乙烯吡咯烷酮(PVP)与Ag+和银粉的相互作用有利于银粉形貌和分散性的提高。采用正向快速加料法,在PVP用量为硝酸银的5%~20%(质量分数),硝酸银溶液浓度为0.1~0.3 mol/L的条件下,可制备出分散性较好、表面光滑的球形银粉,其振实密度可达4.9 g/cm3;通过调节分散剂的用量,能够实现银粉平均粒径在1.02~2.72 μm之间的可控制备。

关键词:微米级银粉;分散机理;聚乙烯吡咯烷酮(PVP);可控制备

中图分类号:TF123.7 文献标志码:A

Preparation of spherical microsized silver powder by liquid reduction method and its dispersion mechanism

GUO Xue-yi1, 2, DENG Duo1, 2, LI Yu1, 2, TIAN Qing-hua1, 2

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. Cleaner Metallurgical Engineering Research Center, Nonferrous Metal Industry of China,

Central South University, Changsha 410083, China)

Abstract: The microsized silver powders were prepared by liquid reduction method using AgNO3 as feed solution and ascorbic acid as reductant. The effects of feeding mode, dispersant, reaction temperature, dispersant dosage and AgNO3 concentration on the morphology and particle size of silver powder were investigated, and the dispersing mechanism was studied. The results show that the interaction between polyvinyl pyrrolidone (PVP) and Ag+ along with silver powder is in favour of the regular spherical morphology and preferable dispersity of silver powder. The optimal dispersive spherical silver powders with smooth surface were prepared with 5%-20% PVP (mass fraction) and 0.1-0.3 mol/L AgNO3 by farward fast feeding mode, the tap density of silver powder can reach 4.9 g/cm3. The particle size of ultrafine silver powders between 1.02-2.72 μm can be prepared controllably through changing the dispersant dosage.

Key words: microsized silver powder; dispersing mechanism; polyvinyl pyrrolidone; controllable preparation

银粉具有优良的导电性和化学稳定性,因此,被广泛运用在电工、电子和电气等领域中。作为一种贵金属功能材料,银粉主要应用于导电浆料、导电胶、印刷电路、电工用合金等材料中。其中,导电浆料对银粉的需求量最大。

一般要求应用于导电浆料中的银粉具有较好的分散性,以及较为合适的粒径。由于纳米银粉经烧结后的表面电阻比微米级(1~10 μm)或亚微米级(0.1~1 μm)银粉的大[1],又存在固液分离困难的问题,导致其应用受到了限制。因此,目前应用于电子浆料中的银粉,粒径一般为微米或亚微米级。对于更高要求应用的银粉,比如太阳能电池正面银浆用银粉,还要求银粉有着较高的振实密度,以减少银浆在烧结过程中的收缩。银粉的振实密度与银粉的形貌、粒径、分散性甚至是银粉表面的光滑度等都有很大的关系。一般来说,分散性好、形貌规则、颗粒表面光滑的银粉振实密度往往更高[2]。

目前制备银粉的方法很多,包括液相还原法[3]、喷雾热分解法[4]、沉淀转换法[5]、水热法[6]、微乳液法[7]、电化学法[8]等,其中液相还原法因其设备简单、工艺条件温和以及成本相对较低而得到广泛运用。液相还原法常用的还原剂包括抗坏血酸[9]、水合肼[10]、葡萄糖[11]、丙酮[12]等,常用分散剂则包括聚乙烯吡咯烷酮(PVP)[13]、明胶[14]、十六烷基三甲基溴化铵(CTAB)[15]等。以PVP为分散剂的研究往往集中于纳米银粉的制备,而对其在微米级银粉制备方面的机理等研究则比较欠缺。甘卫平等[16]进行以PVP为保护剂制备微细银粉的研究,但也并未对其分散机理进行深层次的探讨。

基于以上原因,本文作者以硝酸银为原料,以抗坏血酸为还原剂制备银粉,旨在寻求一种制备高分散性、高振实密度的微米球形银粉的简单工艺。研究发现通过改变分散剂的类型,可实现不同形貌银粉的制备,并研究分散剂影响银粉形貌和分散性的机理。通过控制适当的工艺参数,可制备出分散性好、振实密度高的球形银粉,实现银粉粒径可控。本工艺简单高效、可操作性强,具备批量化生产前景。

1 实验

1.1 实验原料与设备

实验试剂:硝酸银、抗坏血酸、无水乙醇、聚乙烯吡咯烷酮(PVP)、吐温80、聚丙烯醇(PVA-124)、聚乙二醇(PEG-6000)等,均为分析纯;去离子水(自制,电阻率16.25 MΩ·cm)。

实验设备:DF-101S型集热式恒温加热磁力搅拌器、DZ-2BC II型真空干燥箱、Starter 3C型pH计、TDL-40B型低速台式离心机、JY3002型电子天平。

1.2 超细银粉的制备

取适量的硝酸银,配制成一定浓度的硝酸银溶液;称取一定量的分散剂,配制成分散剂溶液,并将其加入到硝酸银溶液中;配制100 g/L的抗坏血酸溶液;调节水浴温度为20 ℃,在充分搅拌下,采用不同的加料方式将硝酸银溶液和抗坏血酸溶液混合使二者完全反应。反应完全后,离心分离,用去离子水和无水乙醇分别洗涤3次,然后放入真空干燥箱恒温50 ℃干燥5~8 h得到超细银粉。

1.3 分析与测试

采用JSM-6360LV型扫描电镜(SEM)观察银粉的表面形貌和分散性;对SEM像中银粉的粒径进行统计得到产物平均粒径和粒径分布;使用Rigaku-TTR III型X射线衍射仪来检测银粉的物相(Cu-Kα靶,管电压40 kV,管电流250 mA);使用Hitachi U-4100型紫外–可见光分光光度计测定硝酸银溶液及分散剂溶液的吸光度;采用ZS-202型振实密度仪对银粉的振实密度进行测试。

2 结果与分析

2.1 加料方式对制备银粉的影响

以用量为硝酸银10%(质量分数)的PVP为分散剂,在AgNO3溶液浓度为0.3 mol/L的条件下,采用正向快速加入法(将还原剂快速倒入硝酸银溶液中)、正向滴加法(将还原剂滴加到硝酸银溶液中)和并流滴加法(还原剂溶液和硝酸银溶液同时加入到底液中)3种不同加料方式将AgNO3溶液和还原剂溶液混合,考察加料方式对制备银粉的影响。所得银粉的微观形貌如图1所示。

从图1可以看出,采用正向快速加入法制备的银粉为表面光滑的球形,分散性较好;采用并流滴加法制备的银粉为多面体的类球形;而采用正向滴加法制备的银粉形貌极不规则。

根据Lamer模型,要想得到单分散的固体颗粒,必须控制产物溶质的过饱和浓度,使成核过程尽可能缩短,让沉淀过程按照“爆发成核,缓慢生长”的模式进行[17],将成核过程和生长过程分离。采用正向快速加入法进行加料时,反应物快速混合并迅速反应,发生爆发成核,并进而生成大量一次粒子,该过程消耗了大量溶质。之后,反应物的浓度大大降低,反应速率减缓,进入不形核、只生长的过程,使得成核和生长过程基本分离。由于反应初期溶质浓度较高,大量一次粒子趋向于聚集生长形成球形颗粒,加上PVP分散剂在生长过程中所起的分散作用,因此,最终可以制备出分散性较好的球形银粉。

采用并流滴加法进行加料时,硝酸银溶液和抗坏血酸溶液同时缓慢滴加到底液中,从而使反应体系中的银离子和抗坏血酸一直维持在一个比较低的浓度,反应速率较慢,溶液中的溶质浓度很低,形核速率和长大速率都比较小。在这种情况下,银粒子的生长趋向于扩散生长,从而生长成如图1(b)所示的多面体形貌。而采用正向滴加法时,抗坏血酸缓慢滴加到硝酸银溶液中,在这个持续时间较长的反应过程中,体系中的抗坏血酸浓度一直较低,而银离子的浓度则从初始浓度慢慢降低至0。因此,在整个反应过程中,银离子的浓度变化较大,导致反应速率变化较大。在反应的不同阶段,晶体的形核速率和长大速率会有较大的差别,生成的银粉形貌也会有很大的差别,从而导致生成了不规则形貌的银粉。

图1 使用不同加料方式制备银粉的SEM像

Fig. 1 SEM images of silver powders prepared by different feeding modes

因此,为了制备出超细球形银粉,适宜采用的加料方式为正向快速加料。对采用该加料方式制备的银粉进行XRD分析,其结果如图2所示。从图2可以看出,银粉在38.12°、44.30°、64.44°和77.40°处有明显的衍射峰,分别对应银的(111)、(200)、(220)和(311)面,与标准晶态银卡片65-2871完全符合,说明所得的样品是单质银。从图2中还可以看出,各个样品的衍射峰相当尖锐,说明制备的银粉结晶度较高。

图2 正向快速加料法制备银粉的XRD谱

Fig. 2 XRD patterns of silver powders prepared by forward feeding mode

图3 加入不同分散剂制得银粉的SEM像

Fig. 3 SEM images of silver powders prepared with different dispersants

2.2 分散剂对制备银粉的影响及机理

在AgNO3溶液浓度为0.3 mol/L、分散剂用量为硝酸银质量10%的条件下,将抗坏血酸溶液快速加入到AgNO3溶液中,考察PVP、吐温80、PVA-124和PEG-6000等4种分散剂对银粉的形貌和分散性的影响。使用不同分散剂制备的银粉微观形貌如图3所示。

从图3可知,不加入分散剂时,制备的银粉为粗糙球形银粉;而加入分散剂后,银粉的分散性和表面形貌都有所改变。使用PVP制备的银粉分散性较好,颗粒表面比较光滑;使用吐温80制备的银粉粒径有所减小,颗粒表面比较粗糙,且从SEM像上来看,有一定程度的团聚;使用PEG-6000和PVA-124制备的银粉为花状球形,表面较粗糙,从更高倍数的SEM像(分别见图3(d)和(e)右上角插图)可以看出,使用这两种分散剂制备的球形花状银粉颗粒是由很多厚度约为100~200 nm的片状一次颗粒聚集生长而成。由于银粉表面越粗糙,其比表面积越大,颗粒间的摩擦力也越大,从而导致银粉的振实密度下降,综合考虑可知,在本体系中,适宜选用的分散剂为PVP。

将浓度为0.05 mol/L硝酸银溶液和2 g/L的不同分散剂溶液各10 mL混合,日光下光照1 h后进行紫外-可见光吸收光谱测试,其结果如图4所示。

从图4可以看出,硝酸银溶液的吸收光谱在300 nm处存在吸收峰,这是银离子的特征吸收峰;而加入了不同分散剂的硝酸银溶液在300 nm处的吸收均有所增强,说明分散剂与银离子之间存在某种相互作用,这可能是由于分散剂与银离子之间形成了配合作用[18]。由于分散剂吐温80、PVP、PVA-124和PEG-6000的分子内存在大量C—N和C=O键,其中的氮原子和氧原子均含有孤电子对,可以给银离子的空sp杂化轨道提供电子云形成配位键。分散剂提供的电子云密度越高,其与银离子形成配位键的能力越强,对应图4在300 nm处的吸收也就越强,由此可知,这4种分散剂与银离子配合时可提供的电子云密度由大到小依次为PVP、吐温80、PVA-124、PEG-6000。PVP给Ag+的空sp杂化轨道提供的更高的电子云密度导致了Ag+更容易得到电子,从而促进了Ag+的光还原生成纳米银,图4中加入PVP的AgNO3溶液在470 nm处的吸收峰即是生成的纳米银粒子的米氏散射造成的吸收峰[19]。

图4 AgNO3溶液及加入不同表面活性剂后AgNO3溶液的紫外-可见光吸收光谱

Fig. 4 Ultraviolet visible adsorption (UV-VIS) spectra of AgNO3 solution and AgNO3 solution added with different dispersants

同时,分散剂与银离子的配合能力越强,银离子被还原后分散剂在银颗粒上的吸附也就越充分,对银粉表面形貌的影响也应越大。由图3(a)可知,不加分散剂制备的银粉表面较粗糙。对比图3中的各分图可以看出,图3(a)所示银粉与图3(d)和(e)的形貌更相似,说明PVA-124和PEG-6000对银粉表面形貌影响较小;而图3(c)所示银粉表面较光滑,说明PVP对银粉的表面形貌影响较大,由此可知,不同分散剂对银粉表面形貌的影响由大到小依次为PVP、吐温80、PVA-124和PEG-6000,这与图4所示各溶液的光谱吸收强弱顺序是一致的。

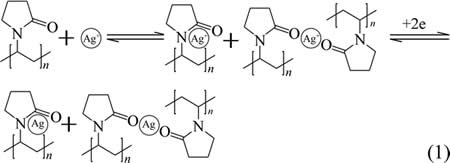

PVP是N-乙烯基-2-吡咯烷酮的聚合物,其结构式为 ,其中,n表示聚合度。由之前的分析可知,PVP容易与Ag+配合形成配合物,当银被还原出来,PVP又会吸附在银表面,从而对银粉生长产生影响。PVP与Ag+以及Ag的吸附可以表示如式(1)所示[20]:

,其中,n表示聚合度。由之前的分析可知,PVP容易与Ag+配合形成配合物,当银被还原出来,PVP又会吸附在银表面,从而对银粉生长产生影响。PVP与Ag+以及Ag的吸附可以表示如式(1)所示[20]:

随着反应的进行,晶体成核和生长形成二次颗粒,在这个过程中,PVP将优先吸附在二次颗粒表面的尖锐部位[21],改变其比表面能,降低该部分的生长速率,从而促进银原子在非尖锐部位沉积,并生长成为表面较光滑的球形颗粒。球形颗粒生成后,PVP均匀吸附在颗粒表面,其长链结构形成的空间位阻不仅会阻碍后续还原的银原子继续在银颗粒上生长,防止银粉粒径过大,又能减少银粉颗粒与颗粒之间的碰撞,减少银粉的团聚,最终制备出表面较为光滑、分散性良好的球形银粉。PVP对银粉形貌和分散性的影响机理如图5所示。

2.3 分散剂用量对制备银粉的影响

在AgNO3溶液浓度为0.3 mol/L,以PVP为分散剂,考察分散剂的用量对银粉形貌和粒径的影响。加入的分散剂用量分别为硝酸银的5%、10%、15%和20%(质量分数)。使用不同的分散剂用量制备所得银粉的微观形貌如图6所示。图7所示为各银粉的粒径分布。

从图6可以看出,随着分散剂用量的增加,银粉的分散性都比较好,且形貌并没有太大变化。随着分散剂用量的增加,银粉的平均粒径分别为2.72、1.95、1.72和1.02 μm,即银粉的平均粒径随着分散剂用量的增加而减小,这也可以从图7的粒径分布图中反映出来。这是由于PVP能与银粉颗粒表面吸附,随着其用量的增加,吸附在银粉颗粒表面上的PVP的量也随之增加,颗粒表面的空间位阻变大,阻碍了随后还原出的银原子与银粉颗粒表面的接触,从而阻碍了其进一步生长;另一方面,由于PVP可促进AgNO3的光还原反应从而生成纳米银粒子,纳米银粒子可作为晶体生长的晶核,PVP用量越多,促进生成的晶核也越多,在一定程度上导致了银粉粒径的减小。因此,随着PVP用量的增加,银粉的粒径减小。

图5 PVP对银粉形貌和分散性的影响

Fig. 5 Effect mechanism of PVP on morphology and dispersity of silver powders

图6 不同分散剂用量制得银粉的SEM像

Fig. 6 SEM images of silver powders prepared with different dispersant dosages

图7 不同分散剂用量制得银粉的粒径分布

Fig. 7 Particle size distributions of silver powders prepared with different dispersant dosages

从以上结果可以说明,通过调节分散剂的用量可以对银粉的粒径实施调控。

2.4 硝酸银溶液浓度对制备银粉的影响

选择PVP用量为10%,考察AgNO3溶液浓度对银粉形貌和粒径的影响。考察的AgNO3溶液浓度分别为0.1、0.2、0.3和0.5 mol/L,不同浓度下所制备银粉的SEM像如图8所示。

从图8可以看出,当AgNO3溶液浓度为0.1~0.3 mol/L时,制备的银粉分散性较好,形貌较规则;当浓度上升到0.5 mol/L,银粉的表面变得更粗糙,并且分散性也相对更差。此外,银粉的平均粒径随着AgNO3溶液浓度的增大而增大,随着AgNO3溶液浓度的提高,银粉的平均粒径分别为1.54、1.84、1.95和3.32 μm。各银粉的粒径分布如图9所示。

根据Weimarn法则[22],沉淀生成粒子的粒径大小取决于晶核的成核速率和生长速率的相对大小,而这二者均与反应物的浓度有关。当AgNO3溶液浓度较低且过饱和度大于其成核的最低过饱和浓度时,成核速率大于晶核的生长速率,在单位时间内晶体成核消耗的物质量多于晶核生长所消耗物质量,从而使得晶核的生长受到抑制。且稀溶液的银离子分散程度较高,因而被还原出来的银粒子向晶核表面扩散迁移的距离也大大增加,从而也一定程度上抑制了晶核的生长,导致银粉平均粒径较小。随着AgNO3溶液浓度的增加,晶核生长速率将最终超过成核速率,在反应开始迅速生成了大量晶核后,随后被还原出来的银粒子大部分都消耗在银晶核的生长上;加之晶核的填充密度很大,导致晶核之间凝聚生长的趋势增加[23]。因此,随着硝酸银溶液浓度的升高,银粉的平均粒径增大。

图8 不同硝酸银浓度制得银粉的SEM像

Fig. 8 SEM images of silver powders prepared with different AgNO3 concentrations

图9 硝酸银浓度对银粉粒径分布的影响

Fig. 9 Effect of AgNO3 concentration on silver particle size distribution

对不同硝酸银浓度制备的银粉进行振实密度测试,所得结果如表1所列。从表1中可以看出,当AgNO3溶液浓度为0.1~0.3 mol/L时,制备的银粉振实密度均较高(>4 g/cm3);当AgNO3浓度为0.5 mol/L时,由于银粉的团聚更严重,使得其振实密度偏低。由此可知,适宜的AgNO3溶液浓度为0.1~0.3 mol/L。

表1 不同硝酸银浓度下制得银粉的振实密度

Table 1 Tap density of silver powders prepared with different AgNO3 concentration

3 结论

1) 优化条件为:采用正向快速加料法,在硝酸银溶液浓度为0.1~0.3 mol/L、PVP用量在5%~20%的条件下,可以制备出表面光滑、分散性较好的球形银粉。当硝酸银溶液浓度为0.1 mol/L、分散剂用量为10%的条件下,银粉的振实密度可达4.9 g/cm3。

2) 加入PVA-124和PEG-6000,制备得到花状球形银粉,加入PVP制备得到表面光滑的球形银粉,加入TW80制备的银粉粒径有所减小,表面较粗糙。PVP能与Ag+配合,并能有效吸附在银颗粒表面,从而使银粉的形貌趋于光滑,控制银粉的粒径,并有效减少颗粒团聚。

3) 随着硝酸银浓度的提高,银粉粒径增大;随着分散剂用量的增加,银粉粒径减小。可通过调节分散剂的用量,在保证银粉分散性和形貌的前提下,有效调节银粉粒径(1.02~2.72 μm)。

REFERENCES

[1] 郭桂全, 甘卫平, 罗 贱, 向 锋, 张金玲, 周 华, 刘 欢. 正交设计法优化高分散超细银粉的制备工艺[J]. 稀有金属材料与工程, 2011, 40(10): 1827-1831.

GUO Gui-quan, GAN Wei-ping, LUO Jian, XIANG Feng, ZHANG Jinling, ZHOU Hua, LIU Huan. Optimization for preparation technique of highly dispersive ultrafine silver powders by orthogonal design[J]. Rare Metal Materials and Engineering, 2011, 40(10): 1827-1831.

[2] 欧阳鸿武, 刘 咏, 王海兵, 黄伯云. 球形粉末堆积密度的计算方法[J]. 粉末冶金材料科学与工程, 2002, 7(2): 87-92.

OUYANG Hong-wu, LIU Yong, WANG Hai-bing, HUANG Bai-yun. Calcination method for random packing of sphere particles[J]. Materials Science and Engineering of Powder Metallurgy, 2002, 7(2): 87-92.

[3] GU Sa-sa, WANG Wei, TAN Fa-tang, GU Jian, QIAO Xue-liang, CHEN Jian-guo. Facile route to hierarchical silver microstructures with high catalytic activity for the reduction of p-nitrophenol[J]. Materials Research Bulletin, 2013, 49: 138-143.

[4] 刘志宏, 刘智勇, 李启厚, 吴厚平, 张多默. 喷雾热分解法制备超细银粉及其形貌控制[J]. 中国有色金属学报, 2007, 17(1): 149-155.

LIU Zhi-hong, LIU Zhi-yong, LI Qi-hou, WU Hou-ping, ZHANG Duo-mo. Morphology control of micro-sized spherical silver powder prepared by spray pyrolysis[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(1): 149-155.

[5] 蒋伟燕. 配位沉淀-热分解法制备纤维状银粉[D]. 长沙: 中南大学, 2010: 33-49.

JIANG Wei-yan. Preparation of the fiber silver powder by coordination-thermal decomposition[D]. Changsha: Central South University, 2010: 33-49.

[6] 尹荔松, 阳素玉, 何 鑫, 范海陆, 安科云, 龚 青. 球形纳米银粒子制备新方法及其表征[J]. 纳米技术与精密工程, 2010, 8(4): 295-299.

YIN Li-song, YANG Su-yu, HE Xin, FAN Hai-lu, AN Ke-yun, GONG Qing. New preparation method and characterization of spheric silver nanoparticles[J]. Nanotechnology and Precision Engineering, 2010, 8(4): 295-299.

[7] ZHANG Jian-ling, HAN Bu-xing, LIU Ming-hua, LIU Dong-xia, DONG Ze-xuan, LIU Jun, LI Dan. Ultrasonication-induced formation of silver nanofibers in reverse micelles and small-angle X-ray scattering studies[J]. Journal of Physical Chemistry B, 2003, 107(16): 3679-3683.

[8] ZHU Jun-Jie, LIAO Xue-Hong, ZHAO Xiao-Ning, CHEN Hong-Yuan. Preparation of silver nanorods by electrochemical methods[J]. Materials Letters, 2001, 49(2): 91-101.

[9] GUO Xue-yi, DENG Duo, TIAN Qing-hua, JIAO Cui-yan. One-step synthesis of micro-sized hexagon silver sheets by the ascorbic acid reduction with the presence of H2SO4[J]. Advanced Powder Technology, 2014, 25(3): 865-870.

[10] 宋永辉, 梁工英, 张秋利, 卢学刚, 魏春阳. 球形纳米银粉的制备研究[J]. 稀有金属材料与工程, 2007, 36(4): 709-712.

SONG Yong-hui, LIANG Gong-ying, ZHANG Qiu-li, LU Xue-gang, WEI Chun-yang. Research on preparation of spherical nanosized silvery powder[J]. Rare Metal Materials and Engineering, 2007, 36(4): 709-712.

[11] 江建军, 谈定生, 刘久苗, 韩月香, 陈 华, 余仲兴. 葡萄糖还原制取超细银粉[J]. 上海有色金属, 2004, 25(1): 5-8.

JIANG Jian-jun, TAN Ding-sheng, LIU Jiu-miao, HAN Yue-xiang, CHEN Hua, YU Zhong-xing. Preparation of ultrafine silver powder by reduction of glucose[J]. Shanghai Nonferrous Metals, 2004, 25(1): 5-8.

[12] HALACIUGA I, LAPLANTE S, GOIA D V. Precipitation of dispersed silver particles using acetone as reducing agent[J]. J Colloid Interface Sci, 2011, 354(2): 620-623.

[13] 魏丽丽, 徐盛明, 徐 刚, 陈崧哲,李林艳. 表面活性剂对超细银粉分散性能的影响[J]. 中国有色金属学报, 2009, 19(3): 595-600.

WEI Li-li, XU Sheng-ming, XU Gang, CHEN Song-zhe, LI Lin-yan. Effects of surfactants on dispersive performance of ultrafine silver powder[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(3): 595-600.

[14] 甘卫平, 张金玲, 张 超, 叶肖鑫, 张 鹿. 化学还原制备太阳能电池正极浆料用超细银粉[J]. 粉末冶金材料科学与工程, 2009, 14(6): 412-416.

GAN Wei-ping, ZHANG Jin-ling, ZHANG Chao, YE Xiao-xin, ZHANG Lu. Preparation of ultra-fine silver powder utilized in paste for solar cell grid electrode[J]. Materials Science and Engineering of Powder Metallurgy, 2009, 14(6): 412-416.

[15] 刘晓刚, 甘卫平, 杨 超, 林 涛, 黎应芬. 太阳能电池用微细银粉的制备[J]. 中国有色金属学报, 2014, 24(4): 987-992.

LIU Xiao-gang, GAN Wei-ping, YANG Chao, LIN Tao, LI Ying-fen . Preparation of ultra-fine silver powder utilized in solar cell[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 987-992.

[16] 甘卫平, 林 涛, 刘晓刚, 黎应芬, 黄 蓓. 二元分散体系制备高分散性微细银粉[J]. 兵器材料科学与工程, 2014, 37(2): 50-54.

GAN Wei-ping, LIN Tao, LIU Xiao-gang, LI YING-fen, HUANG Bei. Preparation of highly dispersive fine silver powders with binary disperse system[J]. Ordnance Material Science and Engineering, 2014, 37(2): 50-54.

[17] 王岳俊, 周康根, 蒋志刚. 加料方式对超细氧化亚铜粉体分散性与粒度稳定性的影响[J]. 无机材料学报, 2012, 27(2): 195-200.

WANG Yue-jun, ZHOU Kang-gen, JIANG Zhi-gang. Effects of reactant mixing mode on dispersibility and particle size stability of cuprous oxide particles[J]. Journal of Inorganic Materials, 2012, 27(2): 195-200.

[18] AO Yi-wei, YANG Yun-xia, YUAN Shuang-long, DING Li-hua, CHEN Guo-rong. Preparation of spherical silver particles for solar cell electronic paste with gelatin protection[J]. Materials Chemistry and Physics, 2007, 104(1): 158-161.

[19] GILS P S, RAY D, SAHOO P K. Designing of silver nanoparticles in gum arabic based semi-ipn hydrogel[J]. International Journal of Biological Macromolecules, 2010, 46(2): 237-244.

[20] ZHANG Zong-tao, ZHAO Bin, HU Li-ming. PVP protective mechanism of ultrafine silver powder synthesized by chemical reduction processes[J]. Journal of Solid State Chemistry, 1996, 121(1): 105-110.

[21] 覃 涛, 叶红齐, 吴 超, 董 虹, 刘贡钢, 郝梦秋. PVP对液相还原法制备微米级银粉颗粒性能的影响[J]. 中南大学学报(自然科学版), 2013, 44(7): 2675-2680.

QIN Tao, YE Hong-qi, WU Chao, DONG Hong, LIU Gong-gang, HAO Meng-qiu. Effects of PVP on properties of micro-sized silver powders prepared by liquid phase reduction method[J]. Journal of Central South University (Science and Technology), 2013, 44(7): 2675-2680.

[22] 黄 凯, 郭学益, 张多默. 超细粉末湿法制备过程中粒子粒度和形貌控制的基础理论[J]. 粉末冶金材料科学与工程, 2005, 10(6): 319-324.

HUANG Kai, GUO Xue-yi, ZHANG Duo-mo. Fundamental theories of particle size and morphology controllingfor ultrafine powders in wet chemical precipitation process[J]. Materials Science and Engineering of Powder Metallurgy, 2005, 10(6): 319-324.

[23] 秦 智, 张为军, 匡加才, 堵永国, 李文换, 杨鹏彪. 高分散性球形银粉的制备研究[J]. 电工材料, 2010(3): 12-15.

QIN Zhi, ZHANG Wei-jun, KUANG Jia-cai, DU Yong-guo, LI Wen-huan, YANG Peng-biao. Research on finely dispersed spherical silver powder[J]. Electronic Material, 2010(3): 12-15.

(编辑 李艳红)

基金项目:湖南有色基金资助项目(Z2011-01-001);广东省产学研项目(2013A100003);博士研究生自主探索创新项目(2015zzts035)

收稿日期:2014-12-29;修订日期:2015-01-12

通信作者:田庆华,副教授,博士;电话:0731-88877863;E-mail:qinghua@csu.edu.cn