DOI: 10.11817/j.issn.1672-7207.2019.12.019

Q460高强钢材及T形对接接头力学性能研究

邢佶慧,陈前,王涛,杨娜

(北京交通大学 土木建筑工程学院,北京,100044)

摘要:为明确高强钢材焊接接头的脆变程度,针对Q460高强钢材及T形对接焊接接头进行试验和数值分析研究。分别从国产Q460钢板母材、热影响区和焊缝处取材,加工19个材性试件,进行单向拉伸试验;加工5个板厚及夹角不同的单面成形全熔透对接焊接T形接头,完成单向拉伸试验;对材性及接头试验结果进行精细化数值模拟,获取Q460钢材基本材性参数、断裂参数和应力-应变关系,分析T形接头试件的破坏模式、抗拉强度及断裂延性指标。研究结果表明:Q460高强钢母材强度符合我国钢结构设计标准要求,焊缝熔敷金属和热影响区塑性变形能力较母材略差。Q460钢T形焊接接头强度符合我国钢结构设计标准要求且有一定安全储备,破坏发生在母材中部,塑性变形能力取决于母材应力状态,基于VGM微观断裂预测理论,能有效预测T形接头断裂性能。

关键词:Q460高强钢;T形;全熔透对接接头;单向拉伸;强度;延性;断裂预测

中图分类号:TU392.4 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2019)12-3097-09

Performance of Q460 high strength steel and T-shape fully penetration butt weld joints

XING Jihui, CHEN Qian, WANG Tao, YANG Na

(School of Civil Engineering, Beijing Jiaotong University, Beijing 100044, China)

Abstract: In order to study the fragility tendency of the high strength steel welded joints, the behaviors of Q460 high strength steel and T shape butt weld connections were systemically tested and numerically simulated. 19 coupons from Chinese Q460 steel plate base metal, heat-affected zone and welding zone were tested under monotonic tensile loads. Five T-shape fully penetration butt weld joints fabricated from Q460 steel with different angles and plate thicknesses were tested under static tensile loads.Basic material parameters and fracture prediction model parameters were identified. The uniaxial stress-strain relationships of these steel materials were built. Additionally, failure mode, strength as well as fracture ductility of T-shape butt weld joints were obtained. The research results show that Q460 high-strength steel base metal strength can meet the strength requirement according to the specification for design of steel structures in China, and the plastic deformability of weld zone and heat-affected zone is slightly worse than that of base metal. The all weld joints can meet the strength requirement according to the specification for design of steel structures in China with enough safety reserve. Fracture initiates at the base metal. Therefore, the plastic deformation capacity of weld joints is determined by stress status in steel plates. The calibrated model parameters along with detailed FE analyses show that the VGM model can predict the failure behavior of T-shape butt weld joints effectively.

Key words: Q460 high strength steel; T-shape; fully penetration butt weld connection; monotonic tension; strength; ductility; fracture

高强钢的推广及应用是建筑科技发展的必然趋势。较普通钢而言,高强钢塑性变形能力差,且焊接技术难,焊接接头有脆变倾向。目前国外学者考虑了钢材母材、焊缝和热影响区研究钢材材性,对高强钢材焊接接头力学性能的研究既考虑了单调加载,又涉及超低周疲劳和冲击荷载。HUANG等[1]测试了SS400,SM490,HT590,HT780及改性的HT590和HT780平板和T形对接接头单拉及循环荷载下的性能;ZRILIC等[2]取自Nionikral 70钢对接头不同部位加工试件进行受弯静载和冲击破坏试验,观察其微观结构差异,获取其开裂敏感性和断裂韧性指标;GUNTHER等[3-4]对S460和S690钢角焊缝及部分熔透对接焊缝T形和十字形接头性能进行试验及数值模拟,考虑低温影响,测试了残余应力,评价了EN1993-1-10和Eurocode3相关规定;SEFCIKOVA等[5]对比了TMCP(热机械控制工艺技术)和淬火S960钢热影响区力学性能,考察了热影响区强度、延性、硬度和冲击强度的变化;JAVIDAN等[6]则探讨了高强钢、超高强钢的热影响区软化效应,考察了焊后钢材屈服强度和应变硬化率等宏观力学指标变化,对比了其微观结构的差异;BARSOUM[7]研究了多种钢材T形单边角焊缝和平板对接接头,发现T形单边角焊缝逐渐熔透为全熔透对接焊缝后,破坏发生在母材上。前人通过试验研究得出:1) 高强钢热影响区金属微观结构发生变化,存在软化现象;2) 焊接工艺如热输入能、冷却速率等对钢材材性影响显著。我国学者关注国产Q460系列钢材焊接接头性能,且开始基于细观损伤理论进行接头断裂模拟。黄东鎏[8]测试了Q460E钢材焊接及力学性能,发现热影响区既存在软化区又有硬化区;施刚等[9]对Q460C平板对接接头试件进行了单调和多种加载制度下的循环加载试验,探讨了不同加载制度的影响,发现接头延性较母材下降约50%;魏晨熙[10]完成4 个 Q460C平板对接接头和10 个正面、侧面角焊缝搭接接头的性能试验,分析了侧面角焊缝搭接接头的承载性能;马学周[11]研究了Q460高强平板对接、管-管对接以及管-板对接多层多道焊接残余应力分布特点,板-板对接焊缝区域的纵向残余拉应力峰值甚至超过母材屈服强度;蒋小华[12]数值模拟了Q460,Q690和Q960钢平板对接接头的残余应力分布,发现其残余应力分布特点类似,屈服强度高的钢材残余应力大;刘希月等[13]则对Q460C母材、焊缝金属及热影响区材料进行了单拉试验,标定微孔扩张模型 VGM和应力修正临界应变模型SMCS2种细观断裂模型参数;随后,施刚等[14]标定了2种Q460钢焊缝材料的VGM和SMCS断裂参数,预测了正面角焊缝的延性断裂。迄今为止,已有文献多研究国产Q460钢角焊缝或平板对接接头,但缺乏T形接头的数值模拟与断裂预测分析。本文在国产Q460钢母材、焊缝和热影响区材性试验基础上,采用单面成形全熔透对接焊接技术加工5个板厚、夹角不同的T形焊接接头,测试其单向拉伸特性,对比多国规范中接头强度的验算公式,观察接头的裂纹发展过程和断裂破坏形态,并基于微细观断裂理论模拟接头的断裂过程,为高强钢焊接节点的研究提供参考。

1 试验

1.1 试件设计

试验机加载能力有限,用于接头试件的板材不宜过厚,而加工焊缝材性试件,又需要板件有一定厚度,因此,采购了8 mm(Q460D)和14 mm(Q460C) 2种厚度规格钢板,薄板直接切割并加工成母材试件,厚度为14 mm的板除取材加工母材圆棒试件外,还切割成边长为400 mm的正方形,经电弧焊单面成形全熔透方法手工对接焊接,加工了焊缝和热影响区圆棒材性试件。

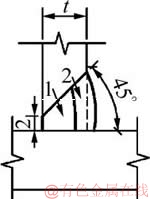

焊接时采用直径为3.2 mm的超低氢E60-15RH焊条。钢板母材及焊条化学成分如表1所示。焊前对钢板进行机械处理,焊后保温缓冷。焊缝为双层单道焊,如图1所示,焊接工艺参数如表2所示。

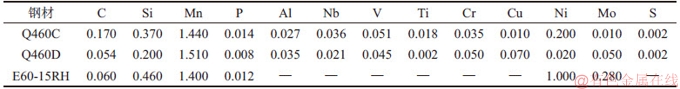

表1 钢板及焊条化学成分(质量分数)

Table 1 Chemical composition of the steels and weld material%

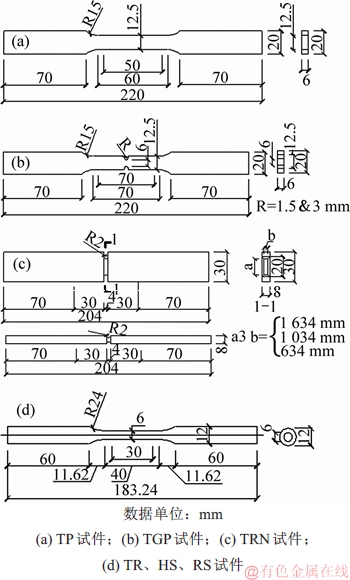

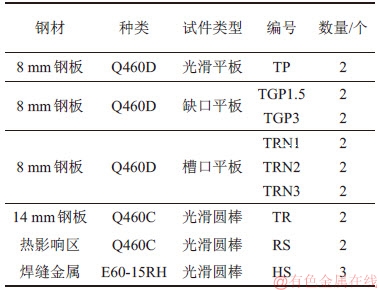

母材试件分为3类,即光滑试件TP、缺口试件TGP和槽口试件TRN,光滑试件用于获取基本材性参数,缺口试件和槽口试件则用于校正断裂参数。因断裂通常发生在母材,焊缝和热影响区仅需加工光滑试件HS和RS。全部试件几何尺寸如图2所示,光滑试件符合文献[15]中相关规定。每种类型试件加工2个,因离散性大焊缝处加工了3个试件,试件编号见表3。

图1 焊缝示意图

Fig. 1 Sketch of weld

表2 焊接工艺参数

Table 2 Welding parameters of coupons

图2 材性试件几何尺寸

Fig. 2 Geometric sizes of all coupons

1.2 试验方案

表3 试件类型及数量

Table 3 Type and number of all coupons

采用MTS 810电液伺服万能材料试验机在室温下完成全部试验。根据试件尺寸分别采用25 mm和50 mm标距MTS引伸计控制加载。按照文献[15]规定,弹性应变加载速率设置为0.015 min-1,屈服后应变速率为0.05 min-1。

1.3 试验结果

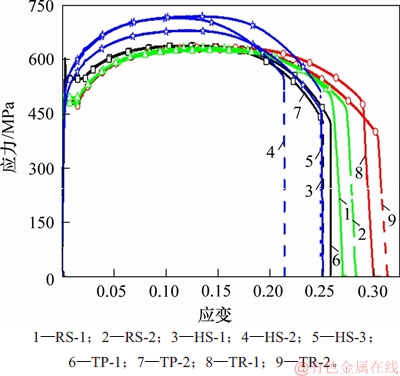

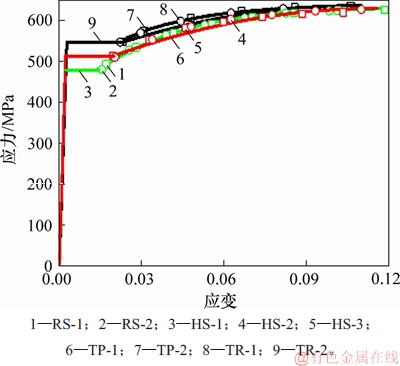

将光滑试件引伸计输出的应力-应变数据绘入图3,并根据图3得出Q460高强钢基本材性参数,见表4。

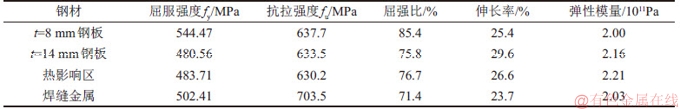

对比图3和表4中TP系列(t=8 mm钢板)和TR系列(t=14 mm钢板)结果可知:取材自不同Q460钢板产品的母材材性试件屈服强度fy差异较大,t=8 mm薄板fy=544.47 MPa,而t=14 mm钢板fy=480.56 MPa,但两者抗拉强度fu均约635 MPa,断裂时伸长率均超过25%,在25.1%~30.2%之间变化,屈服强度低的钢材伸长率更高。另外文献[16]规定,钢材的屈强比限值不应大于0.83。文献[17]规定,钢材的屈强比限值不应大于0.85,因而,TP系列试件仅勉强符合后者规定,而TR系列试件屈强比值更理想。

图3 Q460钢材应力-应变关系

Fig. 3 Relationships between stress and strain of Q460 steel

表4 材性基本参数

Table 4 Basic material parameters for Q460 steel

对比TR系列(t=14 mm钢板母材)和RS系列(t=14 mm钢板热影响区)结果可知:鉴于圆棒试件尺寸限制,所取“热影响区”钢材性能并未显著软化或硬化,尚有屈服平台,仅略微反映出热影响区的脆性特征。而对比TR系列和HS系列(焊缝熔敷金属)可发现:熔敷金属试件无明显屈服平台,强度高,曲线间离散较大,应力-应变曲线下降早,塑性变形能力较母材略差。

1.4 Q460高强钢单拉应力-应变关系的数学描述

采用文献[18]提出的本构模型SHCM(steel hysteretic constitutive model)描述有明显屈服平台的Q460钢材应力-应变关系。采用R-O(Ramberg-Osgood)曲线描述无明显屈服平台的焊缝金属应力-应变关系。

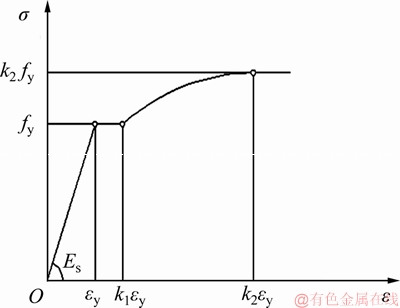

SHCM的单调加载曲线为四段式二次屈服模型,如图4所示。具体的数学表达为

(1)

(1)

式中:σ和ε为应力和应变;Es为钢材弹性模量;fy为屈服应力;εy 为屈服应变;参数k1,k2和k3用于控制单调加载曲线的形状。

表5所示为有明显屈服平台的Q460母材和热影响区钢材SHCM参数汇总。将SHCM模型描述的工程应力-应变曲线与试验曲线对比,如图5所示,可见SHCM曲线形式与选取的参数能够很好地描述Q460钢材的单向拉伸受力状态。

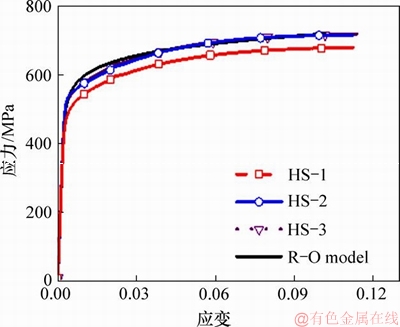

R-O曲线数学公式为

(2)

(2)

式中:ε0和σ0分别为屈服应变和屈服应力,σ0=Eε0;α和n分别为钢材的硬化系数和硬化指数。对焊缝熔敷金属的实验曲线进行拟合,取平均值后得α=0.34,n=14.15。所构建R-O曲线与试验曲线吻合较好,如图6所示。

1.5 Q460高强钢材VGM模型断裂参数

微孔扩张模型(void growth model,VGM)是当前应用最为广泛的微观断裂预测模型[13-14]。当满足以下情况时,金属发生延性断裂:

(3)

(3)

图4 SHCM单调加载应力-应变关系

Fig. 4 Relationship between stress and strain under sketch of monotonic SHCM

表5 Q460钢材SHCM参数汇总

Table 5 Material parameters of SHCM model for Q460 steel

图5 母材、热影响区金属加载曲线

Fig. 5 Loading curves of base metal and heat affected zone metal

式中:DVGM为孔洞成长损伤指数,可当作只与模拟结果有关的需求参数;T为应力三轴度,T=σm/σe,σm为平均应力,σe为von Mises等效应力; 为等效塑性应变;A为应力三轴度系数,需要依据材性试验结果校准;

为等效塑性应变;A为应力三轴度系数,需要依据材性试验结果校准; 为材料单调加载时的损伤极限承载能力,可理解为材料性质,亦需要校准。对结构钢来说,

为材料单调加载时的损伤极限承载能力,可理解为材料性质,亦需要校准。对结构钢来说, 在1.0~5.0变化。

在1.0~5.0变化。

图6 焊缝金属加载曲线

Fig. 6 Weld metal loading curve

图7 材性试件断裂预测结果

Fig. 7 Fracture prediction results for coupons in material tests

由缺口和槽口试件试验结果可拟合出 =1.929和A=1.024。图7所示为材性试件断裂预测结果。由图7可见:实点反映了VGM方法预测出的试件断裂时刻,与实测数据相比误差不超过4%,说明断裂参数的识别结果准确。

=1.929和A=1.024。图7所示为材性试件断裂预测结果。由图7可见:实点反映了VGM方法预测出的试件断裂时刻,与实测数据相比误差不超过4%,说明断裂参数的识别结果准确。

2 T形对接接头力学性能试验

2.1 试验方案

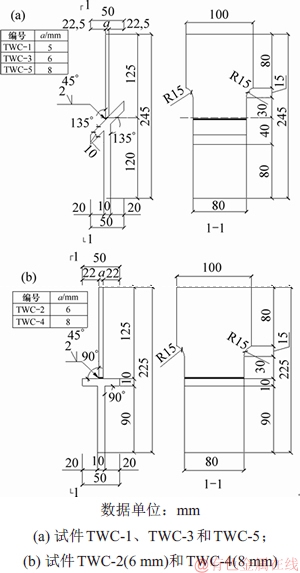

采用8 mm厚钢板分别加工成5,6和8 mm共3种不同厚度板件,与机加工的Q460钢底座经手工电弧焊单面成形全熔透焊接技术立焊成T形接头,焊材与材性试件的相同。焊接时设置引弧板,机械处理,焊后保温缓冷。考虑被连接板件间的夹角多样,底座上表面分别加工成与钢板夹角90°和135°共2种情况,对6 mm及8 mm厚板件夹角90°试件边缘开单边V型坡口。共加工5个接头试件,尺寸及编号如图8所示。因实验机空间有限且引伸计标距为50 mm,板件标准段高度仅为30 mm。

图8 T形对接接头试件几何尺寸

Fig. 8 Geometric sizes of T-shaped weld connection specimen

试验时加载速率与材性试件一致,用引伸计控制加载。

2.2 试验结果

2.2.1 接头强度

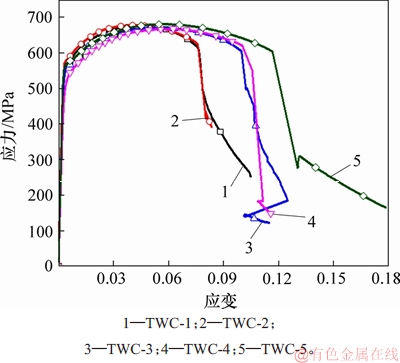

将引伸计输出的荷载-位移曲线按照钢板理想面积转换为“应力-应变”关系后如图9所示。对比图9和图3可见:接头试件的强度受板件厚度和夹角影响较小,所有接头屈服平台显著变短,屈服强度较母材和热影响区增加约16%,较焊缝增加约12%;极限抗拉强度较母材和热影响区增加约6%,较焊缝降低约5%。这样焊缝根部熔敷金属堆积截面放大有关,亦与板件应力状态有关。

图9 T形接头单向拉伸试验结果

Fig. 9 Uniaxial test results of T-shaped butt weld connections

文献[19]规定,t≤16 mm时Q460钢材的抗拉和抗压强度设计值f=410 MPa,抗拉强度最小值fu=550 MPa,一、二级对接焊缝 。在T形接头中,垂直于轴拉或轴压力的全熔透对接焊缝强度按下式验算:

。在T形接头中,垂直于轴拉或轴压力的全熔透对接焊缝强度按下式验算:

(4)

(4)

即

N (5)

(5)

式中:N为轴心拉力或轴心压力; 为焊缝长度;

为焊缝长度; 为对接焊缝的计算厚度。在T形接头中取腹板的厚度,当无法采用引弧板和引出板施焊时,每条焊缝的长度计算时应各减去2a(a为焊接的2个焊件中,较薄焊件的厚度);

为对接焊缝的计算厚度。在T形接头中取腹板的厚度,当无法采用引弧板和引出板施焊时,每条焊缝的长度计算时应各减去2a(a为焊接的2个焊件中,较薄焊件的厚度); 分别为对接焊缝的抗拉和压强度设计值。

分别为对接焊缝的抗拉和压强度设计值。

文献[20]规定,受拉或受压垂直于焊缝轴线的全熔透坡口焊接接头的承载力由母材强度控制。接头承载力设计值 由下式确定:

由下式确定:

(6)

(6)

式中: 为母材的强度设计值;

为母材的强度设计值; 为母材的横截面积;

为母材的横截面积; 为阻力系数,取0.75。

为阻力系数,取0.75。

文献[21]规定,全熔透坡口焊缝的承载力设计值应按被连接件中较弱的部分确定,公式如下:

(7)

(7)

式中:Nu为构件抗拉设计值;fu为抗拉强度;Anet为母材净截面面积;γM2为抗力分项系数,由每个国家自行确定,并列在国家附录里。欧洲规范给出γM2的推荐值为1.25,德国、法国、荷兰、奥地利、比利时、芬兰和捷克等国均选用了该推荐值,而文献[21]附录取值1.10。

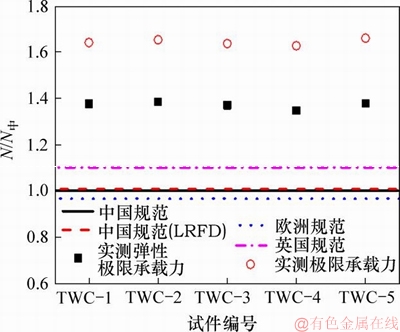

以我国规范设计值N中作为基准,将各国规范给出的设计值和实测结果进行对比结果如图10所示。由图10可见:接头试件实测弹性极限承载力高于各国规范设计值的要求,即便考虑抗力分项系数取值,亦有足够安全储备。相对而言,按照英国规范进行设计与实际情况最接近。

图10 接头强度与多国规范设计承载力的对比

Fig. 10 Comparison of the tested strength and design resistance of the connections according to multi-country specification

2.2.2 接头变形能力

由图9可见:所有接头试件延性均较母材、热影响区和焊缝显著降低,全部接头断裂“伸长率”低于11.7%,甚至低至7.6%。且对比TWC-1,TWC-3和TWC-5结果,薄板的焊接接头延性最差。钢板厚度t由5 mm增至6 mm,接头伸长率提高30.9%,再增至8 mm,90°和135°的接头伸长率可分别提高16.8%和32.5%。对比TWC-2和TWC-3,TWC-4和TWC-5,t=6 mm和t=8 mm时,板件夹角由90o变为135o,接头强度接极限承载力变化分别仅为-1.2%和1.8%,但伸长率却分别相差31.9%和16.3%,夹角为钝角的接头延性高。

2.2.3 断裂模式

全部接头试件均启裂在距焊趾2~3倍板厚(15 ~20 mm)范围内,即钢板标准段中部的母材中间。图11为接头试件裂纹开展过程,由图11可见:母材中部首先出现变薄趋势,而后逐渐形成裂纹,试件承载能力随之急剧下降,裂纹迅速向两侧延伸,到板件边缘区域裂纹斜向发展,直至贯通。这一现象与BARSOUM等[7]研究结果一致。

图11 接头试件裂纹开展过程

Fig. 11 Development of crack in weld connection specimen

3 接头性能数值模拟

3.1 有限元模型

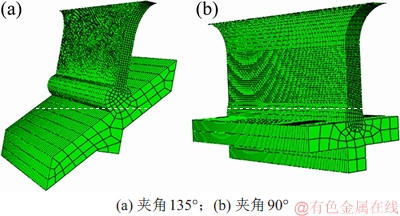

为深入剖析试验结果,了解试验过程中的钢材的应力和应变发展过程,在ABAQUS中建立接头试件夹具范围内的模型,单元类型为C3D8R,如图12所示。

因破坏发生在母材处,母材部位网格尺寸细化为0.2~0.3 mm,焊缝部分按照实际尺寸建模,热影响区按照1.5~2.0 mm范围考虑,粗化网格以提高计算效率。将图3中实测Q460D母材、焊缝和热影响区本构关系转化为钢材真实应力-塑性应变关系,定义模型材性参数。各个试件的底部边界固接,顶部施加板的轴向位移。

图12 接头试件有限元分析模型

Fig. 12 Finite element models of welded joint specimen

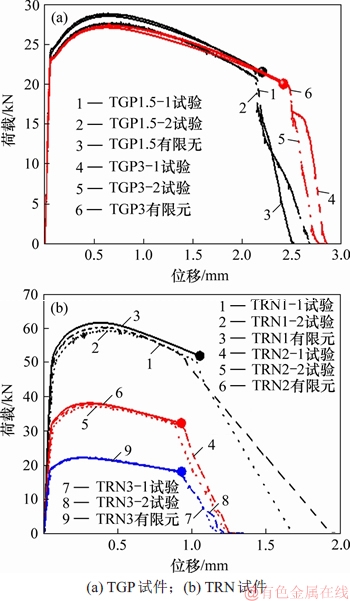

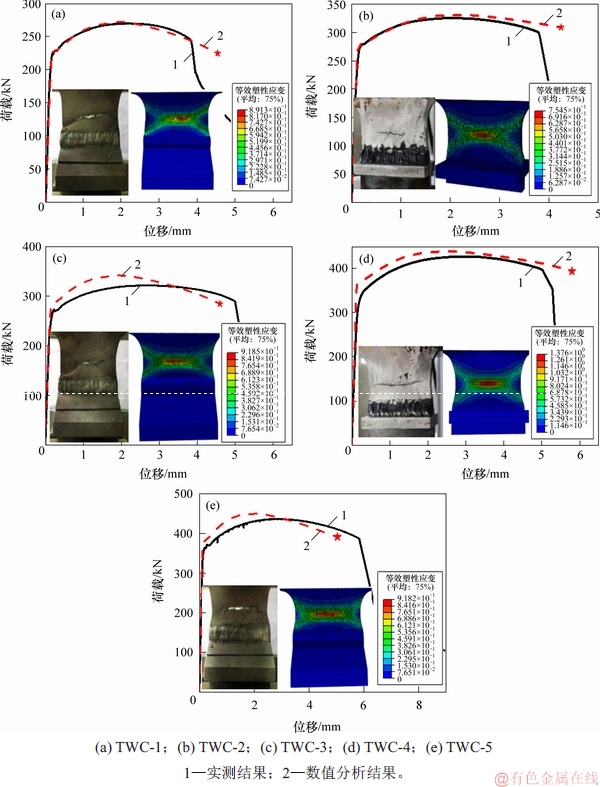

3.2 断裂分析结果

图13所示荷载数值模拟与实测结果的对比,图中星点表示VGM方法预测出的试件断裂时刻。由图13可见:数值模拟与试验结果吻合较好,但因焊缝处存在初始残余应力及几何不确定性,模拟数据与实测情况仍存在一定差异,断裂位移的预测误差为15%左右。

分析计算结果,发现试件应力和应变分布受边界效应影响较大。钢板受轴向拉力,因此,母材中部最先出现轴向塑性应变,但受上部夹具和底座约束,在标准段上、下两处外侧均有侧向变形约束,钢板中部的塑性变形延伸至两侧后呈燕尾状发展,直至试件断裂。由此可知:T形接头试件断裂发生在母材上,断裂延性取决于母材的应力状态,因而,随着钢板厚度的增加和夹角的变化,本文所设计接头试件的延性增加。

图13 荷载数值分析结果与实测结果的对比

Fig. 13 Comparison between simulated and tested results of loading

4 结论

1) Q460高强钢母材单向拉伸的延伸率超过25.1%,屈强比基本符合《建筑抗震设计规范GB 50011—2010》要求;焊缝熔敷金属和热影响区塑性变形能力较母材略差。

2) T形对接接头受拉试件的承载力符合现行《钢结构设计规范GB50017—2017》要求,且有一定安全储备。

3) T形对接接头受拉试件的破坏发生在母材处,延性取决于其应力状态。因焊接、边界约束等因素影响,本文所测试5个接头试件的应力-应变曲线基本无屈服平台,塑性变形能力较材性试件降低,断裂伸长率为7.6%~11.7%。

4) 基于VGM微观断裂预测方法对Q460高强钢焊接接头进行断裂预测结果较为准确。

参考文献:

[1] HUANG Y H, ONISHI Y, HAYASHI K. Inelastic behavior of high strength steels with weld connections under cyclic gradient stress[C]// Proc 11th Wold Conference on Earthquake Engineering (WCEE). Acapulco, Mexico, 1996: 385-390.

[2] ZRILIC M, GRABULOV V, BURZIC Z, et al. Static and impact crack properties of a high-strength steel welded joint[J]. International Journal of Pressure Vessels and Piping, 2007, 84(3): 139-150.

[3] GUNTHER H P, HILDEBRAND J, RASCHE C, et al. Welded connections of high-strength steels for the building industry[J]. Welding in the World, 2012, 56(5/6): 86-106.

[4] KUHLMANN U, GUNTHER H P, RASCHE C. High-strength steel fillet welded connections[J]. Steel Construction, 2008,1(1): 77-84.

[5] SEFCIKOVA K, BRTNIK T, DOLEJS J, et al. Mechanical properties of heat affected zone of high strength steels[J]. IOP Conference Series: Materials Science and Engineering, 2015, 96: 012053.

[6] JAVIDAN F, HEIDARPOUR A, ZHAOXiaoling, et al. Effect of weld on the mechanical properties of high strength and ultra-high strength steel tubes in fabricated hybrid sections[J]. Engineering structures,2016,118: 16-27.

[7] BARSOUM Z, KHURSHID M.Ultimate strength capacity of welded joints in high strength steels[J]. Procedia Structural Integrity, 2017, 5: 1401-1408.

[8] 黄东鎏. Q460E焊接性能分析及匹配焊材研究[D]. 西安: 西安理工大学材料科学与工程学院, 2008: 2-10.

HUANG Dongliu.Welding analysis and research on matching welding materials for Q460E steel[D]. Xi’an: Xi’an University ofTechnology.School of Materials Science and Engineering, 2008: 2-10.

[9] 施刚, 王飞, 戴国欣, 等. Q460C高强度钢材焊缝连接循环加载试验研究[J]. 建筑结构学报, 2012, 33(3): 15-21.

SHI Gang, WANG Fei, DAI Guoxin,et al.Cyclic loading test on welded connection of high strength steel Q460C[J]. Journal of Building Structures, 2012, 33(3): 15-21.

[10] 魏晨熙. Q460高强度钢材焊缝连接受力性能和计算模型研究[D]. 北京: 清华大学土木水利学院, 2013: 1-6.

WEI Chenxi. Research on the structural performance and calculation model of Q460 high strength steel weld connection[D]. Beijing: Tsinghua Univesity.School of Civil Engineering, 2013: 1-6.

[11] 马学周. Q460高强钢多层多道焊残余应力数值计算[D]. 镇江: 江苏科技大学材料科学与工程学院, 2014: 1-7.

MA Xuezhou. Numerical analysis of residual stress in multi-pass welding of Q460 high strength steel[D]. Zhenjiang: Jiangsu University of Science and Technology.School of Materials Science and Engineering, 2014: 1-7.

[12] 蒋小华. 建筑钢结构中典型焊接接头残余应力的数值模拟[D]. 重庆: 重庆大学材料科学与工程学院, 2016: 1-8.

JIANG Xiaohua. Numerical simulation of typical welded joints’ residual stress in construction steel structure[D]. Chongqing:Chongqing University.School of Materials Science and Engineering, 2016: 1-8.

[13] 刘希月, 王元清, 石永久. 基于微观机理的高强度钢材及其焊缝断裂预测模型研究[J]. 建筑结构学报, 2016, 37(6): 228-235.

LIU Xiyue, WANG Yuanqing, SHI Yongjiu. Micromechanical fracture prediction model of high strength steel and its weld[J]. Journal of Building Structures, 2016, 37(6): 228-235.

[14] 施刚, 陈玉峰. 基于微观机理的Q460钢材角焊缝搭接接头延性断裂研究[J]. 工程力学, 2017,34(4): 13-21.

SHI Gang, CHEN Yufeng. Investigation on the ductile fracture behavior of Q460 steel fillet welded joints based on micro-mechanics[J]. Engineering Mechanics, 2017, 34(4): 13-21.

[15] ASTM E8/E8M-16a. Standard test methods for tension testing of metallic materials [S].

[16] GB/T 19879—2015.建筑结构用钢板[S].

GB/T 19879—2015.Steel plates for building structure[S].

[17] GB 50011—2010.建筑抗震设计规范[S].

GB 50011—2010.Code for seismic design of buildings[S].

[18] 王萌. 强烈地震作用下钢框架的损伤退化行为[D]. 北京: 清华大学土木水利学院, 2013: 10-33.

WANG Meng.Damage and degradation behaviors of steel frames under severe earthquake[D]. Beijing: Tsinghua Univesity.School of Civil Engineering, 2013: 10-33.

[19] GB 50017—2017. 钢结构设计标准[S].

GB 50017—2017. Code for design of steel structure[S].

[20] American Institute of Steel Construction. ANSI/AISC 360-16. Specification for structural steel buildings (Chicago) [S].

[21] EN 1993-1-8. Eurocode 3 design of steel structures - part 1-8: design of joints[S].

[22] BS EN 1993-1-1. Eurocode 3 Design of steel structures-part 1-1, general rules and rules for buildings[S].

(编辑 秦明阳)

收稿日期: 2019 -02 -11; 修回日期: 2019 -04 -20

基金项目(Foundation item):中央高校基本科研业务费项目(2016JBM041);国家自然科学基金面上资助项目(51578045) (Project(2016JBM041) supported by the Fundamental Research Funds for the Central Universities; Project(51578045)supported by the National Natural Science Foundation of China)

通信作者:邢佶慧,教授,从事钢结构与空间结构研究;E-mail:jhxing@bjtu.edu.cn