文章编号:1004-0609(2012)05-1276-07

T6时效和T6I6时效对6005A铝合金微观组织和性能的影响

盛晓菲,杨文超,夏承东,龚 静,汪明朴,李 周,张 茜

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用硬度测试、晶间腐蚀试验,透射电镜 (TEM)和高分辨透射电子显微 (HRTEM)分析研究6时效和T6I6时效工艺处理对6005A铝合金硬度和晶间腐蚀性能的影响。结果显示:6005A铝合金经T6峰时效175 ℃、12 h后,虽然硬度达到了120 HV,但存在严重的晶间腐蚀倾向,腐蚀深度约为100 μm,同时,晶界上的析出相呈不连续分布,尺寸较小;经T6I6时效处理后,晶内生成细小的析出相,同时晶界的析出相呈不连续分布,但尺寸较大,此时合金可获得更高的峰值硬度(127 HV),而且其抗腐蚀能力得到显著提高,腐蚀深度约为30 μm。

关键词:6005A铝合金;时效;β″相;腐蚀

中图分类号:TG 146.21 文献标志码:A

Effects of T6 and T6I6 ageing treatments on microstructure and properties of 6005A aluminum alloy

SHENG Xiao-fei, YANG Wen-chao, XIA Cheng-dong, GONG Jing, WANG Ming-pu, LI Zhou, ZHANG Qian

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of T6 and T6I6 ageing treatments on the hardness and intergranular corrosion properties of 6005A aluminum alloy were investigated using hardness test, intergranular corrosion (IGC) test, transmission electron microscopy (TEM) and high resolution transmission electron microscopy (HRTEM) analysis. The results show that the hardness of the alloy in the T6 ageing treatment approaches a maximum value of 120 HV, however, it presents a severe intergranular corrosion with an average corrosion depth of 100 μm. The precipitates with small size are discontinuous at the grain boundaries. Fine precipitates with high density can be obtained in the grains after T6I6 aging treatment, and the precipitates are still discontinuous in the grain boundaries, however, the size of the precipitates is larger than that under T6 ageing treatment. The T6I6 ageing treatment for 6005A aluminum alloy not only increases the maximum hardness (127 HV), but also enhances the intergranular corrosion resistance, and the corrosion depth is only about 30 μm.

Key words: 6005A aluminum alloy; aging treatment; β″ precipitates; corrosion

地铁列车、轻轨列车、高速列车使用铝制车身是实现我国轨道交通高速化、轻量化、现代化的主要途径。因此,选择一种具有优良比强度和良好腐蚀性能的车体大型材用铝合金材料尤为关键。而Al-Mg-Si-Cu系铝合金是可热处理强化型铝合金中唯一没有发现应力腐蚀开裂(SCC)现象的合金[1]。其中,6005A铝合金由于具有优良的挤压性、焊接性、耐蚀性及中等的强度,可挤压出断面形状复杂的宽扁薄壁空心型材, 并能在挤压机上实现在线风冷或水雾冷淬火, 因此广泛应用于轨道交通车辆的制造中。

目前,6005A铝合金的各项研究已经被广泛报 道[2-6],但多集中在对挤压性能、淬火敏感性以及焊接性能等方面的研究,在时效硬化方面却只有关于T6态的报道[7]。作为可热处理强化型铝合金,沉淀硬化是Al-Mg-Si-Cu系铝合金主要的强化机制,其析出序列一般为过饱和固溶体(SSSS)→球状GP区→亚稳针状β″相(共格)→亚稳棒状β′相(半共格)+Q′相→稳定平衡β相(Mg2Si)(非共格)+Q相[8]。

近年来,研究铝合金中的二次时效析出现象成为一个热点[9]。二次时效处理不仅可以提高合金的断裂韧性,还可以在保持强度不降低或略有上升的同时有效提升合金的抗腐蚀性能。本文作者采用硬度测试、晶间腐蚀试验、透射电镜(TEM)和高分辨透射电子显微(HRTEM)等手段研究两种时效(T6时效和T6I6时效)处理对6005A铝合金硬度和晶间腐蚀性能的影响,以便为6005A铝合金应用提供理论依据。

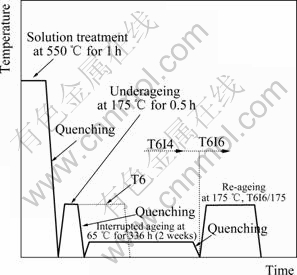

1 实验

采用半连续铸造工艺制备6005A铝合金,在线挤压成厚度为3 mm的板材并在线淬火,其成分(质量分数,%)为Mg 0.65,Si 0.73,Cu 0.13, Mn 0.31,Cr 0.16,Ti≤0.10,Zn≤0.10,Al 余量。截取试样,并在550 ℃厢式电阻炉中固溶1 h,水淬到室温。为了减小自然时效的影响,在15 s内将所取样品放入油浴中时效。其中一部分样品在175 ℃下等温时效不同时间,即T6时效;另一部分样品进行T6I6时效,即先在175 ℃进行0.5 h预时效,再在65 ℃时效336 h(2周),最后将试样在175 ℃继续时效。图1所示为T6时效和T6I6时效的示意图。

硬度测试是在HV-5型小负荷维氏硬度计上进行,载荷为20 N,加载时间15 s,所记录的硬度数据都是经7次测量后,去除最大值和最小值的平均值,误差范围为±3 HV。晶间腐蚀实验按GB/T 7998—2005要求进行,将试样打磨、抛光、清洗、除油,在35 ℃的3%NaCl(质量分数)+1%HCl(体积分数)溶液中浸泡24 h,然后将腐蚀试样沿横向切开并抛光,用Leica DM ILM HC光学显微镜观察腐蚀形貌并测量腐蚀深度。透射电镜样品在MTP-1双喷电解减薄仪上双喷减薄、穿孔。电解液为硝酸与甲醇的混合液,体积比为3:7, 温度为-20~-30 ℃,电压为12~15 V,电流为80~100 mA。在JEOLF-2100型透射电镜上观察,加速电压为200 kV。

图1 T6时效工艺和T6I6时效工艺的示意图

Fig. 1 Schematic diagram showing T6 and T6I6 heat treatments

2 实验结果

2.1 时效硬化曲线及微观组织观察

2.1.1 时效硬化曲线

图2所示为6005A合金经过T6时效和T6I6时效的硬化曲线。由图2可知,6005A合金存在明显的时效硬化效应。6005A铝合金挤压试样经过550 ℃、1 h固溶处理后硬度只有55 HV,但在T6时效过程中,合金硬度在短时间内迅速上升,3 h即达113 HV,12 h达到峰值硬度,约为120 HV。随后,合金硬度开始下降,进入过时效状态,但硬度在降低大约10 HV后,出现一个平台,保持在110~113 HV之间,下降并不明显。直到时效90 h以后,硬度才开始显著的下降,时效 180 h时,仅仅只有84 HV。

6005A铝合金先进行175 ℃、0.5 h预时效、再在65 ℃低温时效336 h(2周)后(T6I6时效),此时,硬度从75 HV上升至86 HV。然后,温度升至175 ℃继续时效(图2中T6I6曲线从此时开始),硬度在短时间内迅速上升,时效6 h后,即达116 HV左右;18 h达到峰值硬度,约为127 HV,高于T6峰时效状态的硬度值,但是出现峰值的时间长于T6时效工艺。随后合金进入过时效状态,硬度迅速下降,没有出现T6时效的硬度平台,78 h时硬度为102 HV;到150 h时,其硬度只有96 HV,但比同时间下T6时效的硬度要高。

图2 6005A合金T6时效和T6I6时效硬化曲线

Fig. 2 Age-hardening curves of 6005A during T6 and T6I6 ageing treatments

2.1.2 微观组织观察

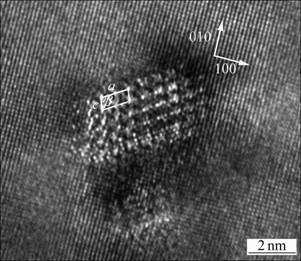

图3所示为6005A铝合金在两种时效热处理工艺下的TEM像。其中,图3(a)~(d)所示分别为6005A铝合金在T6时效不同时间的TEM像。从图3(a)可以看出,时效0.5 h时,即时效初期,大量球状GP区在晶内均匀分布;当达到峰时效状态(见图3(b)),即时效到12 h时,合金中存在2种衬度的析出相,一种是直径约为2~3 nm的粒状析出相,另一种是长度约为20 nm的针状析出相。由析出相晶体几何分析可知,该粒状析出相应该是针状析出相的横截面。针状析出相在基体中分布均匀,同时在这些弥散沉淀相中可以观察到零衬度线的存在(见图3(b)),说明T6峰时效状态下合金中以共格的针状相为主,其尺寸在20 nm左右。对粒状的析出相颗粒进行HRTEM 观察,结果如图4所示。测量得出析出相的点阵参数为a=1.516 nm,c=0.674 nm,a与c之间的夹角约为105.3°,与文献报道的单斜结构β″相点阵参数一致[10-11],因此可判定该粒状或针状析出相为β″相。同时,在图3(b)中也观察到球状GP区的存在,如箭头所示;当合金在时效78 h后,可以观察到板状Q′相的析出(见图3(c))。同时,部分针状β″相已经转变为棒状的β′相,尺寸大约为100 nm,同时仍然能够在基体中看到一些共格的针状β″相存在,尺寸约为30 nm,较峰时效状态有所长大。而当时效时间达到150 h后,Q′相尺寸已经长大到120~200 nm,同时观察到棒状的β′相的存在(见图3(d))。

图3 不同热处理下6005A铝合金的TEM像

Fig. 3 TEM images of 6005A alloy after different heat treatments: (a) T6, 0.5 h; (b) T6, 12 h; (c) T6, 78 h; (d) T6, 150 h; (e) T6I6, 0 h; (f) T6I6, 18 h; (g) T6I6, 78 h; (h) T6I6, 150 h

图3(e)~(h)所示分别为6005A铝合金在T6I6态下时效不同时间的TEM像。图3(e)所示为6005A合金在T6I6、0 h(T6I4)状态下的TEM像,晶内同样均匀分布球状GP区,密度明显增加;当时效至18 h时,即T6I6峰时效状态(见图3(f)),与T6峰时效状态相似,仍然主要以共格的针状β″相为主,平均尺寸在15 nm左右,分布密度远大于T6峰时效态。当时效78 h后(见图3(g)),棒状β′相和板状Q′相在晶内大量分布;同时,可以观察到少量共格的针状β″相,尺寸约为30 nm,数量明显少于T6时效78 h状态的。而当时效时间达到180 h后(见图3(h)),依旧可以观察到棒状β′相的存在,而板状Q′相已经长大到180~240 nm。同时,可以观察到平衡相β相的存在,尺寸约为200 nm。

图4 T6、12 h状态下针状析出相β″相横截面的HRTEM像

Fig. 4 HRTEM image of cross section of β″ phase in state of T6, 12 h

2.2 晶间腐蚀试验和晶界微观观察

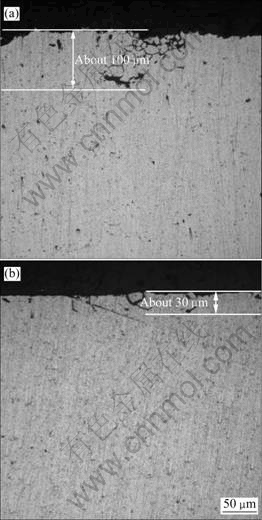

2.2.1 晶间腐蚀试验

图5所示为两种时效工艺下峰值时效状态的晶间腐蚀形貌。由图5(a)可见,在T6工艺处理12 h后的6005A铝合金表现出局部严重晶间腐蚀倾向,部分表层晶粒相互脱离,甚至脱落,发生晶间腐蚀区域腐蚀深度约为100 μm。图5(b)所示为在T6I6工艺处理下的典型的晶间腐蚀形貌。此时,合金中仍然出现局部晶间腐蚀,但是腐蚀深度较T6峰时效状态有明显的改善,发生晶间腐蚀区域腐蚀深度约为30 μm,同时,没有发现明显的晶粒脱落现象。

图5 两种时效状态下6005A铝合金的晶间腐蚀形貌

Fig. 5 Intergranular corrosion micrographs of 6005A alloy after different ageing treatments: (a) T6, 12 h; (b) T6I6, 18 h

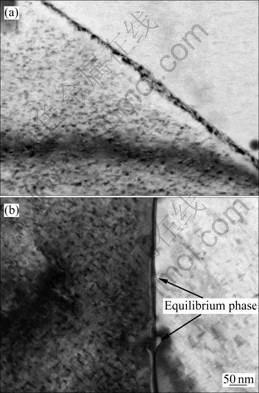

2.2.2 晶界的微观组织观察

图6所示为6005A铝合金在两种时效工艺处理下峰时效状态的晶界处TEM 像。其中图6(a)所示为T6峰时效状态下的晶界照片,由图可以清楚看到晶界上的析出相呈不连续分布,析出相尺寸较小,相互之间间隔比较近。图6(b)所示为T6I6峰时效状态下的晶界照片。相较于图6(a),图6(b)中的晶界析出相更为粗大,相互之间的间隔也更大。

图6 不同热处理下6005A铝合金的晶界TEM像

Fig. 6 TEM images of grain boundaries of 6005A alloy after different heat treatments: (a) T6, 12 h; (b) T6I6, 18 h

3 讨论

3.1 微观组织对硬度的影响

时效硬化型铝合金的强度主要取决于晶内析出相的性质、数量及形貌。要使合金获得高强度就要求晶内析出相数量多而且与基体存在较大的共格畸变,能对位错运动产生较高的阻力[12]。不同时效处理导致合金的晶内析出相性质、形貌及数量和晶界析出相的特征都有明显变化,从而导致不同的硬度和晶间腐蚀 性能。

对比图3(a)和(e)可以发现,在T6态下时效时,合金在175 ℃时效仅0.5 h时,合金的硬度从55 HV升高到75 HV(见图2),此时在合金中主要是球状GP区组织,这些球状GP区组织具有的弹性应变场,对位错运动产生较高的阻力,为合金提供了硬化效应。而在T6I6时效下经历65 ℃时效336 h(2 周)后(见图3(e)),球状GP区的数量和密度明显的增加了,致使合金的硬度从75 HV上升至86 HV(见图2)。

通常认为球状GP区是Al-Mg-Si系合金中针状β″相的先驱组织。随着T6时效的进一步进行,球状GP区不断生成,进而不断转变为β″相。在T6I6时效下,65 ℃时效结束后升至T6时效温度时,部分尺寸在临界尺寸以下的球状GP区发生了回归溶解,然后再析出,最终大部分亚稳的球状GP区演变成了针状β″强化相。因此,相对于T6时效工艺,T6I6时效处理下β″相具有更高的密度。同时由于可形核的球状GP区数量远远大于T6时效,而可扩散形成β″相的原子数量有限,因此,β″相的尺寸较小。由于T6I6时效65 ℃时效336 h(2周)后,大量球状GP区的存在降低了合金的过饱和度,进一步减小了β″相的形成动力,导致T6I6时效工艺出现峰值的时间要长。因此,经过T6I6时效处理,其峰时效状态硬度要明显高于T6时效处理。此外,无论是在T6时效还是T6I6时效下,在峰时效状态下,β″相大量析出的同时,球状GP区依然存在。

T6I6峰时效状态的微观组织对合金的硬度提升有直接的贡献。两种时效条件下的峰时效状态都是以针状的β″相为主导,同时也存在着大量球状GP区。尽管球状GP区和针状β″相对6005A铝合金的硬度都有贡献,但是通常认为针状β″相对位错滑移的阻碍作用比球状GP区的作用更大[12]。由于β″相产生的共格畸变程度比GP区更大,其强化效果更好,这也解释了T6I6时效下峰时效状态下可获得更高的硬度。图3(f)显示出T6I6时效确实增加了主要强化相针状β″相的密度。

无论是T6I6时效还是T6时效,在时效78 h时都能够观察到针状β″相的存在(见图3(c)和(g)),这很可能是T6时效状态下硬度平台的产生原因。而T6I6时效形核的地方比较多,针状β″相更容易转变成棒状β′相。因此,T6I6时效下硬度下降相当快。时效150 h后,无论是T6I6时效还是T6时效下都没有观察到针状β″相(见图3(d)和(h))。但是,T6I6时效下板状Q′相比T6时效下数量更多,且板状Q′相与基体是半共格的,具有一定的共格强化效果,因此,此时T6I6时效的合金硬度大于T6时效状态下的。

3.2 微观组织对晶间腐蚀性能的影响

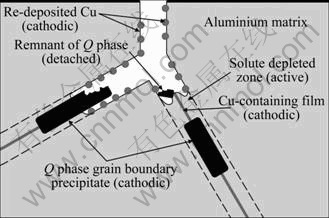

晶界因为具有较高的界面能而成为短路扩撒通道和择优形核位置,导致固溶时不仅存在元素晶界的偏析,而且时效时附近溶质原子也极易向晶界扩散,在晶界上优先析出平衡相。SVENNINGSEN等[13]研究指出,在含Cu的Al-Mg-Si合金中晶界的析出相主要是Q相,因而在图6(a)和(b)中出现在晶界上的析出相应该是Q相。但是,从图6可以看出,在晶界上不连续析出的Q相无法解释T6峰时效状态的严重的晶间腐蚀倾向。SVENNINGSEN等[13]同时认为,在晶界上存在着连续的纳米尺度的Cu富集带,热力学的计算结果表明[14],此时,Cu无法以单质形式存在,也不会以AlCu相(如Al2Cu相)的形式存在,因此,这些Cu富集带极有可能是Q相的先驱。这些分布在晶界上的Q相,还有连续的Cu富集带形成了连续的阴极活性通道,而在晶界附近的无析出带则作为阳极,相互之间形成微电池,导致晶界优先连续的溶解,产生严重的晶间腐蚀。然而,来自Cu富集带和Q相中的Cu能够在酸性的氯化物溶液中溶解然后再沉淀在暴露的晶粒边缘[15-17],继续充当阴极。因此,在T6峰时效状态下,6005A铝合金呈现局部严重的晶间腐蚀倾向,腐蚀深度约为100 μm。该状态下合金晶间腐蚀机制的示意图如图7所示。

然而,在T6I6峰时效状态下,晶间腐蚀性能发生了变化,这可能是因为T6I6时效达到峰时效的时间比T6时效长,再加上之前的长时间低温时效(65 ℃、336 h),晶界上的Cu富集带发生了缩进,至少在局部发生了缩进,在晶界上形成不连续的Cu富集带,打破了原本连续的微电池,且晶界上的Q相较T6峰时效状态发生了长大,相互之间的间隔也有所扩大,Q相充当阴极产生的腐蚀效果进一步减弱。因而,T6I6峰时效状态下没有发生明显的晶界连续溶解,只是导致晶界局部溶解,呈现局部轻微的晶间腐蚀,腐蚀深度约为30 μm。

图7 晶间腐蚀机制示意图[13]

Fig. 7 Conceptual sketch of IGC mechanism[13]

4 结论

1) 6005A铝合金经T6峰时效175 ℃、12 h后,虽然硬度达到了120 HV,但存在严重的晶间腐蚀倾向,腐蚀深度约为100 μm。而经T6I6时效处理后,不仅可以获得更高的峰值硬度(127 HV),而且还能显著提高晶界腐蚀抗力,腐蚀深度仅为30 μm。

2) 获得更高密度的针状β″相是T6I6时效处理工艺峰值硬度高于T6处理的原因。

3) T6I6峰时效后晶界处的析出相呈不连续分布,但尺寸更大,间隔也更大,同时在晶界形成了不连续的Cu富集带,导致经T6I6处理后合金的抗腐蚀性能优于经T6处理后合金的抗腐蚀性能。

REFERENCES

[1] HIRSCH J. Aluminium alloys for automotive application[J]. Materials Science Forum, 1997, 242: 33-50.

[2] HASTING H S, WALMSLEY J C, VAN HA T J, MARIOARA C D, ANDERSEN S J, HOLMERSRAD R. Z-contrast imaging of the arrangement of Cu in precipitates in 6×××-series aluminium alloys[J]. Philosophical Magazine Letters, 2006, 86(9): 589-597.

[3] MARIOARA C D, ANDERSEN S J, STENE T N, HASTING H, WALMSLEY J, VAN H A T J, HOLMESTAD R. The effect of Cu on precipitation in Al-Mg-Si alloys[J]. Philosophical Magazine, 2007, 87: 3385-3413.

[4] 肖从文, 汪明朴, 王正安, 李 周, 郭明星. 6005A 合金的淬火敏感性[J]. 中国有色金属学报, 2003, 13(3): 635-638.

XIAO Cong-wen, WANG Ming-pu, WANG Zheng-an, LI Zhou, GUO Ming-xing. Quench sensitivity of 6005A aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 635-638.

[5] BUHA J, LUMLEY R N, CROSKY A, HONO K. Secondary precipitation in an Al-Mg-Si-Cu alloy[J]. Acta Materialia, 2007, 55(9): 3015-3024.

[6] 杨成功, 单际国, 熊 伟. 车辆6005A铝合金焊接技术研究现状[J]. 焊接, 2009, 10: 13-18.

YANG Cheng-gong, SHAN Ji-guo, XIONG Wei. Welding joining study of the welding of 6005A alloy sheet for rail traffic vehicle[J]. Welding, 2009, 10: 13-18.

[7] 杨文超, 汪明朴, 盛晓菲, 张 茜, 王正安. 轨道交通车辆用6005A合金板材时效析出及硬化行为研究[J]. 金属学报, 2010, 46(12): 1481-1487.

YANG Wen-chao, WANG Ming-pu, SHENG Xiao-fei, ZHANG Qian, WANG Zheng-an. Study of the aging precipitation and hardening behavior of 6005A alloy sheet for rail traffic vehicle[J]. Acta Metallurgica Sinica, 2010, 46(12): 1481-1487.

[8] EDWARDS G A, STILLER K, DUNLOP G L, COUPER M J. The precipitation sequence in Al-Mg-Si alloys[J]. Acta Materialia, 1998, 46(11): 3893-3904.

[9] BUHA J, LUMLEY R N, CROSKY A G. Secondary ageing in an aluminium alloy 7050[J]. Materials Science and Engineering A, 2008, 492: 1-10.

[10] CHEN J H, COSTAN E, VAN M A. Atomic pillarbased nano-precipitate strengthen AlMgSi alloys[J]. Science, 2006, 312: 416-419.

[11] ANDERSEN S J, ZANDBERGE H W, JANSEN J. The crystal structure of the β″ phase in Al-Mg-Si alloys[J]. Acta Materialia, 1998, 46: 3283-3298.

[12] NIE J F, MUDDLE B C, POLMEAT I J. The effect of precipitate shape and orientation on dispersion strengthening in high strength aluminium alloys[J]. Materials Science Forum, 1996, 217: 1257-1562.

[13] SVENNINGSEN G, HURLEN M, CHARLES J, JAN H N, KEMAL N. Effect of artificial aging on intergranular corrosion of extruded AlMgSi alloy with small Cu content[J]. Corrosion Science, 2006, 48: 1528-1543.

[14] SVENNINGSEN G, LARSEN M H, NORDLIEN J H, NISANCIOGLU K. Effect of high temperature heat treatment on intergranular corrosion of AlMgSi(Cu) model alloy[J]. Corrosion Science, 2006, 48: 258-272.

[15] BUCHHEIT R G, MARTINEZ M A, MONTES L P. Evidence for Cu ion formation by dissolution and dealloying the Al2CuMg intermetallic compound in rotating ring-disk collection experiments[J]. Am Ceramic Soc, 2000, 147(1): 119-135.

[16] KOLICS A, BESING A S, WIECKOWSKI A. Interaction of chromate ions with surface intermetallics on aluminum alloy 2024-T3 in NaCl solutions[J]. Journal of the Electrochemical Society, 2001, 148(8): 428-439.

[17] VUKMIROVIC M B, DIMITROV N, SIERADZKI K. Dealloying and corrosion of Al alloy 2024-T3[J]. Journal of the Electrochemical Society, 2002, 149(9): 428-439.

(编辑 龙怀中)

基金项目:国家高技术研究发展计划资助项目(2006AA03Z517);湖南省博士生科研创新项目(CX2010B044)

收稿日期:2011-05-04;修订日期:2011-09-10

通信作者:汪明朴,教授;电话:0731-88830264;E-mail: wangmp@mail.csu.edu.cn