Effect of TiN/Ti multilayer on fretting fatigue resistance of

Ti-811 alloy at elevated temperature

ZHANG Xiao-hua(张晓化), LIU Dao-xin(刘道新)

Corrosion and Protection Research Laboratory, Northwestern Polytechnical University, Xi’an 710072, China

Received 29 July 2008; accepted 27 November 2008

Abstract: The TiN/Ti multilayer was deposited on Ti-811 alloy surface by magnetron sputtering(MS) technique for improving fretting fatigue(FF) resistance of the titanium alloy at elevated temperature. The element distribution, bonding strength, micro-hardness and ductility of the TiN/Ti multilayer were measured. The effects of the TiN/Ti multilayer on the tribological property and fretting fatigue resistance of the titanium alloy substrate at elevated temperature were compared. The results indicate that by MS technique a TiN/Ti multilayer with high hardness, good ductility and high bearing load capability can be prepared. The MS TiN/Ti multilayer, for its good toughness and tribological behavior, can significantly improve the wear resistance and FF resistance of the Ti-811 alloy at 350 ℃.

Key words: fretting fatigue; TiN/Ti multilayer; magnetron sputtering; titanium alloy; elevated temperature

1 Introduction

Titanium alloys have been widely used in manufacturing the fans, compressor disks, and blades of advanced aircraft engines[1-2]. However, titanium alloys are very sensitive to fretting fatigue(FF) damage, which may affect the safe reliability of the aircraft engine compressor[3-5]. Hence, the development of surface modification techniques to improve the fretting fatigue resistance(FFR) of titanium alloys is vital for their safe use in advanced aero-engines[6-9]. To date, no surface treatment methods used to improve the FFR of titanium alloys at elevated temperature have been entirely satisfactory. The beneficial effect of shot peening(SP) on FFR is reduced at elevated temperature due to the compressive residual stress induced by SP relaxation [10]. Although the FFR of titanium alloys can be effectively improved by the use of MoS2 solid lubrication films, the endurance of such MoS2 films is low owing to their poor resistance to elevated temperature[11-12]. To improve the FFR of titanium alloys at elevated temperature, it is necessary to devise other effective surface treatment methods.

TiN coating leads to superior abrasion resistance, low coefficient of friction, high temperature stability, and high hardness. Research has indicated that the tribological and fretting wear performances of metals may be improved by a TiN coating[13]. However, our previous research has shown that the FFR of titanium alloys is significantly reduced by either chemical vapor deposited(CVD) TiN coating or plasma nitriding because of the poor ductility of the coating[14]. The key to improve FFR by surface treatment methods lies in how to improve the anti-friction property while at the same time to preserve anti-fatigue properties. However, the methods for settling the anti-friction and anti-fatigue properties are often incompatible with each other. The anti-friction property can be remarkably improved by hard coatings or surface hardening treatments. However, the fatigue resistance is often reduced due to the poor ductility of the hard treated surface. As a result, the FFR cannot be improved by traditional surface hardening treatments. Hence, structural optimization of coating surface to achieve rational balance of the strength and ductility for preparing coatings thus to improve the FFR of titanium alloys at elevated temperature becomes a subject worth investigation. A method for improving the ductility of the TiN film is to strive for the toughness of a composite. For example, the fracture toughness of a TiN/Ti multilayer is obviously better than that of a TiN single film because of the high ductility of the Ti layer in the TiN/Ti multilayer[15-17]. Magnetron sputtering(MS) can be advantageous when being used to produce multilayer film as the resulting film is of high density, small grain size, and low void ratio. By using MS method to produce TiN/Ti multilayer, the film would then combine the property of strength with good ductility. Nevertheless, research work on improving the FFR of Ti alloys at elevated temperature by the MS TiN/ Ti multilayer has seldom been reported. In this work, properties of an MS TiN/Ti multilayer are studies and the effect and mechanism of the MS TiN/Ti multilayer on the FFR of a titanium alloy at elevated temperature are discussed in view of finding a new method for improving the FFR of titanium alloys under such conditions.

The Ti-811 titanium alloy is an important material for the manufacture of rotary parts used in high temperature sections of advanced aircraft compressors [18]. The present authors have studied the FF behavior of the Ti811 titanium alloy at elevated temperature[19]. But research on surface modification for improving the FFR of this alloy has not been done. Therefore, Ti-811 alloy is selected to be researched in this work.

2 Experimental

2.1 Experiment material

FF specimens and fretting pads were obtained from Ti-811 alloy bars (d 16 mm). Ti-811 alloy is almost composed of almost all α-phases and contains 7.9% Al, 1.0% Mo, 0.99% V, 0.05% Fe, 0.1% C, 0.01% N, 0.001% H, 0.06% O, and balance Ti. The material was treated by double annealing (910 ℃, 1 h, cooled in air; 580 ℃, 8 h, cooled in air). The resulting microstructure is composed of an equiaxial α-phase and intergranular b-phase. The mechanical properties of the alloy are: σb=931 MPa, σ0.2= 890 MPa, d=23% and Y=46%.

2.2 Preparation of TiN/Ti multilayer

A PIEMAD-03 multifunction apparatus was used to prepare the MS TiN/Ti multilayer. The MS target used consisted of 99.99% Ti. The specimen was finely ground using 1 200 grit SiC paper and ultrasonically cleaned with acetone. The surface of the specimen was cleaned with a 1 keV Ar ion beam in a flux of 20 mA/cm2 for 20 min before film deposition. To improve the bonding strength between the coating and substrate, a high-energy assisting ion beam was used to bombard the surface of the coating during deposition. After etching, a layer of pure Ti of about 3 μm was deposited in order to improve adhesion, providing a smooth transition between the ion-cleaned substrate and the films. Subsequently, the N2 gas valve was turned on to introduce the N2 gas into the deposition chamber, and then the TiN film began to grow on the pure Ti layer. The N2 gas valve was turned off when TiN reached 1 μm in thickness, leading to pure Ti layer growing again. When the Ti film grew to 1 μm, the N2 gas valve was turned on again to achieve TiN layer. After repeating the turning on and turning off the N2 gas valve, the TiN/Ti multilayer constructions with the desirable thickness could be produced. The modulation period was 1 μm. A TiN coating with thickness of 3 μm was deposited on the surface of the multilayer. Totally, there were three layers of Ti and three layers of TiN deposited in the multilayer. During the deposition, the argon flow (60 mL/s), the current (1 A), and the bias voltage (-200 V) were kept constant. The nitrogen flow was maintained at 30 mL/s during the TiN deposition.

2.3 Multilayer evaluation for characterization

A HITACHI S-570 scanning electron microscope (SEM) was used to investigate the morphology of the TiN/Ti multilayer. A GDA750 glow-discharge spectrometer was used to determine the elemental distribution on the cross-section of the TiN/Ti multilayer. An HV-1 000 micro-hardness instrument was used to measure the Knoop micro-hardness of the TiN/Ti multilayer with a load of 0.245 N and loading time of 20 s. The bonding strength of the TiN/Ti multilayer to the substrate was evaluated by the method of scratch. The critical force (Lc) that resulted in spalling of the TiN/Ti multilayer was defined as the bonding strength. The ductility of the TiN/Ti multilayer was estimated using a multi-impact tester with a total number of 1×104 impacts. The maximal impact load that resulted in cracking of the coating was defined as the critical ductility load.

The wear resistance of the TiN/Ti multilayer at elevated temperature was evaluated using a ball made of Ti-811 alloy rolling on a fixed disk. The diameter, the surface roughness Ra, and the hardness HK0.245 of the ball were 4.75 mm, 0.05 μm, and 346, respectively. The disk, made of the Ti-811 alloy, had a diameter of 30 mm, a thickness of 8 mm, and a surface roughness Ra of 0.05 μm. The wear tests were conducted under a 5 N load at 350 ℃, which simulated the conditions of aircraft engine compressors.

2.4 Fretting fatigue(FF) test assembly

A PLG-100 C high-frequency fatigue machine was used to conduct FF tests. A schematic drawing of the FF specimens and pad is available elsewhere[19]. The load was set in pull-pull. The contact state between the pad and specimen was flat-to-flat, with a rectangular contact area of 2 mm×6 mm. Relative slip between the specimen and pad was introduced by the difference in elastic deformation between them. The contact pressure of the pad was controlled at 85 MPa using a tensor meter. The span length between the fretting bridge foots was 15 mm. The slip was approximately 36 mm for an axial loading force of 530 MPa in a sinusoidal form at 110 Hz and a stress ratio of 0.1. The FF life reported here was an average of three specimens. Test temperature of 350 ℃ was adopted to simulate the working conditions of aircraft engine compressors. An electrical resistance furnace was used for heating and the temperature was controlled at (350±1) ℃ using a feedback temperature controller with a rectifier and a K-type thermocouple.

3 Results and discussion

3.1 Properties of MS TiN/Ti multilayer

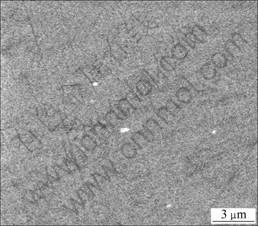

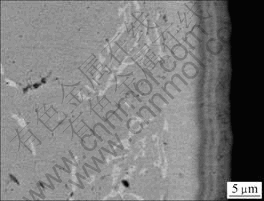

Fig.1 shows the surface SEM morphology of the MS TiN/Ti multilayer. The MS TiN/Ti multilayer has high density, small grain size and low void ratio. Fig.2 shows the cross-section micrograph of MS TiN/Ti multilayer. The alternating dark and bright lining of the TiN/Ti multilayer can be seen. The light-colored layer is Ti, while the deep-colored layer is TiN. A close-knit combination of TiN and Ti layers is evident. No interspace can be seen in the film and the bonding between the film and the substrate is good.

Fig.1 Surface micrograph of MS TiN/Ti multiplayer

Fig.2 Cross-sectional micrograph of MS TiN/Ti multilayer

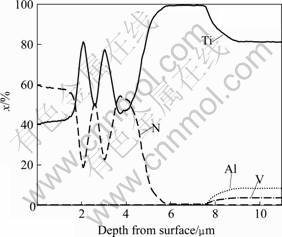

Fig.3 shows the elemental distribution over the cross-section of the MS TiN/Ti multilayer. The thickness of the TiN/Ti multilayer is 8 ?m. Multiple interfaces were formed with gradient variation of the nitrogen content between the TiN and Ti layers. To improve the ductility of the TiN coating and the bond strength between the coating and substrate, a pure Ti interlayer (approximately 3 mm) was deposited between the substrate and the TiN coating. The nitrogen content is seen to increase gradually from the Ti coating to the TiN coating. The mixing interface of the coating element and the substrate element is introduced by the bombardment of the assisting ion beam during the initial deposition stages of the coating, which can improve the bond strength between the coating and substrate.

Fig.3 Elemental distribution curves of MS TiN/Ti multilayer

The micro-hardness test yields a value of HK0.245 2 487 for the MS TiN/Ti multilayer, which is 6.8 times higher than that of the Ti-811 alloy substrate. The high hardness of the coating results from the ceramic phase of the TiN. The hardness of the MS TiN/Ti multilayer is higher than that of the MS TiN/Ti composite film (HK0.245 2015). This is because dislocation movement is prevented by the many interfaces formed in the MS TiN/Ti multilayer, and the anti-deformability capacity of the film is improved accordingly.

The critical bonding strength (Lc) of the MS TiN/Ti multilayer is measured to be 75 N. The film irregularly flakes off at the edge of the scratch (Fig.4). The driving force of crack propagation is reduced by the many interfaces in the MS TiN/Ti multilayer, and so the fast propagation of cracks is prevented. At the same time, the load-bearing capacity of the film is improved as a result of the high hardness.

Fig.4 Morphology of TiN/Ti multilayer after scratching

The multi-impact test indicates that the MS TiN/Ti multilayer has very good ductility and high bonding strength. The coating does not crack or delaminate even when the substrate is impacted to collapse under the maximum load (1 000 N) of the tester (Fig.5).

Fig.5 Impact morphology of TiN/Ti multilayer

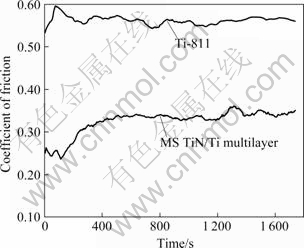

Fig.6 compares variation characteristic between the friction coefficient and friction time of the Ti-811 alloy and the MS TiN/Ti multilayer at 350 ℃. The results indicate that the friction coefficient of the Ti-811 alloy substrate maintains at around 0.55 with passage of time. Whereas friction coefficient of the MS TiN/Ti multilayer stays at around 0.35 for a long period of time, which would be of benefit to improving substrate anti-friction

Fig.6 Comparison of friction coefficient of TiN/Ti multilayer and Ti-811 alloy

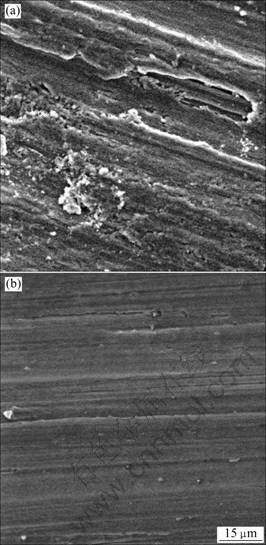

property. This is due to the high hardness and the good lubricating effect of the TiN/Ti multilayer. Also, the MS TiN/Ti multilayer on the titanium alloy does not fracture or break off during the friction process. Fig.7 shows the wear morphologies of Ti-811 alloy and the MS TiN/Ti multilayer. It can be seen that the surface of the Ti-811 alloy is severely worn, with debris and delamination emerging in the wear scar. The damage to the MS TiN/Ti multilayer is light and can be characterized as low ploughing.

Fig.7 Wear morphologies of Ti-811 alloy (a) and TiN/Ti films (b)

3.2 Effect of MS TiN/Ti multilayer on FF life

The average FF lives (FFL) of the Ti-811 alloy at 350 ℃ is 4.36×104 cycles and the average FFL of the Ti-811 alloy coated MS TiN/Ti multilayer at 350 ℃ is 14.99×104 cycles. The FFL of the titanium alloy is improved by 2.44 times through application of the MS TiN/Ti multilayer. This is because the energy produced during the fretting process is consumed by the shearing deformation of the soft Ti layer in the MS TiN/Ti multilayer. The crack propagation driving force is inhibited by the many interfaces between the TiN and Ti layers in the MS TiN/Ti multilayer. When a crack from the Ti layer which has good plasticity enters into the TiN layer which has high hardness, the TiN layer has sufficiently high crack initiation resistance. When a crack enters from the TiN layer into the Ti layer, the crack tip becomes passivated and the direction of propagation of the crack is deviated, resulting in a higher fracture toughness and better FFR. The MS TiN/Ti multilayer displays good anti-friction properties because the hard TiN layer provides a strong support for the soft Ti layer and the tangential force on the fretting contact area can be effectively reduced.

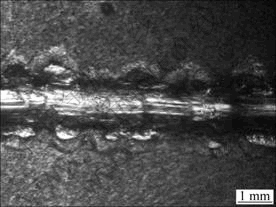

Fig.8 compares the SEM morphologies of fretting fatigue damaged surface of Ti-811 alloy and MS TiN/Ti multilayer. FF damage to the surface of Ti-811 alloy can be characterized as cracks and fatigue detachment. This is attributed to a change in hardness of the material in the two contact interfaces during the fretting progress. Severe plastic deformation occurred near the material surface, and the brittleness of the materials increased. Then micro-cracks initiated in the hardened sub-surface area and gradually propagated to the surface. Patch delamination occurred when the micro-cracks connected with the free surface. The FF damaged surface of the Ti-811 alloy with the MS TiN/Ti multilayer is characterized by delamination. This is because crack propagation is prevented by the interfaces between the layers and the propagating direction of a crack is deviated.

Fig.8 SEM morphologies of fretting fatigue damaged surface: (a) Ti-811 alloy; (b) MS TiN/Ti multilayer

4 Conclusions

1) A TiN/Ti multilayer was prepared on a Ti-811 alloy substrate by magnetron sputtering deposition technique. The TiN/Ti multilayer exhibits high hardness, excellent load-bearing capability, good ductility, and low coefficient of friction, so the wear resistance of the Ti-811 alloy is significantly improved by the TiN/Ti multilayer at 350 ℃.

2) The fretting fatigue life of the Ti-811 alloy with the MS TiN/Ti multilayer is improved by 2.44 times as compared with the uncoated substrate at 350 ℃ because of the excellent wear and fatigue resistance and good ductility of the TiN/Ti multilayer. The crack propagation driving force is reduced by many interfaces in the MS TiN/Ti multilayer. As a result, excellent wear resistance and good anti-fatigue properties can be simultaneously obtained by a single hard coating to control the FF damage.

References

[1] WILLIAMS J C, STARKE E A. Progress in structural materials for aerospace systems [J]. Acta Materialia, 2003, 51: 5775-5799.

[2] ZHOU Y G, ZENG W D, YU H Q. An investigation of a new near-beta forging process for titanium alloys and its application in aviation components [J]. Mater Sci Eng A, 2005, 393: 204-212.

[3] RAY A K, DAS G, RANGANATH V R. Failure of connecting pins of a compressor disc in an aero engine [J]. Engineering Failure Analysis, 2004, 11: 613-617.

[4] BHAUMIK S K, RANGARAJU R, VENKATASWAMY M A. Fatigue fracture of crankshaft of an aircraft engine [J]. Engineering Failure Analysis, 2002, 9: 255-263.

[5] KERMANPUR A, AMIN H S, RAD S Z. Failure analysis of Ti-6Al- 4V gas turbine compressor blades [J]. Engineering Failure Analysis, 2008, 15: 1052-1064.

[6] HUTSON A L, NIINOMI M, NICHOLAS T, EYLON D. Effect of various surface conditions on fretting fatigue behavior of Ti-6Al-4V [J]. International Journal of Fatigue, 2002, 24(12): 1223-1234.

[7] REN W J, MALL S, SANDERS J H, SHARMA S K. Evaluation of coatings on Ti-6Al-4V substrate under fretting fatigue [J]. Surface and Coatings Technology, 2004, 192(2): 177-188.

[8] LEE H, MALL S, SATHISH S. Investigation into effects of re-shot- peening on fretting fatigue behavior of Ti-6Al-4V [J]. Mater Sci Eng A, 2005, 390: 227-232.

[9] LIU D X, HE J W. Comparative study on the fretting fatigue and fretting wear behaviors of titanium alloy subject to various surface modifications [J]. Tribology, 2005, 25(1): 13-17. (in Chinese)

[10] LEE H, MALL S. Stress relaxation behavior of shot peening Ti-6Al-4V under fretting fatigue at elevated temperature [J]. Mater Sci Eng A, 2004, 366: 412-420.

[11] LIU D X, TANG B, HE J W. MoS2 composite films on titanium alloys prepared by ion beam enhanced deposition [J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 454-460. (in Chinese)

[12] ZHOU H, WEN Q P, HAO H. Study of structural and tribological properties of MoS2-Ti composite coatings deposited by unbalanced magnetron sputter [J]. Tribology, 2006, 26(2): 183-187. (in Chinese)

[13] SUNG J H, KIM T H, KIM S S. Fretting damage of TiN coated zircaloy-4 tube [J]. Wear, 2001, 250: 658-664.

[14] LIU D X, CHEN H, HE J W. The effect of plasma nitriding and shot peening on the fretting damage resistance of Ti alloy [J]. Transactions of Metal Heat Treatment, 2001, 22(3): 49-54. (in Chinese)

[15] MA K J, BLOYCE A, BELL T. Examination of mechanical properties and failure mechanisms of TiN and Ti-TiN multilayer coatings [J]. Surface and Coatings Technology, 1995, 76/77: 297-302.

[16] BROMARK M, LARSSON M, HEDENQVIST P, HOGMARK S. Wear of PVD Ti/TiN multilayer coatings [J]. Surface and Coatings Technology, 1997, 90: 217-223.

[17] SRINIVASANA D, KULKARNIB T G, ANAND K. Thermal stability and high-temperature wear of Ti-TiN and TiN-CrN nanomultilayer coatings under self-mated conditions [J]. Tribology International, 2007, 40: 266-277.

[18] ZHAO Y Q, LIU B N. Effect of alloying composition on the mechanical properties of Ti-811 alloy rods [J]. Rare Metals and Engineering, 1994, 23(3): 59-65. (in Chinese)

[19] GAO G R, LIU D X, ZHANG X H. Investigation on fretting fatigue behaviors of Ti-811 alloy at elevated temperature [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 38-43. (in Chinese)

Foundation item: Projects(50671085, 50371060) supported by the National Natural Science Foundation of China; Project(2007AA03Z521) supported by the National High-tech Research and Development Program of China

Corresponding author: ZHANG Xiao-hua; Tel: +86-13193391986; Fax: +86-29-88492344; E-mail: yhzhangxh@nepu.edu.cn

DOI: 10.1016/S1003-6326(08)60312-X

(Edited by YANG Bing)