Ca和Sr元素对高应变速率轧制Mg-5Zn合金动态再结晶和力学性能的影响

来源期刊:中国有色金属学报(英文版)2019年第8期

论文作者:丁天 严红革 陈吉华 夏伟军 苏斌 余宗霖

文章页码:1631 - 1640

关键词:镁合金;高应变速率轧制;动态再结晶;力学性能

Key words:magnesium alloys; high-strain-rate rolling; dynamic recrystallization; mechanical properties

摘 要:利用光学显微镜、扫描电子显微镜、热压缩试验以及拉伸实验研究Ca、Sr元素单一添加以及复合添加对铸态和轧制态Mg-5Zn合金显微组织和力学性能的影响。Ca元素在铸态组织中细化晶粒尺寸的作用比Sr元素明显。高应变速率轧制过程中产生大量的变形孪晶,因此提供大量的动态再结晶形核点。高应变速率轧制过程中,Ca、Sr元素会促进动态析出相的析出,而动态析出相的析出会消耗部分储存能,因此提高了动态再结晶的临界应变值,延迟了动态再结晶的产生。轧制态Mg-5Zn-0.4Ca-0.2Sr合金具有良好的综合力学性能,其极限抗拉强度、屈服强度、断后伸长率分别是317 MPa、235 MPa和24%。

Abstract: Effects of the sole and the combined addition of Ca and Sr on microstructure and mechanical properties of as-cast and as-rolled Mg-5Zn alloys were carefully investigated by OM, SEM, hot-compression testing and tensile testing. Ca is more effective than Sr in the microstructural refinement of as-cast alloys. High-strain-rate rolling (HSRR) produces more deformed twins and thus provides more nucleation sites for dynamic recrystallization (DRX). The addition of Ca and Sr can promote dynamic precipitation during HSRR, the precipitation process would consume the storage energy and thus increases the critical strain value of DRX, resulting in the retarded DRX effect by the addition of Ca and/or Sr. The as-rolled Mg-5Zn-0.4Ca-0.2Sr alloy exhibits a good combination of strength and ductility, with the ultimate tensile strength of 317 MPa, the yield strength of 235 MPa and the elongation to rupture of 24%.

Trans. Nonferrous Met. Soc. China 29(2019) 1631-1640

Tian DING1,2, Hong-ge YAN1,2, Ji-hua CHEN1,2, Wei-jun XIA1,2, Bin SU1,2, Zong-lin YU1

1. School of Materials Science and Engineering, Hunan University, Changsha 410082, China;

2. Hunan Provincial Key Laboratory of Spray Deposition Technology & Application, Hunan University, Changsha 410082, China

Received 21 October 2018; accepted 6 June 2019

Abstract: Effects of the sole and the combined addition of Ca and Sr on microstructure and mechanical properties of as-cast and as-rolled Mg-5Zn alloys were carefully investigated by OM, SEM, hot-compression testing and tensile testing. Ca is more effective than Sr in the microstructural refinement of as-cast alloys. High-strain-rate rolling (HSRR) produces more deformed twins and thus provides more nucleation sites for dynamic recrystallization (DRX). The addition of Ca and Sr can promote dynamic precipitation during HSRR, the precipitation process would consume the storage energy and thus increases the critical strain value of DRX, resulting in the retarded DRX effect by the addition of Ca and/or Sr. The as-rolled Mg-5Zn-0.4Ca-0.2Sr alloy exhibits a good combination of strength and ductility, with the ultimate tensile strength of 317 MPa, the yield strength of 235 MPa and the elongation to rupture of 24%.

Key words: magnesium alloys; high-strain-rate rolling; dynamic recrystallization; mechanical properties

1 Introduction

Magnesium alloys are the lightest metallic structural materials which have extensive applications in the field of aerospace, transportation vehicles and consumer electronics (3C), owing to their advantages such as low density, high specific strength and stiffness, good damping performance, and almost absolute recyclability [1-3]. Due to the hexagonal close-packed (HCP) structure, conventional Mg alloys exhibit hard formability, low strength and poor ductility, and these shortcomings strongly limit their widespread applications in the important structure field [4]. Consequently, it is of great significance to take some effective measures to improve their mechanical properties. It is well-known to all that two main ways can be used to improve their mechanical properties. One is to achieve grain refinement by severe plastic deformation (SPD) and the other is micro-alloying. Extensive investigations have been carried to explore the action mechanisms of micro-alloying. The micro-alloying elements mainly include rare earth (RE), Ca, Sr and so on. Especially, the alkaline earth elements such as Ca and Sr are widely available at the low price, which is advantageous for the commercial applications. Moreover, Ca and Sr can also reduce the grain size, weaken the basal texture, improve creep resistance as well as have similar effects to RE elements [5-8]. Therefore, it is a hot topic to improve the mechanical properties of Mg alloys by the addition of low-cost Ca and Sr elements.

Among the conventional Mg alloys, the Mg-Zn alloy system shows a significant application potential for the development of high performance Mg alloys due to the high solubility of Zn in Mg and these two elements can form many different kinds of stable intermetallic compounds (MgZn2, Mg4Zn7 and MgZn) [9]. For example, the as-extruded ZK60 alloy shows the yield tensile strength (YTS) of 262 MPa and the ultimate tensile strength (UTS) of 338 MPa [10]. At present, considerable researches have been conducted on the Mg-Zn-Ca alloys since the Ca addition can promote the formation of fine Mg-Zn precipitates during deformation, which is beneficial to the improvement in mechanical properties. It is reported that the as-cast Mg-2Zn-1.2Ca alloy experienced solution treatment and unidirectional rolling exhibits excellent tensile properties with UTS, YTS and elongation (El) of 227 MPa, 111 MPa and 6.8%, respectively [11]. DU et al [6] have reported that the Mg-6Zn-0.8Ca alloy extruded at 300 °C with the extrusion ratio of 12:1 and the extrusion speed of 10 mm/s shows YTS of 230 MPa, UTS of 304 MPa and El of 15.3%. Similarly, LEE et al [12] have found that the Mg-3Zn-0.5Ca alloy rolled at 350 °C exhibits UTS of 293 MPa, YTS of 260 MPa and El of 8.6%. In our previous study, the 0.6 wt.% Ca addition contributes to the improvement in mechanical properties of the as-rolled Mg-4Zn alloys, but the higher Ca addition brings about the plasticity loss [13]. As compared with the Ca element, Sr is also an effective alloying element for the improvement in mechanical properties of Mg alloys. Many studies are conducted on the Mg-Al alloy system. However, there are few studies on the effects of Sr on the microstructure and mechanical properties of the binary Mg-Zn alloy system. MASOUMI and PEKGULERYUZ [8] have reported that the grain refining effect of Sr is more pronounced at the lower level than that at the higher level in the as-cast and as-rolled Mg-1Zn alloys. YUASA et al [14] have reported that the as-rolled Mg-1.5Zn-0.2Sr alloy has UTS of 209 MPa, YTS of 122 MPa and El of 21%. Together with Mg or Al in the Mg-Al-Zn system, Sr can reduce the amount of the β phase and refine its size since the stable phases such as Mg17Sr2 and Al4Sr are formed at high temperatures (the melting points are 740 °C and 624 °C, respectively). These stable particles are the preferred nucleation sites for dynamic recrystallization (DRX) during the deformation process. As discussed above, Sr is an important alloying element in improving the mechanical properties of Mg alloys.

Up to now, most studies have been focused on the effects of single element alloying on the microstructure and mechanical properties of Mg alloys. However, there are very limited researches on the effects of double element alloying. Therefore, four alloy compositions such as Mg-5Zn, Mg-5Zn-0.6Ca, Mg-5Zn-0.6Sr, Mg- 5Zn-0.4Ca-0.2Sr are designed to compare the effects of single and double micro-alloying of Ca and Sr on the microstructure and mechanical properties of the Mg-Zn alloy prepared by high-strain-rate rolling (HSRR).

2 Experimental

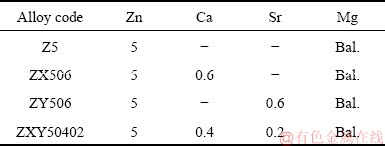

The nominal compositions of the experimental alloys are shown in Table 1. The Mg-5Zn, Mg-5Zn- 0.6Ca, Mg-5Zn-0.6Sr and Mg-5Zn-0.4Ca-0.2Sr alloys were encoded as Z5, ZX506, ZY506 and ZXY50402, respectively. The experimental alloy billets were prepared by permanent mold casting and then were treated by the different homogenization processes to eliminate the composition segregation in the as-cast state. The homogenization treatment of Z5 was conducted at (300 °C, 2 h) + (330 °C, 30 h), and that of the other alloys is (300 °C, 2 h) + (330 °C, 30 h) + (420 °C, 2 h). The as-homogenized alloy plates with a thickness of 10 mm were preheated at 300 °C for 10 min before rolling and were rolled with a thickness reduction of 80% in a single pass. The average strain rate  is 9.1 s-1.

is 9.1 s-1.

Table 1 Nominal compositions of as-studied alloys

The as-cast and as-rolled samples for microstructure observation were etched in a solution of 0.3 g picric acid, 1 mL acetic acid, 1.5 mL water and 10 mL alcohol after mechanical polishing and the corrosion time was about 10 s. The microstructure was examined by a LeitzMM-6 optical microscope (OM). The average grain size was measured by the Nano-Measure software and the average DRX volume fraction was evaluated by the Image-Pro Plus 6.0 software. The phase constitutions of these four alloys were analyzed by a D5000 X-ray diffraction instrument with Cu Kα at a scanning rate of 8 (°)/min. The micro-compositional analysis of some certain phases was conducted on a EVO MA10 scanning electron microscopy (SEM) equipped with the Oxford X-MaxN energy dispersive spectroscopy (EDS). The tensile specimens of the as-rolled plates were cut into flat along the rolling direction with the gauge section of 15 mm × 4 mm × 2 mm and were tested on the Instron 3369 tensile testing machine at room temperature. The tensile fracture was observed by FEI Quanta 2000 scanning electron microscope (SEM). Compression tests were also conducted on a Gleeble-3500 compression machine under the conditions similar to HSRR with the cylindrical specimen (d8 mm× 10 mm) heated at 300 °C for 3 min before testing and then the hot-compressed specimen was quenched into water immediately.

3 Results and discussion

3.1 Microstructures of as-cast alloys

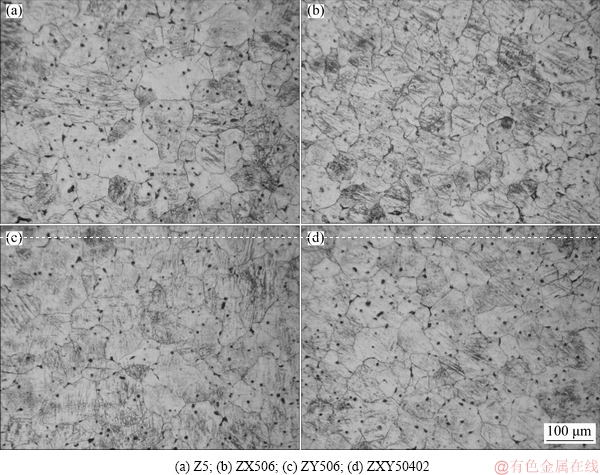

The microstructures of as-cast alloys are shown in Fig. 1. The average grain size and the morphologies of the second phase particles in the as-cast alloys are different. The average grain sizes of Z5, ZX506, ZY506 and ZXY50402 alloys are 66, 45, 58 and 48 μm, respectively. There are two reasons for grain refinement effect of Ca and Sr on the Mg-Zn binary alloys. On one hand, being the surface active elements, Ca and Sr can be enriched in front of the solid-liquid interface, which can generate the constitutional under-cooling and thus refine the grain size [1,15]. On the other hand, Ca and Sr elements have the relatively high growth restriction factors (GRFs) owing to the high segregation energy in Mg alloys. The higher the GRF is, the more obvious the grain refinement in Mg alloys is. Once the initial concentration effect is ignored, the GRF values of Ca and Sr are 11.94 and 3.51, respectively. Therefore, the refining effect of Ca is more obvious than Sr, which is in good consistency with the Refs. [16,17].

Fig. 1 OM images of as-cast alloys

The morphologies and the distribution states of the second phase particles are quite different in these alloys. As seen from Fig. 1(a), the Z5 alloy contains some divorced spherical second phase particles dispersed mainly within grains and a small portion of the semi- continuous second phase along the grain boundaries. As seen from Fig. 1, most of the semi-continuous compounds tend to distribute along the grain boundaries and only a few spherical second phase particles are distributed within the grains of ZX506, ZY506 and ZXY50402.

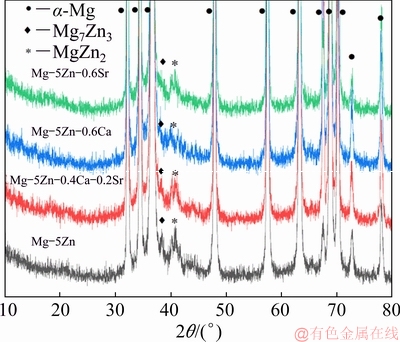

The XRD patterns of as-cast alloys with Ca and/or Sr are shown in Fig. 2. The as-cast alloys are mainly composed of α-Mg, Mg7Zn3 and MgZn2.

Fig. 2 XRD patterns of as-cast alloys

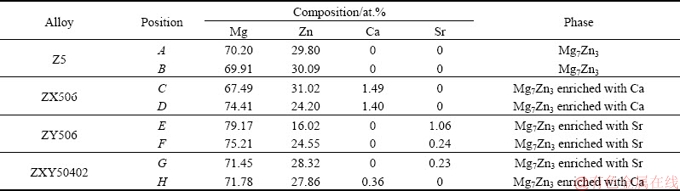

The Mg7Zn3 phase is distributed both in the grain interiors and at the grain boundaries, which is confirmed by the SEM observation (Fig. 3) and the EDS analysis (Table 2). The micro-alloying elements of Ca and Sr are mainly enriched in the Mg7Zn3 phase and almost no ternary phase is formed. However, some researchers have reported that the Ca2Mg6Zn3 and Mg11Zn4Sr3 ternary phases, accompanied with the addition of Ca and Sr, are distributed along the grain boundaries [18,19].

3.2 Microstructures of as-homogenized alloys

The OM images of as-homogenized alloys are shown in Fig. 4. As compared with as-cast alloys, the grain boundary straightness, a slight grain growth and the dissolution of the second phases in the matrix occur in the as-homogenized alloys. However, as seen from Fig. 4, a small number of the spherical second phase particles are undissolved in the as-homogenized alloys. Due to the high melting point of MgZn2 (about 590 °C) [20], it is difficult to be dissolved in the matrix during the present homogenization process.

Fig. 3 SEM images of as-cast alloys

Fig. 4 OM images of as-homogenized alloys

Table 2 EDS analysis results of intermetallic in as-cast alloys

3.3 Microstructures of as-rolled alloys

The OM images of as-rolled alloys are shown in Figs. 5 and 6. The average DRX grain sizes and the DRX volume fractions are shown in Table 3. As shown in Fig. 5, DRX occurs in the as-rolled alloys and the DRX extents are quite different. DRX contains two basic processes, i.e. nucleation and growth. In recent years, many excellent researches have been conducted on the basic mechanism for recrystallization nucleation, which is one of the most important factors affecting the micro-structural evolution. Grain boundary nucleation (GBN) [21], sub-grain boundary migration (SBM) [22], shear bands nucleation (SBN) [23], deformation twinning nucleation [24] and particle stimulated nucleation (PSN) [25] are the main recrystallization nucleation mechanisms in Mg alloys. Our previous works have indicated that dislocation movement and rearrangement are not easily achieved during HSRR due to the hexagonal close-packed crystal structure, resulting in stress concentration and promoting the formation of a large number of deformation twins. The deformation twinning boundaries are the preferential sites for the nucleation of DRX, which is referred to deformation twinning nucleation [26,27].

Fig. 5 OM images of as-rolled alloys (RD-TD)

Fig. 6 OM images of as-rolled alloys (RD-TD, high magnification)

Table 3 DRX grain sizes and volume fractions of as-rolled alloys

As seen from Fig. 6, some small fine DRX grains are formed in the deformation twins. As compared with Z5, more deformation twins are observed in ZX506, ZY506 and ZXY50402. The reason for this can be ascribed to that the addition of Ca and Sr promotes dynamic precipitation during HSRR, the latter of which restricts the grain growth of DRX, and thus a massive deformation twins are retained. In addition, Ca and Sr can reduce the stacking fault energy for Mg alloys [14]. Meanwhile, the reduced stacking fault energy leads to the higher twinning density, which is beneficial to the twin nucleation, thus increasing the number of twins [28].

As shown in Table 3, ZX506, ZY506 and ZXY50402 have more fine DRX grain sizes and lower DRX volume fractions than Z5. Besides, the DRX grain size and the DRX volume fraction of ZX506 are the smallest among these alloys, indicating that the minor addition of Ca, Sr and Ca/Sr can hinder the DRX process in the Z5 alloy and the grain refinement effect of Ca is more pronounced than Sr. This is associated with the inhibited effect of dynamic precipitates on the DRX grain growth.

The Ca and/or Sr addition promotes dynamic precipitation not only due to the easy formation of the Ca-Zn and Sr-Zn atomic clusters in the Mg-Zn alloys since a negative mixing enthalpy is involved, which can act as the preferential nucleation sites for dynamic precipitation [29], but also owing to the formation of a large amount of dislocation entanglement and proliferation during HSRR [20]. It should be noted that the storage energy and stress concentration are involved in the deformation regions during HSRR, which provide more nucleation sites and a higher driving force for precipitation, thus promoting the dynamic precipitation. The fine dynamic precipitates hinder dislocation movement and inhibit DRX, resulting in the DRX regions with fine grains and the un-DRX regions. Moreover, Ca and Sr atoms have a solute drag effect in the matrix, the latter of which slows down the dislocation motion and inhibits DRX [30]. From the kinetics point of view, DRX occurs more easily in the alloys with low stacking fault energy than those with high stacking fault energy [31].

Up to now, many researchers have calculated and simulated the effects of Ca and Sr on the stacking fault energy of Mg alloys by the first principle theory. The results show that the Ca and Sr elements can reduce the stacking fault energy of magnesium alloys, and the effect of Sr elements on reducing stacking fault energy is more obvious [32-34]. In addition, YUASA et al [14] have also reported that the Ca, Sr and Ba elements can reduce the stacking fault energy of the binary Mg-Zn alloy, and the effect of Sr is more obvious than that of Ca when studying the cold tensile formability of Mg-Zn alloys by the group II elements. Therefore, ZY506 exhibits a higher DRX degree than ZX506.

3.4 Effects of Ca and/or Sr on DRX critical point

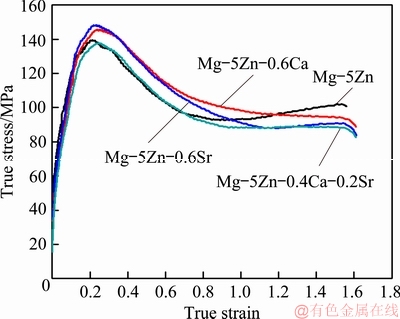

Hot compression experiments were conducted under the similar rolling deformation conditions to further study the effects of micro-alloying elements such as Ca and Sr on the DRX critical point of Mg-5Zn alloy. The typical true stress-true strain curves are shown in Fig. 7. The Ca and/or Sr addition has an effect on the flow behavior of Mg-5Zn alloy.

Fig. 7 Typical true stress-true strain curves of as-studied alloys

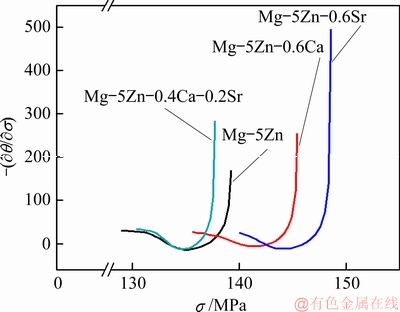

As seen from Fig. 7, the flow stress initially increases with the increasing strain for all the alloys, featured with the classical work hardening up to a critical point (corresponding to σc), indicating that the as-studied alloys are going to undergo DRX. Then, the flow stress decreases at a rate that decays with the increasing strain up to the steady state, featured with the classical work softening, which is attributed to DRX. As discussed above, DRX brings about work softening and reduces work hardening. σc and εc (the strain at σc, critical strain for DRX) are the two important parameters for DRX, which can be derived from the typical true stress-true strain curve. The former corresponds to the stress of the alloy at the onset of DRX, while the latter is a measure of the strain needed to initiate DRX. The specific values of σc and εc for DRX are shown in Table 4.

Table 4 Critical true strain (εc) and true stress (σc) of DRX for as-studied alloys

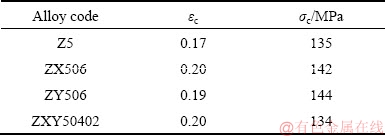

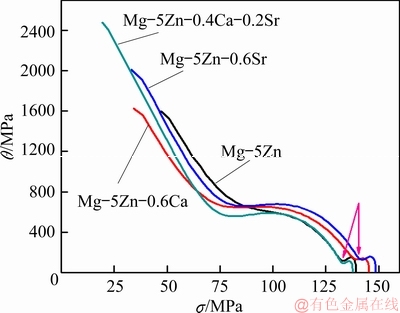

According to POLIAK et al [35], the critical condition for the onset of DRX is determined according to the following relations  /

/ σ(-

σ(-  θ/

θ/  σ)=0, θ=(dσ/dε)ε,T. Nominally, the onset of DRX is located at the inflection point of the θ-σ plot, i.e. the concave point on the curve, indicated by Fig. 8. In order to express the specific conditions of the onset of DRX more clearly and accurately, the -(

σ)=0, θ=(dσ/dε)ε,T. Nominally, the onset of DRX is located at the inflection point of the θ-σ plot, i.e. the concave point on the curve, indicated by Fig. 8. In order to express the specific conditions of the onset of DRX more clearly and accurately, the -(  θ/

θ/  σ)-σ curves are shown in Fig. 9, where the minimum -(

σ)-σ curves are shown in Fig. 9, where the minimum -(  θ/

θ/ σ) value corresponds to the onset of DRX.

σ) value corresponds to the onset of DRX.

Fig. 8 Flow stress dependence of strain-hardening rate curves of as-studied alloys

As shown in Table 4, both Ca and Sr retard the DRX process of the Mg-5Zn alloy. This can be attributed to the enhanced effect of Ca and Sr on dynamic precipitation in the Mg-5Zn alloy. In our recent study, dynamic precipitation would be prior to DRX during hot deformation and those fine dynamic precipitates are about 100 nm in size [36], which cannot be used as the preferential nucleation sites for DRX since the critical particle size for PSN is bigger than 1 μm [37]. SU et al [38] have found that a large number of dynamic precipitates would push the peak strain to a higher value in the Mg-Al-Ca alloys, indicating that dynamic precipitation retards DRX. From the energy point of view, nucleation and growth of dynamic precipitates consume a portion of the storage energy during the deformation process and thus result in the higher critical strain of DRX, indicating that the DRX process is retarded.

Fig. 9 Flow stress dependence of -( θ/

θ/ σ) curves of as-studied alloys

σ) curves of as-studied alloys

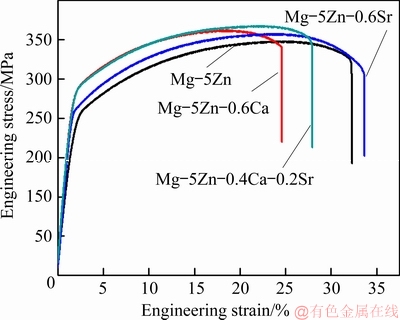

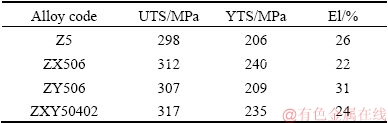

3.5 Mechanical properties

The typical tensile curves of the as-rolled Mg-5Zn-based alloys are shown in Fig. 10. UTS, YTS and El of the as-rolled alloys at room temperature are listed in Table 5.

Fig. 10 Typical tensile curves of as-studied alloys

Table 5 Mechanical properties of as-studied alloys

Interestingly, the effects of Ca and Sr on the mechanical properties of the Mg-5Zn alloy are quite different. The 0.6 wt.% Ca addition in the as-rolled Mg-5Zn alloy contributes to the enhanced strength but results in the plasticity loss. However, the 0.6 wt.% Sr addition is beneficial to the improvement of both strength and plasticity, but the strengthening effect is not so obvious as Ca. The ZXY50402 alloy has the best combination of mechanical properties among these alloys, with UTS of 317 MPa, YTS of 235 MPa and El of 24%.

Grain refinement strengthening is the most important strengthening means in Mg alloys. According to the Hall-Petch formula σ=σ0+kd-1/2 [39], the yield strength is closely related to the grain size of the alloys. Generally speaking, the reduced grain size leads to the higher yield strength. According to the relevant literature [40], the values of σ0 and k for Mg-5.1Zn were reported to be 70 MPa and 217 MPa/μm1/2, respectively. Therefore, the changes of yield strength by the different dynamic recrystallization grain sizes approximately are 190, 223, 202 and 207 MPa, respectively. The addition of Ca and/or Sr in the Mg-5Zn alloy refines the DRX grain size, contributing to the strength improvement. Additionally, the larger area of the deformed region is associated with the higher yield strength [10], which is attributed to the dislocation entanglement from work hardening during HSRR.

As mentioned above, the ZX506 alloy exhibits the highest YTS among these alloys. As compared with ZX506, the ZY506 alloy exhibits the lower UTS and the higher El. Sr can weaken the texture and reduce the critical shear stress of the base slip and the prismatic slip in Mg alloys, and thus enhances the ductility [8,27]. Although Ca can also weaken the texture in Mg alloys [10], the as-rolled ZX506 alloy exhibits a relatively low ductility due to the large area of the un-DRX regions. The micro-structural inhomogeneity is detrimental to the ductility since the un-DRX regions contain high-density dislocations and are hard to coordinate the dislocation movement. The as-rolled ZXY50402 alloy exhibits good comprehensive mechanical properties with UTS of 317 MPa, YTS of 235 MPa and El of 24%, which provides a new idea for the development of new wrought Mg alloys. As discussed above, the DRX grain size, the DRX volume fraction and the dynamic precipitates have effects on the mechanical properties of the as-studied alloys.

3.6 Tensile fracture

The SEM tensile fracture images of the as-rolled alloys are shown in Fig. 11. The size and the number of dimples and tearing edges are different for the as-rolled alloys.

Fig. 11 SEM tensile fracture images of as-rolled alloys

As seen from Figs. 11(a) and (c), more uniform dimples can be detected on the fracture surfaces of Z5 and ZY506, indicating that the ductile fracture is the main fracture mode of these two alloys. However, the dimples are much larger and deeper in ZY506, which is in good consistency with its high ductility. As seen from Figs. 11(b) and (d), the tiny dimples and some cleavage-type facets are observed on the fracture surfaces of ZX506 and ZXY50402. Therefore, the quasi-cleavage fracture is the dominant fracture mechanism for these two alloys. More dimples are detected in ZXY50402 than ZX506, which is in good consistency with the relatively high ductility of ZXY50402.

4 Conclusions

(1) The sole and the combined addition of Ca and Sr can refine DRX grains and inhibit DRX. The average grain sizes are 2.0, 2.7 and 2.5 mm respectively under the same deformation processing, which are derived from the deformation twin nucleation and the pinning effect of precipitates. Ca has a more obvious refining effect than Sr.

(2) The sole and the combined addition of Ca and Sr can increase the critical strain for DRX and reduce the DRX volume fraction during deformation, which can be ascribed to the enhanced dynamic precipitation. A portion of the storage energy is consumed by dynamic precipitation and thus the critical strain for DRX is elevated.

(3) The Sr addition improves the ductility of the as-rolled Mg-5Zn alloy, while the Ca addition enhances its strength. The ZXY50402 alloy exhibits the best combination of strength and ductility with UTS of 317 MPa, YTS of 235 MPa and El of 24%.

References

[1] GUAN Shao-kang, ZHU Shi-jie, WANG Li-guo, YANG Qing, CAO Wen-bo. Microstructures and mechanical properties of double hot-extruded AZ80+xSr wrought alloys [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1143-1151.

[2] SUN Yue-hua, WANG Ri-chu, PENG Chao-qun, FENG Yan, YANG Ming. Recent progress in Mg-Li matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2019, 29(1): 1-14.

[3] JIA Qing-gong, ZHANG Wen-xin, SUN Yi, XU Chun-xiang, ZHANG Jin-shan, KUAN Jun. Microstructure and mechanical properties of as-cast and extruded biomedical Mg-Zn-Y-Zr-Ca alloy at different temperatures [J]. Transactions of Nonferrous Metals Society of China, 2019, 29(3): 515-525.

[4] MA Ru, LU Yue, WANG Ling, WANG Yi-nong. Influence of rolling route on microstructure and mechanical properties of AZ31 magnesium alloy during asymmetric reduction rolling [J]. Transactions of Nonferrous Metals Society of China, 2018, 28(5): 902-911.

[5] BUZOLIN R H, MOHEDANO M, MENDIS C L, MINGO B, TOLNAI D, BLAWERT C, KAINER K U, PINTO H, HORT N. Corrosion behaviour of as-cast ZK40 with CaO and Y additions [J]. Transactions of Nonferrous Metals Society of China, 2018, 28(3): 427-439.

[6] DU Yu-zhou, QIAO Xiao-guang, ZHENG Ming-Yi, WANG De-bao, WU Kun, GLOVIN I S. Effect of microalloying with Ca on the microstructure and mechanical properties of Mg-6mass%Zn alloys [J]. Materials and Design, 2016, 98: 285-293.

[7] LIU Hong-hui, NING Zhi-liang, YI Jun-ying, MA Qian, SUN Hai-chao, HUANG Yong-jiang, SUN Jian-fei. Effect of Dy addition on microstructure and mechanical properties of Mg-4Y-3Nd-0.4Zr alloy [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(4): 797-803.

[8] MASOUMI M, PEKGULERYUZ M. The influence of Sr on the microstructure and texture evolution of rolled Mg-1%Zn alloy [J]. Materials Science and Engineering A, 2011, 529: 207-214.

[9] BOEHLERT C J, KNITTEL K. The microstructure, tensile properties, and creep behavior of Mg-Zn alloys containing 0-4.4wt.%Zn [J]. Materials Science and Engineering A, 2006, 417(1-2): 315-321.

[10] DU Yu-zhou, ZHENG Ming-yi, QIAO Xiao-guang, WANG De-bao, PENG Wen-qiang, WU Kun, JIANG Bai-ling. Improving microstructure and mechanical properties in Mg-6mass%Zn alloys by combined addition of Ca and Ce [J]. Materials Science and Engineering A, 2016, 656: 67-74.

[11] LI Qi, HUANG Guang-jie, HUANG Xin-de, PAN Shi-wei, TAN Chao-lan, LIU Qing. On the texture evolution of Mg-Zn-Ca alloy with different hot rolling paths [J]. Journal of Magnesium and Alloys, 2017, 5(2): 166-172.

[12] LEE J Y, YUN Y S, SUH B C, KIM N J, KIM W T, KIM D H. Comparison of static recrystallization behavior in hot rolled Mg-3Al-1Zn and Mg-3Zn-0.5Ca sheets [J]. Journal of Alloys and Compounds, 2014, 589: 240-246.

[13] ZOU Zheng-yang. Study on microstructure, properties and bio-corrosion behaviors of the fine-grained Mg-4Zn based alloy plates [D]. Changsha: Hunan University, 2015. (in Chinese)

[14] YUASA M, MIYAZAWA N, HAYASHI M, MABUCHI M, CHINO Y. Effects of group II elements on the cold stretch formability of Mg-Zn alloys [J]. Acta Materialia, 2015, 83: 294-303.

[15] YANG Ming-bo, DUAN Cheng-yu, WU De-yong, PAN Fu-sheng. Effects of minor Ca on as-cast microstructures and mechanical properties of Mg-3Ce-1.2Mn-0.9Sc and Mg-4Y-1.2Mn-0.9Sc alloys [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1698-1708.

[16] LEE Y C, DAHLE A K, STJOHN D H. The role of solute in grain refinement of magnesium [J]. Metallurgical and Materials Transactions A, 2000, 31(11): 2895-2906.

[17] STJOHN D H, QIAN Ma, EASTON M A, CAO Peng, HILDEBRAND Z. Grain refinement of magnesium alloys [J]. Metallurgical and Materials Transactions A, 2005, 36(7): 1669-1679.

[18] CHENG Mei-xing, CHEN Ji-hua, YAN Hong-ge, SU Bin, YU Zhao-hui, XIA Wei-jun, GONG Xiao-le. Effects of minor Sr addition on microstructure, mechanical and bio-corrosion properties of the Mg-5Zn based alloy system [J]. Journal of Alloys and Compounds, 2017, 691: 95-102.

[19] HRADILOVA M, VOJTECH D, KUBASEK J, CAPEK J, VLACH M. Structural and mechanical characteristics of Mg-4Zn and Mg-4Zn-0.4Ca alloys after different thermal and mechanical processing routes [J]. Materials Science and Engineering A, 2013, 586: 284-291.

[20] CHEN Chao, CHEN Ji-hua, YAN Hong-ge, SU Bin, SONG Ming, ZHU Su-qin. Dynamic precipitation, microstructure and mechanical properties of Mg-5Zn-1Mn alloy sheets prepared by high strain-rate rolling [J]. Materials and Design, 2016, 100: 58-66.

[21] ION S E, HUMPHREYS F J, WHITE S H. Dynamic recrystallization and the development of microstructure during the high temperature deformation of magnesium [J]. Acta Metallurgica, 1982, 30(10): 1909-1919.

[22] HUMPHREYS F J, HATHERLY M. Recrystallization and related annealing phenomena [M]. 2nd ed. Amsterdam: Elsevier, 2004.

[23] STANFORD N, BARNETT M R. The origin of “Rare Earth” texture development in extruded Mg-based alloys and its effect on tensile ductility [J]. Materials Science and Engineering A, 2008, 496(1-2): 399-408.

[24] BASU I, AL-SAMMAN T. Twin recrystallization mechanisms in magnesium-rare earth alloys [J]. Acta Materialia, 2015, 96: 111-132.

[25] ROBSON J D, HENRY D T, DAVIS B. Particle effects on recrystallization in magnesium-manganese alloys: Particle-stimulated nucleation [J]. Acta Materialia, 2009, 57(9): 2739-2747.

[26] ZHU Su-qin, YAN Hong-ge, CHEN Ji-hua, WU Yuan-zhi, LIU Jie, TIAN Jin. Effect of twinning and dynamic recrystallization on the high strain rate rolling process [J]. Scripta Materialia, 2010, 63(10): 985-988.

[27] ZHU Su-qin, YAN Hong-ge, LIAO Xiao-zhou, MOODY S J, SHA Gang, WU Yuan-zhi, RINGER S P. Mechanisms for enhanced plasticity in magnesium alloys [J]. Acta Materialia, 2015, 82: 344-355.

[28] ZHANG Yong, TAO Nai-rong, LU Ke. Effect of stacking-fault energy on deformation twin thickness in Cu-Al alloys [J]. Scripta Materialia, 2009, 60(4): 211-213.

[29] LANGELIER B, SHA Gang, KORINEK A, DONNADIEU P, RINGER S P, ESMAEILI S. The effects of microalloying on the precipitate microstructure at grain boundary regions in an Mg-Zn-based alloy [J]. Materials and Design, 2017, 119: 290-296.

[30] SADEGHI A, HOSEINI M, PEKGULERYUZ M. Effect of Sr addition on texture evolution of Mg-3Al-1Zn alloy during extrusion [J]. Materials Science and Engineering A, 2011, 528(7-8): 3096-3104.

[31] UEKI M, HORIE S, NAKAMURA T. Factors affecting dynamic recrystallization of metals and alloys [J]. Metal Science Journal, 1987, 3(5): 329-337.

[32] WANG W Y, SHANG Shun-li, WANG Yi, MEI Zhi-gang, DARLING K A, KECSKES L J, MATHAUDHU S N, HUI Xi-dong, LIU Zi-kui. Effects of alloying elements on stacking fault energies and electronic structures of binary Mg alloys: A first-principles study [J]. Materials Research Letters, 2014, 2(1): 29-36.

[33] DONG Qing, LUO Zhe, ZHU Hong, WANG Le-yun, YING Tao, JIN Zhao-hui, LI De-jiang, DING Wen-jiang, ZENG Xiao-qin. Basal-plane stacking-fault energies of Mg alloys: A first-principles study of metallic alloying effects [J]. Journal of Materials Science & Technology, 2018, 34(10): 1773-1780.

[34] WU Yi-feng, LI Shuang, DING Zhi-gang, LIU Wei, ZHAO Yan-hui, ZHU Yun-tian. Effect of charge redistribution factor on stacking-fault energies of Mg-based binary alloys [J]. Scripta Materialia, 2016, 112: 101-105.

[35] POLIAK E I, JONAS J J. A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization [J]. Acta Materialia, 1996, 44(1): 127-136.

[36] WU Jiang, CHEN Ji-hua, YAN Hong-ge, XIA Wei-jun, SU Bin, YU Lang, LIU Geng-shuo, SONG Ming. Enhancing the mechanical properties of high strain rate rolled Mg-6Zn-1Mn alloy by pre-rolling [J]. Journal of Materials Science, 2017, 52(17): 10557-10566.

[37] HUMPHREYS F J. The nucleation of recrystallization at second phase particles in deformed aluminum [J]. Acta Metallurgica, 1977, 25(11): 1323-1344.

[38] SU Jing, KABOLI S, KABIR A S H, JUNG I H, YUE S. Effect of dynamic precipitation and twinning on dynamic recrystallization of micro-alloyed Mg-Al-Ca alloys [J]. Materials Science and Engineering A, 2013, 587: 27-35.

[39] DU Yu-zhou, ZHENG Ming-yi, QIAO Xiao-guang, PENG Wen-qiang, JIANG Bai-ling. Effect of La addition on the microstructure and mechanical properties of Mg-6wt.%Zn alloys [J]. Materials Science and Engineering A, 2016, 673: 47-54.

[40] OH-ISHI K, MENDIS C L, HOMMA T, KAMADO S, OHKUBO T, HONO K. Bimodally grained microstructure development during hot extrusion of Mg-2.4Zn-0.1Ag-0.1Ca-0.16Zr (at.%) alloys [J]. Acta Materialia, 2009, 57(18): 5593-5604.

丁 天1,2,严红革1,2,陈吉华1,2,夏伟军1,2,苏 斌1,2,余宗霖1

1. 湖南大学 材料科学与工程学院,长沙 410082;

2. 湖南大学 湖南省喷射沉积技术与应用重点实验室,长沙 410082

摘 要:利用光学显微镜、扫描电子显微镜、热压缩试验以及拉伸实验研究Ca、Sr元素单一添加以及复合添加对铸态和轧制态Mg-5Zn合金显微组织和力学性能的影响。Ca元素在铸态组织中细化晶粒尺寸的作用比Sr元素明显。高应变速率轧制过程中产生大量的变形孪晶,因此提供大量的动态再结晶形核点。高应变速率轧制过程中,Ca、Sr元素会促进动态析出相的析出,而动态析出相的析出会消耗部分储存能,因此提高了动态再结晶的临界应变值,延迟了动态再结晶的产生。轧制态Mg-5Zn-0.4Ca-0.2Sr合金具有良好的综合力学性能,其极限抗拉强度、屈服强度、断后伸长率分别是317 MPa、235 MPa和24%。

关键词:镁合金;高应变速率轧制;动态再结晶;力学性能

(Edited by Xiang-qun LI)

Foundation item: Projects (51471066, 51571089) supported by the National Natural Science Foundation of China; Project (2019JJ40044) supported by the Natural Science Foundation of Hunan Province, China

Corresponding author: Hong-ge YAN, Tel: +86-731-88823554, E-mail: yanhg68@163.com;

Ji-hua CHEN, Tel: +86-731-88823554, E-mail: jihuachen2005@163.com

DOI: 10.1016/S1003-6326(19)65070-3