DOI:10.19476/j.ysxb.1004.0609.2018.05.01

喷射成形7055铝合金的热变形行为及显微组织演变

熊尚武1,潘清林2,张豪3,范曦3,王向东2,刘丽丽2

(1. 中南大学 轻合金研究院,长沙 410083;

2. 中南大学 材料科学与工程学院,长沙 410083;

3. 江苏豪然喷射成形合金有限公司,镇江 212009)

摘 要:采用Gleeble-3500热模拟试验机对经过致密化的喷射成形7055铝合金进行热压缩试验。热压缩之后的样品使用金相显微镜和透射电镜观察。结果表明:随着热变形温度的升高或应变速率的降低,峰值应力逐渐减小。该合金的热压缩流变应力行为可以用双曲正弦形式的方程表示,也可以用Zener-Hollomon参数来描述。喷射成形7055铝合金热变形过程中组织演变可以使用Zener-Hollomon参数定量表征,其软化机制主要为动态回复和动态再结晶。随着lnZ值的降低,合金的软化机制由动态回复逐渐转变为动态再结晶且再结晶尺寸变大。变形后合金中分布的高密度、纳米级的Al3Zr粒子可有效阻碍合金在热变形中的动态再结晶。

关键词:喷射成形7055铝合金;热变形;本构方程;软化机制。

文章编号:1004-0609(2018)-05-0863-09 中图分类号:TG146.2 文献标志码:A

Al-Zn-Mg-Cu系合金由于具有高比强度,良好的韧性和耐腐蚀性等优点被广泛应用于汽车工业和航空工业[1-2]。7055铝合金在上个世纪90年代早期由ALCOA公司开发,作为结构材料被用于波音777的机翼上壁板。对于喷射成形技术制备的材料而言,其有着准快速冷凝固材料的优异性能,相比于传统铸造工艺,该技术下材料的冷凝速度大幅提高,可以达到1×102~1×104 K/s,这样带来的效果就是显著的组织细化,细小且分布均匀的第二析出相,成分偏析得到显著的抑制,综合力学性能得到有效的提高。和快速冷凝技术相比,喷射成形的优点在于材料的熔炼到成形可以一步工序完成,节省人力物力,提高了生产效率并且可以控制材料的质量和含氧量。

由于喷射成形的7055铝合金具有上述优点,因而这种工艺生产的7055铝合金在工业应用尤其在航空航天领域具有很大的潜力。由于材料的力学性能与显微组织有关,而热加工工艺参数又极大地影响了材料显微组织的形貌[3]。热模拟实验可模拟工业锻造,挤压以及各种热加工工艺[4]。因此,通过热模拟实验进而建立该合金的热压缩本构方程并研究其组织特点对于该合金的工业应用具有极大的意义。7055铝合金属于高层错能合金,在热塑性变形过程中动态回复强烈,位错密度难以升高,不易发生非连续动态再结晶(DDRX)。仅在变形温度和速度均较高的情况下,可能出现部分非连续动态再结晶,7055铝合金热变形时主要发生连续动态再结晶(CDRX)[5-6]。连续动态再结晶是金属变形时位错不断向小角度晶界聚集,从而转变为大角度晶界,形成新的细小晶粒的过程。金属晶粒度随连续动态再结晶进行而显著减小,得到非常细小的晶粒组织,能够显著提高铝合金的力学性能。因此,铝及铝合金的动态再结晶在工业应用中具有重要意义。研究表明动态回复和动态再结晶的发生与Zener-Hollomon参数有直接关系。该参数可以综合描述变形温度、应变速率对热变形过程中流变应力及显微组织演变的影响[7-11]。因此,Zener-Hollomon参数是表征铝合金热变形过程中组织演变非常有效的参数。

近年来,金属热变形显微组织预测和控制成为国际上材料科学领域研究的热门方向,其本质是对金属变形组织演变规律的研究。对于7055铝合金热变形行为及显微组织演变规律的研究是当前的热点。YAN 等[12]在研究热变形温度对7055铝合金热处理组织和力学性能的影响时发现动态再结晶在变形温度较高时更容易发生。李周兵等[13]在研究热轧变形量对7055铝合金组织与力学性能的影响时发现随着变形量的增加,合金局部发生动态再结晶。李晨等[14]在研究变形温度和变形道次对7055铝合金显微组织的影响时发现变形温度的升高和变形道次的减少均能有效的减少动态再结晶的发生。祝令状等[15]在研究喷射成形7055铝合金热变形行为时通过建立应变补偿的本构方程并且得到了可以预测喷射成形7055流变应力行为的数学模型。闫亮明等[16]在研究7055铝合金热变形时发现在350~430 ℃范围内应变速率较低的区域为加工性较好的区域。然而目前关于喷射成形7055铝合金热变形流变应力行为及显微组织演变的文章非常少。因此,本文作者通过热模拟试验,对不同温度和不同应变速率下该合金的显微组织进行研究并建立该合金的热压缩本构方程,深入研究喷射成形7055铝合金的流变应力行为及其组织的演变规律。

1 实验

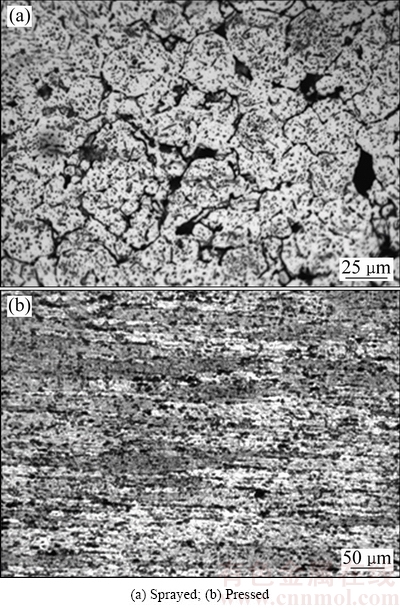

实验采用的是经过致密化处理的喷射成形7055铝合金材料,其成分(质量分数)为:7.91%Zn,1.98%Mg,2.42%Cu,0.12%Zr,0.096%Fe,0.082%Si,0.004%Mn,0.004%Cr,0.007%Ni,0.014%Ti,余量Al。实验材料为喷射成形7055铝合金d500 mm坯锭,坯锭的金相组织见图1(a)。可以看出,喷射成形7055铝合金坯锭组织的晶粒为平均尺寸在30~50 μm的细小等轴晶,但是这些等轴晶附近也伴随着一些孔隙。坯锭经过致密化处理后的组织如图1(b)所示。可以明显观察到晶粒被拉长,孔隙消失了,说明致密性得到了提高。

采用线切割将经过致密化之后的铝锭切割为直径10 mm、高度为15 mm的热压缩试样。热压缩试验在Gleeble-3500热模拟试验机上进行,热压缩试验前先在热模拟试验机上保温3 min,升温速率为5 ℃/s,并且在试样两端贴上石墨贴片以减少试样与压头的摩擦,避免出现侧翻、腰鼓等不均匀变形现象。热压缩温度分别为340、370、410和450 ℃。每种温度下的应变速率分别为0.001、0.01、0.1和1 s-1,真应变为0.8。由Gleeble-3500热模拟试验机采集应力、应变和温度等数据,并绘制出不同条件下的真应力-真应变曲线。热压缩后的样品采用水冷的方式快速淬火,试样淬火转移时间小于1 s以保持试样高温变形时的组织并进行金相组织和透射电镜观察。金相的腐蚀剂为Keller试剂,并使用Polyver-met大型金相显微镜观察。电镜薄膜样品采用电解双喷减薄,电解液为硝酸和甲醇的混合溶液,其体积分数比为1:2,电压15~20 V,电流为50~70 mA,温度控制在-20 ℃以下,然后在JEM-2100F场发射高分辨率透射电镜下观察合金组织。

图1 喷射成形7055铝合金不同状态下的组织

Fig. 1 Optical structure of spray-formed 7055 aluminum alloy under different states

2 结果与讨论

2.1 流变应力行为

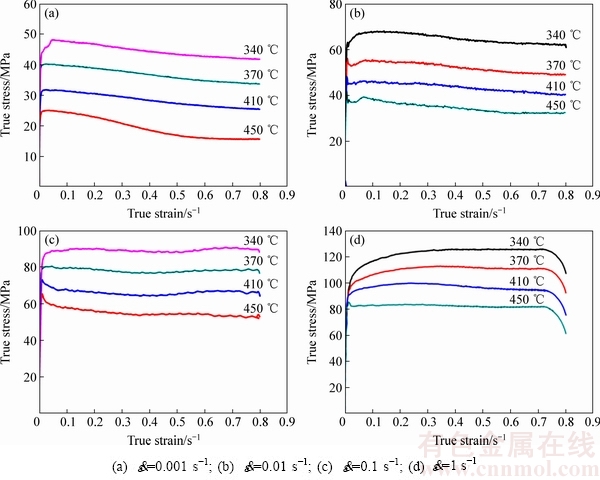

图2所示为喷射成形7055铝合金的真应力-真应变曲线。如图2所示,应变速率保持恒定的条件下,随着变形温度的升高,合金的峰值应力逐渐减小;在温度保持恒定的条件下,随着应变速率的下降,合金的峰值应力逐渐减小。当温度为340 ℃,流变应力会随着应变增加到达一个峰值,然后趋于稳定的应力值,属于典型的动态回复时的真应力-真应变曲线。当温度为450 ℃,流变应力会随着应变的增加到达峰值后迅速下降然后再趋于稳定,属于典型的动态再结晶时的真应力-应变曲线。对于中间温度,则分别呈现出动态回复和动态再结晶的特征。出现这种情形的原因在于,在更高的变形温度下,合金形变时热激活过程加强,可以激活更多的滑移系,便于位错向晶界附近聚集,因而更容易形成亚晶粒,并且亚晶粒在高的变形温度下更容易长大[17],从而更有利于再结晶晶粒的形成。

图2 喷射成形7055铝合金真应力应-真变曲线

Fig. 2 True stress-true strain curve of spray formed 7055 aluminum alloy

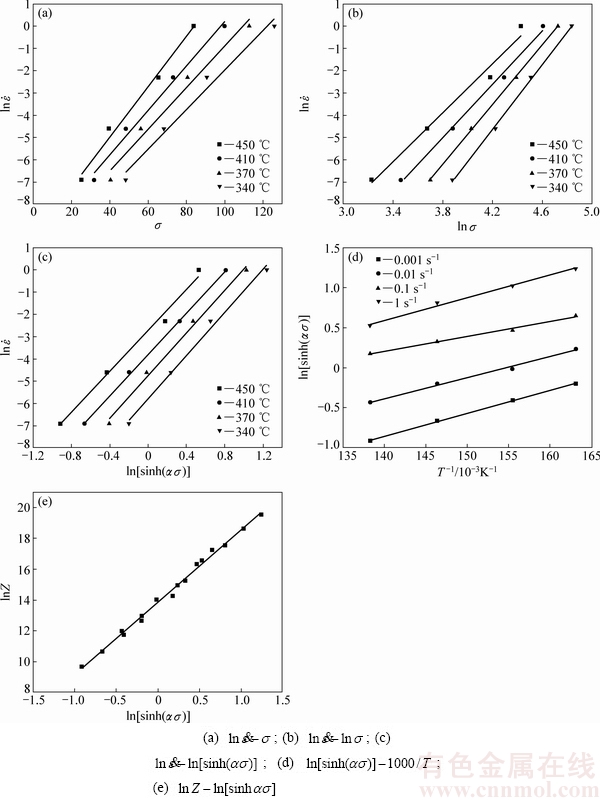

2.2 本构方程

在高温热变形试验中,流变应力σ受变形温度T和应变速率 的影响。他们之间的关系可以用下面的函数表示[18-20]:

的影响。他们之间的关系可以用下面的函数表示[18-20]:

(1)

(1)

Z=f2(σ)=A2exp(βσ) (2)

式中:A1、A2、n1和β均为常数;Z是Zener-Hollomon参数;Q为热变形激活能;R为理想气体常数,其值为8.31385 J·mol-1·K-1。式(1)适用于低流变应力的情况,式(2)适用于高流变应力的情况。此外,双曲线正弦方程式则可以表示任意流变应力状态,本研究采用由Sellars和Tegart提出的双曲线正弦方程,尤其适用于铝合金的热变形行为[2, 4, 21, 22-25]。

Z=f(σ)=A[sinh(ασ)]n (3)

式中:A和n是常数;α是应力因子并且也是可以调整的参数,α=β/n1,这里β等于 散点图斜率的平均值,如图3(a)所示;n1为散点图

散点图斜率的平均值,如图3(a)所示;n1为散点图 斜率的平均值,如图3(b)所示;所以α的值为0.01689 MPa-1。因此,本构方程(4)可以从(1)到(3)得到:

斜率的平均值,如图3(b)所示;所以α的值为0.01689 MPa-1。因此,本构方程(4)可以从(1)到(3)得到:

(4)

(4)

将式(4)两边取自然对数可以得到:

(5)

(5)

当温度一定时,对式(5)取偏微分可以得到[26-27]:

(6)

(6)

所以n值等于图3(c)中斜率的平均值。当应变速率一定时对式(5)求偏微分得到:

(7)

(7)

显然S为图3(d)中斜率的平均值。因此,S也可以表示为

(8)

(8)

所以Q的值可以表示为

(9)

(9)

从(8)式中可以求出热激活能Q。将(3)式两边取自然对数可以得到:

lnZ=lnA+nln[sinh(ασ)] (10)

式中:Z为Zener-Hollomon参数,它描述了不同变形温度和应变速率对合金热变形过程中流变应力的影

响。从图3(e)中求出A的值。

综上所述,A=1.04×106 s-1,α=0.01550 MPa-1,n=4.72298,Q=99.68 kJ/mol。

因此喷射成形7055铝合金的本构方程为

(11)

(11)

由于激活能Q对热变形的难易程度具有重要的指导作用(热激活能越高合金的热变形越难进行),因而在热变形中激活能是一个重要的物理参数[28]。

图3 喷射成形7055铝合金在不同变形条件下的峰值应力拟合图

Fig. 3 Peak stress fitting under different deformation conditions of sprayed-formed 7055 aluminum alloy

2.3 高温塑性变形过程中的组织演变

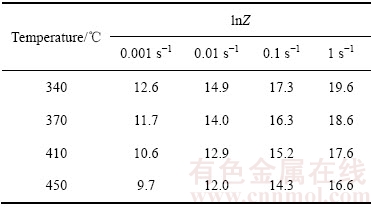

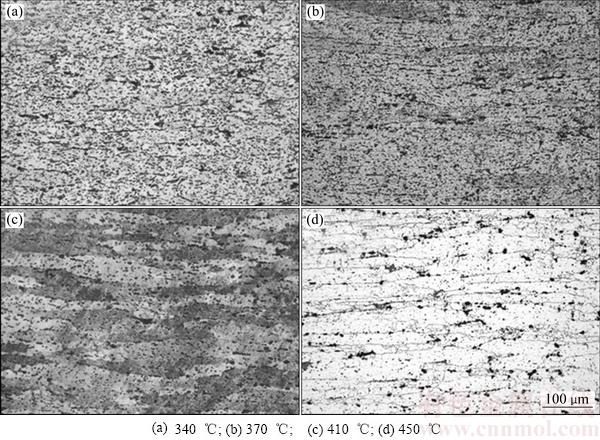

根据不同变形条件下峰值应力计算所得的lnZ值列于表1。图4所示为喷射成形7055铝合金在应变速率为0.001 s-1时不同温度条件下的金相组织。如图4所示,随着温度的升高细小的等轴晶逐渐增多。在变形温度为340 ℃(lnZ=12.6)的合金金相组织中存在大量晶界较粗大的近似胞状组织,这表明此时发生了较大程度的动态回复(见图4(a));温度升高到370 ℃(lnZ=11.7)时,合金组织中存在大量被拉长的晶粒,胞状组织减少,动态回复逐渐减弱(见图4(b));当变形温度为410 ℃(lnZ=10.6)和450 ℃(lnZ=9.7)时,虽然都出现了大量细小的等轴晶粒但是450 ℃时的再结晶晶粒数量明显更多(见图4(c)和4(d));这表明合金此时发生了较大程度的动态再结晶。由此可见,随着温度的升高(lnZ值的降低),合金的软化机制由动态回复逐渐转变为动态再结晶,与图2表现出的规律正好吻合。

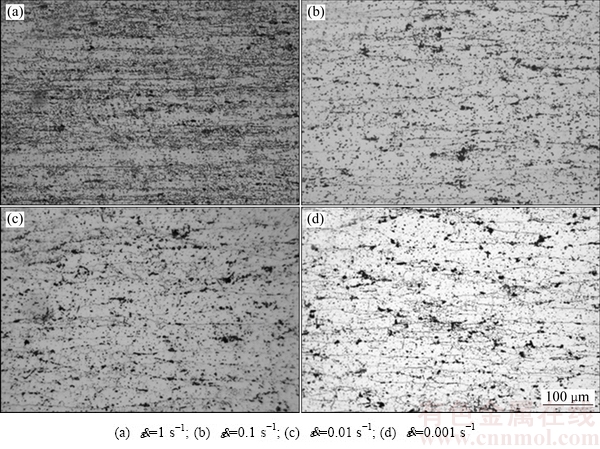

图5所示为喷射成形7055铝合金在变形温度为450 ℃时不同应变速率下的金相组织。可以看到纤维组织周围伴随着大量细小的等轴晶(见图5(a));随着应变速率降低细小的等轴晶发生了长大且这些等轴晶的晶界越来越清晰(见图5(b)和图5(c));进一步观察发现,当变形条件为(450 ℃,1 s-1,lnZ=16.6)(见图5(a))时,组织中出现的再结晶晶粒相较于变形条件为(450 ℃,0.001 s-1,lnZ=9.7)(见图5(d))的再结晶晶粒更细小数量更多。这是由于在同一个温度下,更低的应变速率会导致更长的变形时间,位错有充足的时间和能量进行攀移和交滑移,位错销毁和重排也进行得更充分,并且晶粒长大过程就是“大吞并小”的过程,因此,在更低变形速率的条件下晶粒有充足的时间合并长大。这表明随着应变速率的降低(lnZ值的降低),合金组织的动态再结晶现象越来越显著,再结晶晶粒尺寸变大。

表1 不同变形条件峰值应力下对应的lnZ值

Table 1 Calculated value of lnZ under peak stress of different deformation conditions

喷射成形7055铝合金在热变形过程中表现出明显的阶段性,这主要是因为其流变力学行为与位错组态,位错的产生和运动密切相关。合金不同lnZ取值的TEM像如图6所示。当合金变形条件为(340 ℃,0.01 s-1,lnZ=14.9)时,可以观察到大量的位错缠结(见图6(a)),同时由于交滑移过程增强,亚晶界可以吸收大量位错并形成大角度晶界(见图6(b));随着lnZ值降低到12.0(450 ℃,0.01 s-1)时,位错密度显著降低,再结晶晶粒尺寸增大且晶界更加明晰锋锐,这表明此时动态再结晶过程占主导地位,如图6(c)所示。出现这种现象的原因在于当温度较高时,原子热激活能力增强,可以激活原来不利于变形的滑移系,从而形成更多的亚晶界,亚晶在应力和热激活作用下吸收亚晶界附近的大量位错并逐渐成长为细小的再结晶晶粒。因此,变形温度越高(即lnZ值越小),变形后的合金位错密度越低,晶界越清晰,动态再结晶尺寸也越大。

图4  =0.001 s-1时不同温度条件下的喷射成形7055铝合金热压缩金相组织

=0.001 s-1时不同温度条件下的喷射成形7055铝合金热压缩金相组织

Fig. 4 Optical microstructure of spray-formed 7055 aluminum alloy at strain rate of 0.001 s-1 and different temperatures

图5 450 ℃时不同应变速率下的喷射成形7055铝合金热压缩金相组织

Fig. 5 Optical microstructure of spray-formed 7055 aluminum alloy at 450 ℃ and different strain rates

图6 不同热变形条件下喷射成形7055铝合金的TEM像

Fig. 6 TEM images of spray formed 7055 aluminum alloy under different hot deformation conditions

结合表1和以上分析,不难发现动态再结晶过程在lnZ值越小的时候更容易发生。即随着温度升高或应变速率降低,该合金的组织变化趋势为由动态回复的特征组织向动态再结晶的特征组织转变。值得注意的是,图6(d)中可以观察到许多纳米级、弥散分布、与基体共格的Al3Zr粒子,该粒子具有L12型立方结构[29-30],对位错和亚晶界具有强烈的钉扎作用,因此可以阻碍变形过程中再结晶的发生。

3 结论

1) 喷射成形7055铝合金的热压缩峰值应力随着温度的升高,应变速率的降低而逐渐减小。

2) 采用Sellars和Tegart提出的双曲线正弦本构方程模型并使用线性回归的方法求得喷射成形7055的高温热变形的4个参数,结构因子A=1.04×106 s-1,应力水平参数α=0.01550 MPa-1,应力指数n=4.72298,变形激活能Q=99.68 kJ/mol;并且该合金的高温流变力学行为满足以下本构方程:

3) 喷射成形7055铝合金热变形过程中组织演变可以使用Zener-Hollomon参数定量表征,其软化机制主要为动态回复和动态再结晶。随着lnZ值的降低,合金的软化机制由动态回复逐渐转变为动态再结晶且再结晶晶粒尺寸越来越大。纳米级的Al3Zr粒子可以有效阻碍合金热变形过程中再结晶。

REFERENCES

[1] Rajamuthamilselvan M, Ramanathan S. Hot deformation behavior of 7075 alloy[J]. Journal Alloys and Compounds, 2011, 509: 948-952.

[2] Jin N P, Zhang H, Han Y, WU W X, CHEN J H. Hot deformation behavior of 7150 aluminum alloy during compression at elevated temperature[J]. Material Characterization, 2009, 60: 530-536.

[3] ZHEN L, HU H, WANG X Y, WANG X Y, ZHANG B Y, SHAO W Z. Distribution characterization of boundary misorientation angle of 7050 aluminum alloy after high-temperature compression[J]. Journal of Materials Processing Technology, 2009, 209: 754-761.

[4] 陈学海, 陈康华, 梁 信, 陈送义, 方华婵. 7085铝合金热变形的流变应力行为和显微组织[J]. 粉末冶金材料科学与工程, 2011, 16(2): 225-230.

CHEN Xue-hai, CHEN Kang-hua, LIANG Xin, CHEN Song-yi, FANG Hua-chan. Flow stress behavior and microstructure of 7085 aluminum alloy during hot deformation[J]. Material Science and Engineering of Powder Metallurgy, 2011. 16(2): 225-230.

[5] GOURDET S, MONTHEILLET F. A model of continuous dynamic recrystallization[J]. Acta Materialia, 2003, 51: 2685-2699.

[6] 王少阳, 陈文琳, 李志杰, 杨 栋, 周 瑞. 金属热变形组织晶粒度预报的应用现状[J]. 热加工工艺, 2012,41(6): 165-167.

WANG Shao-yang, CHEN Wen-lin, LI Zhi-jie, YANG Dong, ZHOU Rui. Application status of hot deformation metal grain size predicted[J]. Hot Working Technology, 2012, 41(6): 165-167.

[7] DENG Y, YIN Z M, HUANG J W. Hot deformation behavior and microstructural evolution of homogenized 7050 aluminum alloy during compression at elevated temperature[J]. Materials Science and Engineering A, 2011, 528: 1780-1786.

[8] LI B, Pan Q L, YIN Z M. Microstructural evolution and constitutive relationship of Al-Zn-Mg alloy containing small amount of Sc and Zr during hot deformation based on Arrhenius-type and artificial neural network models[J]. Alloys and Compounds, 2014, 584: 406-416.

[9] LIU W Y, ZHAO H, LI D. Hot deformation behavior of AA7085 aluminum alloy during isothermal compression at elevated temperature[J]. Materials Science and Engineering A, 2014, 596: 176-182.

[10] LI B, PAN Q L, YIN Z M. Characterization of hot deformation behavior of as-homogenized Al-Cu-Li-Sc-Zr alloy using processing maps[J]. Materials Science and Engineering A, 2014, 614: 199-206.

[11] LIN J P, LEI T C, AN X Y. Dynamic recrystallization during hot compression in Al-Mg alloy[J]. Scripta Metallurgica et Materialia, 1992, 26(12): 1869-1874.

[12] YAN Liang-ming, SHEN Jian, LI Zhou-bing. Effect of deformation temperature on microstructure and mechanical properties of 7055 aluminum alloy after heat treatment[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 625-630.

[13] 李周兵, 闫亮明, 沈 建. 热轧变形量对7055铝合金组织与力学性能的影响[J]. 特种铸造及有色合金, 2013, 33(1): 1-4.

LI Zhou-bing, YAN Liang-ming, SHEN Jian. Effect of hot rolling deformation amount on microstructure and mechanical properties of 7055 aluminum alloy[J]. Special Casting and Nonferrous Alloys, 2013, 33(1): 1-4.

[14] 李 晨, 李志辉, 黄树晖, 李锡武, 闫宏伟, 刘红伟, 张永安, 熊柏青. 7055铝合金多道次热变形及固溶处理中的组织演 变[J]. 材料热处理学报, 2015, 36(12): 55-60.

LI Chen, LI Zhi-hui, HUANG Shu-hui, LI Xi-wu, YAN Hong-wei, LIU Hong-wei, ZHANG Yong-an, XIONG Bai-qing. Microstructure evolution of 7055 aluminum alloy during multi-pass hot deformation and solution treatment process[J]. Transactions of Materials and Heat Treatment, 2015, 36(12): 55-60.

[15] 祝令状, 李忠华, 张 桢, 周小军. 喷射成形7055铝合金热变形行为模拟[J]. 航空材料学报, 2016, 36(1): 18-25.

ZHU Ling-zhuang, LI Zhong-hua, ZHANG Zhen, ZHOU Xiao-jun. Hot deformation simulation of spray formed 7055 aluminum alloy[J]. Journal of Aeronautical Materials, 2016, 36(1): 18-25.

[16] 闫亮明, 沈 建, 李周兵, 李俊鹏, 闫晓东, 毛柏平. 基于神经网络的7055铝合金流变应力模型和加工图[J]. 中国有色金属学报, 2010, 20(7): 1296-1301.

YAN Liang-ming, SEHNG Jian, LI Zhou-bing, LI Jun-peng, YAN Xiao-dong, MAO Bai-ping. Modelling for flow stress and processing map of 7055aluminum alloy based on artificial neural networks[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1296-1301.

[17] SAKAI T, BELYAKOV A. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions[J]. Progress in Materials Science, 2014, 60: 130-207.

[18] Cerri E, Evangelista E, Forcellese A, MCQUEEN H J. Comparative hot workability of 7012 and 7075 alloys after different pretreatment[J]. Materials Science and Engineering A, 1995, 197: 181-198.

[19] McQueen H J, Ryan N D. Constitutive analysis in hot working[J]. Materials Science and Engineering A, 2002, 322: 43-63.

[20] Zener C, Hollomon J H. Effect of strain rate upon plastic flow of steel[J]. Journal of Applied Physics, 1944, 15: 22-27.

[21] Hu H E, Zhen L, ZHANG B Y, Yang L, CHEN J Z. Deformation behavior and microstructure evolution of 7050 aluminum alloy during high temperature deformation[J]. Materials Science and Engineering A, 2008, 488: 64-71.

[22] MENG G, LI B l, LI H m, HUANG H, NIE Z R. Hot deformation and processing maps of an Al-5.7wt.%Mg alloy with erbium[J]. Materials Science and Engineering A, 2009, 517: 132-137.

[23] Medina S F, Hernandez C A. General expression of the Zener-Hollomon parameter as a function of the chemical composition of low alloy and microalloyed steels[J]. Acta Materialia, 1996, 44(1): 137-148.

[24] Abbasi S M, Shokuhfar A. Prediction of hot deformation behavior of 10Cr-10Ni-5Mo-2Cu steel[J]. Materials Letters, 2007, 61: 2523-2526.

[25] Zhou M, Clode M P. Constitutive equations for modeling flow softening due to dynamic recovery and heat generation during plastic deformation[J]. Mechanics of Materials, 1998, 27: 63-76.

[26] LI W, LI H, Wang Z X, ZHENG Z Q. Constitutive equations for high temperature flow stress prediction of Al-14Cu-7Ce alloy[J]. Materials Science and Engineering A, 2011, 528: 4098-4103.

[27] Rokni M R, Zarei-Hanzaki A, Roostaei A A, ABEDI H R. Constitutive base analysis of a 7075 aluminum alloy during hot compression testing[J]. Materials and Design, 2011, 32: 4955-4960.

[28] ZHANG H, JIN N p, CHEN J h. Hot deformation behavior of Al-Zn-Mg-Cu-Zr aluminum alloys during compression at elevated temperature[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(2): 437-442.

[29] KNIPLING K, DUNAND D, SEIDMAN D. Precipitation evolution in Al-Zr and Al-Zr-Ti alloys during aging at 450~600 ℃[J]. Acta Materialia, 2008, 56: 1182-1195.

[30]  M, PONGRATZ P, DEGISCHER H P. Coherency loss of Al3(Sc,Zr) precipitates by deformation of an Al-Zn-Mg alloy[J]. Acta Materialia, 2012,60: 4247-4254.

M, PONGRATZ P, DEGISCHER H P. Coherency loss of Al3(Sc,Zr) precipitates by deformation of an Al-Zn-Mg alloy[J]. Acta Materialia, 2012,60: 4247-4254.

Hot deformation behavior and microstructure evolution of spray formed 7055 aluminum alloy

XIONG Shang-wu1, PAN Qing-lin2, ZHANG Hao3, FAN Xi3, WANG Xiang-dong2, LIU Li-li2

(1. Central South Light Alloys, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

3. Jiangsu Haoran Spray Forming Alloys Co., Ltd., Zhengjiang 212009, China)

Abstract: The hot compression tests of spray formed 7055 aluminum alloy after densification were performed on Gleeble-3500 system in the temperature range from 340 ℃ to 450 ℃ and at strain rate range from 0.001 s-1 to 1 s-1. The sample after hot compression was observed using optical microscopy and transmission electron microscopy. The results show that the peak stress levels decrease with the increase of deformation temperature or the decrease of strain rate. The flow stress behavior of the alloy during hot compression can be represented by equation of hyperbolic sine form, which can be also described by Zener-Hollomon parameter. The microstructure evolution of spray formed 7055 aluminum alloy can be quantificationally characterized by Zener-Hollomon parameter and the main softening mechanism is dynamic recovery and dynamic recrystallization. With the decreasing of Z value, the softening mechanism of alloy gradually transformed from dynamic recovery to dynamic recrystallization and the size of recrystallized grains become larger and larger. Nano-scaled Al3Zr particles of high densities precipitating in the aluminum after deformation can effectively inhibit the dynamic recrystallization of experiment alloy.

Key words: spray formed 7055 aluminum alloy; hot deformation; constitutive equation; softening mechanism

Foundation item: Project supported by the Special Materials Project of National Large Aircraft Engineering, China

Received date: 2017-03-06; Accepted date: 2017-05-03

Corresponding author: PAN Qing-lin; Tel: +86-731-88876378; E-mail: pql@csu.edu.cn

(编辑 何学锋)

基金项目:国家大飞机工程材料专项资助项目

收稿日期:2017-03-06;修订日期:2017-05-03

通信作者:潘清林,教授,博士;电话:0731-88876378;E-mail:pql@csu.edu.cn