Numerical simulation analysis on multi-layer low-temperature heating method of asphalt pavement in hot in-place recycling

来源期刊:中南大学学报(英文版)2020年第12期

论文作者:马登成 兰芬

文章页码:3793 - 3806

Key words:asphalt pavement; hot in-place recycling; heating speed; heating uniformity; multi-layer; low-temperature

Abstract: Asphalt mixture pavement reheating is one of the important steps in hot in-place recycling (HIR). To improve the heating speed of asphalt pavement in HIR, based on the numerical analysis model of asphalt mixture heating process, a new multi-layer low-temperature heating method (MLHM) was proposed. Considering input heat flux, the thermal capacity and thermal resistance of asphalt mixture, the heat transfer model was established based on energy conservation law. By heating the asphalt mixture in layers, it changes the situation that the heat energy can only be input from the upper surface of the asphalt mixture pavement. Through the simulation of the heating method of asphalt mixture in the existing technology, the result shows that the existing heating methods lead to serious aging or charring of the asphalt mixture. By MLHM, the upper and the bottom of the asphalt mixture are heated at the same time, and the heating temperature is lower than other heat methods, which not only reduces the heating thickness and increases the heating area of the asphalt mixture pavement, but also improves the heating speed, saves the energy resource and ensures the heating quality. Especially, by MLHM, the heating uniformity is better and speed is faster.

Cite this article as: MA Deng-cheng, LAN Fen. Numerical simulation analysis on multi-layer low-temperature heating method of asphalt pavement in hot in-place recycling [J]. Journal of Central South University, 2020, 27(12): 3793-3806. DOI: https://doi.org/10.1007/s11771-020-4577-6.

J. Cent. South Univ. (2020) 27: 3793-3806

DOI: https://doi.org/10.1007/s11771-020-4577-6

MA Deng-cheng(马登成)1, LAN Fen(兰芬)2

1. National Engineering Laboratory for Road Maintenance Equipment, Chang’an University, Xi’an 710064, China;

2. Xi’an Municipal Facilities Management Center, Xi’an 710016, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Abstract: Asphalt mixture pavement reheating is one of the important steps in hot in-place recycling (HIR). To improve the heating speed of asphalt pavement in HIR, based on the numerical analysis model of asphalt mixture heating process, a new multi-layer low-temperature heating method (MLHM) was proposed. Considering input heat flux, the thermal capacity and thermal resistance of asphalt mixture, the heat transfer model was established based on energy conservation law. By heating the asphalt mixture in layers, it changes the situation that the heat energy can only be input from the upper surface of the asphalt mixture pavement. Through the simulation of the heating method of asphalt mixture in the existing technology, the result shows that the existing heating methods lead to serious aging or charring of the asphalt mixture. By MLHM, the upper and the bottom of the asphalt mixture are heated at the same time, and the heating temperature is lower than other heat methods, which not only reduces the heating thickness and increases the heating area of the asphalt mixture pavement, but also improves the heating speed, saves the energy resource and ensures the heating quality. Especially, by MLHM, the heating uniformity is better and speed is faster.

Key words: asphalt pavement; hot in-place recycling; heating speed; heating uniformity; multi-layer; low-temperature

Cite this article as: MA Deng-cheng, LAN Fen. Numerical simulation analysis on multi-layer low-temperature heating method of asphalt pavement in hot in-place recycling [J]. Journal of Central South University, 2020, 27(12): 3793-3806. DOI: https://doi.org/10.1007/s11771-020-4577-6.

1 Introduction

Currently, asphalt pavement maintenance and rehabilitation are getting more and more attention [1]. To save materials and protect the environment, asphalt recycling is very important [2]. The hot in-place recycling (HIR) can fully recover asphalt pavement materials, which is considered to be one of the most economical and environmentally recycling methods [3-6].

During the HIR, heating procedure is closely related to the quality of recycled asphalt pavement. To avoid aggregate degradation, the asphalt is melt and its viscosity is reduced before complete scarifying and/or milling process [7, 8]. However, the quick heating of asphalt pavement is still a difficult problem in the HIR. Therefore, the heating of asphalt pavement has become the research focus. The researches [4, 9] show that to ensure the quality of asphalt pavement regeneration, at the end of the heating process, the bottom temperature of the asphalt pavement should be more than 100 °C, and the surface temperature of asphalt pavement should be less than 180 °C. Therefore, to achieve the result is very important. To achieve the result, a lot of studies have been reported on energy source types in HIR. However, it has been proven that only choosing different energy sources types can not solve the heating difficult problem of HIR [10-17]. Therefore, more and more researchers are focusing on the heating methods of asphalt pavement. HUANG et al [18] put forward a one-way continuous heating method, but it is difficult to heat the interior of the pavement with unidirectional continuous heating method. GU et al [19] proposed a multi-stage heating method, compared with single-step heating method, which can save 60% of time and 30% of energy consumption, but requires more heating equipment and increases construction costs. The relationship between heating characteristics and heat input in the HIR process is studied, and a control method to maintain this relationship is proposed; however, the heating power control is too complex [20]. A constant temperature heating method (CTHM) is proposed, by adjusting the input heat flux to ensure that the surface temperature of asphalt pavement is always kept at 180 °C, but it is difficult to adjust the input heat flux and its heating speed is not fast enough [21]. Also, some researchers reported that a reciprocating intermittent heating method (RIHM) can achieve better heating effect [9, 22]. However, the heating effect of excessively aged upper pavement layer is not fully satisfactory by existing heating methods. Furthermore, the heating speed is still not fast enough. Besides, many simulation methods have been used to simulate and calculate the heating temperature field of asphalt pavement, such as the Laplace transform and inverse Laplace transform [23], the discrete element method (DEM) [9], the separation of variables and Duhamel’s principle [24], the finite control volume method [25], the finite element model in software FEMMASSE, COMSOL, ABAQUS and MATLAB [26-29]. The above researches mainly focuse on the heating of asphalt pavement before being scarified and/or milled in HIR, but neglect the influence of reheating of asphalt mixture pavement after being scarified and/or milled in HIR.

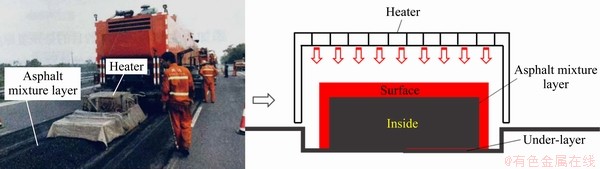

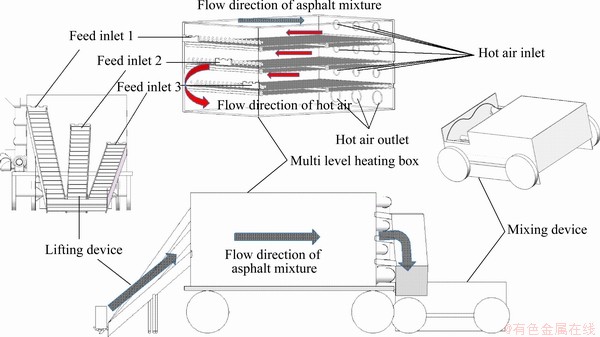

During the HIR, the surface temperature of preheated asphalt pavement can reach 553 K (180 °C), while the bottom layer temperature is still around 363 K (90 °C). Because the asphalt pavement temperature is required to be above 393 K (120 °C) in the subsequent paving process, the heated and milled asphalt pavement materials need to be reheated during construction to ensure the pavement regeneration quality. However, the asphalt pavement is difficult to be heated; to achieve the construction temperature in HIR, it is necessary to reheat the asphalt mixture. Usually, a heater is installed at the bottom of the mixer, and the heat flux output from the heater can only input to the upper surface of the asphalt mixture pavement, as shown in Figure 1. Because the asphalt mixture layer after the distribution is too thick, the existing reheating process only makes the temperature of the upper layer of the asphalt mixture rise, but the temperature of the internal asphalt mixture doesn’t increase significantly and the temperature gradient is large. Also, the existing construction speed of HIR is about 1.5 m/min to 3 m/min, so the heating time is too short [30, 31].

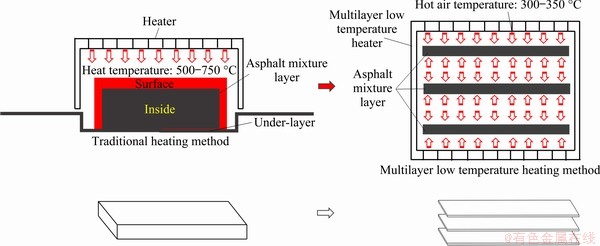

To satisfy the construction speed and temperature, either increasing the temperature of the asphalt pavement before being milled, or increasing reheating speed of the asphalt mixture layer after being milled, mostly by increasing the temperature of the heat source, which easily led to uneven heating of asphalt pavement and severe aging or charring of surface asphalt binder, it is necessary to study a new method to deal with the reheating procedure of asphalt pavement. Based on the existing research status and technology of asphalt pavement during HIR, starting from changing the form of heat input from the surface of asphalt mixture layer and reducing the thickness of heat transfer inside the pavement, a new multi-layer low-temperature heating method (MLHM) is proposed, and a multi-layer heating device with hot air circulation is designed, which is applied to the reheating process during HIR. After the asphalt mixture is milled, lifted and layered, MLHM is carried out to realize the rapid and uniform heating of the asphalt mixture layer, as shown in Figure 2. Through establishing a new heat transfer model based on energy conservation law to analyze the temperature field distribution, the temperature field distributions with various heating methods were discussed using the new heat transfer model to simulate the heating process during the HIR. Through comparative analyses by MLHM, the upper and bottom of the asphalt mixture are heated at the same time by heating the asphalt mixture in layers, which reduces the heating thickness of the asphalt mixture pavement and increases the heating area. This new heating method changes the situation that the heat energy can only be input from the upper surface of the asphalt mixture pavement in the existing heating mode. Compared with the existing heating methods, the heating temperature by MLHM is not more than 300 °C, while the heating temperature of other heating methods is mostly 550-750 °C, or even more than 1000 °C. Therefore, without adjusting the input heat flux and/or heating power, the surface temperature of asphalt pavement is always kept at 180 °C. The asphalt aging is avoided and the heating quality is guaranteed. Especially, the heating uniformity and speed by MLHM is better and faster compared with other heat methods.

Figure 1 Traditional heating method

Figure 2 Multi-layer low-temperature heating method

In this study, through computer simulation, the heating parameters are optimized to meet the requirements of reheating, and the heating quality and uniformity are analyzed. Compared with the existing heating methods during HIR, MLHM has quicker heating speed and a smaller temperature gradient.

2 Heat transfer model and heating mechanism of MLHM

2.1 Heat transfer model

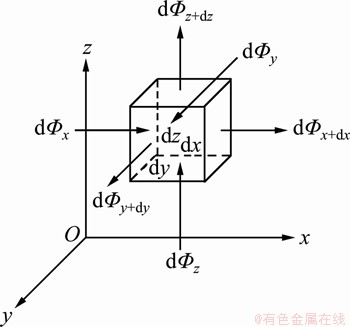

In many studies, asphalt is considered to be a hot isotropic material, and it was discretized into limited micro-storage and heat pipes during the simulation [21-27]. Through the conduction analysis of the infinitesimal unit cube (MUC), the heat passing through the MUC is decomposed in three directions, as shown in Figure 3.

Heat exchange can happen at every surface of MUC, and there is no heat source in the asphalt pavement. According to Fourier law, the heat flow input of MUC can be described as follows:

(1)

(1)

where fxyz is the heat input to a MUC; fx, fy, fz are the heat input to a MUC in x-, y-, z-direction, respectively.

Figure 3 Heat passing through infinitesimal unit cube

The heat flow out of the MUC can be described as follows:

(2)

(2)

where fxyz-dxdydz is the heat output from a the MUC; fx+dx, fy+dy, fz+dz are the heat output from a MUC in x, y, z directions, respectively.

The thermal energy input of the MUC can be divided into two parts. One is the heat absorbed by the MUC, and the other is the heat output from the MUC. The heat absorbed by the MUC is used to raise the temperature of the MUC, and the heat output from the MUC is used to heat the subsequent MUC. According to the law of energy saving, in the heating process of asphalt pavement, the thermal equation can be described as follows:

(3)

(3)

where fdxdydz is the heat absorbed by the MUC, and it can be described as follows:

(4)

(4)

Heat absorbed by the MUC in unsteady state can be described as follows:

(5)

(5)

where ρ is density of MUC; c is specific heat capacity; T is temperature; t is time; x, y and z are rectangular coordinates.

For a special asphalt pavement material, its thermal parameters are constant. Only the value of input heat flux affects the heating procedure, which is reflected in the change of temperature field. In the heating process, the heat energy is transferred from the surface layer to the next layer. Therefore, according to the laying material and thickness, the heat transfer model of MUC is set as shown in Figure 4.

Figure 4 Heat transfer model of MUC

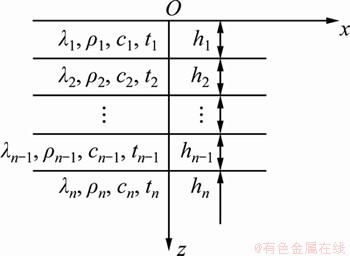

In HIR, the heat energy is mainly transferred by the large flat wall on the asphalt pavement. For any micro-unit of asphalt mixture, its temperature changes continuously with the change of heating time, so the temperature function T (x, y, z, t) of asphalt pavement is not only related to the space location, but also related to the change of time. Therefore, the temperature field of asphalt pavement can be described as follows:

(6)

(6)

In Eq.(6), g0=h1, ρ1, ρ2, …, ρn are the density of different asphalt pavement layers; c1, c2, …, cn are specific heat capacity of different asphalt pavement layers; T1, T2, …, Tn are the temperature of different asphalt pavement layers.

ρ1, ρ2, …, ρn are the density of different asphalt pavement layers; c1, c2, …, cn are specific heat capacity of different asphalt pavement layers; T1, T2, …, Tn are the temperature of different asphalt pavement layers.

2.2 Multi-layer low-temperature heating mechanism

According to Eq. (6), the main factors that affect the rate of energy transfer in the heating process of asphalt mixture pavement layer are as follows: the thickness of asphalt mixture pavement layer, the thermal conductivity of asphalt mixture materials, specific heat capacity, density and the heat flow density from the asphalt mixture pavement layer surface. Also, there are fluid temperature (i.e., ambient temperature) and fluid velocity (i.e., hot air speed) involved in the boundary conditions. Thermal conductivity, specific heat capacity and density are the thermal physical parameters of asphalt mixture, which cannot be changed. Similarly, the hot air speed and ambient temperature in the external environment are not controllable. Normally, by increasing the heat flow density, the heating rate of the asphalt mixture pavement can be improved. But if the heat flow density is continuously increased, the power loss would be increased, and the aging of the asphalt mixture would be intensified [30]. Therefore, it is necessary to decrease the heating thickness of asphalt pavement to improve the heating rate of asphalt pavement. Because the thermal conductivity of asphalt mixture is poor, the time that heat energy is transferred from the surface to the interior of asphalt mixture pavement is too long. Therefore, the thickness of the asphalt mixture layer is one of the important factors that affect its heating rate.

Based on the above analysis, in this study, the multi-layer low-temperature heating mechanism is: by reducing the heating thickness of the asphalt mixture layer, the heat transfer speed in the asphalt mixture can be accelerated, and the heating speed can be increased in a short time without increasing the power. The multi-layer heating device is designed with three layers to distribute the asphalt mixture layer and use the hot air for reheating. It changes the original heating mode that the asphalt mixture layer can only receive heat through the top surface, and then transfer heat to the structure interior. This heating method changes the heat transfer of the single surface layer into the heat transfer of the top and bottom surfaces of the three layers of asphalt mixture pavement at the same time, so the heating thickness becomes 1/3 of the original thickness and the heating area increases six times that of the original area. Therefore, in this way, the heating speed of the inner of the asphalt mixture layer can be greatly improved, and the heating speed of the whole asphalt mixture layer can be increased in a short time. Also, the hot air recycling and its temperature is not more than 300 °C, it can ensure the uniformity and quality of heating, avoid the aging of asphalt, and improve the availability of heat energy, achieving the “green, non-pollution and quick” maintenance requirements.

3 Heating device and discussions

3.1 Structural design and optimization of multi- layer heating device

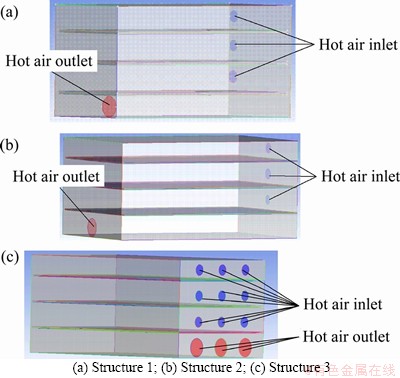

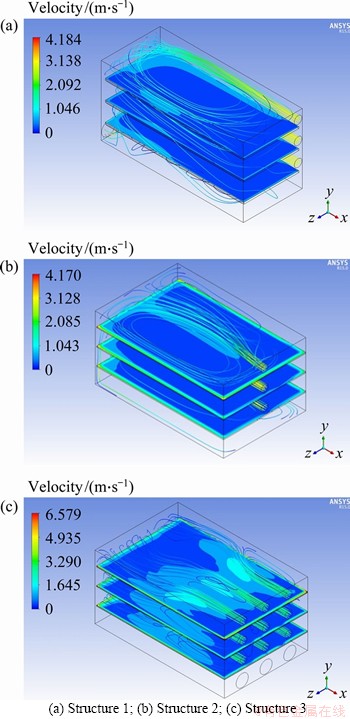

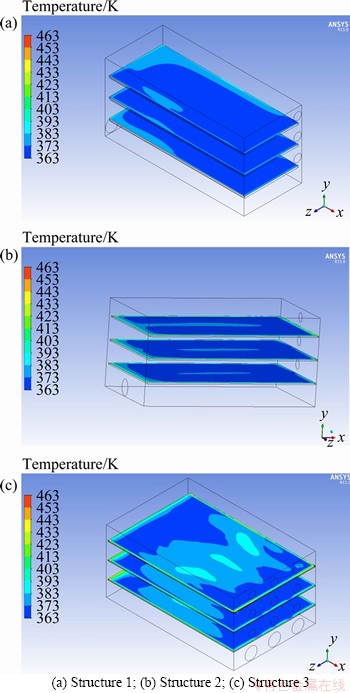

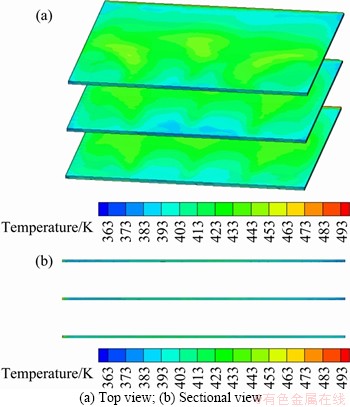

To increase the contact time between hot air and asphalt mixture layer to improve thermal efficiency, making the asphalt mixture layer and hot air convectively heat, three typical hot air heating device structures are designed, as shown in Figure 5. Figure 6 and Figure 7 show the hot air traces and temperature fields corresponding to each structure in Figure 3. In the simulation, in order to facilitate the flow of hot air, the design principle of the total area of hot air inlet and outlet is to ensure that the total areas of the air inlet and outlet are equal.

Figure 5 Multi-layer low-temperature device structure:

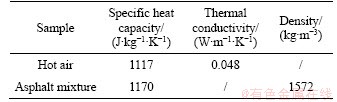

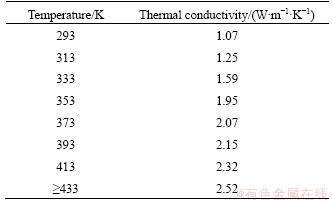

Because the thermal physical parameters of the hot air and the thermal conductivity of the asphalt mixture change with temperature, the thermal physical parameters of the hot air and the thermal conductivity of the asphalt mixture are selected. Linear interpolation has been used to obtain more accurate simulation results by LI et al [13]. The thermal physical parameters of materials are shown in Table 1, which are referenced to the parameters by HUANG et al [9] and ZHANG et al [22]. The thermal conductivity of the asphalt mixture is set according to Table 2, which is referenced to the parameters by XU et al [21] and XUE et al [32]. According to the construction speed in HIR, the heating time is 120 s, the hot air speed is 3 m/s, hot air temperature is 573 K (300 °C), and the initial temperature of the asphalt mixture is 363 K (90 °C).

Table 1 Thermal physical parameters of material

Table 2 Thermal conductivity of asphalt mixture at different temperatures

As shown in Figure 5(a), the hot air inlets and outlets are arranged diagonally, three hot air inlets are uniformly distributed on the three layers of asphalt mixture pavement layer, and the air outlet is arranged at the bottom of the heating device. As shown in Figure 5(b), the hot air inlets are arranged in the middle of the heating device, and the air outlet is arranged on the opposite side of the hot air inlet. To extend the flow path of the hot air in heating device, promote the heat exchange and improve the heating speed, each layer of the heating device is evenly designed with three hot air inlets, and the air outlets are arranged on the same side of the air inlets and at the bottom of the heating device, as shown in Figure 5(c).

The hot air traces inside the heating device with three structures are shown in Figure 6. The temperature fields of the asphalt mixture pavement inside the heating device of three structures are shown in Figure 7.

As shown from Figure 6(a), because the air inlets and air outlet are arranged diagonally, in the heating device, the hot air on one side of the air inlets is more than that on the other side of the air outlet. As shown in Figure 7(a), the temperature of the asphalt mixture pavement layer near the air inlets is significantly higher than that on the other side of the air outlets. The difference in temperature of the asphalt mixture pavement layer is up to 20 K, and the heating is nonuniform. After heating for 120 s, the temperature in the middle of the asphalt mixture pavement layer is the initial temperature 363 K, which indicates that the internal part of the asphalt mixture pavement is not heated, and the overall heating effect of the asphalt mixture pavement is too poor.

Figure 6 Hot air traces inside heating device:

As seen from Figure 6(b), the hot air inlets are arranged in the middle, and the hot air traces are distributed from the middle to both sides. As seen from Figure 6(c), the uniform distribution of hot air on the same layer reduces the difference in temperature of asphalt mixture on the same layer and improves the temperature uniformity. At the same time, the average temperature of the surface of three layers of asphalt mixture is 370 K, and the temperature in the middle of the asphalt mixture pavement is 365 K.

Figure 7 Temperature field of each asphalt mixture pavement:

As shown in Figure 5(c), three hot air outlets are uniformly arranged in each layer that makes the hot air distribution in each layer more uniform. Corresponding to Figure 6(c) about temperature field, it can be seen that the top surface temperature of asphalt mixture pavement has increased significantly, mostly between 374 K and 390 K, and the temperature distribution is more uniform than that of structure 1 and structure 2. The temperature of the middle part of the surface layer reaches 370 K, which indicates that the temperature of the middle part of the surface layer can be significantly increased by this heating method. Because the multi-layer heating mode makes the top surface and the bottom surface of the asphalt mixture pavement be heated at the same time, the temperature in the middle of each pavement is the lowest position in the whole asphalt mixture pavement, so the temperature increasing value in the middle of the pavement is the minimum temperature, increasing the value of the whole asphalt mixture pavement. It is considered that the use of device structure 3 can ensure the overall temperature increase of asphalt mixture pavement, and has obvious heating effect.

Therefore, for the multi-layer low-temperature heating device structure as shown in Figure 8, each layer of chain plate is driven by a motor, and a screw distributor is arranged at its feed inlets so that the mixture of each feed inlets is evenly distributed on the chain plate, and a scraper is arranged in front of the screw distributor, so that the thickness of the asphalt mixture pavement on each layer of chain plate can be adjusted.

3.2 Coupling simulation analysis and optimal parameter combination

The temperature and hot air speed of hot air have an important influence on the heating efficiency and heating quality of asphalt mixture pavement layer. If the hot air speed is too slow, it will reduce the rate of convective heat transfer between the hot air and the asphalt pavement, and the heating efficiency is too low. If the hot air speed is too quick, the hot air cycle will be shortened and the heat energy utilization rate will be reduced. Also, the hot air temperature is too high, which will cause the aging of the asphalt pavement. Therefore, it is necessary to determine a suitable parameter range for the hot air parameters in MLHM.

Studies have shown that when the hot air speed is greater than 20 m/s, the utilization rate of thermal energy will be greatly reduced, and the hot air temperature is too high and will also cause the aging of asphalt pavement [4, 8, 13]. By the existing heating method, the hot air temperature range is from 773 K to 1023 K, while the temperature range of hot air is 573 K to 623 K with MLHM.

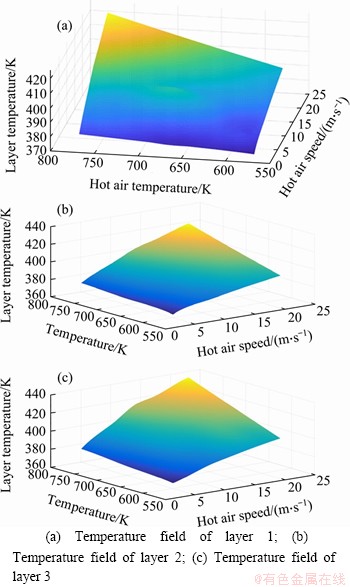

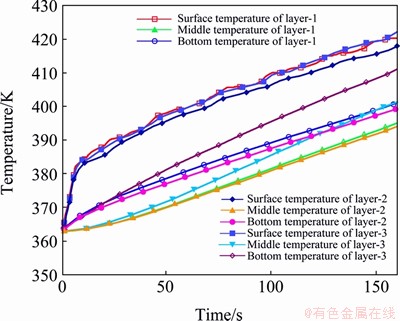

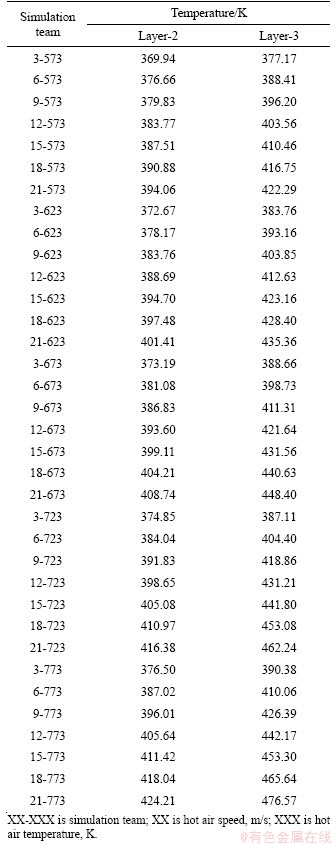

Therefore, in order to obtain a wider range of simulation data, we select the hot air speed range as 3-21 m/s and the temperature range as 573-623 K. Based on the construction speed in HIR, the corresponding heating time is 120 -160 s, the initial temperature of the asphalt mixture layer is 363 K,and a total of 35 groups for simulations are performed. The simulation results are shown in Appendix 1.

Figure 8 Schematic diagram of multi-level heating box structure

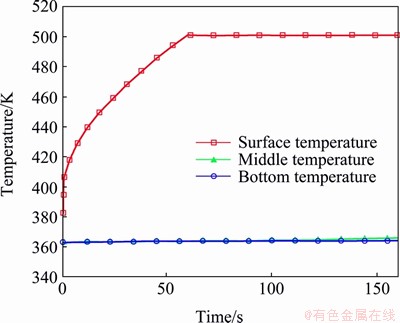

The data in Appendix 1 were linearly interpolated by Matlab software to obtain the temperature field of each layer of the asphalt mixture layer under the simultaneous effects of hot air speed and hot air temperature, as shown in Figure 9. When the heating parameters are the same, the temperature of the layer 3 is the highest among the three layers, and the temperature of the layer 2 is the lowest. The effect of hot air speed on the temperature field of the pavement is greater than the hot air temperature. Combined with the data analysis of Figure 9 and Appendix 1, through the Fluent software post-processing, the temperature fields of the asphalt mixture pavement temperature exceeding 453 K (180 °C) are extracted. Among them, when the hot air speed is 21 m/s, the hot air temperature is 573 K, and the heating time is 160 s, the asphalt mixture has the least aging under the heating parameters. This is because the temperature range of hot air is 573-623 K with MLHM. While the heating temperature of other heating methods is mostly 823-1023 K, or even more than 1273 K. And with MLHM, the upper and bottom of the asphalt mixture are heated at the same time by heating the asphalt mixture in layers, which reduces the heating thickness of the asphalt mixture pavement and increases the heating area. Therefore, the asphalt aging is avoided and the heating quality is guaranteed.

Figure 9 Temperature field of different layer in heating process:

4 Heating methods and discussions

To compare and analyze the heating effect of the existing secondary heating method and the MLHM, in the simulation, the existing hot air circulation heating method uses the same heating parameters as the MLHM, that is, the hot air speed is 21 m/s, the hot air temperature is 573 K and the heating time is 160 s. The infrared radiant heating method uses the existing process heating parameters, that is, the radiant temperature is 1073 K, the S2S radiant model is used, the radiant emissivity is 0.92, the upper surface of the asphalt mixture pavement layer is the coupling surface, its emissivity is 0.9 and the heating time is 160 s. In the first 60 s, infrared radiation heating is performed, and in the last 100 s, only the mixture layer is insulated, so that heat energy is transmitted to the inside of the asphalt mixture pavement layer through the upper surface. The initial temperature of the asphalt mixture pavement layer by three heating methods is 363 K.

4.1 Hot air heating method (HAHM)

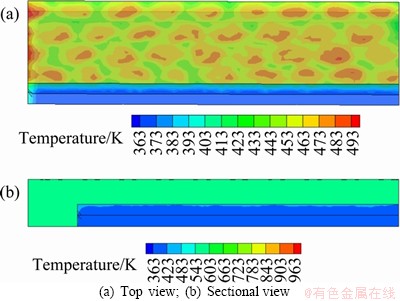

Figure 10 shows the temperature field of asphalt mixture pavement layer in HAHM. Figure 11 shows the average temperature of different layers in HAHM. As shown in Figure 10(a), after being heated for 160 s, the surface temperature of the asphalt mixture layer has increased obviously. The surface temperature range is 413-493 K and the temperature gradient is large, so the heating is not uniform. The temperature in most areas exceeds 473 K, and the asphalt mixture pavement layer temperature in the hot air vent area basically exceeds 483 K, and in some areas it even exceeds 493 K, indicating that the asphalt mixture in this area has been severely aging.

As shown in Figure 10(b), the hot air temperature is 573 K. Although the surface temperature of the asphalt mixture pavement layer is significantly increased to 483 K, its internal temperature is still around 363 K, indicating that the bottom of the asphalt mixture pavement layer is not be heated. This result can also be seen in Figure 11 that the surface average temperature of the asphalt mixture layer is about 460 K, but the average temperatures of the middle and bottom of the asphalt mixture pavement layer are around 362.5 K. The hot air temperature by the existing heating method is 500-750 K. By this method, the temperature gradient and aging of the asphalt mixture pavement layer after heating will be more serious. It is well known that if the hot air temperature is increased, the heating speed will be improved, but the heating quality will be decreased for the surface temperature of asphalt mixture pavement layer exceeds 453 K (180 °C). If the hot air temperature is decreased, the heating quality will be guaranteed, but the heating time will be extended. Therefore, with HAHM, the needs of HIR cannot be met.

Figure 10 Temperature field of asphalt mixture pavement layer in HAHM:

Figure 11 Average temperature of different layer in HAHM

4.2 Infrared radiation heating method (IRHM)

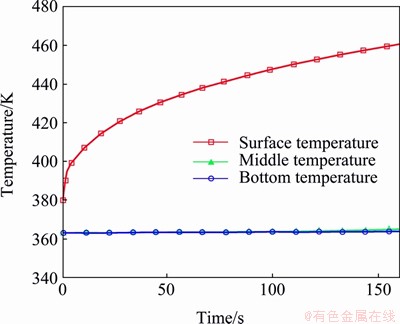

Figure 12 shows the temperature field of asphalt mixture pavement layer in IRHM. As shown in Figure 12(a), after heating for 160 s, the surface temperature of asphalt mixture pavement layer has exceeded 493 K, indicating that the upper surface of the asphalt mixture pavement layer has all been aged. But as shown in Figure 12(b), the temperature of the middle and bottom asphalt mixture pavement layer is about 373 K, indicating that the middle and bottom asphalt mixture pavement layers are not fully heated. Therefore, with IRHM, only the part of the upper surface of the asphalt mixture is heated, and the heating uniformity is poor.

Figure 12 Temperature field of asphalt mixture pavement layer in IRHM:

Figure 13 shows the average temperature of different layers in IRHM. As seen in Figure 13, when the heating time reaches 60 s, the surface average temperature of asphalt mixture pavement layer has reached about 500 K, so the asphalt has been aged. After 160 s, the temperature range of asphalt mixture pavement layer is 373-500 K and its temperature gradient is large, so the heating is not uniform. Because the asphalt mixture pavement layer is in loose particle state when it is reheated 2 times, the infrared radiation is more likely to cause the asphalt film on the aggregate surface to age. Therefore, during HIR, when using infrared radiation to heat the asphalt pavement, a lower heating temperature and an intermittent heating method should be adopted to avoid the asphalt film on the aggregate surface from being burned. However, this requires a longer heating time.

Figure 13 Average temperature of different layer in IRHM

Based on the above analysis, in the existing process of heating the asphalt mixture pavement, whether, with HAHM or IRHM, the surface temperature rises rapidly, but its internal materials are not fully heated. Because the thermal conductivity of asphalt is poor and the internal heat transfer needs time, in the case of short-time heating, it is difficult to ensure the overall temperature rise of the asphalt mixture. The heating quality and uniformity of the asphalt mixture pavement layer are poor. To deal with the problems in HAHM and IRHM, RIHM is advised. The objective is to keep the surface temperature of asphalt pavement at 453 K (180 °C) as nearly as possible. The reheater has a constant and large output heat flux, and heats the asphalt mixture pavement layer intermittently by reciprocating on the asphalt pavement. However, it has been confirmed in Ref. [21] that this heating method still requires a long heating time.

4.3 Multi-layer low-temperature heating method (MLHM)

A new heat method called MLHM is proposed. In this method, the key feature is that the upper and bottom of the asphalt mixture pavement layer are heated at the same time by heating the asphalt mixture in layers. This new heating method changes the situation that the heat energy can only be input from the upper surface of the asphalt mixture pavement in the existing heating mode. Compared with the existing heating methods, the heating temperature of MLHM is not more than 573 K (300 °C), while the heating temperature of other heating methods is mostly 823-1023 K (550-750 °C), or even more than 1273 K (1000 °C). Therefore, the MLHM uses low-temperature heating asphalt mixture, without adjusting the input heat flux and/or heating power, so the surface temperature of asphalt mixture pavement layer is always kept 453 K (180 °C) to ensure the heating quality easily.

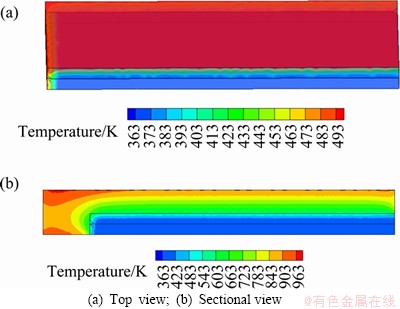

The temperature field in MLHM is shown in Figure 14. As shown in Figure 14(a), after heating for 160 s, the maximum temperature of the surface asphalt mixture pavement layer does not exceed 453 K, and the minimum temperature of the internal asphalt mixture pavement layer is above 394 K. As seen from Figure 14(b), the temperature range of every layer is 393-453 K, the minimum temperature after heating is higher than the initial temperature by more than 30 K, and the entire asphalt mixture pavement layer is fully heated, which can meet the requirements of the construction temperature in HIR. This indicates that the heating uniformity with MLHM is better than that with HAHM or IRHM. The reason for the poor heating uniformity of the existing heating methods is that the heating temperature is too high and the asphalt mixture pavement layer is too thick, resulting in serious aging or charring of surface asphalt and increasing energy consumption at the same time. Although the MLHM uses the same heat parameters (hot air temperature is 573 K, hot air speed is 21 m/s) as the HAHM, with HAHM, circular nozzle sprays hot air directly onto the asphalt mixture pavement surface for heating, belonging to fluid jet model. MLHM belongs to a large flat wall heat conduction model, and its convective heat transfer is more uniform. Its temperature gradient is small. With MLHM, the heating quality and uniformity of the asphalt mixture have been greatly improved and the aging of asphalt mixture is avoided.

Figure 14 Temperature field of asphalt mixture layer in MLHM:

Figure 15 shows the average temperature of different layers in MLHM. After 160 s heating, the average temperature range of the three-layer asphalt mixture is 393-423 K, proving that with MLHM, better heating uniformity and faster heating speed of asphalt mixture pavement layer can be obtained, and the quality of the asphalt pavement after regeneration is obtained.

Also, with MLHM, the heat temperature is 573 K (300 °C), far lower than that of the traditional heating method, as the low thermal conductivity of the asphalt mixture limits the transfer rate of heat energy in its internal. When using the traditional heating method (HAHM/IRHM), the asphalt mixture pavement layer is too thick to be heated. With MLHM, its thickness is 1/3 of the original, and the heating area is increased by 6 times. Although the lower heating temperature is adopted, the increased heating area makes the heat energy more conducive to transfer to the asphalt mixture layer, and the heating is more uniform, reducing the aging or charring of the surface asphalt mixture due to the high temperature, and improving the heating quality of the mixture.

Figure 15 Temperature of different layers in MLHM

5 Conclusions

In this study, based on the mathematical model of heat transfer of asphalt mixture layer and the analysis of influencing factors of the heat transfer process, the MLHM was proposed, and the temperature field of asphalt, mixture pavement with various heating methods was discussed. The main conclusions are summarized as follows:

1) Based on the theory of heat conduction, the mathematical model of heat transfer of the asphalt mixture pavement layer is established. The factors affecting the heating of pavement are analyzed.

2) Starting from reducing the heating thickness of asphalt mixture pavement, the MLHM is put forward and its heating mechanism is analyzed. The multi-layer hot air circulation heating device is designed to heat RAP after being lifted and layered in HIR. Through numerical simulation, the structure of the heating device is optimized and the heating uniformity and speed are improved.

3) The existing heating method of asphalt mixture pavement layer is simulated and analyzed. Whether the hot air circulation heating or the infrared radiation heating can only ensure the surface temperature of the asphalt mixture pavement layer to increase, and the inside temperature of the asphalt mixture pavement layer has no obvious change. The heating uniformity is poor, and the utilization rate of heat energy is low, and the surface of the asphalt mixture pavement layer is seriously aged. So the heating quality is very poor, seriously affecting the quality of the recycled pavement.

4) With MLHM, the heating thickness of the asphalt mixture layer is reduced. The overall temperature of the asphalt mixture pavement layer increases uniformly and rapidly. The aging or charring of the asphalt mixture is avoided, and the quality of the recycled pavement is improved. However, in practical application, the heating parameters of multi-layer low-temperature heating devices need to be further determined according to different pavement materials.

Contributors

The general idea and method of this paper were developed by MA Deng-cheng. MA Deng-cheng was responsible for the full-text writing. LAN Fen carried out numerical simulation and edited the draft of manuscript. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

MA Deng-cheng and LAN Fen declare that they have no conflict of interest.

Appendix 1

160 s heating simulation result record table

References

[1] CAO Rui-jun, LENG Z, HSU S C. Comparative eco- efficiency analysis on asphalt pavement rehabilitation alternatives: Hot in-place recycling and milling-and-filling [J]. Journal of Cleaner Production, 2019, 210: 1385-1395.

[2] AURANGZEB Q, AL-QADI I L. Asphalt pavements with high reclaimed asphalt pavement content [J]. Transportation Research Record: Journal of the Transportation Research Board, 2014, 2456(1): 161-169.

[3] BRAHAM A. Comparing life-cycle cost analysis of full- depth reclamation versus traditional pavement maintenance and rehabilitation strategies [J]. Transportation Research Record: Journal of the Transportation Research Board, 2016, 2573(1): 49-59.

[4] MA T, HUANG X, ZHAO Y, ZHANG Y, WANG H. Influences of preheating temperature of RAP on properties of hot-mix recycled asphalt mixture [J]. Journal of Testing and Evaluation, 2016, 44(2): 762-769. DOI: 10.1520/ JTE20150157.

[5] PASANDIN A R, PEREZ I, OLIVEIRA J R M, SILVA H M R D, PEREIRA P A A. Influence of ageing on the properties of bitumen from asphalt mixtures with recycled concrete aggregates [J]. Journal of Cleaner Production, 2015, 101: 165-173.

[6] PERDIKOU S, NICHOLAIDES D. Weather effects on recycled concrete used as a paving material for roads [J]. Natural Hazards, 2014, 72(1): 109-117.

[7] HAFEEZ I, OZER H, AL-QADI I L. Performance characterization of hot in-place recycled asphalt mixtures [J]. Journal of Transportation Engineering, 2014, 140(8): 04014029.

[8] LIU Yang, WANG Hai-nian, TIGHE S, PICKEL D, YOU Zhan-ping. Study on impact of variables to pavement preheating operation in HIR by using FEM [J]. Construction and Building Materials, 2020, 243: 1-11. DOI: 10.1016/ j.conbuildmat. 2020. 118304.

[9] HUANG Kai, XU Tao, LI Guo-feng, JIANG Rui-lin. The feasibility of DEM to analyze the temperature field of asphalt mixture [J]. Construction and Building Materials, 2016, 106: 592-599. DOI: 10.1016/j.conbuildmat.2015.12. 192.

[10] PUENTE E, LAZARO D, ALVEAR D. Study of tunnel pavements behaviour in fire by using coupled cone calorimeter-FTIR analysis [J]. Fire Safety Journal, 2016, 81: 1-7.

[11] ZHAO Jie-wen, HUANG Xiao-ming, TAO Xu. Combustion mechanism of asphalt binder with TG–MS technique based on components separation [J]. Construction and Building Materials, 2015, 80: 125-131. DOI: 10.1016/j.conbuildmat. 2014.11.056.

[12] YAO Ze-guang. Research on heating technologies of bituminous mixes and old asphalt pavement [D]. Xi’an: Chang’an University, 2014. DOI: 10.7666/d.D558198. (in Chinese)

[13] LI Xuan, MA Deng-cheng, YANG Shi-min, Heating method for in-place heat recycling of asphalt pavement [J]. Journal of Central South University (Natural Science and Technology), 2016, 47(4): 1290-1296. DOI: 10.11817/j.issn. 1672-7207.2016.04. 027. (in Chinese)

[14] RIAHI E, ALLOU F, BOTELLA R, FAKHARI TEHRANI F, DUBOIS F, ABSI J, PETIT C, PEREZ-JIMENEZ F E. Modelling self-heating and thixotropy phenomena under the cyclic loading of asphalt [J]. Road Materials and Pavement Design, 2017, 18(sup2): 155-163.

[15] SUN Tong-sheng. Thermoelectric coupling model for asphalt mixtures based on microwave heating [J]. International Journal of Applied Electromagnetics and Mechanics, 2013, 43(4): 353-363. DOI: 10.3233/JAE-131722.

[16] ZHANG Yi-fei. Simulation research for antennas and arrays of heating equipment of microwave road maintenance vehicle [D]. Xi’an: Chang’an University, 2012. DOI: 10.7666/d.D236062. (in Chinese)

[17] BENEDETTO A,CALVI A. A pilot study on microwave heating for production and recycling of road pavement materials [J]. Construction and Buildng Material, 2013, 44: 351-359. DOI: 10.1016/j.conbuildmat.2013.02.082.

[18] HUANG Kai, XU Tao, LI Guo-feng, JIANG Rui-lin. Heating effects of asphalt pavement during hot in-place recycling using DEM [J]. Construction and Building Materials, 2016, 115: 62-69. DOI: 10.1016/j.conbuildmat. 2016.04.033.

[19] GU Hai-rong, DONG Qiang-zhu, LIANG Feng-dian, LI Jin-ping, JIAO Sheng-jie. Asphalt pavement heating speed in multi-stage hot in-place recycling [J]. China Journal of Highway and Transport, 2017, 30(11): 170-176. DOI:10. 19721/j.cnki. 1001-7372.2017.11.019. (in Chinese)

[20] DONG Qiang-zhu, GU Hai-rong, ZHANG Hui, LI Jin-ping, YUE Ke. Heating power control in asphalt pavement in-place hot recycling [J]. China Journal of Highway and Transport, 2016, 29(4): 153-158. (in Chinese)

[21] XU Xin-xin, GU Hai-rong, DONG Qiang-zhu. Quick heating method of asphalt pavement in hot in-place recycling [J]. Construction and Building Materials, 2018, 178: 211-218. DOI:10.1016/j.conbuildmat.2018.05.091.

[22] ZHANG De-yu, HUANG Xiao-ming, MA Tao, CHEN Chen, JIN Jing, GU Fan. Simulation analysis on heating temperature field of asphalt pavement in hot in-place recycling [J]. Journal of Southeast University (Natural Science and Technology), 2010, 40(6): 1282-1287. (in Chinese)

[23] WANG Dong. Analytical approach to predict temperature profile in a multilayered pavement system based on measured surface temperature data [J]. Journal of Transportation Engineering, 2012, 138(5): 674-679. DOI:10. 1061/(ASCE)TE.1943-5436.0000362.

[24] UULU A T, KATSUCHI H, KIM H, YAMADA H, IJIMA Y. Study on thermal parameters of asphalt concrete for countermeasures against high surface temperature of pavement in tunnel [J]. Road Materials and Pavement Design, 2019: 1-15. DOI:10.1080/14680629.2019.1651757.

[25] POURANIAN M R, HAJJ E Y. Prediction of asphalt pavement temperature profile with finite control volume method [J]. Transportation Research Record: Journal of the Transportation Research Board, 2014, 2456: 96-106. DOI: 10.3141/2456-10.

[26] SI Wei, MA Biao, ZHOU Xue-yan, REN Jun-ping, TIAN Yu-xiang, LI Yi. Temperature responses of asphalt mixture physical and finite element models constructed with phase change material [J]. Construction and Building Materials, 2018, 178: 529-541. DOI: 10.1016/j.conbuildmat.2018.04. 220.

[27] TELTAYEV B B, AITBAYEV K. Modeling of transient temperature distribution in multilayer asphalt pavement [J]. Geomechanics and Engineering, 2015, 8(2): 133-152. DOI: 10.12732/ijpam.v108i3.18.

[28] MAGHSOUDI P, SHAHRIARI G, RASAM H, SADEGHI S. Flow and natural convection heat transfer characteristics of non-Newtonian nanofluid flow bounded by two infinite vertical flat plates in presence of magnetic field and thermal radiation using Galerkin method [J]. Journal of Central South University, 2019, 26(5): 1294-1305. DOI: 10.1007/s11771- 019-4088-5.

[29] MALEKI H, ALSARRAF J, MOGHANIZADEH A, HAJABDOLLAHI H, SAFAEI M R. Heat transfer and nanofluid flow over a porous plate with radiation and slip boundary conditions [J]. Journal of Central South University, 2019, 26(5): 1099-1115. DOI: 10.1007/s 11771-019-4074-y.

[30] GUO Xiao-hong, YANG Jian-min, LI Peng-wei. The research of heating grade and construction speed in hot in-place recycling technology [J]. Highway Engineering, 2013, 38(3): 213-218. (in Chinese)

[31] SHU Qin, HU Zhu-yun, REN Da-cheng, GUO Xiao-hong. Heating gradient and mechanical operation parameter control of asphalt pavement in the process of geothermal regeneration [J]. Journal of Chongqing Jiaotong University (National Science Edition), 2014, 33(5): 56-60. DOI: 10.3969/j.issn.1674-0696.2014.05.12. (in Chinese)

[32] XUE Qiang, LIU Lei, ZHAO Ying, CHEN Yi-jun, LI Jiang-shan. Dynamic behavior of asphalt pavement structure under temperature-stress coupled loading [J]. Applied Thermal Engineering, 2013, 53(1): 1-7. DOI: 10.1016/ j.applthermaleng.2012.10.055.

(Edited by YANG Hua)

中文导读

沥青路面就地热再生多层低温加热方法的数值仿真

摘要:沥青路面就地热再生中对沥青路面铣刨后的料垄进行二次加热是施工中的重要步骤之一。为了提高就地热再生中沥青路面回收材料的二次加热速度,基于沥青混合料加热过程的数值分析模型,提出一种新的多层低温加热方法,并对其进行加热机理分析。在考虑输入热流量、沥青混合料的比热和热阻基础上,根据能量守恒定律建立沥青路面回收材料的传热模型,并进行数值仿真与对比分析。结果表明:通过分层加热沥青路面回收材料铺层,改变了现有加热方法中热能只能从其上表面输入的情况;现有的加热方法会导致沥青混合料铺层严重老化或炭化。多层低温加热方法可以同时对沥青混合料铺层上下表面进行加热,由于采取了分层、低温加热,不仅减小了加热厚度,增加了沥青混合料铺层的加热面积,而且加热温度低于其他加热方式的,因此提高了加热速度,节省了能源,保证了加热质量。与其他加热方法相比,多层低温加热方法表现出了更好的加热均匀性和加热效率。

关键词:沥青路面;就地热再生;加热速度;加热均匀性;多层低温加热

Foundation item: Project(2017JM5077) supported by the Natural Science Basic Research Plan in Shaanxi Province, China; Projects (300102259109, 300102259306) supported by the Fundamental Research Funds for the Central Universities, China

Received date: 2020-05-12; Accepted date: 2020-10-15

Corresponding author: MA Deng-cheng, PhD, Associate Professor; Tel: +86-18629691016; E-mail: mdc8235@163.com; ORCID: https://orcid.org/0000-0003-4063-0472