文章编号:1004-0609(2008)06-0953-06

新型炭材料用糠酮树脂的固化特性

夏伦刚,张红波,熊 翔,左劲旅,尹 健

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用热重法(TG)和差示扫描量热法(DSC)研究了新型炭材料用糠酮树脂的固化过程,分析固化剂含量及升温速率对固化反应的影响,确定磷酸/糠酮树脂固化体系的固化工艺,计算固化反应表观活化能和反应级数,得到了糠酮树脂固化反应动力学方程。并利用热重-质谱联用技术(TG-MS)研究树脂在固化过程中的气态产物。结果表明:糠酮树脂的固化反应是一个复杂的反应过程,升温速率和固化剂含量对固化反应都会产生重要的影响。对于本固化体系,固化剂含量以7%(质量分数)为最佳,该固化体系固化反应起始温度和最佳固化温度分别为102.32和159.07 ℃,反应活化能为73.33 kJ/mol,反应级数为0.9;糠酮树脂的固化反应气态产物以H2O为主,另有少量的CO、CH4和CO2。

关键词:新型炭材料;糠酮树脂;固化反应动力学;气态产物

中图分类号:TQ 324.1 文献标识码:A

Curing reaction of furfural acetone resin used for

new carbon materials

XIA Lun-gang, ZHANG Hong-bo, XIONG Xiang, ZUO Jin-lü, YIN Jian

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The curing process of furfural acetone resin used for new carbon materials was studied by thermogravimetry-differential scanning calorimetry technology (TG-DSC) and thermogravimetry-mass spectrometric coupling technique (TG-MS). The effects of curing agent content and heating rate on curing reaction were analyzed; the curing mechanism of furfural acetone resin and gaseous products evolved during curing process were investigated. The results show that the curing agent content and heating rate both have great influence on curing reaction. In this experiment, the optimal curing agent content is 7% (mass fraction) of phosphorus acid, and for this system the initial curing temperature and the optimal curing temperature are 102.32 and 159.07 ℃, respectively; the apparent activation energy is 73.33 kJ/mol and the order of curing reaction is 0.9; the main gaseous products during the curing reaction are H2O and small amount of CO, CH4 and CO2.

Key words: new carbon materials; furfural acetone resin; curing kinetics; gaseous products

糠酮树脂是呋喃树脂(furan resin)的一种,是指分子结构中含有呋喃环的一种热固性树脂,它是由糠醛本身进行缩聚,或者与其他单体进行共聚得到的产物。糠酮树脂具有非常优异的耐强酸(氧化性酸除外)、强碱和有机溶剂的特性,有优良的耐热性,在许多领域得到广泛的应用[1]。它含炭量较高,在氮气气氛中经1 000 ℃炭化处理,残炭率为58%,是较为理想的炭/炭复合材料及玻璃炭材料等新型炭材料的炭前驱体[2-4]。

糠酮树脂的固化是新型炭材料制备过程中的一个重要步骤[5]。由于高分子有机反应的复杂性,得到最终产物要经过多种中间环节,因此,糠酮树脂的固化机理很复杂,而且固化是放热反应,反应剧烈,固化过程难以控制,而前躯体的固化状况对随后制备的炭/炭复合材料等新型炭材料的显微结构影响很大[6-8]。因此,系统研究糠酮树脂的固化反应无论是对理论还是实际生产都具有重要的意义。

热分析技术是研究高分子材料固化反应机理的理想方法[9]。刘天舒等[10]和吴晓青等[11]采用DSC技术分别对用作纤维增强复合材料基体的环氧树脂和用作高温复合材料基体的改性双马来酰亚胺树脂的固化过程进行了研究,确定了各自固化体系的固化反应动力学方程和固化工艺参数,深入揭示了树脂体系的固化机理。将热分析与质谱分析等在线分析技术联用,对于进一步完整阐明材料的热学性能与结构的关系具有重要意义[12],但热重-质谱联用技术在呋喃树脂固化过程中的相关应用研究国内却未见报道。本文作者采用热重法(TG)和差示扫描量热法(DSC)研究以磷酸作固化剂的糠酮树脂的固化反应,采用热重-质谱联用技术(TG-MS)进一步分析糠酮树脂在固化过程中的气态产物,揭示糠酮树脂的固化机理,为优化固化工艺和控制材料的性能提供理论依据。

1 实验

1.1 实验原料

FA-2糠酮呋喃树脂为常熟市杜威化工有限公司生产,由等物质的量比的糠醛和丙酮在碱性催化剂存在下反应生成;粘度(25 ℃)为40~150 MPa?s;含水率≤1%;灰分≤3%。固化剂为工业磷酸,纯度≥85%。

1.2 热分析实验

采用美国TA仪器公司生产的SDTQ600同步热分析仪对样品进行热重分析(TG)和差示扫描量热分析(DSC),参比物为Al2O3,保护气为N2,流量100 mL/min。以5 ℃/min的升温速率对添加不同含量固化剂的固化体系进行升温扫描,参考已有的生产经验选择固化剂添加量为4%、7%和10%(质量分数,下同);以不同的升温速率对固化剂含量为7%的固化体系进行升温扫描,升温速率分别为2.5、5、10和20 ℃/min。

1.3 TG-MS实验

TG-MS系统由两部分组成,热重分析仪是法国SETARAM公司生产的TGA92型热天平,精度为10-6 g;质谱仪是瑞士Balzers公司生产的Omnistar小型质谱仪,在线纪录质量数为1~300的各种物质的瞬时逸出速率曲线。

将加入7%的固化剂的样品充分搅拌后放入三氧化二铝坩埚中,以Ar为保护气,流量为100 mL/min。先通入保护气一定时间以置换炉中空气,待质谱基线稳定后,再以5 ℃/min的升温速率升至1 000 ℃。最终结果取3次实验的平均值。

2 结果与讨论

2.1 热分析研究结果

2.1.1 固化剂含量对固化反应的影响

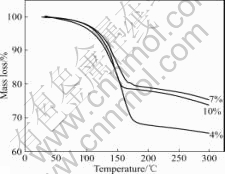

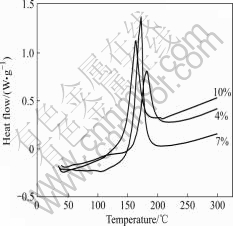

图1和2所示分别为添加不同含量固化剂的固化体系以5 ℃/min的速率升温得到的TG和DSC曲线,表1所列为由图2中DSC曲线得出的主要固化参数。由图1所示TG曲线可以看出,固化剂含量为7%时,在固化结束后固化体系的质量损失最小,表明大部分树脂以交联固化状态留存了下来;当固化剂含量增加到10%时,固化体素的质量损失增加,固化反应的起始温度和峰值温度都降低(见DSC曲线),其原因是:固化剂含量增加促进了树脂体系固化反应的进行,使反应温度降低,交联固化反应更剧烈,短时间内放出大量的热和气态产物将部分来不及固化的树脂带离反应体系,使质量损失增加;当固化剂含量减少到4%时,固化体系的质量损失更大,达32.05%,同时反应起始温度和峰值温度都明显升高(见DSC曲线)。这是由于此时固化剂不足,不足以使全部树脂固化,未固化的树脂大部分在高温下挥发掉,造成质量损失较大。

图1 固化体系以5 ℃/min等速升温时的TG曲线

Fig.1 TG curves of curing system at heating rate of 5 ℃/min

图2 固化体系以5 ℃/min等速升温时的DSC曲线

Fig.2 DSC curves of curing system at heating rate of 5 ℃/min

由表1的固化参数可知:固化剂含量为4%时反应热最小,为158 J/g;固化剂含量为10%时反应热为213.5 J/g,而固化剂为7%时反应热最大,为275.5 J/g。结合上述对热重曲线分析的结果,表明固化剂含量为7%时固化反应最充分,该固化剂含量最有利于固化反应的进行。

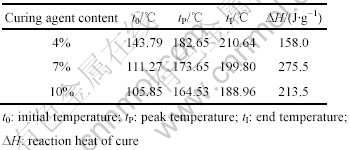

表1 固化体系以5 ℃/min等速升温时的主要固化参数

Table 1 Curing kinetics parameters of curing system at heating rate of 5 ℃/min

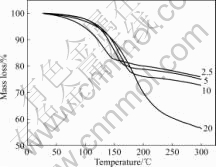

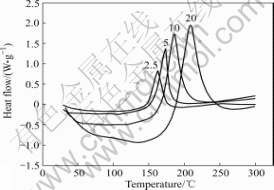

2.1.2 不同升温速率对固化反应的影响

图3和4所示分别为固化剂含量为7%时不同升温速率下固化体系的TG和DSC曲线,表2所列为由图4中DSC曲线得出的主要固化参数。从图表中可知:升温速率为2.5 ℃/min时,固化体系的质量损失最小,为18.1%,固化反应热最大,为278.4 J/g;升温速率增大到20 ℃/min时,质量损失增大到37.66%,固化反应热减小到236.5 J/g;随着升温速率的增大,质量损失增加,固化反应热减少,固化反应的起始温度和峰值温度都提高,固化时间缩短,固化温度范围变宽。这是因为升温速率增加,则dH/dt越大,即单位时间产生的热效应增大,热惯性也越大,产生的温度差就越大,固化反应放热峰相应地向高温移动[13]。结果表明:缓慢升温有利于固化的充分进行;升温速率达到10 ℃/min后,固化反应比较剧烈,单位时间内放出大量的热,使一部分来不及固化的树脂挥发掉,使体系质量损失增加,不利于提高固化样的产出率。

图3 固化体系含7%固化剂时不同升温速率下的TG曲线

Fig.3 TG curves of curing system with 7% curing agent at different heating rates

图4 固化体系含7%固化剂时不同升温速率下的DSC曲线

Fig.4 DSC curves of curing system with 7% curing agent at different heating rates

从图4所示的DSC曲线还可以看到,随着升温速率的增大,曲线上固化峰之前的吸热反应峰越来越明显,表明固化反应发生前有大量水分和部分液态树脂蒸发掉了,增加了固化体系的质量损失,不利于固化的进行。

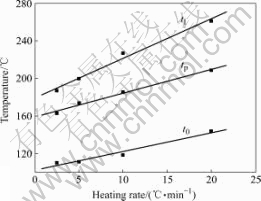

2.1.3 固化工艺的确定

磷酸/糠酮树脂体系的固化温度随升温速率的不同而不同,这使得实际固化温度难以确定,而树脂固化通常是在恒温下进行的。为了消除这种差异,通常采用T-β外推法[14]来求得升温速率为零时的固化温度,从而确定最佳固化工艺。

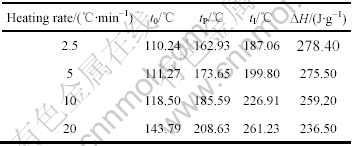

表2 固化体系含7%固化剂时不同升温速率下的主要固化参数

Table 2 Curing parameters of curing system with 7% curing agent at different heating rates

根据T-β外推法,温度T与升温速率β成线性关系,其变化规律符合下式:

T=A+Bβ

将4种不同扫描升温速率β下固化反应放热峰的起始温度t0,峰顶温度tp和终止温度tI对升温速率β作图,并进行线性拟合,得到3条直线,如图5所示。将图5中的直线外推至β = 0时得到3个纵坐标值,即体系的等温固化温度。由此求得固化反应的起始温度、峰值温度和终止温度分别为102.32、159.07和179.24 ℃,即添加7%的磷酸作固化剂时,树脂的固化起始温度为102.32 ℃。因此,该固化体系的最佳固化工艺为:从102.32 ℃缓慢升温至159.07 ℃恒温固化,最后再升温到179.24 ℃保温一段时间使其完全固化。

图5 温度与升温速率的关系

Fig. 5 Relationships between temperature and heating rate

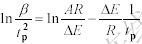

2.1.4 固化反应动力学计算

固化反应动力学参数如表观活化能和反应级数等对了解固化反应有重要的意义。表观活化能的大小直接决定了固化反应的难易程度,固化体系只有获得大于表观活化能的能量,反应才能进行;而反应级数的大小是反应复杂与否的宏观表征,通过反应级数的计算可粗略地估计固化反应机理[15]。

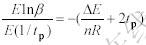

树脂的固化反应表观活化能一般可由KISSINGER方程求得[16]:

式中 β为升温速率,℃/min;tp为固化反应峰值温度,K;?E为表观活化能,kJ/mol;A为频率因子;R为摩尔气体常数,8.314 41 J/(mol?K)。

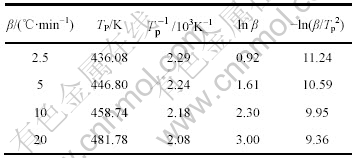

表3所列为根据图4中的DSC曲线所得出的部分固化参数及数据处理结果。根据表3中的数据,按KISSINGER方程,以-ln( )对1/tP作图,进行线性拟合得到一直线,其斜率为?E/R,如图6所示。求得直线的斜率为8.82×103,截距为-9.099 5。计算得到表观活化能为?E=73.33 kJ/mol,频率因子A=7.89×107 min-1

)对1/tP作图,进行线性拟合得到一直线,其斜率为?E/R,如图6所示。求得直线的斜率为8.82×103,截距为-9.099 5。计算得到表观活化能为?E=73.33 kJ/mol,频率因子A=7.89×107 min-1

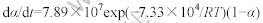

糠酮树脂固化反应级数可由RANE方程求得[17]:

当ΔE/nR>2tp时,则2tP可以忽略。根据表3中的数据,以ln β对1/tP作图,经过线性拟合得到一条直线,直线的斜率为-ΔE/(nR),如图6所示。求得直线斜率为-9.77×103,即 E/(nR) =9.77×103,则可以得到反应级数为n=0.9。

E/(nR) =9.77×103,则可以得到反应级数为n=0.9。

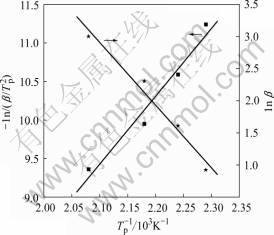

反应级数满足0.9≤n≤1.1,所以其满足一级动力学方程[18]:

式中 α为反应固化度。根据 ARRHENNIUS方程k=Aexp(-?E/RT),将k代入动力学方程得到一级动力学方程:

代入固化反应动力学参数?E和A的值,得到康酮树脂体系固化反应动力学方程:

表3 升温速率对固化反应特征的影响及动力学数据处理

Table 3 Effects of heating rate on curing reaction and results of kinetics calculation

通过固化动力学方程可以进一步预测在恒温条件下该糠酮树脂的固化反应特性,揭示固化度与固化时间以及反应温度的关系。

图6 树脂体系的-ln ( )—1/TP及lnβ—1/TP关系曲线

)—1/TP及lnβ—1/TP关系曲线

Fig.6 Relationship curves of –ln( )—1/TP and ln β—1/TP of curing system

)—1/TP and ln β—1/TP of curing system

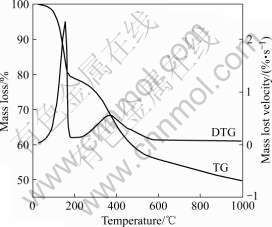

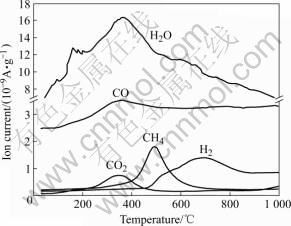

2.2 TG-MS结果及分析

固化剂含量为7%的固化体系在Ar气氛下加热时的TG-DTG曲线及气体逸出曲线分别如图7和8。由图7中固化反应的瞬时质量损失速率图(DTG)中可以看出,在300 ℃以前,固化体系只有一个明显的质量损失峰,最大质量损失速率发生在145 ℃左右,为0.052%?s-1。在100 ℃前的一小段温度范围内,有不太明显的小质量损失峰,应该是固化体系中的少量水分挥发所致。这可以通过与气体逸出曲线的对照分析得到证实。由图8可知,在300 ℃以前的固化反应过程中,主要气态产物为H2O和少量的CO、CH4和CO2,这与文献[19]报道结果相符。文献[19]认为糠酮树脂的固化反应产物主要是水,由自由氢氧基团形成,随后甲基断裂,作为副产品生成甲烷,呋喃环随着打开,接着是碳的二氧化物,一氧化物和水裂解释放出来。从图8中的水逸出曲线可知,在150 ℃左右出现了水的第一个强峰,因此,水的生成是固化质量损失的主要原因。在300 ℃以后,CO2、H2O和CH4等气体相继出现峰值,表明固化后体系还会有进一步的反应质量损失,这些反应及其机理涉及到糠酮树脂的炭化,这是作者下一步的研究内容,在此不再赘述。

图7 固化体系在Ar气氛下加热时的TG及DTG曲线

Fig.7 TG and DTG curves of curing system heated in Ar

图8 固化体系在Ar气氛下加热时的气体逸出曲线

Fig.8 Evolution of gaseous productions of curing reaction heated in Ar

3 结论

1) 磷酸/糠酮树脂体系的固化反应是一个复杂的反应过程,固化剂含量和升温速度对固化反应都会产生重要的影响。固化剂为7%时,反应放热量最大,质量损失最小,固化效果最好。升温速率越低,反应放热量越大,质量损失越小,越有利于固化,但实际生产过程中应综合考虑各种因素的影响。由本研究结果得出的较佳固化工艺为:从102.32 ℃缓慢升温至159.07 ℃恒温固化,最后再升温到179.24 ℃保温一段时间使其完全固化。

2) 糠酮树脂添加7%的磷酸作固化剂时固化反应表观活化能为73.33 kJ/mol,反应级数为0.9,固化反应动力学方程为

dα/dt=7.89×107exp(-7.33×104/RT) (1-α)

3) 糠酮树脂固化反应气态产物以H2O为主,另有少量的CO、CH4和CO2。

REFERENCES

[1] 傅 旭. 树脂与塑料[M]. 北京: 化学工业出版社, 2005.

FU Xue. Resin and plastic[M]. Beijing: Chemistry Industry Press, 2005.

[2] 付东升, 张康助, 孙福林, 姚冬梅. 碳/碳复合材料的基体前躯体研究进展[J]. 化工新型材料, 2003, 31(6): 19-21.

FU Dong-sheng, ZHANG Kang-zhu, SUN Fu-lin, YAO Dong-mei. Research progress in matrix precursors for carbon-carbon composites[J]. New Chemical Materials, 2003, 31(6): 19-21.

[3] FITZER E. The future of carbon-carbon composites[J]. Carbon, 1987, 25(2): 163-169.

[4] UOTA M, YADA M, KUROKI M, MACHIDA M, KIJIMA T. Carbons from furan-polymers prepared in the presence of a double-chain amphiphile[J]. Carbon, 2004, 42: 2207–2213.

[5] 沈曾明. 新型碳材料[M]. 北京: 化学工业出版社, 2003.

SHENG Zeng-ming. New carbon material[M]. Beijing: Chemistry Industry Press, 2003.

[6] WANG Z, LU Z, HUANG X, XUE Z, CHEN L. Chemical and crystalline structure characterizations of polyfurfuryl alcohol pyrolyzed at 600 ℃[J]. Carbon, 1998, 36(1/2): 51-59.

[7] JUBSILP C, DAMRONGSAKKUL S, TAKEICHI T, RIMDUSIT S. Curing kinetics of arylamine-based polyfunctional benzoxazine resins by dynamic differential scanning calorimetry[J]. Thermochimica Acta, 2006, 447(2): 131-140.

[8] 熊 翔, 黄伯云, 肖 鹏. 单向C/C复合材料的液相法制备及其显微结构[J]. 中国有色金属学报, 2003, 13(6): 1430-1434.

XIONG Xiang, HUANG Bai-yun, XIAO Peng. Microstructures of unidirectional fibre-reinforced C/C composites fabricated by liquid method[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6):1430-1434.

[9] 于伯龄, 姜胶东. 实用热分析[M]. 北京: 纺织工业出版社, 1990.

YU Bo-ling, JIANG Jiao-dong. Practical thermal analysis[M]. Beijing: Textile Industry Press, 1990.

[10] 刘天舒, 张宝艳, 陈祥宝. 3234中温固化环氧树脂体系的固化反应动力学研究[J]. 航空材料学报, 2005, 25(1): 45-47.

LIU Tian-shu, ZHANG Bao-yan, CHEN Xiang-bao. Study on the cure kinetics of middle temperature curing 3234 epoxy resin system[J]. Journal of Aeronautical Materials, 2005, 25(1): 45-47.

[11] 吴晓青, 魏俊富, 李嘉禄. 差示扫描量热法研究改性双马来酰亚胺的固化过程[J]. 复合材料学报, 1999, 16(2): 34-38.

WU Xiao-qing, WEI Jun-fu, LI Jia-lu. Study on the curing reaction of modified BMI CDR-9418 with DSC[J]. Acta Materiae Compositae Sinica, 1999, 16(2): 34-38.

[12] PAPPA A, MIKEDI K, TZAMTZIS N, STATHEROPOULOS M. Chemometric methods for studying the effects of chemicals on cellulose pyrolysis by thermogravimetry-mass spectrometry [J]. Journal of Analytical and Applied Pyrolysis, 2003, 67(2): 221-235.

[13] OZAWA T. Kinetic analysis of derivative curves in thermal analysis[J]. Journal of Thermal Analysis, 1970, 2(3): 301-324.

[14] PRIME R B, SACHER E. Kinetics of epoxy cure: 2. The system bisphenol-A diglycidyl ether/polyamide[J]. Polymer, 1972, 13(9): 455-458.

[15] 陈少锋, 谢建良, 邓龙江. DSC法研究聚异氰酸酯/环氧树脂胶粘剂的固化反应动力学及固化工艺[J]. 中国胶粘剂, 2006, 15(6): 1-4.

CHEN Shao-feng, XIE Jian-liang, DENG Long-jiang. Study on curing reaction kinetics and curing technics of poly-isocyanate/epoxy resin adhesive by DSC[J]. China Adhesive, 2006, 15(6): 1-4.

[16] KISSINGER H E. Reaction kinetics in differential thermal analysis[J]. Analytical Chemistry, 1957, 29(11): 1702-1706.

[17] CRANE L W. Analysis of curing kinetics in plymer composites[J]. Polym Sci Polym Letter Edition, 1973, 11: 533-538.

[18] 曾秀妮, 段跃新. 840S环氧树脂体系固化反应特性[J]. 复合材料学报, 2007, 24(3): 100-104.

ZENG Xiu-ni, DUAN Yue-xin. Curing reaction characteristics of 840S epoxy resin[J]. Acta Materiae Compositae Sinica, 2007, 24(3): 100-104.

[19] SAVAGE G. Carbon-carbon composites[M]. Cambridge: Champan & Hall, 1993: 130-138.

基金项目:国家重点基础研究发展计划资助项目(2006CB600902)

收稿日期:2007-10-11;修订日期:2007-12-24

通讯作者:张红波,教授,博士;电话:0731-8877393;E-mail: zhanghb @hnu.cn

(编辑 何学锋)