几何特征对高深宽比微结构零件注射成型充填深度的影响

蒋炳炎,楚纯朋,汤美林,沈龙江

(中南大学 机电工程学院,湖南 长沙,410083)

摘 要:采用基于Navier-Stokes运动方程开发的Moldflow MPI 6.0软件,以聚甲基丙烯酸甲酯 (PMMA)材料为对象, 在型腔压力为100 MPa、熔体温度为250 ℃、不同模具温度下,研究零件几何特征(微结构所在位置、微结构形状、微结构截面尺寸、微结构深宽比和微结构型腔截面尺寸)对微结构充填深度的影响。研究结果表明:微结构与型腔末端间距越小,充填越深,但当微结构与型腔末端间距超过某一值时,微结构充填深度与其位置无关;微结构倾角越小,充填越深;微结构截面尺寸越大,充填时熔体所受阻力越小,充填越深;型腔截面尺寸与微结构尺寸相差越小,越有利于微结构充填;微结构充填深度与其深宽比无关。

关键词:微结构零件;充填深度;深宽比;几何特征

中图分类号:TG249.9 文献标识码:A 文章编号:1672-7207(2008)05-1000-05

Influence of part’s geometry characters on filling length of injection molded parts with high aspect ratio micro structures

JIANG Bing-yan, CHU Chun-peng, TANG Mei-lin, SHEN Long-jiang

(School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: With Moldflow MPI 6.0 software based on Navier-Stokes momentum equation for PMMA material, the influences of geometry characters of a part, such as micro structures’ position, shape, section dimension, aspect ratio and cavity’ width, on the filling length of micro structures were investigated under the cavity pressure 100 MPa, and at melt temperature 250 ℃ with different mold temperatures. The results show that the distance between microstructure and cavity terminal is smaller, the filling is longer, but when the distance surpasses one value, the filling length has nothing to do with the position of the microstructure. The smaller the microstructure inclination angle, the longer the filling. The bigger the size of microstructure section, the smaller the resistance of the melts in filling, and the longer the filling. The difference between the size of the cavity section and the size of the microstructure is less, the filling is more advantageous, but the filling length of microstructure has nothing to do with the high aspect ratio.

Key words: parts with micro structures; filling length; high aspect ratio; geometry character

随着微/纳米科学技术的不断发展,对高深宽比微结构零件的需求越来越大[1-2]。微注射成型技术是生产批量、高效、低耗、精密成型微结构零件的最佳技术之一。然而,由于微结构零件型腔远远小于常规型腔,不但增加了熔体充填难度,同时,也提高了熔体冷却速度,因此,高深宽比微结构零件成型极其困难[3-7]。微结构充填深度是微结构零件的关键参数之一。YU等[8-9]以聚丙烯(PP)和聚甲基丙烯酸甲酯(PMMA)材料为对象,对深宽比为5,微结构宽度为50 μm或100 μm的较长和较短2种矩形模型进行注射成型仿真,发现微结构的充填深度与注射速度、模具温度、熔体流变能力以及微结构的位置有关,且模具温度影响最大。Young[10]的研究结果表明,微结构的充填深度与模具温度和注射速度有关,而且微结构越宽,其充填越深。Shen等[11-12]以齿轮为例,研究了注射时间、模具温度、注射温度以及注射压力等成型参数对微结构充填的影响,认为模具温度是影响最大的成型工艺参数[13-15]。目前,微结构注射成型的成型工艺参数是学术界研究的重点,但是,人们对几何特征对微结构充填深度的影响研究较少。在此,本文作者研究微结构位置、形状、截面尺寸、深宽比以及型腔的截面尺寸对微结构充填深度的影响。

1 虚拟实验方案

1.1 物理模型

微结构注射成型件是微注射成型零件中一类非常重要的零件,它是指零件质量不以mg为计量单位,主体尺寸大于1 mm,但是具有微米级的结构或精度,如导光板、DVD/CD光碟、微透镜、微流体芯片等。根据这一定义,抽象出微结构注射成型件2D物理模型,如图1所示。其中: 为微结构到浇口所在边平行距离;

为微结构到浇口所在边平行距离; 为型腔高度;

为型腔高度; 为微结构高度;

为微结构高度; 为微结构宽度;

为微结构宽度; 为型腔长度,为8 mm;

为型腔长度,为8 mm; /

/ 为微结构深宽比;θ为微结构倾角。图1(c)所示为多微结构物理模型,各微结构宽均为0.1 mm,模型高为2 mm,厚为1 mm,各微结构位置从左到右依次为A,B,C,D,E和F。

为微结构深宽比;θ为微结构倾角。图1(c)所示为多微结构物理模型,各微结构宽均为0.1 mm,模型高为2 mm,厚为1 mm,各微结构位置从左到右依次为A,B,C,D,E和F。

(a) 单微结构物理模型;(b) 微结构放大图;(c) 多微结构物理模型

图1 微结构注射成型件2D物理模型

Fig.1 2D physical model of injection molded parts with micro structures

1.2 模型建立与网格划分

利用Pro/ENGINEER Wildfire2.0 建立微结构零件模型。由于网格质量直接影响后续数值计算分析结果的精确性,质量太差的网格甚至会导致计算中止,所以,将网格导入HYPERMESH中进行前处理。Lee[16]的研究结果表明,中平面网格不能处理非均匀几何特征,且其不适用网格密度相差很大的模型,因此,对微结构注射成型件采用3D网格进行划分。为了获得微结构充填深度的准确值,加速计算的收敛速度,在微结构及其附近区域采用较高的网格划分密度,然后,导入MoldFlow软件中再次生成3D网格,微结构处网格划分如图2所示。采用扇形浇口,直接设在模型左边,使熔体从型腔左边流往右流。

图2 微结构网格处理

Fig.2 Gridding on micro structure

1.3 试验材料

材料采用LG Chemical公司型号为IG-840的聚甲基丙烯酸甲脂( PMMA),其性能参数如表1所示。

表1 材料PMMA性能参数

Table 1 Characteristic parameters of PMMA

2 仿真结果与分析

虚拟实验中将型腔压力设为100 MPa,熔体温度为250 ℃,在不同模具温度下,采用MoldFlow MPI 6.0的Flow功能模块对各种不同物理模型进行充填仿真,以研究微结构所在位置、微结构截面尺寸、微结构形状、微结构深宽比以及型腔截面尺寸对微结构充填深度的影响。

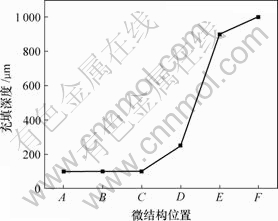

2.1 微结构位置对充填深度的影响

图1(c)所示的多微结构注射成型件模型,微结构A,B,C,D,E和F距型腔末端的距离依次减小。为使仿真效果更加明显,在模具温度tw=25 ℃时进行仿真分析。微结构距离浇口较近时,其充填深度较低,随着距离的增大,微结构的充填深度逐渐增大,最后趋于定值,如图3所示。当物料到达微结构的入口处时,因为型腔尚未充满,未形成足够的压力,因此,在入口处发生冻结,塑料不再流入;当型腔充满达到高压后,物料会依次冲破冻结时间较短的微结构入口,对微结构进行充填。因此,离浇口越远的微结构充填深度越大。

图3 微结构位置对其充填深度的影响

Fig.3 Influence of micro structures’ position on its filling length

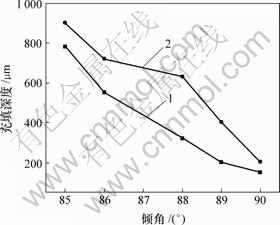

2.2 微结构形状对充填深度的影响

图1(b)中θ表示微结构倾角角度。当 长度不变,倾角不同时,微结构形状也不同。为了研究微结构截面形状对其充填深度的影响,在模具温度分别为90 ℃和95 ℃时,对不同倾角的微结构进行仿真分析。随着微结构倾角角度的减小,微结构的充填深度逐渐增加,如图4所示。微结构倾角角度越小,熔体从型腔进入微结构时方向角改变得越小。故当微结构相同时,截面速度越大,微结构充填越深。

长度不变,倾角不同时,微结构形状也不同。为了研究微结构截面形状对其充填深度的影响,在模具温度分别为90 ℃和95 ℃时,对不同倾角的微结构进行仿真分析。随着微结构倾角角度的减小,微结构的充填深度逐渐增加,如图4所示。微结构倾角角度越小,熔体从型腔进入微结构时方向角改变得越小。故当微结构相同时,截面速度越大,微结构充填越深。

1—90 ℃; 2—95 ℃

图4 微结构形状对其充填深度的影响

Fig.4 Influence of micro structures’ shape on its filling length

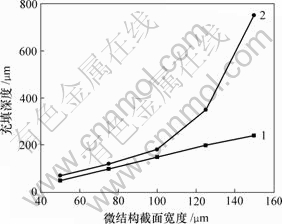

2.3 微结构截面尺寸对充填深度的影响

如图1(a)所示, =

= ,改变长度

,改变长度 ,但深宽比均为10,分别在模具温度为90 ℃和95 ℃时进行充填仿真,结果如图5所示。可见,随着微结构截面尺寸的增加,其充填深度逐渐增大;微结构截面尺寸 越大,熔体从型腔进入微结构时受到的流动阻力越小,微结构越容易充填;微结构截面尺寸越大,熔体与模壁的相对接触面积越小,熔体的冷却时间也就越长,从而增加了熔体在微结构里的流动深度。

,但深宽比均为10,分别在模具温度为90 ℃和95 ℃时进行充填仿真,结果如图5所示。可见,随着微结构截面尺寸的增加,其充填深度逐渐增大;微结构截面尺寸 越大,熔体从型腔进入微结构时受到的流动阻力越小,微结构越容易充填;微结构截面尺寸越大,熔体与模壁的相对接触面积越小,熔体的冷却时间也就越长,从而增加了熔体在微结构里的流动深度。

1—90 ℃; 2—95 ℃

图5 微结构截面尺寸对其充填深度的影响

Fig.5 Influence of micro structures’ section dimension on its filling length

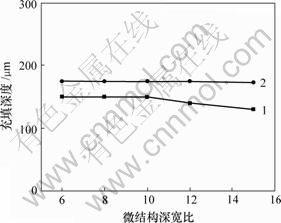

2.4 微结构深宽比对充填深度的影响

如图1(a)所示,宽度均为100 μm,改变微结构的深宽比,在模具温度分别为90 ℃和95 ℃时进行充填仿真。可见,当模具温度tw=90 ℃时,深宽比小于10的微结构充填深度相差不大,但随着深宽比的增大,微结构充填深度逐渐减小,但改变量不大;当tw= 95 ℃时,各种微结构充填深度几乎一致,如图6所示。可见,微结构深宽比增大只会加快进入微型腔熔体的冷却速度,从而影响微结构的充填,但是,随着模具温度的增加,这种影响就会逐渐减小,甚至消失。

1—90 ℃; 2—95 ℃

图6 微结构深宽比对其充填深度的影响

Fig.6 Influence of micro structures’ aspect ratio on its filling length

2.5 型腔截面尺寸对充填深度的影响

如图1(a)所示,afgh表示型腔截面,分别改变型腔宽度和型腔高度,在模具温度分别为90 ℃和95 ℃时,对其进行仿真分析,结果见图7。可见,随着型腔截面尺寸的减小,微结构的充填深度在总体上逐渐增大。微结构截面与型腔截面相差越小,熔体流进微结构时所受的阻力越小,充填深度也就越深。

1—90 ℃; 2—95 ℃

(a) 型腔宽度;(b) 型腔高度

图7 型腔截面尺寸对微结构充填深度的影响

Fig.7 Influence of cavity’ section dimension on micro structures’ filling length

3 结 论

a. 微结构充填深度与其位置有关,微结构与型腔末端间距越小,充填越深,且充填深度与其型腔末端间距呈非线性递减,但当微结构与型腔末端间距超过某一值时,微结构充填深度与其位置无关。

b. 微结构充填深度与其形状有关,微结构倾角越小,充填越深。

c. 微结构充填深度与其截面尺寸有关,微结构截面尺寸越大,充填时熔体所受阻力越小,充填越深。

d. 微结构充填深度与其深宽比无关,即截面尺寸相同,而深宽比不同的微结构在相同条件下,其充填深度几乎相同。

e. 微结构充填深度与型腔截面尺寸有关,型腔截面尺寸与微结构尺寸相差越小,越有利于微结构充填。

参考文献:

[1] R?tting O, R?pke W, Becker H, et al. Polymer microfabrication technologies[J]. Microsystem Technologies, 2002, 8(1): 32-36.

[2] Studer V, Pépin A, Chen Y. Nanoembossing of thermoplastic polymers for microfluidic applications[J]. Applied Physics Letters, 2002, 80(19): 3614-3616.

[3] Yao D. Rapid thermal response injection molding for microfabrication[D]. Amherst: The University of Massachusetts, 2001.

[4] Harris C, Despa M S, Kelly K W. Design and fabrication of a cross flow micro heat exchanger[J]. Microelectromechanical Systems, 2002, 9(4): 502-508.

[5] 钱晓蓉, 沈宏继. 微流体动力学研究发展与现状[J]. 航空精密制造技术, 2005, 41(6): 11-14.

QIAN Xiao-rong, SHEN Hong-ji. Development on hydrokinetic of microfluidic flow[J]. Aviation Precision Manufacturing Technology, 2005, 41(6): 11-14.

[6] Kari M, Joni H, Pertti P, et al. Replication of submicron features using amorphous thermoplastics[J]. Polymer Engineering and Science, 2002, 42(7): 1600-1608.

[7] 蒋炳炎, 翁 灿, 罗建华, 等. 考虑结晶潜热的LDPE微结构件注射成型模内温度场[J]. 中南大学学报: 自然科学版, 2006, 37(3): 532-536.

JIANG Bing-yan, WENG Can, LUO Jian-hua, et al. Cavity temperature of LDPE injection molded parts with microstructure region considering latent heat[J]. Journal of Central South University: Science and Technology, 2006, 37(3): 532-536.

[8] XU Guo-jun, YU Li-yong, Lee L J, et al. Experimental and Numerical studies of injection molding with microfeatures[J]. Polymer Engineering and Science, 2005, 45(6): 866-875.

[9] YU Li-yong, Chee G K, Lee L J. Experimental investigation and numerical simulation of injection molding with micro-features[J]. Polymer Engineering and Science, 2002, 42(5): 871-888.

[10] Young W B. Simulation of the filling process in molding components with micro channels[J]. Microsystem Technologies, 2005, 2: 410-415.

[11] Shen Y K, Wu W Y. An analysis of the three dimensional micro injection molding[J]. International Communications in Heat and Mass Transfer, 2002, 29(3): 423-431.

[12] Shen Y K, Yeh S L, Chen S H. Three dimensional non Newtonian computations of micro injection molding with the finite element method[J]. International Communications in Heat and Mass Transfer, 2002, 29(5): 643-652.

[13] Sha B, Dimov S S, Pham D T, et al. Study of factors affecting aspect ratios achievable in micro-injection molding[C]// Proceedings of First International Conference on Multi-Material Micro Manufacture. Kurstruhe, Germany, 2005: 107-110.

[14] Despa M S, Kelly K W, Collier J R. Injection molding using high aspect ratio micro structures mold inserts produced by L IGA techniques [C]//Proceedings of SPIE —The International Society for Optical Engineering. Bellingham: SPIE, 1998: 286-294.

[15] Michaeli W, Spennemann A. A new injection molding technology for micro parts[J]. Journal of Polymer Engineering, 2001, 21(23): 87-98.

[16] Lee J L. Modeling and simulation in polymer micro-injection molding[C]//第一届高聚物成形加工与材料物性预测国际学术研讨会论文集. 北京: 化学工业出版社, 2006: 15-30.

Lee J L. Modeling and simulation in polymer micro-injection molding[C]//Proceeding of the 1st International Congress on Modeling, and Simulation in Polymer Engineering and Science. Beijing: Chemical Industry Press, 2006: 15-30.

收稿日期:2007-12-08;修回日期:2008-03-06

基金项目:国家自然科学基金资助项目(50475140)

通信作者:蒋炳炎(1963-),男,浙江浦江人,教授,从事微注射成型理论和应用研究;电话:0731-8836035;E-mail: jby@mail.csu.edu.cn