DOI: 10.11817/j.issn.1672-7207.2018.11.007

时效状态对7020铝合金疲劳性能的影响

王勇1,唐建国1, 2,邓运来1, 2,林化强3,单朝军2,张勇2,刘胜胆2,叶凌英2

(1. 中南大学 轻合金研究院,湖南 长沙,410083;

2. 中南大学 材料科学与工程学院,湖南 长沙,410083;

3. 中车青岛四方机车车辆股份有限公司,山东 青岛,266000)

摘要:研究不同时效状态下7020铝合金的疲劳强度及疲劳裂纹扩展性能,并分别利用透射电镜和扫描电镜对合金的显微组织及疲劳断口进行观察分析。研究结果表明:欠时效、峰时效和过时效3种时效态合金在循环数为107次时的条件疲劳极限分别为131,114和127 MPa;欠时效合金具有最低的疲劳裂纹扩展速率,峰时效合金的疲劳裂纹扩展速率最高;随着时效程度加大,过时效合金的疲劳裂纹扩展性能有所改善;欠时效合金中可切过的GP区增加位错滑移的可逆性并促进裂纹的偏折,而峰时效合金中主要为η'相,不可切过的η'相以及较大的晶内和晶界无析出带(PFZ)之间的强度差导致疲劳裂纹容易萌生和扩展;过时效合金晶内晶界强度差减小以及相关的裂纹闭合机制使其疲劳性能得到改善。

关键词:7020铝合金;时效;疲劳强度;疲劳裂纹扩展

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2018)11-2684-08

Effect of aging conditions on fatigue behavior of 7020 aluminum alloy

WANG Yong1, TANG Jianguo1, 2, DENG Yunlai1, 2, LIN Huaqiang3, SHAN Zhaojun2, ZHANG Yong2, LIU Shengdan2, YE Lingying2

(1. Light Alloy Research Institute, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

3. China Railway Rolling Stock Corporation Qingdao Sifang Co., Ltd., Qingdao 266000, China)

Abstract: The fatigue strength and fatigue crack growth behavior of 7020 aluminum alloy under different aging conditions were investigated. The microstructures and fractographies of the alloy were examined by transmission electron microscopy(TEM) and scanning electron microscopy(SEM). The results show that when cycle number is 107, the fatigue strength of 7020 aluminum alloy in under-aged, peak-aged and over-aged conditions are 131, 114 and 127 MPa, respectively. The fatigue crack growth rate of under-aged alloy is the least and that of peak aged alloy is the highest. With the increase of aging degree, the fatigue crack growth property of over aged alloy is improved. The shearable GP zones in under-aged alloy enhance the reversibility of dislocation slip and induce the deflection of fatigue crack. In contrast, the non-shearable η' is dominant in peak aged alloy. Together with the large strength differential between grain interior and precipitation free zone(PFZ) of grain boundary, the non-shearable η' makes the fatigue crack easy to initiate and propagate. The reduction of strength differential and related crack closure mechanisms improve fatigue behavior of over aged alloy.

Key words: 7020 aluminum alloy; aging; fatigue strength; fatigue crack growth

7020铝合金具有良好的挤压成型性能、较高的比强度、良好的耐蚀性能和焊接性能,被广泛地应用于高速列车车体结构材料[1-2]。合金在服役过程中,长期处于承载、加速、减速等循环交变应力环境中,不但要求其具有良好的力学性能和耐蚀性能,而且要求其具有较高的疲劳性能。目前,我国高速铁路和高速列车技术研究正处于快速发展阶段,高速列车底架用枕梁、牵引梁等型材作为高速列车极为重要的承载部件之一,其长期服役后的疲劳失效将严重影响高速列车的运行安全。因此,开展7020铝合金疲劳性能的研究具有十分重要的意义。影响合金疲劳性能的显微组织因素主要有晶粒尺寸、织构、第二相和晶界等[3-7],时效析出相的大小、数量、分布和形态等在很大程度上决定了材料疲劳性能。Al-Zn-Mg合金的时效析出顺序可以归纳为[8-12]:过饱和固溶体—GP区—η'亚稳相—η平衡相。时效初期形成的GP区与铝基体共格,能够被可动位错切过[13]。随着时效程度的加深,半共格的η'相开始生成,合金达到峰时效强度时的主要强化相即η'相[12]。较大的η'相和与基体非共格的η相无法被可动位错切过。CHEN等[4]研究了时效析出相对7055铝合金疲劳裂纹扩展速率的影响,并基于位错的可逆滑移模型,提出欠时效和T77态合金中与基体共格的析出相可以提高疲劳裂纹扩展抗力。DESMUKH等[5]研究了时效处理对7010铝合金疲劳性能的影响,发现过时效态合金中粗大、不可切过的相促进了合金的均匀变形,裂纹扩展速率提高的同时疲劳强度也有所提高;此外,晶界析出相和晶界附近无析出带的形成也提高了裂纹的扩展速率。而GURBUZ等[14-15]的研究表明,较大的不可切过的析出相有利于降低疲劳裂纹扩展速率;苏雷什[16]的研究表明,在潮湿环境下,过时效态合金会发生明显的氧化物诱发裂纹闭合现象,因此,有必要进一步研究不同时效状态对疲劳强度及裂纹萌生与扩展的影响。本文通过将7020铝合金分别处理至欠时效、峰时效和过时效状态,研究时效引发的显微组织改变对其疲劳强度及疲劳裂纹扩展性能的影响。

1 实验

实验所用材料为7020铝合金挤压型材,其化学成分见表1。铸锭均匀化后进行热挤压及在线淬火,室温停放72 h后进行双级时效处理,即于90 ℃保温12 h后在170 ℃下分别保温1,4和11 h,将合金分别处理到欠时效、峰时效和过时效状态。

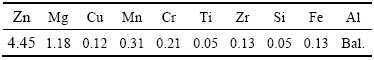

表1 7020铝合金的化学成分(质量分数)

Table 1 Chemical composition of the 7020 aluminum alloy %

室温拉伸实验在CRIMS拉伸机上进行,依照GB/T 228.1—2010“金属材料 拉伸实验 第1部分:室温试验方法”进行实验。试样沿挤压方向切取,拉伸速率为2 mm/min,每种时效状态取3个平行试样。疲劳裂纹扩展实验在MTS Landmark高频疲劳试验机上进行,依照GB/T 6398—2000“金属材料疲劳裂纹扩展速率试验方法”进行实验。采用紧凑拉伸CT试样,取样方向为L-T方向(其中L表示轧制方向,T表示宽度方向),应力比(R=σmin/σmax)为0.1,正弦波加载,加载频率为10 Hz,实验环境为室温、大气环境。

采用Tecnai G2 20型透射电子显微镜(TEM)进行观察,加速电压为200 kV。试样先采用机械减薄至 100 μm以下,冲成直径为3 mm的圆片后在双喷电解减薄仪上制备,电解液为20%硝酸+80%甲醇(体积分数)混合溶液,电压为20 V,实验温度为-30 ℃。采用ZEISS EVO MA10型扫描电子显微镜(SEM)观察疲劳断口,加速电压为20 kV。

2 结果与分析

2.1 力学性能

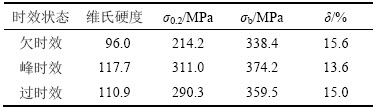

表2所示为不同时效处理后合金的维氏硬度及室温拉伸性能,其中,σ0.2为屈服强度,σb为抗拉强度,△为伸长率。从表2可见:欠时效态合金的硬度和屈服强度均最低,屈服强度只有214.2 MPa;伸长率最高,达到15.6%;峰时效态的合金具有最高的维氏硬度和强度以及最低的伸长率,屈服强度和伸长率分别为311.0 MPa和13.6%;过时效态合金的屈服强度为290.3 MPa,比峰时效态合金的屈服强度低6.7%,而伸长率则较之提高10.3%,达到15.0%。

表2 不同时效状态下合金的力学性能

Table 2 Mechanical properties of the alloys in different ageing conditions

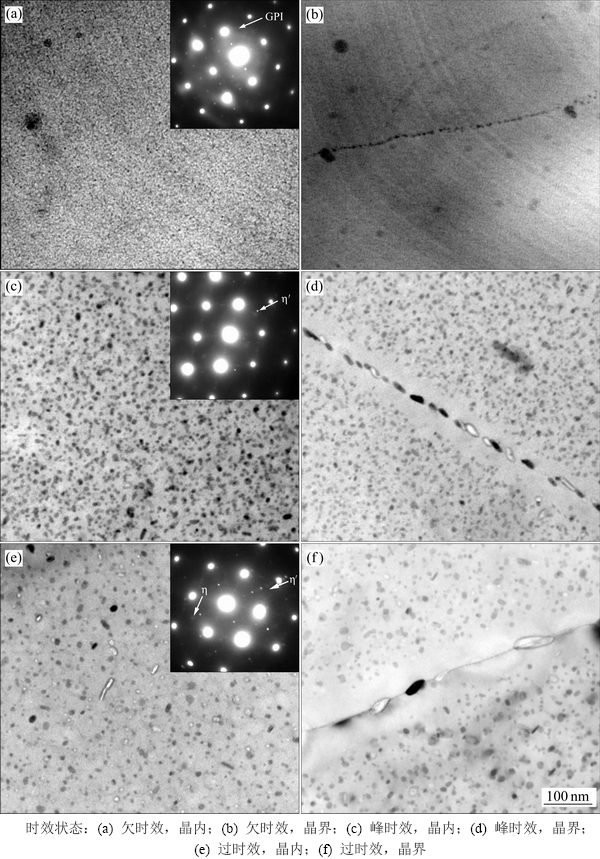

2.2 显微组织

图1所示为不同时效态7020铝合金的TEM明场像及所对应的选区电子衍射(SAED)花样。由图1(a)和图1(b)可以看出:欠时效态合金晶内分布着大量直径为1~2 nm的细小析出相。从其<100>Al方向的衍射花样可以看到,在{1,(2n+1)/4,0}Al处存在明显的衍射斑点,表明其晶内析出相主要为GPI区,时效初期形成的GPI区与铝基体共格并且可以被位错切过。由图1(b)可以看出:其晶界上已经产生较小且较为连续的析出相,但并未观察到明显的晶界无析出带(PFZ)。峰时效态合金的晶内析出相明显增大。从其<110>Al方向的衍射花样可以看出:在1/3{220}Al和2/3{220}Al处存在明显的衍射斑点,表明其晶内析出相主要为弥散分布的η'相,平均直径约7 nm;其晶界处存在明显的无析出带,宽度约68 nm,晶界析出相较为连续,沿晶界方向长度约为22 nm。过时效态合金的晶内析出相进一步粗化,平均直径达到约9 nm,且密度明显降低,此时,其析出相之间的间距明显大于峰时效态合金析出相的间距,结合衍射花样可知其析出相主要为较大的η'相和η相;晶界PFZ宽度达到97 nm,晶界析出相较大且断续分布,沿晶界方向宽度约为50 nm。

图1 不同时效态7020铝合金TEM明场像及选区电子衍射花样

Fig. 1 TEM bright field images and corresponding SAED patterns of 7020 aluminum alloys in different aging conditions

2.3 疲劳强度

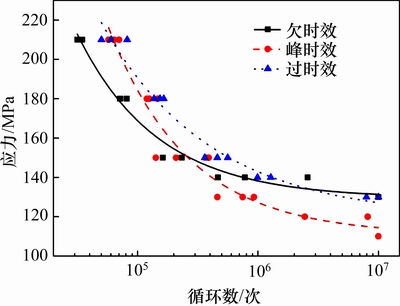

图2所示为不同时效状态下的S-N曲线(其中N为循环次数(用来表征疲劳寿命),S为加载应力)。N的拟合公式[17]为

(1)

(1)

式中:A,B和E为拟合系数。将3种时效状态下合金的循环次数分别按式(1)进行拟合。

图2 不同时效状态下合金的S-N曲线

Fig. 2 S-N curves of the alloys in different ageing conditions

欠时效状态:

(2)

(2)

峰时效状态:

(3)

(3)

过时效状态:

(4)

(4)

由图2可以看出:在较高应力阶段(应力>150 MPa),由于接近欠时效合金的屈服强度,较容易萌生裂纹,导致其疲劳寿命明显低于峰时效态和过时效态合金的疲劳寿命,特别是在循环次数低于105次的低周疲劳阶段,其裂纹萌生与扩展方式与高周疲劳阶段的有一定差异。而在低应力的高周疲劳阶段,欠时效态合金和过时效态合金的疲劳寿命显著高于峰时效态合金的疲劳寿命。随着循环应力下降,S-N曲线逐渐接近水平,欠时效、峰时效和过时效态3种合金在循环数为107次时的疲劳强度极限分别为131,114和127 MPa。

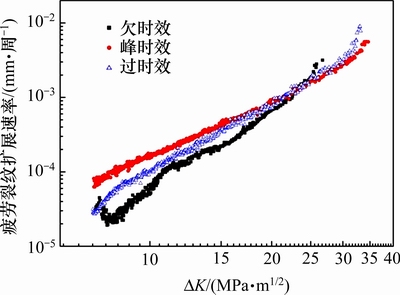

2.4 疲劳裂纹扩展

图3所示为不同时效状态下合金的疲劳裂纹扩展速率曲线。其中,曲线的线性部分即疲劳裂纹扩展的稳定扩展Paris区,符合下列公式:

(5)

(5)

式中:c和n为材料试验常数;△K为应力强度因子范围;da/dN为疲劳裂纹扩展速率。

表3所示为3种时效状态下不同△K所对应的疲劳裂纹扩展速率。由表3可知:在△K=10 MPa·m1/2时,欠时效态合金的裂纹扩展速率最低,为6.09× 10-5 mm/次;峰时效态合金的裂纹扩展速率最高,达到1.49×10-4 mm/次;过时效态合金的裂纹扩展速率为9.72×10-5 mm/次,比峰时效态合金的裂纹扩展速率降低了34.8%。随着△K增加,裂纹扩展速率差距逐渐缩小,当△K>20 MPa·m1/2时,二者裂纹扩展速率已经基本没有差别。值得注意的是,欠时效态合金在疲劳裂纹扩展的初始阶段出现裂纹扩展速率下降的现象,这是典型的疲劳短裂纹扩展现象,即疲劳短裂纹的扩展速率随短裂纹长度增加而降低,之后又随裂纹长度增加而增加,这种现象的产生可能与裂纹尖端与晶界的相互作用及裂纹的偏折和闭合程度有关[16]。

图3 不同时效状态下合金的疲劳裂纹扩展速率曲线

Fig. 3 Curves of fatigue crack growth rate of the alloys in different aging conditions

表3 3种时效状态下不同△K所对应的疲劳裂纹扩展速率

Table 3 Fatigue crack growth rate corresponding to various △K in different ageing conditions

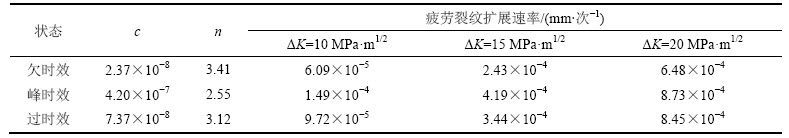

图4所示为不同时效状态下合金的疲劳裂纹扩展路径。由图4可以看出:欠时效合金的裂纹扩展路径最曲折,而峰时效态合金和过时效态合金的裂纹扩展路径较平直。这种差异主要是由时效引起的显微组织不同造成的,而裂纹扩展路径的曲折程度对疲劳裂纹扩展速率有很大影响。

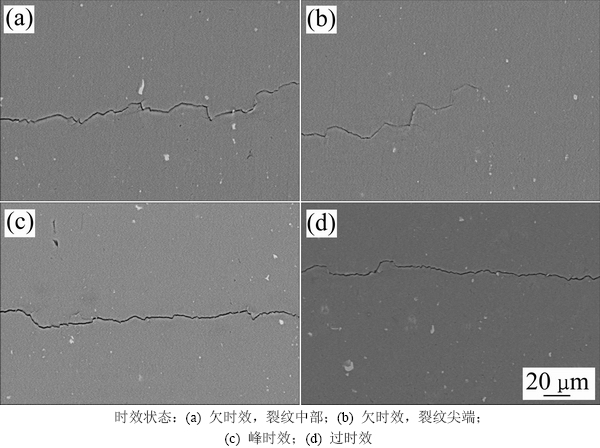

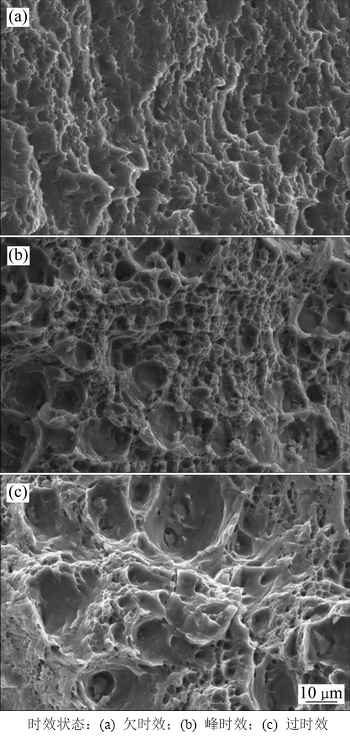

2.5 疲劳断口

图5所示为不同时效状态下的疲劳裂纹扩展Paris区(△K=15 MPa·m1/2)的断口形貌。由图5可以看出:疲劳裂纹以穿晶模式扩展,存在由撕裂棱分隔的疲劳断片,欠时效态合金的断口较粗糙且断片尺寸最小,表明其裂纹偏折较明显,峰时效和过时效态合金中还出现了微孔洞。在高倍镜下可以清晰地观测到平行排布的疲劳辉纹,Laird塑性钝化模型很好地解释了疲劳条带形成的原因,在该模型中每条带可以视作1次应力循环的扩展痕迹,裂纹的扩展方向与条带垂直[18]。经测量,欠时效态合金疲劳辉纹的平均宽度为0.18 μm,峰时效态合金疲劳辉纹平均宽度为0.43 μm,过时效态合金疲劳辉纹平均宽度为0.34 μm。测量结果与表3所示结果吻合,再次验证了欠时效态合金的裂纹扩展速率最低,过时效态次之,峰时效态裂纹扩展速率最高。

图4 不同时效状态下合金的疲劳裂纹扩展路径

Fig. 4 Fatigue crack growth paths in different ageing conditions

图5 不同时效状态下合金的疲劳裂纹扩展Paris区断口形貌

Fig. 5 SEM fractographs of Paris regime of alloys in different aging conditions

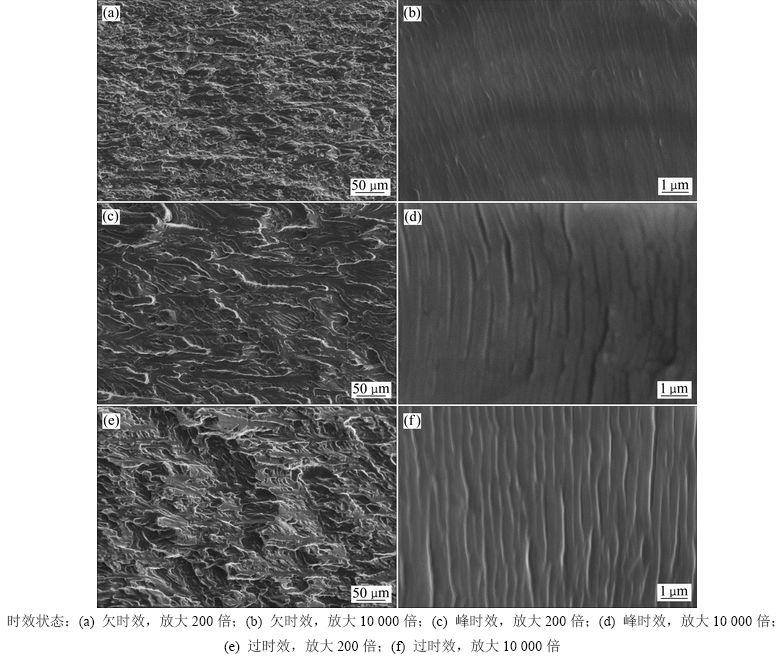

图6所示为不同时效状态下合金疲劳瞬断区的形貌。3种时效状态下合金的断口形貌都以韧窝状的塑性断口为主,接近于合金的拉伸断口形貌。欠时效态合金的塑性最好,其断口上存在大量细小的韧窝;相比于峰时效合金,过时效合金的韧窝变得大而深,这主要是因为时效程度加深使得合金塑性提高。

图6 不同时效状态下合金的瞬断区断口形貌

Fig. 6 SEM fractographs of rupture regime of alloys under different aging conditions

3 讨论

材料的疲劳总寿命是指光滑试样的疲劳裂纹萌生的循环数与疲劳裂纹扩展到失效断裂的循环数之和,而疲劳裂纹扩展又分为低扩展速率的近门槛值区、稳定扩展的Paris区和高扩展速率的瞬断区。由于瞬断区存在的时间极短,故本文主要讨论疲劳裂纹萌生和较低△K下的裂纹扩展。对合金疲劳性能有显著影响的晶粒尺寸、初生相形貌和再结晶程度等微观组织结构特征在时效阶段不会发生改变,因此,不同时效状态对于合金疲劳性能的影响主要是由晶内和晶界时效析出相以及晶界无析出带的差异造成的。

欠时效合金具有最强的疲劳裂纹扩展抗力和较大的高周疲劳强度,这主要是由于欠时效合金的时效析出相与基体共格并且可以被位错切过。位错在裂纹尖端塑性区内的运动具有可逆性:当应力加载时,位错滑移直到它们遇到障碍,形成位错堆积并产生一定的应力;当应力卸载时,向后的应力促使位错反向运动。欠时效合金中由于滑移面上的可切过析出相已被破坏,当应力卸载时大量位错在滑移面上反向运动,降低了裂纹尖端的局部应力集中以及塑性累积水平,从而降低了疲劳裂纹扩展速率。相反,不可切过的析出相会阻碍位错的可逆运动,导致裂纹扩展速率较高。此外,可切过的析出相造成不均匀的滑移分布和晶体学的裂纹扩展。与峰时效和过时效合金相比,欠时效合金的裂纹是高度锯齿状和晶体学方式扩展的穿晶裂纹(见图4),其裂纹扩展路径最曲折。苏雷什等[16, 19]的研究表明,即使裂纹路径存在很小偏折(与裂纹长度相比),也可能使裂纹扩展速率降低几个数量级,特别是在疲劳的近门槛区,这主要是由于裂纹偏折导致应力卸载时2个相对的疲劳断裂面提前接触,产生显著的粗糙诱发裂纹闭合效应,从而降低了疲劳裂纹扩展速率。

峰时效合金的析出相尺寸显著增大,主要为η'相,细小而弥散的η'析出相会阻碍位错的运动而使其具有较高的强度。析出相尺寸改变会使位错通过析出相时的机制产生变化。KOV CS等[13]对切过和绕过2种机制进行了分析,得到如下关系式:

CS等[13]对切过和绕过2种机制进行了分析,得到如下关系式:

(6)

(6)

(7)

(7)

式中:τcutting和τorowan分别为位错切过和绕过粒子时所需的切应力;f为粒子的体积分数;R为粒子半径;Γ为反向畴界能;G为剪切模量;b为柏氏矢量; 为泊松比;r0为位错芯半径。由式(6)和式(7)可知:切过机制的强化效应随析出相体积分数和尺寸增大而增大,而绕过机制随析出相体积分数降低和尺寸增加而减小。因此,存在1个临界尺寸,当析出相尺寸小于临界尺寸时位错切过析出相,而大于临界尺寸时位错绕过析出相。对于Al-Zn-Mg合金,这一临界直径约为6 nm[13, 20-21]。7020铝合金峰时效态的析出相直径约为7 nm,其不能被位错切过,弥散分布的析出相阻碍了位错的可逆滑移,导致疲劳裂纹扩展速率较高。而且由于峰时效态合金的基体和晶界上较软的PFZ的强度相差很大,使晶界上产生额外的应变集中而导致其开裂。

为泊松比;r0为位错芯半径。由式(6)和式(7)可知:切过机制的强化效应随析出相体积分数和尺寸增大而增大,而绕过机制随析出相体积分数降低和尺寸增加而减小。因此,存在1个临界尺寸,当析出相尺寸小于临界尺寸时位错切过析出相,而大于临界尺寸时位错绕过析出相。对于Al-Zn-Mg合金,这一临界直径约为6 nm[13, 20-21]。7020铝合金峰时效态的析出相直径约为7 nm,其不能被位错切过,弥散分布的析出相阻碍了位错的可逆滑移,导致疲劳裂纹扩展速率较高。而且由于峰时效态合金的基体和晶界上较软的PFZ的强度相差很大,使晶界上产生额外的应变集中而导致其开裂。

随着时效程度增加,过时效态合金的析出相变为较粗大的η'相和η相,不能被位错切过,其疲劳强度增加而裂纹扩展速率下降。这主要是由于粗大的晶内析出相可以使变形更加均匀[22-23],同时,基体强度下降导致其与晶界PFZ之间的强度差变小,反而提高了晶界的变形抗力,从而导致在较低应力水平下合金疲劳裂纹萌生困难。而且在低△K的近门槛区,裂纹尖端的塑性区很小,位错滑移距离很短而过时效合金的析出相间距较大,这降低了位错与析出相之间相互作用的概率并有利于位错的可逆滑移及裂纹闭合,从而使低△K时的裂纹扩展速率降低。随着△K增加,裂纹尖端的塑性区增大,位错滑移距离也增加,位错绕过较大的析出相并形成位错环,阻碍了可逆滑移,导致△K较高时裂纹扩展速率较快。此外,苏雷什等[16, 24]的研究表明,在大气环境下进行疲劳试验时,会发生显著的氧化物诱发裂纹闭合现象,低应力比、低△K水平及高循环频率等因素由于对断裂面的凹凸不平处发生微动磨损和摩擦有利,从而促进了这个过程。时效处理引入的析出相变化对于铝合金的断裂面在疲劳过程中的氧化具有决定性影响,过时效态合金在疲劳过程中所形成的氧化层厚度要远大于欠时效态和峰时效态合金的氧化层厚度,在应力卸载时会导致裂纹提前闭合,从而降低了疲劳裂纹扩展速率。

4 结论

1) 欠时效态7020铝合金晶内分布着大量细小且可切过的GPI区,峰时效和过时效态合金晶内的η'相和η相不可切过;晶界PFZ宽度和析出相尺寸随着时效程度加深不断增大。

2) 欠时效和过时效态合金的疲劳强度较高,峰时效合金的疲劳强度最低,欠时效、峰时效和过时效态3种合金在循环数为107次时的条件疲劳极限分别为131,114和127 MPa。

3) 欠时效态合金的疲劳裂纹扩展速率最低,过时效态合金次之,峰时效态合金最高;欠时效合金中可切过的GP区增加了滑移的可逆性并促进了裂纹的偏折,峰时效合金中不可切过的η'相阻碍了位错的可逆滑移;过时效合金析出相间距增加及相关的闭合机制使其疲劳性能得到改善。

参考文献:

[1] 肖涛, 林化强, 叶凌英, 等. 腐蚀条件对Al-Zn-Mg铝合金强韧性能的影响[J]. 中国有色金属学报, 2016, 26(7): 1391-1399.

XIAO Tao, LIN Huaqiang, YE Lingying, et al. Effect of corrosin conditions on strength and toughness of Al-Zn-Mg aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(7): 1391-1399.

[2] 杨涛, 叶凌英, 刘胜胆, 等. 预时效对7020铝合金组织与性能的影响[J]. 中南大学学报(自然科学版), 2017, 48 (3): 578-584.

YANG Tao, YE Lingying, LIU Shengdan, et al. Effect of pre-aging on microstructures and mechanical properties of 7020 aluminum alloy[J]. Journal of Central South University(Science and Technology), 2017, 48(3): 578-584.

[3] 周明哲, 易丹青, 王斌, 等. 固溶处理对2E12铝合金组织及疲劳断裂行为的影响[J]. 中南大学学报(自然科学版), 2012, 43(1): 66-73.

ZHOU Mingzhe, YI Danqing, WANG Bin, et al. Effect of solution treatment on fatigue behavior of 2E12 aluminum alloy[J]. Journal of Central South University(Science and Technology), 2012, 43(1): 66-73.

[4] CHEN Junzhou, ZHEN Liang, YANG Shoujie, et al. Effects of precipitates on fatigue crack growth rate of AA 7055 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(12): 2209-2214.

[5] DESMUKH M N, PANDEY R K, MUKHOPADHYAY A K. Effect of aging treatments on the kinetics of fatigue crack growth in 7010 aluminum alloy[J]. Materials Science & Engineering A, 2006, 435/436(5): 318-326.

[6] DE P S, MISHRA R S, BAUMANN J A. Characterization of high cycle fatigue behavior of a new generation aluminum lithium alloy[J]. Acta Materialia, 2011, 59(15): 5946-5960.

[7] 陈宇强, 宋文炜, 潘素平, 等. T6I4和T6I6时效处理对7050铝合金疲劳性能的影响[J]. 中南大学学报(自然科学版), 2016, 47(10): 3332-3340.

CHEN Yuqiang, SONG Wenwei, PAN Suping, et al. Influence of T6I4 and T6I6 aging treatments on fatigue properties of 7050 Al alloy[J]. Journal of Central South University(Science and Technology), 2016, 47(10): 3332-3340.

[8] STILLER K, WARREN P J, HANSEN V, et al. Investigation of precipitation in an Al-Zn-Mg alloy after two-step ageing treatment at 100 ℃ and 150 ℃[J]. Materials Science and Engineering A, 1999, 270(1): 55-63.

[9] BERG L K, GJ NNES J, HANSEN V, et al. GP-zones in Al-Zn-Mg alloys and their role in artificial aging[J]. Acta Materialia, 2001, 49(17): 3443-3451.

NNES J, HANSEN V, et al. GP-zones in Al-Zn-Mg alloys and their role in artificial aging[J]. Acta Materialia, 2001, 49(17): 3443-3451.

[10] ENGDAHL T, HANSEN V, WARREN P J, et al. Investigation of fine scale precipitates in Al-Zn-Mg alloys after various heat treatments[J]. Materials Science and Engineering A, 2002, 327(1): 59-64.

[11] SHA Gang, CEREZO A. Early-stage precipitation in Al-Zn-Mg-Cu alloy(7050)[J]. Acta Materialia, 2004, 52(15): 4503-4516.

[12] CHEN Junzhou, ZHEN Liang, YANG Shoujie, et al. Investigation of precipitation behavior and related hardening in AA 7055 aluminum alloy[J]. Materials Science & Engineering A, 2009, 500(1/2): 34-42.

[13] KOV CS I, LENDVAI J, UNGAR T, et al. Mechanical properties of AlZnMg alloys[J]. Acta Metallurgica, 1980, 28(12): 1621-1631.

CS I, LENDVAI J, UNGAR T, et al. Mechanical properties of AlZnMg alloys[J]. Acta Metallurgica, 1980, 28(12): 1621-1631.

[14] GURBUZ R, SARIOGLU F. Fatigue crack growth behaviour in aluminium alloy 7475 under different aging conditions[J]. Materials Science and Technology, 2001, 17(12): 1539-1543.

[15] XIA Peng, LIU Zhiyi, BAI Song, et al. Enhanced fatigue crack propagation resistance in a superhigh strength Al-Zn-Mg-Cu alloy by modifying RRA treatment[J]. Materials Characterization, 2016, 118(7): 438-445.

[16] 苏雷什. 材料的疲劳[M]. 王中光, 译. 北京: 国防工业出版社, 1999: 343-357.

SURESH S. Fatigue of materials[M]. WANG Zhongguang, trans. Beijing: National Defense Industry Press, 1999: 343-357.

[17] ISO 12107:2012(E), Metallic materials-fatigue testing-statistical planning and analysis of data[S].

[18] 束德林. 工程材料力学性能[M]. 2版. 北京: 机械工业出版社, 2007: 113-115.

SHU Delin. Mechanical properties of engineering materials[M]. 2nd ed. Beijing: China Machine Press, 2007: 113-115.

[19] 薛喜丽, 郑子樵, 胡芳, 等. 时效制度对2A97铝锂合金疲劳裂纹扩展速率的影响[J]. 稀有金属材料与工程, 2016, 45(12): 3319-3324.

XUE Xili, ZHEN Ziqiao, HU Fang, et al. Effect of aging conditions on the fatigue crack propagation rate of 2A97 aluminum-lithium alloy[J]. Rare Metal Materials and Engineering, 2016, 45(12): 3319-3324.

[20] 韩念梅. 7050铝合金厚板断裂韧性的研究[D]. 长沙: 中南大学材料科学与工程学院, 2011: 61-63.

HAN Nianmei. Investigation on the fracture toughness of 7050 aluminum alloy thick plate[D]. Changsha: Central South University. School of Materials Science and Engineering, 2011: 61-63.

[21] MARLAUD T, DESCHAMPS A, BLEY F, et al. Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2010, 58(14): 4814-4826.

[22] KAMP N, SINCLAIR I, STARINK M J. Toughness-strength relations in the overaged 7449 al-based alloy[J]. Metallurgical and Materials Transactions A, 2002, 33(4): 1125-1136.

[23] CHEN Xu, LIU Zhiyi, LIN Mao, et al. Enhanced Fatigue Crack Propagation Resistance in an Al-Zn-Mg-Cu Alloy by Retrogression and Reaging Treatment[J]. Journal of Materials Engineering and Performance, 2012, 21(11): 2345-2353.

[24] SURESH S, VASUD VAN A K, BRETZ P E. Mechanisms of slow fatigue crack growth in high strength aluminum alloys: role of microstructure and environment[J]. Metallurgical & Materials Transactions A, 1984, 15(2): 369-379.

VAN A K, BRETZ P E. Mechanisms of slow fatigue crack growth in high strength aluminum alloys: role of microstructure and environment[J]. Metallurgical & Materials Transactions A, 1984, 15(2): 369-379.

(编辑 伍锦花)

收稿日期:2017-11-06;修回日期:2018-01-06

基金项目(Foundation item):国家重点研发计划项目(2016YFB0300901);国家自然科学基金资助项目(51474240);中山市科技局重大专项(2016A1001) (Project(2016YFB0300901) supported by the National Key Research and Development Program of China; Project(51474240) supported by the National Natural Science Foundation of China; Project(2016A1001) supported by the Key Research and Development Program of Zhongshan City)

通信作者:唐建国,博士,副教授,从事铝合金材料加工制备研究;E-mail: jgtang@csu.edu.cn