Characterization of CdZnTe crystal grown by bottom-seeded Bridgman and Bridgman accelerated crucible rotation techniques

WANG Tao(王 涛), JIE Wan-qi(介万奇), XU Ya-dong(徐亚东), ZHA Gang-qiang(查钢强), FU Li(傅 莉)

State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xian 710072, China

Received 10 August 2009; accepted 15 September 2009

Abstract: The growth of CdZnTe crystals with diameter up to 60 mm using bottom-seeded Bridgman method as well as Bridgman accelerated crucible rotation technique (ACRT-B) was investigated. Both ingots exhibit high yields, where single crystal with the volume exceeding 200 cm3 is produced. The crystal properties of two ingots were compared in the aspects of yields, crystalline quality and composition uniformity. For CdZnTe ingot grown by bottom-seeded Bridgman method, the full width at half-maximum (FWHM) of X-ray rocking curve was determined to be 36″, indicating a better crystalline quality than ingot grown by ACRT-B method, which gave FWHM of 56″. The composition distribution of Zn and In in CdZnTe was determined by using electron probe microanalysis (EPMA) and inductively coupled plasma mass spectrometry (ICP-MS), respectively. The effective segregation coefficients of Zn kZn and In kIn in the two ingots were evaluated by fitting the experimental data with the Pfann equation.

Key words: seed crystals; cadmium compounds; accelerated crucible rotation technique; Bridgman technique

1 Introduction

Wide bandgap compound semiconductor cadmium zinc telluride (Cd1-xZnxTe, CdZnTe or CZT) was widely used for lots of applications because of its excellent photoelectric properties [1-3]. When x is 0.04, it is used as epitaxial substrates of Hg1-yCdyTe. When x is 0.05-0.2, it can be used for the fabrication of high performance X-ray and γ-ray detectors. However, large-size low defect CZT single crystals are difficult to produce due to the problems of polycrystal, inhomogeneity etc[4-5]. The yields of the ingots are very low, and further limit the industrial application.

Among all the methods developed for the melt growth of Cd1-xZnxTe, the modified vertical Bridgman method (MVB) has attracted more and more attentions because of its low cost, good reproducibility and high-usage. Techniques including accelerated crucible rotation technique (ACRT) and seeding technique are often introduced. ACRT is believed to enhance the melt mixing and improve the growth interface shape, suitable for high quality ternary compound semiconductor fabrication[6]. The application of ACRT was first introduced by CAPPER et al[7] in the vertical Bridgman method for the growth of CdTe and CdZnTe. The process parameters which are strictly required for ACRT-B were studied experimentally and numerically [8-12]. In comparison, seeding technique in CZT crystal growth is much more difficult because of its complexity[4]. Successful reports on this method can only be seen recently [13-14] in Vertical Bridgman method.

In this work, we report our new progress on the growth of large diameter CZT crystal with bottom- seeded Bridgman method as well as ACRT-VB method. CZT crystals grown with the two methods are compared to evaluate the effects of ACRT and seeding.

2 Experimental

The growth procedure of the bottom-seeded Bridgman crystal is as follows. Firstly, the raw materials of Cd (7N), Zn (7N), Te (7N) and the dopant of In (7N) were loaded into the carbon-coated quartz crucible. The crucible was sealed under vacuum up to 5×10-5 Pa and synthesized in a rocking furnace. Then, the poly- crystalline materials were taken out and feed into another crucible, which was arranged an oriented seed ingot

previously. Finally, the crystal growth was carried out in a five-zone furnace. The temperature gradient at the growth interface was 10-20 K/cm, and the withdrawing rate was 1-1.5 mm/h. In contrast, the ACRT crystal was produced from one crucible from beginning to end with similar growth parameters.

Ingots with the diameter of 60 mm and the length of 160 mm were successfully prepared by bottom-seeded Bridgman method, as well as ACRT-B method. Here, we denote CZT1 as the typical ingot grown by bottom-seeded method and CZT2 as the typical ingot grown by ACRT-B method.

X-ray rocking curves of CZT crystals were measured by a PANalytical X’Pert Pro diffractometer. In the PL measurements, the samples were attached on a cold copper finger in a closed-cycle cryostat to keep the sample temperature at 10 K. An argon ion laser with the wavelength of 488 nm was used to excite the PL spectrum. Electron probe microanalysis (EPM) and inductively-coupled plasma mass spectrometer (ICP-MS) were used for composition determination of Zn and In in CZT, respectively.

3 Results and discussion

3.1 Macroscopic features

For comparison, the macroscopic features of CZT1 and CZT2 were evaluated firstly. A large grain dominates CZT1 throughout the ingot. Twins and small grains can only be seen at the edge of the ingot, which are probably caused by stresses between the ingot and the crucible. In CZT2, one large grain is separated by several large penetration twins perpendicular to the growth axis. The crystallographic orientations of CZT grains can be determined by referring to the orientations of the twins, which are usually (111) faces. The crystallographic orientation of the main grain was thus determined to be almost parallel to (111) face in CZT1 and perpendicular to (111) face in CZT2. The preferred orientation of CZT1 inherits from the orientation of the seed, and the preferred orientation of CZT2 is probably determined by the introduction of ACRT, which exhibit reproducible behaviors in our crystals. Single crystals with volume up to 200 cm3 and 100 cm3 are obtained from samples CZT1 and CZT2, respectively.

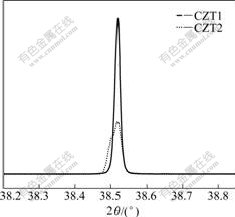

3.2 X-ray rocking curve

X-ray rocking curve is widely used to evaluate the structural quality of CdZnTe. The full width at half-maximum (FWHM) of the rocking curve is a measure of crystal defect concentration and mosaic spread. Typical X-ray rocking curves of ingots CZT1 and CZT2 are shown in Fig.1. The FWHM for CZT1 is determined to be 36″. This value is limited by the diffracto-meter’s resolution of 30″. However, crystal CZT2 shows broader FWHM of 56″. The result indicates that the structural quality of CZT is greatly improved by using bottom-seeded Bridgman method. The introduction of seed increases the crystallization dynamics and defects usually caused by constitute supercooling are depressed.

Fig.1 Typical X-ray rocking curves of ingots CZT1 and CZT2

3.3 Low-temperature photoluminescence measurements

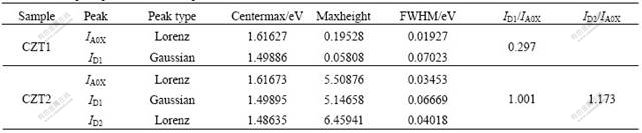

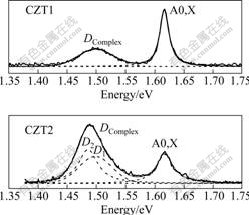

Low-temperature photoluminescence (PL) spectro- scopy provides an overall picture of crystal quality and can help in identifying the presence of defect levels. Typical PL spectra of ingots CZT1 and CZT2 are shown in Fig.2. The spectra were fitted with Gaussian and/or Lorenz curves, where the parameters are shown in Table 1.

The Dcomplex peak is often thought to be excited from different origins including the complexes of donors combined with Cd vacancies and dislocations. As shown in Fig.2, Dcomplex peaks are fitted with one Gaussian curve ID1 in ingot CZT1, while one Gaussian curve ID1

Table 1 Fitted peak parameters of samples CZT1 and CZT2

and one Lorenz curve ID2 in ingot CZT2. The ID1 peak is often attributed to dislocations and the intensity ratio of ID1/IA0X can be used to evaluate the dislocation intensity in CZT [15]. The value of ID1/IA0X in ingot CZT1 is 0.2972, much lower than 1.001 (ID2/IA0X) in ingot CZT2, clearly indicating a lower dislocation intensity and thus a better crystal quality. The peak ID2 is thought to be related to donors combined with Cd vacancies. We do not see ID2 peak in ingot CZT1. This may indicate lower Cd vacancy concentration in ingot CZT1.

Fig.2 Typical PL spectra of ingots CZT1 and CZT2

3.4 Zn distribution

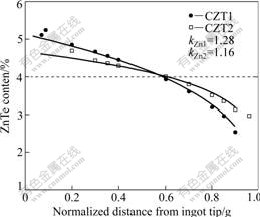

The Zn axial segregations are determined by measuring Zn concentration distribution in the center of the wafers along the ingot CZT. Fig.3 shows the distribution of Zn along ingot CZT1 and CZT2. Since, the withdraw rate of crucible is low enough, the growth process of ingot CZT can be regarded as a steady state unidirectional crystallization process. Zn segregation in ingot CZT can thus be evaluated by using Pfann equation, given by

Cs/C0=k(1-g)(k-1) (1)

Fig.3 Zn distribution along centerlines of ingots CZT1 and CZT2

where C0 is the initial Zn concentration in ingot CZT; g is the solidified fraction of the ingot; Cs is the impurity concentration of Zn at the interface on the solid side; kZn in ingot CZT1 and CZT2 are determined to be 1.28 and 1.16, respectively. We can then conclude that the introduction of ACRT has homogenized the melt composition and thus reduced the segregation of Zn.

3.5 In distribution

The In distribution along ingot CZT1 and CZT2 are also evaluated by using the pfann equation, as shown in Fig.4. The effective segregation coefficients of In (kIn) are determined to be 0.19 in CZT1 and 0.5 in CZT2. This result again indicates that the introduction of ACRT can effectively homogenize the melt composition and make the effective segregation coefficients approach to 1.

Fig.4 In distribution along growth direction in ingots CZT1 and CZT2

4 Conclusions

1) Both ingots exhibit high yields, where single crystal with the volume exceeding 200 cm3 is produced using bottom-seeded Bridgman method.

2) For CdZnTe ingot grown by bottom-seeded Bridgman method, the full width at half-maximum (FWHM) of X-ray rocking curve is determined to be 36″, indicating a better crystalline quality than ingot grown by ACRT-B method, which gave FWHM of 56″.

3) The effective segregation coefficient of Zn (kZn) for bottom-seeded Bridgman crystal is 1.28, and for ACRT crystal, kZn is 1.16.

4) The effective segregation coefficients of In dopant (kIn) is determined to be 0.19 and 0.5 for bottom-seeded Bridgman crystal and ACRT-B grown crystal, respectively.

References

[1] KENNETH Z. Cadmium telluride [M]. New York: Academic Press; 1978.

[2] SCHLESINGER T E, TONEY J E, YOON H, LEE E Y, BRUNETT B A, FRANKS L, JAMES R B. Cadmium zinc telluride and its use as a nuclear radiation detector material [J]. Materials Science and Engineering: R: Reports, 2001, 32(4/5): 103-189.

[3] LEBRUN F. Semiconductor detectors for soft gamma-ray astrophysics [J]. Nuclear Instruments & Methods in Physics Research Section A-Accelerators Spectrometers Detectors and Associated Equipment, 2006, 563(1): 200-204.

[4] RUDOLPH P. Fundamental studies on Bridgman growth of CdTe [J]. Progress in Crystal Growth and Characterization of Materials, 1994, 29(1/4): 275-381.

[5] TERTERIAN S, CHU M, TING D. Distribution of the high resistivity region in CdZnTe and its effects on gamma-ray detector performance [J]. Journal of Electronic Materials, 2004, 33(6): 640-644.

[6] DUTTA P S. Ⅲ-Ⅴ Ternary bulk substrate growth technology: a review [J]. Journal of Crystal Growth, 2005, 275(1/2): 106-112.

[7] CAPPER P, HARRIS J E, O’KEEFE E, JONES C L, ARD C K, MACKETT P, DUTTON D. Bridgman growth and assessment of CdTe and CdZnTe using the accelerated crucible rotation technique [J]. Materials Science & Engineering B, 1993, B16(1/3): 29-39.

[8] LIU X H, JIE W Q, ZHOU Y H. Numerical analysis of Cd1-xZnxTe crystal growth by the vertical Bridgman method using the accelerated crucible rotation technique [J]. Journal of Crystal Growth, 2000, 219(1/2): 22-31.

[9] YECKEL A, DERBY J J. Effect of accelerated crucible rotation on melt composition in high-pressure vertical Bridgman growth of cadmium zinc telluride [J]. Journal of Crystal Growth, 2000, 209(4): 734-750.

[10] CAPPER P. Role of accelerated crucible rotation in the growth of Hg1-xCdxTe and CdTe/CdZnTe [J]. Progress in Crystal Growth and Characterization of Materials, 1994, 28(1/2): 1-55.

[11] LI G, ZHANG X, HUA H, JIE W. A modified vertical Bridgman method for growth of high-quality Cd1-xZnxTe crystals [J]. Journal of Electronic Materials, 2005, 34(9): 1215-1224.

[12] LI G Q, JIE W Q, HUA H, GU Z. Cd1-xZnxTe: Growth and characterization of crystals for X-ray and gamma-ray detectors [J]. Progress in Crystal Growth and Characterization of Materials, 2003, 46(3): 85-104.

[13] LI L, LU F, SHAH K, SQUILLANTE M, CIRIGNANO L, YAO W, OLSON R W, LUKE P, NEMIROVSKY Y, BURGER A, WRIGHT G., JAMES R B. A new method for growing detector-grade cadmium zinc telluride crystals [C]//IEEE Nuclear Science Symposium and Medical Imaging Conference. San Diego, CA: IEEE, 2001: 2396-2400.

[14] LI L, LU F, LEE C, YAO H W, BURGER A, GROZA M, WRIGHT G W, JAMES R B, OLSEN R, LUKE P, SHAH K, CIRIGNANO L, SQUILLANTE M R, OUIMETTE D. New Progress in Large-size CZT Single Crystal Growth for Nuclear Radiation Detectors [C]// FRANKS LA, BURGER A, JAMES RB. Proceedings of SPIE-The International Society for Optical Engineering. San Diego, CA: IEEE, 2004: 41-47.

[15] YANG G, JIE W Q, WANG T, LI G Q, LI W W, HUA H. Correlation between ingot diameter and crystal properties of CdZnTe: In grown by the modified Bridgman method [J]. Crystal Growth & Design, 2007, 7(2): 435-438.

(Edited by LI Yan-hong)

Foundation item: Project(50772091) supported by the National Natural Science Foundation of China; Project(2008044185) supported by China Postdoctoral Science Foundation

Corresponding author: WANG Tao; Tel: +86-29-88460445; Email: czt.nwpu@gmail.com