文章编号:1004-0609(2012)02-0427-07

C/C复合材料表面原位生长SiCw的工艺

李 军1, 2,谭周建1,廖寄乔1, 2,张 翔1,李丙菊1

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 湖南金博复合材料科技有限公司,益阳 413000)

摘 要:以三氯甲基硅烷(CH3SiCl3, MTS)为先驱体原料,采用化学气相沉积法在C/C复合材料基体上原位生长碳化硅晶须,研究稀释气体流量、催化剂以及沉积温度对碳化硅晶须生长的影响。结果表明:有催化剂存在时可以制备具有较高长径比的SiCw,无催化剂制备的SiC主要以短棒状或球状SiC为主;随着稀释气体流量或者沉积温度的增加,SiCw的产率是先增加、后减少,在1 100 ℃、载气和稀释气体流量均为100 mL/min时,制备的碳化硅晶须的产率最高,晶须质量最好。

关键词:碳化硅晶须;C/C复合材料;稀释气体流量;催化剂;沉积温度

中图分类号:TB 332 文献标志码:A

Technology of in-situ growing SiCw on surface of C/C composites

LI Jun1, 2, TAN Zhou-jian1, LIAO Ji-qiao1, 2, ZHANG Xiang1, LI Bing-ju1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Hunan Kingbo Carbon-carbon Composites Co., Ltd., Yiyang 413000, China)

Abstract: The silicon carbide whiskers were deposited on C/C composites by chemical vapor deposition (CVD) with methyltrichlorosilane (MTS) as the precursor. The effects of dilute gas flow, catalyst and deposition temperature on the growth of silicon carbide whiskers were investigated. The results show that silicon carbide whiskers (SiCw) with high length-diameter ratio are obtained when there is catalyst, but cosh-like or globular-like silicon carbides are got without catalyst, and with the increase of deposition temperature or the dilute gas flow, the yield of SiCw firstly increases and then decreases, and the highest yield and high quality of silicon carbide whiskers are obtained under the conditions as: deposition temperature of 1 100 ℃ and flow of carry gas and dilute gas both for 100 mL/min.

Key words: SiC whiskers; C/C composites; dilute gas flow; catalyst; deposition temperature

碳化硅晶须是一种直径为纳米级至微米级的单晶纤维,具有高强度、高硬度、高弹性模量及低密度、耐腐蚀、稳定的化学性质、强抗高温氧化能力等优良特性,在制备高温金属基、陶瓷基复合材料中得到广泛的应用[1-5]。SiC晶须增强陶瓷基复合材料始于20世纪90年代,WANG等[3]对SiC晶须的氮化硅基复合材料中晶须取向的研究表明,当晶须方向基本一致且晶须与基体界面弱连接时,此方向中的断裂韧性具有极大值,抗折强度和断裂韧性分别为1 038 MPa和10.7 MPa·m1/2;YE等[4]用SiC晶须增强氧化铝的实验研究表明,当SiC晶须的体积分数为20%时,SiCw/Al2O3复合材料的弯曲强度达508 MPa,断裂韧性为8.78 MPa·m1/2,比纯铝的断裂韧性提高了近一倍。近年来,为解决碳/碳(C/C)复合材料高温抗氧化涂层容易开裂的问题,碳化硅晶须被作为增韧材料用于高温抗氧化涂层的制备中[6-8],取得了一定的效果,但是,由于碳化硅晶须是通过人工的方式掺杂进入涂层体系的,晶须的分散均匀性难以保证,同时,这种掺杂碳化硅晶须增韧涂层只能单方面地提高涂层自身的抗氧化能力,而在改善涂层和C/C基体之间的热膨胀性能不匹配方面没有任何作用,而后者往往才是导致涂层破坏的关键。研究表明[9-12],如果晶须和基体相互交织缠结在一起,不仅可提高晶须和基体的层间剪切强度,而且可以缓冲或阻止涂层内部裂纹的扩散。因此,有必要系统地研究C/C复合材料表面原位生长SiCw的生长工艺,包括稀释气体流量、催化剂以及沉积温度对CVD SiCw的影响。到目前为止尚未见到系统研究C/C复合材料表面原位生长SiCw的文献报道。因此,有必要开展相关的研究,同时也为制备SiCw增韧的高温抗氧化涂层工作开展基础性研究。在本研究中,本文作者在C/C复合材料基体上原位生长SiCw,目的是在C/C基体和碳化硅涂层之间制备一层碳化硅晶须过渡层,使其作为基体和SiC涂层之间的缓冲带,一方面提高涂层和基体的结合强度,一方面利用晶须的拔出桥连与裂纹转向机制降低涂层中的裂纹尺寸和数量,从而达到提高涂层的防氧化性能和热震性能目的。

1 实验

1.1 样品制备

所用沉积基体为C/C复合材料,由湖南金博复合材料科技有限公司生产,其密度为1.6 g/cm3,试样尺寸为15 mm×10 mm×5 mm,试样用600号碳化硅砂纸打磨,再用超声波清洗后烘干,然后把样品分为两组,一组样品不作处理待用;另一组样品表面加载Ni-La-Al催化剂,催化剂的加载方法见文献[13-15]。SiC晶须的制备工艺为以三氯甲基硅烷(CH3SiCl3, MTS)为先驱体原料,H2用作载气和稀释气体,采用质量流量控制器(S49-33/MT)控制气体流量,通过鼓泡法把MTS带入反应室,载气流量为100 mL/min,稀释气体的变化范围为50~200 mL/min,沉积温度范围为1 000~1 150 ℃,压力为常压。

1.2 性能表征

通过扫描电镜(SEM,JSM-6360LV)观察SiCw的微观形貌,X射线能谱仪(EDS, EDX-GENESIS 60S型)分析晶须成分。由于试样尺寸相同,以试样的质量增加率(w)来表征SiCw的产率,w的计算公式如下:

(1)

(1)

式中:m0和m1分别为试样沉积前和沉积后的质量,用灵敏度为±0.1 mg 的电子天平称量试样质量。

2 结果与讨论

2.1 稀释气体流量对CVD SiCw的影响

固定载气(H2)流量为100 mL/min,沉积温度为 1 100 ℃,压力为常压,沉积时间为3 h,以H2为稀释气体,气体流量分别为50、100、150和200 mL/min,研究不同稀释气体流量对CVD SiCw的影响。

2.1.1 稀释气体流量对SiC晶须的产率的影响

图1所示为稀释气体流量分别为50、100、150和200 mL/min时试样的质量增加率曲线。

图1 不同稀释气体流量下CVD SiCw的质量增加率曲线

Fig. 1 Mass gain rate curve of CVD SiCw at different flow rates of dilute gas

从图1中可以得出,SiCw产率与稀释气体流量不是成简单的线性关系,而是先增加,后减少。研究认为[16-17],增大稀释气体流量,会降低反应表面气体的温度,造成沉积速度下降。在CVD制备碳化硅时,一般以Ar或者H2为稀释气体时,但是H2和Ar在作为稀释气体时,两者在CVD过程中所起的作用不同。Ar不参与反应,其作用主要是平衡反应区的温度差,通过调节其流量而使试样沉积更均匀,所以Ar的影响比较单一。相对而言,H2在CVD过程中所起的作用就比较复杂,H2参与反应的事实已经被很多研 究[16, 18]证明。当H2流量比较小时,H2参与反应对SiCw产率的影响是主要的,对反应表面温度的影响是次要的,所以这个阶段随着H2流量的增加,SiCw产率迅速增加,图1中H2流量为100 mL/min时的质量增加

率几乎是50 mL/min时的3倍。但是,随着H2流量的增加,对反应表面温度的影响逐渐增大,导致了碳化硅产率下降。总之,以H2为稀释气体制备SiCw时,需要考虑H2对反应有利和不利的因素。在本研究中,H2流量为100 mL/min时,SiCw的产率最高。

2.1.2 稀释气体流量对SiCw微观形貌的影响

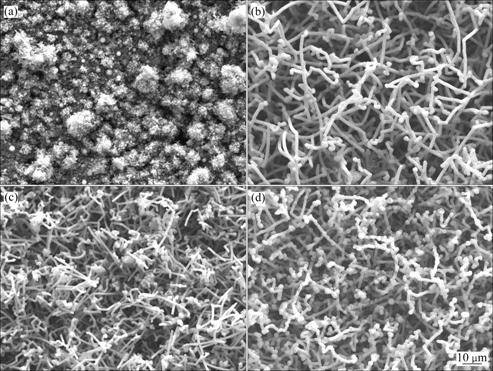

图2所示为H2流量分别为50、100、150和200 mL/min时试样表面碳化硅的微观形貌。从图2中可以看出,当H2流量为50 mL/min时,并不能获得SiCw;只有当H2流量大于等于100 mL/min时,才能完全获得SiCw。

在CVD过程中,H2/MTS的分解产物包括CH3、SiCl3、SiCl2、CH4、HCl、SiCl4,其中CH3、SiCl3是SiC生成的基础,CH4、SiCl4是二次反应的产物,一般认为不参与表面反应[19]。SiCI2易于吸附在反应表面,当有H2时能进一步反应生成Si和HCl。在本研究中,当H2流量为50 mL/min时,H2的流量不足以满足与SiCl2反应的要求,导致在反应初期生成的碳化硅晶体表面掺杂了部分SiCl2,阻碍了碳化硅晶体定向生长成为SiC晶须。只有增加H2流量,才有利于满足与SiCl2反应的要求,碳化硅晶体才能有连续生长成为SiCw的条件。所以当氢气流量大于等于100 mL/min时,均能生成SiCw。

图2 不同稀释气体流量下CVD SiCw的微观形貌

Fig. 2 Morphologies of CVD SiCw at different dilute gas flow rates: (a) 50 mL/min; (b) 100 mL/min; (c) 150 mL/min; (d) 200 mL/min

2.2 催化剂对CVD SiCw的影响

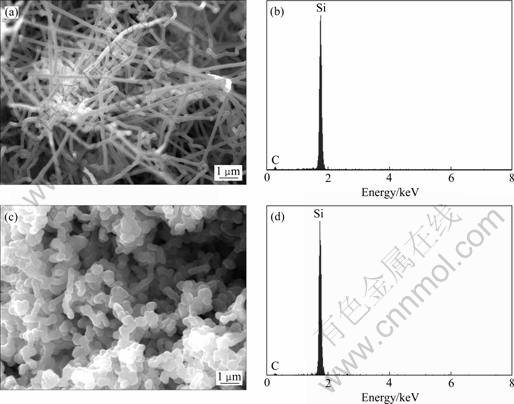

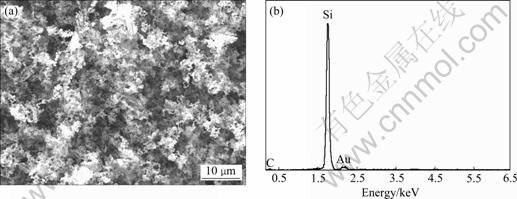

根据2.1节的分析,在其它条件不变的情况下,载气和稀释气体流量均为100 mL/min时为SiCw的最佳制备工艺。在此工艺下,研究催化剂对CVD制备SiC w的影响。图3所示为表面加载有催化剂的样品和表面未作处理的样品化学气相沉积1 h后样品表面的微观形貌和元素分析谱。

图3 加催化剂和无催化剂制备的SiCw的微观形貌和元素分析

Fig. 3 Micrographs((a), (c)) and surface EDS analyses((b), (d)) of SiCw obtained with((a, (b)) and without ((c), (d)) catalyst

从图3中可以看出,有催化剂制备的碳化硅是有较高的长径比的SiCw,相比而言,无催化剂制备的碳化硅主要以短棒状或球状SiC为主。在CVD SiCw的过程中,SiCw主要通过气-液-固(V-L-S)机理生成,催化剂的作用体现在:一方面,催化剂可与反应体系中的其它组分(主要MTS分解产生的CH3和SiCl3)在较低的温度下形成低共熔液相,这对CH3和SiCl3分解产生的áC?和áSi?是有利的,当分解产生的áC?和áSi?达到一定过饱和度时,开始形成SiC晶核并析出在液体与基体的界面上,随着原料的持续供给,SiC晶核沿一维方向连续生长生成SiCw。同时,这种溶解析出的生长机制相应地减少了无液相催化剂存在部位SiC的成核与长大,从而降低碳化硅颗粒出现的几率;另一方面,催化剂的使用能够降低反应的活化能,加速中间相原料CH3和SiCl3的生成和分解,从而加快SiCw的沉积速率。当SiC达到饱和时析出碳化硅晶核,在催化剂的作用下沿着液-固界面的轴向连续、均匀的生长,因此得到的SiCw表面光滑,形貌好。

2.3 沉积温度对CVD SiCw的影响

根据2.1节和2.2节的研究结果,在固定载气和稀释气体流量均为100 mL/min、有催化剂存在时,重点研究沉积温度对CVD SiCw的影响。

图4所示为沉积温度分别为1 000、1 050、1 100、1 150 ℃沉积时间为1 h时试样的质量增加率的曲线。

从图4中可以得出,SiCw的产率与沉积温度不是成简单的线性关系,而是先增加、后减少,拐点是 1 100 ℃。热力学分析表明[20]:由MTS分解沉积SiC涂层,一般在900~1600℃进行,在较低的温度,沉积速率受表面反应限制,当温度增高时,表面反应速率以指数升高,所以,物质传递会成为控制因素。图4中在1 000~1 100 ℃,沉积速率与温度之间呈很好的线性关系,说明沉积过程主要受表面反应控制,在 1 100~1 150 ℃,随着沉积温度的升高,沉积速率下降,说明当温度大于等于1 100 ℃时,CVD过程的控制因素发生了变化,刘荣军等[20-21]的研究表明,在1 000~1 300 ℃,随着温度的升高,SiC的沉积速率是逐渐增大的,且当温度大于等于1 150 ℃时,SiC的沉积速率迅速增大。而在本研究中,1 150 ℃时,SiC的沉积速率相对1 100 ℃是下降的,这可能是催化剂影响造成的,前面催化剂对CVD SiCw的影响的研究结果表明,催化剂能加速中间相原料CH3和SiCl3的生成和分解,在本研究中,当温度大于等于1 100 ℃时,由于MTS分解过快,造成催化剂被包覆失去活性,导致SiC沉积速率下降,虽然温度的升高能增大SiC的沉积速率,但是增加作用没有催化剂的作用明显,所以,1 150 ℃时SiC沉积速率下降。且实验过程中发现,随着温度的升高,基体表面沉积的SiC的颜色逐渐由银白色变成黑色。制备的SiC的微观形貌差异很大。

图4 不同沉积温度CVD SiCw的质量增加率曲线

Fig. 4 Mass gain rate curve of CVD SiCw at different deposition temperatures

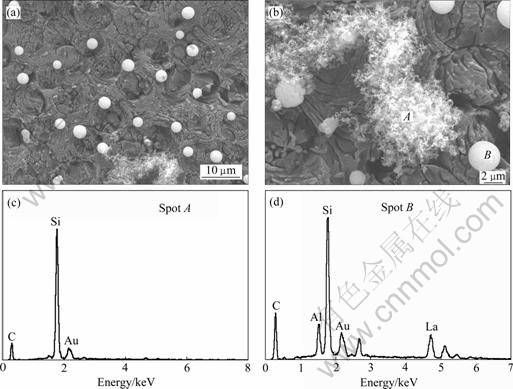

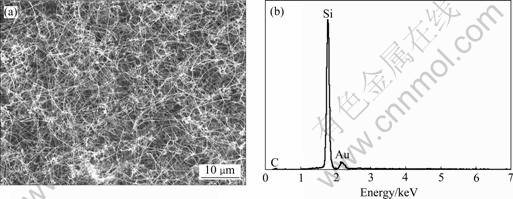

图5~8所示分别为1 000、1 050、1 100、1 150 ℃沉积时间为1 h制备的SiCw的微观形貌和元素分析 结果。

从图5~8中可以看出,1 000 ℃时只有极少量的SiCw生成,C/C基体表面分布有许多催化剂颗粒,B点的EDS结果表明催化剂颗粒表面有少量SiC生成,可能因为浓度不足没有定向生成SiCw;1 050 ℃及 1 100 ℃时,C/C基体表面被浓密的SiCw覆盖;1 150 ℃时,C/C基体表面主要是SiC颗粒及少量短棒状的SiC。

图5 沉积温度为1 000 ℃制备的SiCw的表面形貌和元素分析

Fig. 5 Surface micrographs((a), (b)) and EDS analyses((c), (d)) of SiCw at deposition temperature of 1 000 ℃

图6 沉积温度为1 050 ℃制备的SiCw的表面形貌和元素分析

Fig. 6 Surface micrograph and surface EDS analyses of SiCw at deposition temperature of 1 050 ℃

图7 沉积温度为1 100 ℃制备的SiCw的表面形貌和元素分析

Fig. 7 Surface micrograph and surface EDS analyses of SiCw at deposition temperature of 1 100 ℃

图8 沉积温度为1 150 ℃制备的SiCw的表面形貌和元素分析

Fig. 8 Surface micrograph and surface EDS analyses of SiCw at deposition temperature of 1 150 ℃

化学气相沉积法制备SiCw的机理主要是V-L-S机理,且催化剂在整个过程中起着关键的作用。在1 000 ℃时,由于温度低,MTS分解缓慢,只生成了很少量的SiCw,当温度升高到1 050 ℃时,大量的SiCw生成;在1 100 ℃时,MTS的分解速度与SiCw的生长速度达到一致,此时SiCw的产率最高;随着温度的进一步升高,MTS分解过剩,导致催化剂表面被过多的分解产物覆盖,失去活性,SiCw的定向生长受到影响,形成了颗粒状和短棒状碳化硅。综上所述,在本研究中, 1 100 ℃是制备SiCw的最佳温度。

3 结论

1) SiCw的产率随稀释气体流量的增加先增加、后减少,当稀释气体流量为100 mL/min时,SiCw的产率最高,且只有当稀释气体流量大于等于100 mL/min时,才能完全获得SiCw。

2) 有催化剂能制备有较高长径比的SiCw,无催化剂制备的SiC主要以短棒状或球状SiC为主。

3) SiCw的产率随沉积温度的增加先增加、后减少,拐点是1 100 ℃。1 000 ℃时,只有极少量的SiCw生成,C/C基体表面分布有许多催化剂颗粒;1 050 ℃及1 100 ℃时,C/C基体表面被浓密的SiCw覆盖;1 150 ℃时,C/C基体表面主要生成颗粒状和短棒状SiC,1 100 ℃是制备SiCw的最佳温度。

REFERENCES

[1] 聂立芳, 张玉军, 魏红康. 碳化硅晶须增韧陶瓷基复合材料的研究进展[J]. 山东陶瓷, 2006, 29(2): 16-19.

NIE Li-fang, ZHENG Yu-jun, WEI Hong-kang. Recent researches and developments of SiC whisker-reinforced ceramic-matrix composites[J]. Shandong Ceramics, 2006, 29(2): 16-19.

[2] 宋祖伟, 李旭云, 蒋海燕, 刘希光, 戴长虹. 碳化硅晶须合成工艺的研究[J]. 无机盐工业, 2006, 38(1): 29-31.

SONG Zu-wei, LI Xu-yun, JIANG Hai-yan, LIU Xi-guang, DAI Chang-hong. Study on synthesis technology of silicon carbide whiskers[J]. Inorganic Chemicals Industry, 2006, 38(1): 29-31.

[3] WANG Chang-an, HUANG Yong, ZHAI Hong-xiang. The effect of whisker orientation in SiC whisker-reinforced Si3N4 ceramic matrix composites[J]. Journal of the European Ceramic Society, 1999, 19(10): 1903-1909.

[4] YE F, LEI T C, ZHOU Y. Interface structure and mechanical properties of Al2O3-20vol%SiCw ceramic matrix composite[J]. Materials Science and Engineering A, 2000, 281(1/2): 305-309.

[5] WANG Chang-an, HUANG Yong. Improved sinterability of SiC(w)/Si3N4 composites by whisker-oriented alignment[J]. Materials Science and Engineering A, 2005, 390(1/2): 319-325.

[6] 付前刚. SiC晶须增韧硅化物及SiC/玻璃高温防氧化涂层的研究[D]. 西安: 西北工业大学, 2007.

FU Qian-gang. Study on the SiC whisker-toughened silicides and SiC/glass oxidation protective coatings[D]. Xi’an: Northwestern Polytechnical University, 2007.

[7] LI He-jun, FU Qian-gang, SHI Xiao-hong, LI Ke-zhi, HU Zhi-biao. SiC whisker-toughened SiC oxidation protective coating for carbon/carbon composites[J]. Carbon, 2006, 44(3): 602-605.

[8] FU Qian-gang, LI He-jun, SHI Xiao-hong, LI Ke-zhi, ZHANG Wei, HUANG Min. A SiC whisker-toughened SiC-CrSi2 oxidation protective coating for carbon/carbon composites[J]. Applied Surface Science, 2007, 253(8): 3757-3760.

[9] XU J, ZHANG H, JIANG G, ZHANG B, LI W. SiC whisker reinforced MoSi2 composite prepared by spark plasma sintering from COSHS-ed powder[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(S2): s504-s507.

[10] SUN L, PAN J. Fabrication and characterization of TiCw/MoSi2 and SiCw/MoSi2 composites[J]. Materials Letters, 2002, 53(1/2): 63-67.

[11] 周振中, 李铁虎, 艾艳玲, 宋发举. Ni/SiO2催化制备炭/炭复合材料研究[J]. 炭素技术, 2005(5): 1-5.

ZHOU Zhen-zhong, LI Tie-hu, AI Yan-ling, SONG Fa-ju. Study of catalytic fabrication of C/C composites with Ni/SiO2 as catalyst[J]. Carbon Techniques, 2005(5): 1-5.

[12] 李 军, 谭周建, 张 翔, 廖寄乔. 原位生长碳纳米管对化学气相沉积SiC涂层的影响[J]. 中国有色金属学报, 2011, 21(2): 418-424.

LI Jun, TAN Zhou-jian, ZHANG Xiang, LIAO Ji-qiao. Effect of in-situ carbon nanotubes on chemical vapor deposition SiC coatings[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(2): 418-424.

[13] 周建伟, 廖寄乔, 王占锋. 原位生长碳纳米管对炭/炭复合材料导热性能的影响[J]. 中国有色金属学报, 2008, 18(3): 383-387.

ZHOU Jian-wei, LIAO Ji-qiao, WANG Zhan-feng. Effect of in-situ carbon nanotube on thermal conductivity of carbon/carbon composites[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 383-387.

[14] 廖寄乔, 王占锋, 周建伟. 采用浸渍-还原法在炭纤维表面制备纳米镍催化剂颗粒[J]. 中南大学学报: 自然科学版, 2007, 38(6): 1033-1038.

LIAO Ji-qiao, WANG Zhan-feng, ZHOU Jian-wei. Synthesis of nano-nickel particles on carbon fibers by impregnation-reduction method[J]. Journal of Central South University: Natural Science, 2007, 38(6): 1033-1038.

[15] 李 军, 张 翔, 廖寄乔, 谭周建. SiC晶须的原位生长及其在C/C复合材料抗氧化涂层中的应用[J]. 粉末冶金材料科学与工程, 2010, 15(3): 277-282.

LI Jun, ZHANG Xiang, LIAO Ji-qiao, TAN Zhou-jian. In-situ growth of SiC whiskers and application in anti-oxidation coating of C/C composite materials[J]. Materials Science and Engineering of Powder Metallurgy, 2010, 15(3): 277-282.

[16] 刘荣军, 张长瑞, 周新贵, 曹英斌, 刘晓阳. 稀释气体对化学气相沉积SiC涂层生长行为的影响[J]. 硅酸盐学报, 2004, 32(12): 1563-1566.

LIU Rong-jun, ZHANG Chang-rui, ZHOU Xin-gui, CAO Ying-bin, LIU Xiao-yang. Effect of diluent gases on growth behavior of chemical vapor deposited SiC coatings[J]. Journal of the Chinese Ceramic Society, 2004, 32(12): 1563-1566.

[17] LEE Y J, CHOI D J, KIM S S, LEE H L, KIM H D. Comparison of diluent gas effect on the growth behavior of horizontal CVD SiC with analytical and experimental data[J]. Surface and Coatings Technology, 2004, 177/178: 415-419.

[18] 黄 浩, 陈大明, 仝建峰, 李宝伟. 石墨表面CVD SiC涂层微观结构研究[J]. 航空材料学报, 2008, 28(2): 50-54.

HUANG Hao, CHEN Da-ming, TONG Jian-feng, LI Bao-wei. Microstructure study of the SiC coatings on graphite by CVD[J]. Journal of Aeronautical Materials, 2008, 28(2): 50-54.

[19] LOURNAGNE F, LANGLAIS F, NASLAIN R. Reactional mechanisms of the chemical vapour deposition of SiC-based ceramics from CH3SiCl3/H2 gas precursor[J]. Journal of Crystal Growth, 1995, 155(17): 205-213.

[20] 刘荣军, 张长瑞, 周新贵, 曹英斌, 刘晓阳, 张 彬. 低温化学气相沉积SiC涂层显微结构及晶体结构研究[J]. 硅酸盐学报, 2003, 31(11): 1107-1111.

LIU Rong-jun, ZHANG Chang-rui, ZHOU Xin-gui, CAO Ying-bin, LIU Xiao-yang, ZHANG Bin. Microstructure and crystal structure of SiC coatings deposited at low temperature[J]. Journal of the Chinese Ceramic Society, 2003, 31(11): 1107-1111.

[21] 刘荣军, 张长瑞, 刘晓阳, 周新贵, 曹英斌. CVD过程中温度对SiC涂层沉积速率及组织结构的影响[J]. 航空材料学报, 2004, 24(4): 22-26.

LIU Rong-jun, ZHANG Chang-rui, LIU Xiao-yang, ZHOU Xin-gui, CAO Ying-bin. The effects of deposition temperature on the deposition rates and structures of CVD SiC coatings[J]. Journal of Aeronautical Materials, 2004, 24(4): 22-26.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2012AA03A207);国家重点基础研究发展计划资助项目(2011CB605800);国家自然科学基金委员会创新研究群体科学基金资助项目(51021063)

收稿日期:2010-12-24;修订日期:2011-04-08

通信作者:廖寄乔,教授,博士;电话:0731-88877944;E-mail: liaojiqiao@126.com