DOI:10.19476/j.ysxb.1004.0609.2018.09.08

基于CAFE模拟钛合金丝材电弧增材制造凝固过程的组织演变

李晗嫣1, 2,陈文革1,张飞奇1, 2,高红梅1,任澍忻1

(1. 西安理工大学 材料科学与工程学院,西安 710048;

2. 陕西天成航空材料有限公司,咸阳 712000)

摘 要:采用CAFE(Cellular automation finite element)对Ti6Al4V合金丝材电弧增材制造的快速凝固过程进行模拟计算。通过建立不同阶段(堆积层)的三维模型,建立晶体形核与生长模型,并结合三维热传导(包含结晶潜热释放)模型,研究了不同阶段的温度场对固-液转变、初始β晶形核及生长等影响。结果表明:初始阶段初始β晶取向杂乱且晶粒尺寸细小;随着增材高度的增加,水平方向温度梯度变缓,平均固-液转变糊状区域宽度增加,初始β晶平均晶粒尺寸增加,晶体取向趋于热流传递方向(垂直于冷基板方向);其模拟结果与实际增材制造后的初始β晶组织形貌基本一致。

关键词:CAFE;合金丝材;电弧;增材制造;Ti6Al4V;晶体生长

文章编号:1004-0609(2018)-09-1775-09 中图分类号:TG146.2 文献标志码:A

钛及钛合金因比强度高、耐蚀性良好以及生物相容性等优良特点,被广泛应用在航空航天、化工及生物医学等领域。但由于钛的易氧化、熔点高、价格高、对缺口敏感等问题使得其深加工受到种种限制,而增材制造则是一种很好的选择,不仅能大幅度提高钛合金材料的利用率,并且可以制造出完全致密、结构复杂、力学性能优异的元件[1]。其中,金属丝材电弧增材制造方法具有能量高、扫描速度快及熔池体积较大的特点,已应用于大尺寸形状、低成本及高效快速成形的构件中,但金属丝材增材制造过程中,如何控制复杂的凝固过程,从而影响组织变化来改善其材料的使用性能,是人们迫切需要解决的问题之一[2-4]。

金属的凝固过程是快速传热及传质的过程,很难被直接观察,研究人员利用数值模拟计算方法研究凝固组织,有利于理解不同材料成型凝固过程对组织形成的影响。近年来,最接近凝固过程中晶体生长的随机模型主要以元胞自动机(Cellular automation,CA)及其衍生模拟方法为主,其基本思想就是基元胞根据相近领域元胞的变化规则,来改变自己状态,并且这个基元胞去影响下一个元胞的变化,如此不断进行演变,这与金属凝固过程具有相似性。根据这个原理,RAPPAZ[5]和GANDIN等[6-7]将CA方法引入到了金属凝固组织计算中,并与有限元(Finite element, FE)法温度场方法进行结合,形成高效率的CAFE凝固组织计算模型,其过程是将温度场与晶体形核生长分别计算,再由温度场去影响晶体形核生长。目前,已经应用到众多材料制备工程中,张璞等[8]基于CAFE模型研究了镍基合金定向凝固过程显微组织转变,阐明了温度与冷却速度对凝固过程的影响;张颖娟等[9]利用CAFE方法研究真空自耗电弧熔炼钛合金铸锭的凝固过程、缩松及缩孔的模拟,结果表明CAFE方法对于晶粒结构、柱状晶生长及其缩孔缩松缺陷可完整有效地进行模拟;庞瑞朋等[10]基于3D-CAFE方法对缓冷、空冷和水冷条件下430铁素体不锈钢铸件凝固过程的组织过程形成进行了模拟,解释了不同条件下等轴-柱状晶转变机理;仲红刚等[11]使用 CAFE 模型预测水平单向凝固实验中Al-4.5%Cu 合金试样的温度场和显微组织模拟,结果表明 CAFE 模型可以较准确地预测柱状晶向等轴晶转变(CET)位置和等轴晶晶粒尺寸;卜晓兵等[12]采用有限元和元胞自动机结合的CA-FE 模型,通过加入空位形成能的固相扩散系数,对Al-Cu 合金的凝固组织进行了三维模拟和预测,其结果能够准确地反映等轴晶和柱状晶的分布位置、比例和大小等;SALUJA等[13]在CAFE基础上进行了改进,对Al6061-T6两种材料摩擦焊后晶粒生长过程进行模拟,并预测其晶粒尺寸;DEZFOLI等[14]利用CAFE方法模拟在不同条件制备多晶硅锭晶体生长过程,得到晶粒尺寸结果与实际相符。

本文作者根据电弧丝材增材制造过程,利用SolidWorks软件针对不同增材制造阶段及整体重熔凝固分别进行了三维建模,基于ProCAST软件包进行网格划分,采用凝固模块及CAFE模块进行重熔凝固及增材制造的模拟,研究了Ti6Al4V合金丝材电弧增材制造不同阶段(堆积层)的温度场对固液转变、初始β晶形核及生长、晶体取向等现象的影响。

1 实验

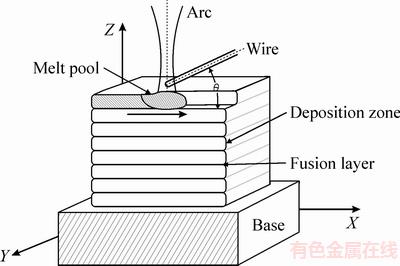

实验材料采用规格为d 2 mm的Ti6Al4V合金拉拔线材,选用水冷铜基板,铜具有高的热传导率,可以一直保持冷态,避免钛合金与基板发生焊连。在纯氩气保护下,首先引燃电弧,调整电流和电压约250 A和20 V,待电弧稳定后,调整钨极与基板之间的距离约为15 mm,以约30°角度送给钛合金丝材,进给速度2 mm/s,钛合金丝材与钨极同一水平面做“S”型路线堆积,堆积第二层完毕,再上升约2 mm重复堆积第二层,直到完成所需样品,钛合金电弧增材制造过程如图1所示。

图1 钛合金丝材电弧增材制造的示意图

Fig. 1 Schematic illustration of wire+arc additive manufacturing titanium alloy

2 三维几何模型

根据电弧增材制造过程,钛合金丝材以“S”型路径堆积在基板上,第一层堆积完毕后垂直上升2 mm,沿着原路径反方向继续堆积第二层,如此堆积成型反复8到10层,建立不同阶段沉积模型如图2所示,其中扫掠总长度为80 mm,宽度40 mm,模拟过程中对不同增材阶段的三维几何模型进行分割计算,以减少计算量,防止软件出错崩溃。有限元基本的面网格采用Quad-Tria格式划分面网格,Quad-Tria格式主要以面正方形网格为主,在小角度边角或不规则处自动转变为三角形网格,以减少在体划分网格过程中对模型的损失,并提高体划分模型质量。宏观网格划分为1 mm,微观计算时网格再细分为100×100× 100,三维单位体积上元胞网格数为1×106。

图2 钛合金丝材增材制造的三维模型

Fig. 2 Three-dimensional model of wire+arc additive manufacturing titanium alloy

3 熔池凝固的CAFE耦合模型

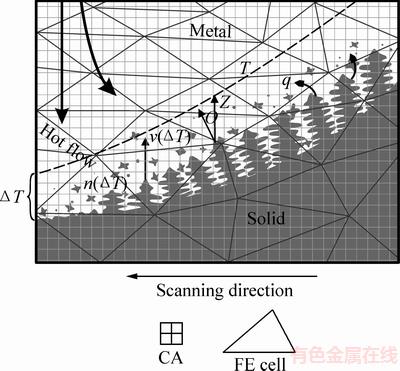

图3所示为电弧快速增材制造熔池中凝固过程的CA与FE耦合模型示意图,在CAFE模拟凝固过程中,有限元法(FE)计算凝固过程中的温度场变化,CA 法模拟计算微观上晶粒的形核与生长变化。元胞(CA)根据FE节点的温度来改变物质液固状态转变,在过冷度满足形核条件时,元胞开始形核,并且随着过冷度的增加,晶体开始生长。在生长过程中FE节点对移动热源、热传导及结晶潜热等重新计算,以更新FE节点的温度,使不同状态的元胞继续形核或长大[15]。

图3 Ti6Al4V丝材电弧增材制造快速凝固过程的CAFE耦合模型

Fig. 3 CAFE coupled model of rapid solidification process of wire+arc additive manufacturing Ti6Al4V alloy

3.1 晶体形核与生长模型

3.1.1 形核模型

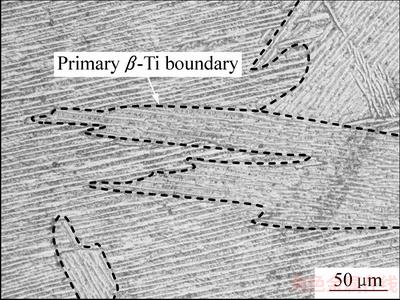

晶体形核采用RAPPAZ[5]提出的连续随机高斯分布形核模型,包括均匀形核和非均匀形核,CA模拟过程中假设均匀形核发生在熔体内,非均匀形核发生热交换面,计算时给熔体区域赋予体形核参数,热交换面赋予面形核参数。Ti6Al4V为两相钛合金,在丝材电弧增材制造过程中,合金从液态将直接转变为初生β晶核(见图4),模拟计算中用到的形核密度n与过冷度关系如下[5]:

(1)

(1)

式中:dn/d(ΔT)表示过冷度增加d(ΔT)时形核密度增加,连续随机高斯分布形核模型:

(2)

(2)

式中:ΔTmax是平均形核过冷度;ΔTσ是形核过冷度的标准方差;nmax是正态分布积分中最大的形核密度。

图4 Ti6Al4V丝材增材制造的室温显微组织

Fig. 4 Microstructure of wire+arc additive manufacturing Ti6Al4V alloy at room temperature

3.1.2 生长动力模型

生长动力模型采用KGT模型[16],前沿过冷度ΔT组成为

ΔT=ΔTc+ΔTt+ΔTr+ΔTk (3)

式中:ΔTc为溶质扩散过冷度;ΔTt为热力学过冷度;ΔTr为固液界面曲率过冷度;ΔTk为生长动力学过冷度。

KGT生长模型全面的考虑到了晶体生长包含的各种因素,包括尖端生长曲率、过冷度、溶质扩散等因素,经过计算简化的出晶体的生长速率v与过冷度的关系如下:

(4)

(4)

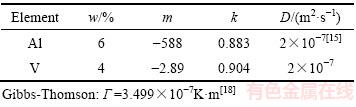

式中:a2、a3为生长动力学系数;由液相线斜率m、平衡分配系数k、固液前沿溶质扩散系数D和材料的Gibbs-Thomson系数求得。

3.2 三维热传导

热传导表示热量通过合金内部高温向低温的热量传递,如图2所示,在金属凝固过程中会有结晶潜热的释放,从而提高了局部的温度[17],在有限元(FE)法进行传热计算中,考虑到结晶潜热释放,快速凝固过程中计算三维的热微分方程式为

(5)

(5)

式中:T为热力学温度;λ为热导率;ρ为密度;cp为定压比热容,由不同温度下热焓计算;q为单位体积内单位时间所释放的热量。

(7)

(7)

式中:L为潜热,由固-液热焓之差计算; 为液-固转变率;fn为固相系数;t为时间。

为液-固转变率;fn为固相系数;t为时间。

4 模拟参数

模拟过程中参数设置:重力沿Z轴方向取值-9.8 m/s2,模拟材料使用Ti6Al4V材料的标准成分为6%Al、4%V及90%Ti,初始温度1750 ℃熔融堆积,初始铜基板温度为100 ℃,热对流系数3000 W/(m2·K)。Ti6Al4V丝材电弧增材制造过程形核参数见表1;生长动力学系数可利用ProCAST(2016)软件,根据式(4)并采用表2中的数据计算可得,计算的结果分别为a2=2.67431×10-6,a3=3.59481×10-7。

表1 Ti6Al4V丝材电弧增材制造的形核参数

Table 1 Nucleation parameters of wire+arc additive manufacturing Ti6Al4V alloy

表2 Ti6Al4V合金的生长动力因子计算参数

Table 2 Calculating parameters for growth kinetics factors of Ti6Al4V alloy

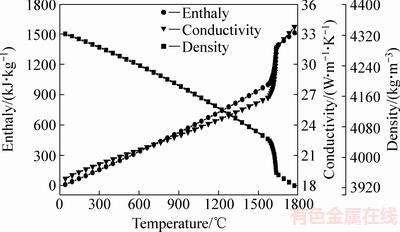

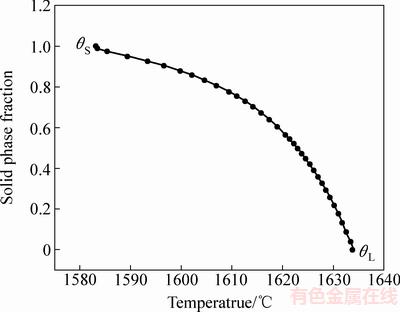

计算热传导所使用的材料物理参数:由ProCAST(2016)软件根据Ti6Al4V合金标准成分计算得到合金的固相线温度θS=1583 ℃,液相线温度θL=1633 ℃,合金材料热物理性能参数(热焓、热导率及密度)取值如图5,热焓和热导率随着温度升高而升高,密度随着温度升高而降低,钛合金由固态向液态转变时,材料热物理性能变化最快;凝固系数取值如图6所示,模拟计算时,当温度高于1633 ℃时合金全部为液态,随着温度降低,计算区域部分处于糊状区域,合金开始转变为固态,当温度低于1583 ℃时合金全部转变为固态。

图5 Ti6Al4V合金的热物理性能参数

Fig. 5 Physical properties of Ti6Al4V alloy

图6 Ti6Al4V合金凝固过程中所用的固相分数

Fig. 6 Solid phase fraction of Ti6Al4V alloy in solidification process

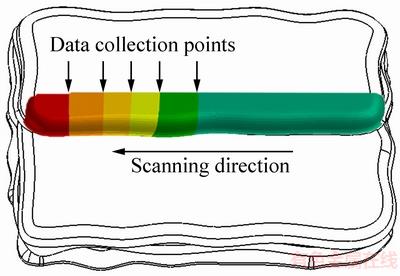

为了分析不同堆积层的水平温度梯度对初始β晶的影响,取扫掠后的温度梯度测量方法,以每层中间完整的一道次扫掠堆积边缘的熔池为0点,向扫掠反向进行温度数据收集,不同温度位置收集位置如图7所示。

图7 Ti6Al4V合金丝材电弧增材制造的水平温度梯度数据收集点

Fig. 7 Data collection points of temperature-gradient of wire+arc additive manufacturing Ti6Al4V alloy

5 模拟结果与讨论

5.1 不同堆积层的凝固过程模拟

实际增材制造是逐层进行凝固的,本工作中将首先简化模型,对不同阶(堆积层)的凝固过程的温度场及初始β晶形成进行模拟分析。

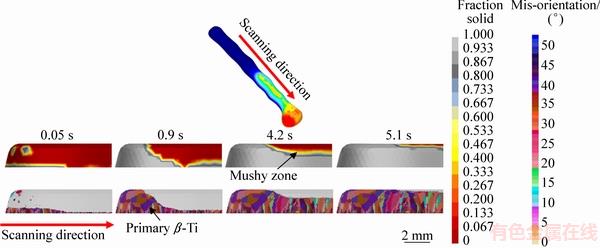

图8所示为首层第一道完成后的温度场分布示意图、起始阶段凝固变化和初始β晶生长情况,温度场主要沿着增材扫掠方向二维线性变化,温度由高 (1750 ℃)到低(100 ℃),凝固随着温度场移动变化而变化,初始出现固相的位置位于底部及边角少量部分,凝固随着由左至右的扫掠方向不断快速进行,可以看出固-液转变的糊状区域分布较窄,初始β晶快速生长为多而细小的晶体。在实际凝固过程中,晶体生长发生在糊状区域,即刚开始为液态,通过形核、竞争生长全部液体转变为固态合金。温度直接影响糊状区域大小,这是因为首层熔池堆积在铜冷基板上,受到约1700 K大的过冷度,糊状区减小,同时基板可作为异质形核核心,增加了晶体的形核率及固液转变速率。

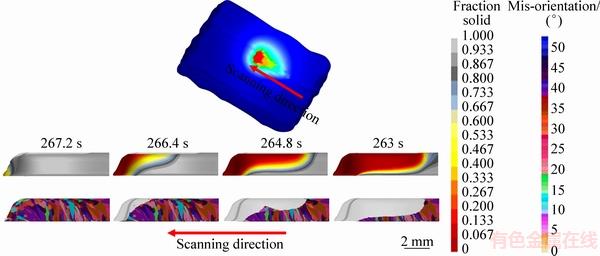

图9所示为稳定增材制造时的温度场分布示意图、稳定阶段的液固转变和此时初始β晶的形成模拟结果,以熔池方向为中心,由近及远向四周的温度不断降低,由右至左为扫掠方向,与初始阶段相比较,固液糊状区域变宽,初始β晶生长为较粗大的枝状晶。第二层以上将在钛合金表面继续堆积,钛合金的热传导率(18~34 W/(m·K))远低于铜基板(380 W/(m·K))的热传导率,电弧不断输入热量及释放凝固潜热,低的钛合金热传导率使得堆积熔池可以保持到一个较高的温度,获得较慢的凝固速度,降低了固液转变速率,糊状区增加,此时将抑制其他晶向的生长,而近似于择优方向的枝晶将更容易生长,择优方向生长的晶体将不断长大直到彼此接触,获得相对较大的晶体。

图8 Ti6Al4V合金在电弧增材制造初始阶段的温度梯度示意图、液固转变及初始β晶形核生长

Fig. 8 Temperature gradient schematic, liquid-solid transition and primary β-Ti nucleation-growth of wire+arc additive manufacturing Ti6Al4V alloy at first stage

图9 Ti6Al4V合金在电弧增材制造稳定阶段的温度梯度示意图、液固转变及初始β晶形核生长

Fig. 9 Temperature gradient schematic, liquid-solid transition and primary β-Ti nucleation-growth of wire+arc additive manufacturing Ti6Al4V alloy at stabilization stage

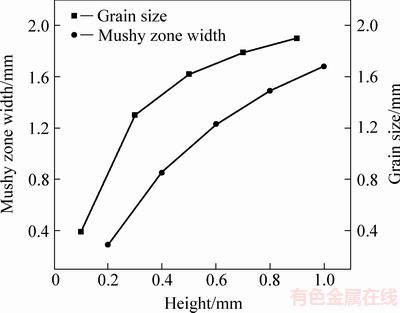

进一步全面分析堆积层高度的增加对初始β晶生长的影响,逐层进行温度场及晶体形核生长的模拟分析。图10所示为每层一次完整扫掠后的水平温度梯度图,可以看出堆积层数越高温度梯度越平缓,且首层温度梯度明显大于其他层;图11所示为增材高度与平均糊状区域及晶粒截面平均直径的关系,可以看出糊状区域及晶粒界面平均直径随着高度增加而不断增加。温度梯度平缓主要是因为钛合金热传导系数降低,而电弧不断在输入热量,散热主要是通过钛合金堆积层进入到基板,这就使得高度越高合金的水平温度梯度越平缓。温度梯度平缓直接使得熔池可以处于一个较高的温度,形成较小的过冷度,固液转变变缓慢,糊状区域增加,而沿Z轴正方向(<001>取向)的温度梯度相对其他方向的梯度较大,初始β晶生长沿<001>方向的晶体生长速度最大,首先达到了固液前沿,阻碍了其他取向晶体的生长,大部分择优取向生长的晶体不断长大直到相互接触变成全部固体。

图10 不同高度下丝材电弧增材制造Ti6Al4V合金的水平温度梯度

Fig. 10 Temperature-gradient of wire+arc additive manufacturing Ti6Al4V alloy at different heights

图11 不同高度下Ti6Al4V合金丝材电弧增材制造的平均糊状区宽度及平均晶粒尺寸关系曲线

Fig. 11 Relationship curves of average mushy zone width and grain size of wire+arc additive manufacturing Ti6Al4V alloy at different heights

5.2 整体重熔凝固过程的模拟

上述模拟仅是将每层分开来进行模拟分析,解释了电弧增材制造过程中堆积高度的变化对初始β晶大小的影响,而在实际过程中,在电弧扫掠过程中上表面已经凝固的合金会发生少量的重熔现象(见图12),将与新堆积的合金进行有效地冶金结合。

图13所示为考虑重熔进行全域模拟后的不同位置晶粒与实验结果对比,以及上下表面的晶粒<001>取向极图。由图13可以看出,模拟与实际增材制造的表面初始β晶情况基本相似。凝固开始时,首先在试样底部出现了一层细小且取向随机分布的等轴晶区,随着增材高度的增加,晶粒数目减少,晶粒尺寸增大。模拟结果显示底面首层的晶粒细小且取向各异,而顶部晶粒较为粗大且择优取向的晶体较多。这是因为首层具有较大的过冷度,冷基板可做为异质形核核心,因而在基板首层将大量形核,各个取向晶体都可以得到快速生长,邻近的生长晶粒彼此接触不再继续生长,形成细晶层。热流传递主要为垂直方向,因此上中部位则有较高的温度,钛合金的初始β枝晶以垂直方向择优方向继续生长。

图12 钛合金丝材电弧增材制造过程中重熔示意图

Fig. 12 Schematic diagram of titanium alloy remelting during wire+arc additive manufacturing

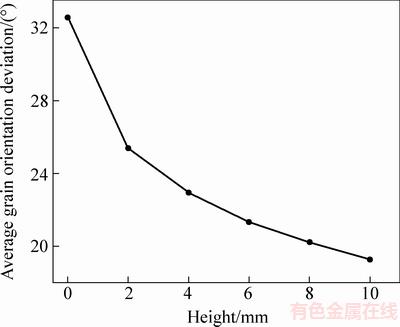

为了研究随着堆积高度增加晶体生长方向的变化,分别取2 mm高度界面上的平均晶体取向偏差值,图14是以<001>晶向为基准的不同截面平均晶体取向偏差与高度之间关系,可以看出随着高度的增加平均晶体取向偏差从混乱的较大值(32.56°)到较小值(19.283°),表明了晶体生长方向趋于相同;且首层与第二层的平均取向偏差值差异最大。在凝固过程中,首层主要与冷的铜基板传热,大的过冷度以及可利用的异质形核面使其晶体取向非常混乱。随着高度增加,水平温度梯度减缓,过冷度减小,在凝固前沿有利于择优方向的晶体生长,而其他取向的晶粒将会抑制发展,最终大部分凝固后的晶粒取向将向<001>晶向靠拢,这与上述对晶粒尺寸的分析结果相一致。

6 结论

1) 在丝材电弧增材制造的不同阶段,随着制造高度增加,水平方向凝固温度梯度不断变缓,平均固-液转变的糊状区宽度增加,其值由0.29 mm到1.68 mm,初始β晶平均晶粒尺寸增加,其值由0.39 mm到1.9 mm。

图13 Ti6Al4V合金丝材电弧增材制造中初始β-Ti的实际与模拟结果对照及上下表面的晶粒<001>取向极图

Fig. 13 Comparison of actual experiment and simulated results of primary β-Ti crystals of wire+arc additive manufacturing Ti6Al4V alloy, and polar diagrams of <001> grain orientation deviations

图14 不同堆积高度的截面平均晶体取向偏差

Fig. 14 Statistic of grain orientation deviation in different heights section

2) 通过CAFE方法模拟整体Ti6Al4V丝材电弧增材制造合金的凝固组织,显示其凝固过程,一开始初始β晶取向杂乱且晶粒尺寸细小,随着增材高度增加的增加,晶体取向趋于热流传递传递方向(Z轴正方向),不同截面上的平均晶体取向偏差值由32.56°到较小值19.283°;最终模拟结果出Ti6Al4V丝材电弧增材制造凝固后的形貌与实际实验增材制造后的初始β晶形貌相一致。

REFERENCES

[1] QIAN Ting-ting, LIU Dong, TIAN Xiang-jun, LIU Chang-meng, WANG Hua-ming. Microstructure of TA2/TA15 graded structural material by laser additive manufacturing process[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(9): 2729-2736.

[2] SZOST B A, TERZI S, MARTINA F, BOISSELIER D, PRYTULIAK A. A comparative study of additive manufacturing techniques: Residual stress and microstructural analysis of CLAD and WAAM printed Ti-6Al-4V components[J]. Materials & Design, 2016, 89: 559-567.

[3] 李涤尘, 贺健康, 田小永, 刘亚雄, 张安峰, 连 芩, 靳忠民, 卢秉恒. 增材制造: 实现宏微结构一体化制造[J]. 机械工程学报, 2013, 49(6): 129-135.

LI Di-chen, HE Jian-kang, TIAN Xiao-yong, LIU Ya-xiong, ZHANG An-feng, LIAN Qin, JIN Zhong-min, LU Bing-heng. Additive manufacturing: Integrated fabrication of macro/ microstructures[J]. Chinese Journal of Mechanical Engineering, 2013, 49(6): 129-135.

[4] ABE T, SASAHARA H. Dissimilar metal deposition with a stainless steel and nickel-based alloy using wire and arc-based additive manufacturing[J]. Precision Engineering, 2016, 45: 387-395.

[5] RAPPAZ M. Modeling of microstructure formation in solidification processes[J]. International Materials Reviews, 1989, 34(1): 93-124.

[6] GANDIN Ch-A, RAPPAZ M. A 3D cellular automaton algorithm for the prediction of dendritic grain growth[J]. Acta Materialia, 1997, 45(5): 2187-2195.

[7] GANDIN C A, DESBIOLLES J L, RAPPAZ M. A three-dimensional cellular automation-finite element model for the prediction of solidification grain structures[J]. Metallurgical and Materials Transactions A, 1999, 30(12): 3153-3165.

[8] 张 璞, 侯 华, 赵宇宏, 靳玉春, 赵宇辉, 睦怀明. 基于CAFE模型的镍基合金定向凝固过程显微组织模拟[J]. 中国有色金属学报, 2016, 26(4): 782-789.

ZHANG Pu, HOU Hua, ZHAO Yu-hong, Jin Yu-chun, ZHAO Yu-hui, MU Huai-ming. Microstructure simulation during directional solidification of nickel-based alloy based on CAFE model[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(4): 782-789.

[9] 张颖娟, 寇宏超, 李鹏飞, 钟 宏, 胡 锐, 李金山, 周 廉. 真空自耗电弧熔炼TC4铸锭的凝固组织和缩松缩孔的模拟[J]. 特种铸造及有色合金, 2012, 32(5): 31-34.

ZHANG Ying-juan, KOU Hong-chao, LI Peng-fei, ZHONG Hong, HU Yue, LI Jin-shan, ZHOU Lian. Simulation on solidification structure and shrinkage porosity(hole) in TC4 ingot during vacuum arc remelting process[J]. Special Casting & Nonferrous Alloys, 2012, 32(5): 31-34.

[10] 庞瑞朋, 王福明, 张国庆, 李长荣. 基于3D-CAFE法对430铁素体不锈钢凝固热参数的研究[J]. 金属学报, 2013, 49(10): 1234-1242.

PANG Rui-peng, WANG Fu-ming, ZHANG Guo-qing, LI Chang-rong. Study of solidification thermal parameters of 430 ferrite stainless steel based on 3D-CAFE method[J]. Acta Metallurgica Sinica, 2013, 49(10): 1234-1242.

[11] 仲红刚, 曹 欣, 陈湘茹, 张捷宇, 翟启杰. Al-Cu 合金水平单向凝固组织预测及实验观察[J]. 中国有色金属学报, 2013, 23(10): 2792-2799.

ZHONG Hong-gang, CAO Xin, CHEN Xiang-ru, ZHANG Jie-yu, ZHAI Qi-jie. Numerica and experimental investigation of solidification structure in horizontal directional solidification process of Al-Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(10): 2792-2799.

[12] 卜晓兵, 李落星, 张立强, 朱必武, 王水平. Al-Cu 合金凝固微观组织的三维模拟及优化[J]. 中国有色金属学报, 2011, 21(9): 2195-2201.

BU Xiao-bin, LI Luo-xin, ZHANG Li-qiang, ZHU Bi-wu, WANG Shu-ping. Three-dimensional numerical simulation and optimization of solidification structure of Al-Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(9): 2195-2201.

[13] SALUJA R S, NARAYANAN R G, DAS S. Cellular automata finite element (CAFE) model to predict the forming of friction stir welded blanks[J]. Computational Materials Science, 2012, 58: 87-100.

[14] DEZFOLI A R A, HWANG W S, AUGUSTO J, SHUKUR A K, TZENG S. Modeling of poly-crystalline silicon ingot crystallization during casting and theoretical suggestion for ingot quality improvement[J]. Materials Science in Semiconductor Processing, 2016, 53: 36-46.

[15] 付作鑫, 谢 明, 沈 月, 张吉明, 杨有才. CAFE法凝固组织数值模拟的应用研究进展[J]. 材料导报, 2012, 26(11): 154-158.

FU Zuo-xin, XIE Ming, SHEN Yue, ZHANG Ji-ming, YANG You-cai. Recent developments in numerical simulation of solidification using CA-FE method[J]. Materials Review, 2012, 26(11): 154-158.

[16] KURZ W, GIOVANOLA B, TRIVEDI R. Theory of microstructural development during rapid solidification[J]. Acta Metallurgica, 1986, 34(5): 823-830.

[17] 杨雪梅. 全域铸锭宏微观耦合的数值模拟研究[D]. 天津: 河北工业大学, 2015.

YANG Xue-mei. The numerical simulation research of the global ignot macro micro coupling[D]. Tianjin: Heibei University of Technology, 2015.

[18] CHASSAING G, POUGIS A, PJILIPPON S, LIPINSKI P, FAURE L, MERIAUX J, DEMMOU K, LEFEBVRE A. Experimental and numerical study of frictional heating during rapid interactions of a Ti6Al4V tribopair[J]. Wear, 2015, 342(15): 342-343.

Evolution of titanium alloy wire arc additive manufacturing solidification process based on CAFE simulation

LI Han-yan1, 2, CHEN Wen-ge1, ZHANG Fei-qi1, 2, GAO Hong-mei1, REN Shu-xin1

(1. School of Material Science and Engineering, Xi’an University of Technology, Xi’an 710048, China;

2. Shaanxi Tian Cheng Aerospace Co., LTD., Xianyang 712000, China)

Abstract: CAFE model was adopted to simulate the rapid solidification process of Ti6Al4V alloy wire arc additive manufacturing. Moreover, the influences of temperature field on solid-liquid transition as well as the initial I-Ti nucleation and growth in different manufacturing stages were analyzed by three-dimensional mode in different stages (deposition layer), grain nucleation and growth model and three-dimensional heat transferring (including latent heat release) model. The results show that β-Ti crystal has extremely disordered orientation and fine grain size in initial solidification stage (the first layer). Besides, with the increase of manufacturing sample height and the decrease of temperature gradient, both the average mushy zone width and average primary β-Ti grain size increase, and the crystal orientation tends to heat transfer direction (vertical cold-board direction). Final, the results of initial β-Ti crystal growth simulation basically conform to the actual additive manufacturing.

Key words: CAFE; alloy wire; arc; additive manufacturing; Ti6Al4V; crystal growth

Foundation item: Project(2017080CG/RC043) supported by the Plan for Supporting Science and Technology of Xi’an, China

Received date: 2017-08-24; Accepted date: 2018-01-24

Corresponding author: CHEN Wen-ge; Tel: +86-29-82312383; E-mail: wgchen001@263.net

(编辑 何学锋)

基金项目:西安市科技支撑项目(2017080CG/RC043)

收稿日期:2017-08-24;修订日期:2018-01-24

通信作者:陈文革,教授,博士;电话:029-82312383;E-mail:wgchen001@263.net