文章编号:1004-0609(2016)-01-0016-07

铜含量对Al-50%Sip复合材料显微组织和力学性能的影响

吴 翔,王日初,彭超群,蔡志勇

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用热压法制备添加0~6%铜含量(质量分数)的Al-50%Sip(质量分数)复合材料,研究Cu含量对复合材料显微组织和力学性能的影响,对混合粉末进行差示扫描量热分析(DSC),采用扫描电镜(SEM)和X射线衍射仪(XRD)研究试样的显微组织和相组成,并测试复合材料的拉伸和抗弯性能。结果表明:单质Cu粉的加入降低混合粉末的熔点,有利于在相对较低的温度下实现材料的致密化。当Cu含量低于2%时,材料的组织均匀致密,Si颗粒未出现明显粗化;但当Cu含量高于2%时,组织均匀性随Cu含量的增加而逐渐下降;随着Cu含量增加,复合材料的抗拉强度和抗弯强度呈先上升后下降的趋势;在Cu含量为2%时,复合材料的抗拉强度和抗弯强度分别达到最大值(268和423 MPa),较未添加Cu的复合材料分别提高66.5%和46.9%,材料的弹性模量和布氏硬度随Cu含量的增加逐渐上升。

关键词:铝硅复合材料;Al-50%Sip合金;热压;显微组织;抗拉强度;抗弯强度;弹性模量;硬度

中图分类号:TG146.2 文献标志码:A

硅颗粒增强铝基复合材料是一种具有轻质、低膨胀、高导热、机加工性能好以及物理性能可设计等优点的电子封装材料,且价格相对低廉,可回收利用,符合当今世界可持续发展的要求,由此获得越来越多国内外学者的关注[1-3]。

目前,制备硅颗粒增强铝基复合材料的方法主要有熔铸法[4]、熔渗法[5]、喷射沉积法[6-8]、粉末冶金法以及真空热压法[9]。熔铸法设备简单、成本低,但Si相尺寸过于粗大,同时难以避免疏松、缩孔等问题[10]。熔渗法难以获得具有一定强度和孔径的骨架,且由于Al液不能完全浸透骨架,导致材料难以完全致密化。喷射沉积法制备的坯件无宏观偏析,显微组织细小均匀,但制备工艺复杂且设备要求较高。由于沉积锭坯存在一定的孔隙度,必须经过后续加工来提高其致密度。传统的粉末冶金法是将一定比例的铝粉和硅粉以及粘结剂均匀混合,先压制成型再置于保护气氛下烧结致密化,要求硅含量不能太高,且存在粉末易氧化和材料不够致密等缺点。热压法与传统的粉末冶金法最大的不同是其在真空和较大的压力条件下烧结成型,可获得近乎完全致密化的材料,且Al-Si界面结合良好,综合性能优良。

近年来,硅颗粒增强铝基复合材料的研究取得一定进展,但在实际应用过程中也暴露出一系列问题,如强度达不到使用要求、高盐环境下耐腐蚀性能力较差以及焊接过程中易开裂等,这主要是由于硅颗粒增强铝基复合材料的研究主要集中在材料的制备工艺和性能方面,没有对基体的微合金化进行深入的研究。

本文作者通过热压法制备Cu含量为0~6%(质量分数)的Al-50%Sip(质量分数)复合材料,并通过固溶和时效处理对复合材料进行强化,研究Cu含量对Al-50%Sip复合材料的组织和力学性能的影响。

1 实验

本实验所用原材料由中南大学金属研究所提供,Al-50%Si(质量分数)粉末(纯度为99.9%)和电解Cu粉(纯度为99.9%)粒度均小于75 μm。首先将Al-50%Si粉末和Cu粉分别按质量比均匀混合,如表1所列。将混合粉末装入尺寸为50 mm×50 mm的硬质合金模具中冷压成型,压力为350 MPa,保压时间为20 min,得到相对密度为80%~85%的冷压坯料。在石墨模具(尺寸为50 mm×50 mm)内表面均匀涂上一层BN浆料,烘干后将冷压坯料置于其中进行热压烧结,烧结

压力为40 MPa,升温速率为10 ℃/min,烧结温度为560 ℃,保压时间为120 min,烧结后试样尺寸为50 mm×50 mm×10 mm。然后对试样进行固溶和时效处理,固溶处理工艺为:510 ℃保温4 h淬火,时效处理工艺为在150 ℃时效24 h。

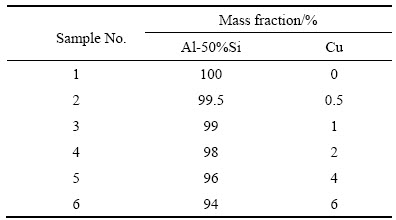

表1 试样成分

Table 1 Compositions of samples

采用Perkin-Elmer DSC 7型差示扫描量热分析仪分析混合粉末的热性能。材料热处理在箱式电阻炉中进行。试样经磨样、抛光和腐蚀后在FEI QUANTA-200扫描电子显微镜上观察其显微组织。采用810 Material Test System型进行室温拉伸实验和三点抗弯测试,加载速率均为0.2 mm/min,变形试样横截面为矩形,平行端直径为5 mm,标距为15 mm。抗弯试样尺寸为5 mm×12 mm×50 mm,跨距为30 mm,拉伸试样和抗弯试样每组3根,测试结果取平均值。利用HBV-30X型布氏硬度仪测量5个点的硬度值,载荷为7.35 kN,加载时间为30 s,测试结果取平均值。采用阿基米德排水法测量材料密度。

2 结果与讨论

2.1 DSC分析

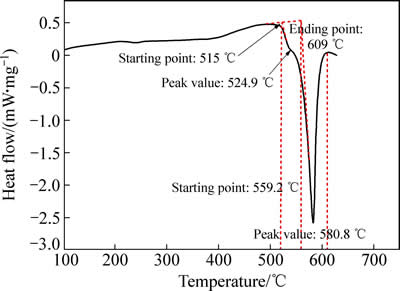

图1所示为Al-50%Si粉末添加2% Cu混合粉末的DSC曲线。由图1可知,混合粉末在100~650 ℃之间有两个熔化吸热峰,第一个峰不是很明显,起始于515 ℃,说明混合粉末在该温度下开始发生反应,因此复合材料的固溶温度应低于515 ℃,且尽量接近该温度。第一个峰的峰值对应524.9 ℃,由于与第二个峰离得比较近而产生部分重叠;根据Al-Si-Cu三元相图,525 ℃为Al-Si-Cu三元共晶点。最大共晶吸热峰起始于559.2 ℃,峰值位于580.8 ℃;根据Al-Si二元相图,577 ℃为Al-Si二元共晶点,这与DSC检测结果非常接近。当温度升到609 ℃时,混合粉末全部熔化为液相。根据DSC曲线可知,Cu元素的加入能有效降低合金粉末的熔点,560 ℃热压时即可产生部分液相,从而在相对较低的温度就能实现复合材料的致密化,并有效抑制Si相的粗化,提高材料的力学性能[11]。

图1 添加2% Cu的Al-50%Sip粉末DSC曲线

Fig. 1 DSC curves of Al-50%Sip powder adding 2% Cu

2.2 Cu含量对Al-50%Sip复合材料显微组织的影响

图2所示为不同Cu含量Al-50%Sip复合材料的显微组织。复合材料的组织主要由Al基体和Si颗粒组成,两相界面结合良好,Si颗粒表面较圆滑,没有尖锐的棱角,且有不同程度的互连现象。如图2(a)所示,当不含Cu时,Si颗粒细小均匀,大小为2~12 μm,且2~5 μm的细颗粒较多,此时材料相对密度为99.5%。添加Cu的Al-50%Sip复合材料相对密度均接近或达到100%,在热压烧结过程中,Al-Si-Cu液相的产生促进粉末颗粒的重排,并起到粘结剂的作用,填充粉末颗粒之间的间隙和孔洞,使粉末颗粒之间粘结更紧密,从而实现复合材料的致密化[12]。当Cu含量低于2%时,随Cu含量增加,Si相分布没有明显变化,组织仍比较均匀,Si相仅发生少量长大,如图2(b)~(d)所示。当Cu含量达到4%时,少数Si颗粒出现粗化,组织均匀性下降,如图2(e)所示。特别是当Cu含量达到6%时,晶粒异常长大特别明显,部分Si颗粒达50 μm以上,组织很不均匀,如图2(f)所示。可知,当Cu含量高于4%时,Cu元素的添加将严重破坏Al-50%Sip复合材料组织的均匀性。

Al-50%Sip复合材料热压过程中Si颗粒的长大可以用Ostwald熟化理论解释。由混合粉末DSC曲线(见图1)可知,复合材料在560 ℃热压烧结时出现部分液相,液相烧结时颗粒尺寸越大,其长大驱动力越大,而颗粒长大的速度与颗粒大小的差值有关,差值越大,长大速度越快[13-15]。在热压烧结过程中,细小的Si颗粒会优先溶解并聚集在较大Si颗粒上。在一定范围内,Cu含量越高,出现的液相越多,细小Si颗粒的溶解速率以及Si在基体中的扩散速率也越大。当Cu含量低于2%时,基体中生成的液相较少,细小Si颗粒溶解和扩散的速率较低,能均匀地在较大Si颗粒表面析出,表现为大部分Si颗粒均匀长大,没有明显粗化。当Cu含量高于4%时,生成的液相较多,此时细小的Si颗粒的溶解和扩散过程大大加快,导致图2(e)和(f)中的Si颗粒异常长大。

图2 不同Cu含量的Al-50%Sip复合材料显微组织

Fig. 2 Microstructures of Al-50%Sip composites with different Cu contents

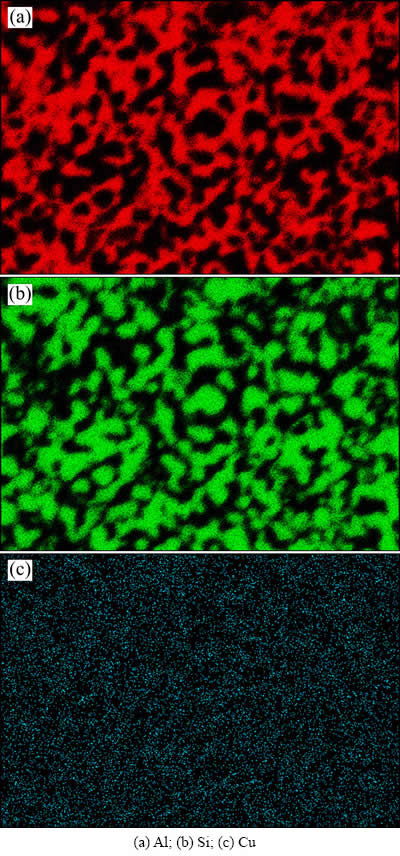

图3所示为图2(c)的SEM面分析图,可知,Si颗粒和基体界限分明,没有发生有害的界面反应,Cu元素在Al基体中均匀分布,固溶和时效处理后没有富Cu相残留。

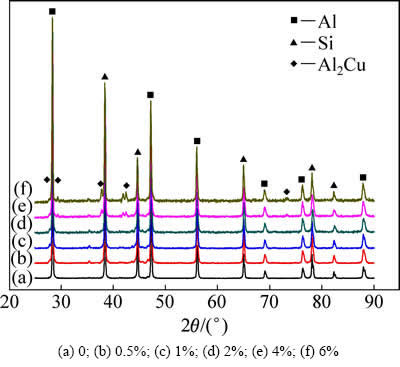

图4所示为不同Cu含量Al-50%Sip复合材料的XRD谱。未添加Cu的Al-50%Sip复合材料中只有α(Al)相和Si相,添加Cu的复合材料中还出现θ(Al2Cu)相,随着Cu含量增加,复合材料中的θ(Al2Cu)相含量不断增加。对于Al-Cu系基体合金,热压过程中Al和Cu相互扩散,在原始Cu颗粒处生成θ(Al2Cu)相,Al和θ(Al2Cu)相在548 ℃发生共晶反应生成液相[16-17]。这一过程在图1的DSC曲线中并没有得到体现,即在548 ℃处没有明显的吸热峰,只在524.9 ℃和580.8 ℃处检测到两个吸热峰,可能是由于548 ℃处的吸热峰被524.9 ℃和580.8 ℃处的两个吸热峰叠加覆盖。

2.3 Cu含量对Al-50%Sip复合材料力学性能的影响

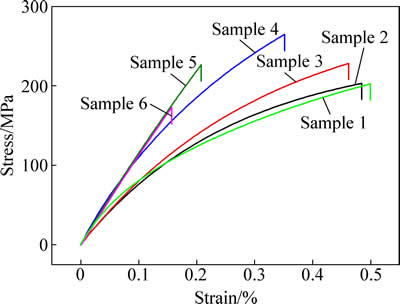

未添加合金元素的Al-50%Sip复合材料的强化机制主要是颗粒强化,添加合金元素后的复合材料还具有热处理强化的潜能[18]。添加Cu的Al-50%Sip复合材料在固溶和时效处理后析出的θ(Al2Cu)相非常细小,在扫描电镜下难以观察到。通过XRD谱能检测出少量θ(Al2Cu)相的存在,再结合SEM面分析图,可知θ(Al2Cu)相在基体中分布均匀,可起到强化基体的效果。图5所示为不同Cu含量的Al-50%Sip复合材料在固溶和时效处理后的拉伸应力-应变曲线。由图5可看出,Cu含量不同时,曲线走势和形状基本一致,说明不同Cu含量的Al-50%Sip复合材料有相似的流变应变特征。图5中曲线没有出现明显的屈服现象,这是由于复合材料中的Si含量高达50%,硬脆相较多,材料有较高的强度和刚度。随着Cu含量增加,材料的伸长率略微减小,材料的塑性随着Cu含量的增加越来越差。

图3 添加2% Cu的Al-50%Sip复合材料SEM元素面分析图

Fig. 3 Elemental maps of Al-50%Sip composite with 2% Cu

图4 Al-50%Sip复合材料的XRD谱

Fig. 4 XRD patterns of Al-50%Sip composites with different Cu contents

图5 不同Cu含量Al-50%Sip复合材料的应力-应变曲线

Fig. 5 Stress-strain curves of Al-50%Sip composites with different copper contents

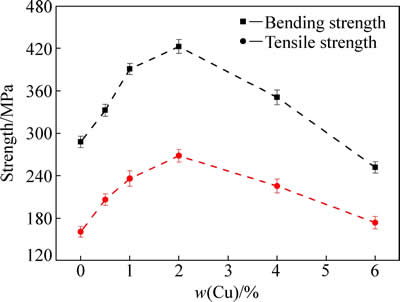

Al-50%Sip复合材料的抗拉强度和抗弯强度与Cu含量的关系如图6所示。由图6可看出,抗拉强度随Cu含量的增加先增大后减小,当Cu含量为2%时,达到最大值268 MPa,与未加Cu的Al-50%Sip复合材料的(161 MPa)相比提高66.5%;当Cu含量为6%时,相比未加Cu时抗拉强度几乎没有提高。抗弯强度和抗拉强度的变化趋势大致相同;当Cu含量为2%时,抗弯强度达到最大值(423 MPa),与未加Cu的Al-50%Sip复合材料的(288 MPa)相比提高46.9%;当Cu含量为6%时,抗弯强度甚至低于未加Cu的Al-50%Sip复合材料的。

图6 Al-50%Sip复合材料的抗拉强度和抗弯强度与Cu含量的关系

Fig. 6 Relationship between tensile strength, bending strength of Al-50%Sip composites and Cu content

添加合金元素的Al-50%Sip复合材料抗拉强度和抗弯强度主要取决于以下两个方面:一是增强体Si相的尺寸大小;二是合金元素对基体的强化作用。由图2可知,当Cu含量不超过2%时,Si颗粒没有发生异常长大现象,同时,由于θ(Al2Cu)相对基体的强化作用,复合材料的抗拉强度和抗弯强度得到较大提升。当Cu含量超过4%时,Si颗粒发生异常长大现象,破坏了组织均匀性,同时由于生成过多硬脆相θ(Al2Cu),Al-50%Sip复合材料的抗拉强度和抗弯强度明显下降。

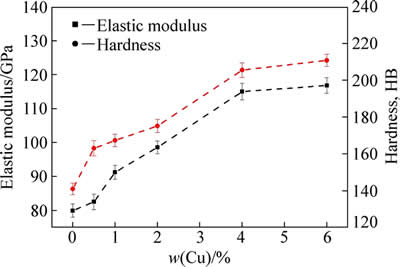

图7所示为Al-50%Sip复合材料的弹性模量和布氏硬度与Cu含量的关系。由图7可看出,随着Cu含量升高,复合材料的弹性模量和布氏硬度增加,两者的变化趋势基本相同,这是由于Cu固溶在Al中形成θ(Al2Cu)相,而θ(Al2Cu)相是一种熔点高、强度高、硬度高和脆性大的金属间化合物,添加的Cu越多,生成的θ(Al2Cu)相也越多,材料的硬度也就越高,其抵抗变形的能力也就越强,因此,复合材料的弹性模量也会随着Cu含量的增加逐渐增大。

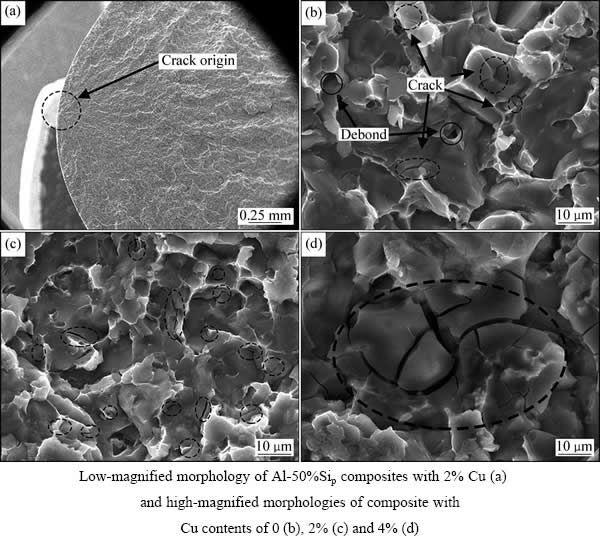

图8(a)所示为Cu含量2%的Al-50%Sip复合材料宏观断口,整个断面非常平整,断口垂直于拉伸方向,呈放射状花样,属于典型的脆性断裂。Cu含量对Al-50%Sip复合材料的宏观断口形貌没有很大影响,裂纹均萌生于拉伸试样表面,然后逐步向内部扩展,说明材料内部组织没有夹杂孔洞等缺陷。一般认为颗粒增强复合材料的力学性能随增强体颗粒尺寸增大而降低,但对于Al-50%Sip复合材料,其力学性能还与组织中的Si颗粒形态有关。如图8(b)所示,当不含Cu时,Si颗粒上有裂纹,极少数细小的Si颗粒从基体中脱粘,这是由于未加Cu的Al-50%Sip复合材料组织中2~5 μm的极细Si颗粒较多,部分Si颗粒没有相连,基体与Si颗粒界面结合强度不够高,而小颗粒增强复合材料容易发生增强体与基体脱粘[19],加之Al基体强度不够高,使Al-50%Sip复合材料的力学性能不够理想。当Cu含量低于2%时,断口的微观形貌基本相同,如图8(c)所示,Si颗粒没有发生脱粘现象,出现裂纹的Si颗粒数明显增加,这是由于大部分Si颗粒相互连接,且尺寸较均匀,在裂纹扩展过程中大部分Si颗粒所承受的位错应变能基本一致,表现为多个Si颗粒同时断裂。当Cu含量高于4%时,过多的Cu使Si颗粒不均匀长大,颗粒聚集区域的应力集中程度随聚集区长径比的增加而增加[19-20],因此大颗粒的Si所承受的载荷较多,材料内部Si颗粒上载荷分布不均匀导致大颗粒Si优先断裂,如图8(d)所示,大颗粒Si上产生较多的裂纹。因此,Cu含量过高反而导致复合材料的力学性能下降。

图7 Al-50%Sip复合材料的弹性模量和布氏硬度与Cu含量的关系

Fig. 7 Relationship between elastic modulus, Brinell hardness of Al-50%Sip composites and Cu content

图8 Al-50%Sip复合材料拉伸断口形貌

3 结论

1) 单质Cu粉的加入降低Al-50%Sip复合材料热压致密化的温度,部分液相的产生有利于粉末颗粒之间扩散粘结,从而实现材料的致密化。

2) 热压过程中液相的出现加速细小Si颗粒的溶解以及较大Si颗粒的长大,当Cu含量小于2%时,Si颗粒长大并不明显,复合材料的组织均匀致密;当Cu含量高于2%时,复合材料的组织均匀性逐渐下降。

3) 添加Cu元素的Al-50%Sip复合材料经固溶处理和时效处理后,随着Cu含量增加,复合材料塑性越来越差,拉伸强度和抗弯强度先增加后降低,当Cu含量为2%时,拉伸强度和抗弯强度分别达最大值268和423 MPa。材料的弹性模量和布氏硬度则随Cu含量的增加逐渐提高。

4) Al-50%Sip复合材料的断裂形式为典型的脆性断裂,Cu元素的加入提高了基体与增强相的结合强度,当Cu含量低于2%时,载荷在大部分Si颗粒上均匀分布;当Cu含量高于4%时,载荷集中分布于粗大的Si颗粒上,表现为复合材料的抗拉强度和抗弯强度降低。

REFERENCES

[1] 解立川, 彭超群, 王日初, 王小锋, 蔡志勇, 刘 兵. 高硅铝合金电子封装材料研究进展[J]. 中国有色金属学报, 2012, 22(9): 2578-2587.

XIE Li-chuan, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, CAI Zhi-yong, LIU Bing. Research progress of high aluminum-silicon alloys in electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2578-2587.

[2] 李婷婷, 彭超群, 王日初, 王小锋, 刘 兵. 电子封装陶瓷基片材料的研究进展[J]. 中国有色金属学报, 2010, 20(7): 1365-1374.

LI Ting-ting, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LIU Bing. Research progress in ceramic substrate material for electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1365-1374.

[3] CAI Zhi-yong, WANG Ri-chu, ZHANG Chun, PENG Chao-qun, WANG Lin-qian. Microstructure and properties of Al/Sip composites for thermal management applications[J]. Journal of Materials Science: Materials in Electronics, 2015, 26(6): 4234-4240.

[4] 魏朋义, 傅恒志. 熔体搅拌Al-12%Si合金的组织细化[J]. 中国有色金属学报, 1996, 6(1): 98-102.

WEI Peng-yi, FU Heng-zhi. Microstructure refinement of Al-12%Si by melts stirring[J]. The Chinese Journal of Nonferrous Metals, 1996, 6(1): 98-102.

[5] 胡 锐, 朱冠勇, 白海琪, 李金山, 傅恒志. 高含量Sip/Al复合材料的无压浸渗机制[J]. 中国有色金属学报, 2004, 14(11): 1822-1827.

HU Rui, ZHU Guan-yong, BAI Hai-qi, LI Jin-shan, FU Heng-zhi. Pressureless infiltration mechanism of high content Sip/Al composite[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(11): 1822-1827.

[6] 刘文水, 王日初, 彭超群, 莫静贻, 朱学卫, 彭 健. 喷射沉积电子封装用高硅铝合金的研究进展[J]. 中国有色金属学报, 2012, 22(12): 3446-3455.

LIU Wen-shui, WANG Ri-chu, PENG Chao-qun, MO Jing-yi, ZHU Xue-wei, PENG Jian. Research progress of spray deposited high Si-Al alloys for electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(12): 3446-3455.

[7] SRIVASTAVA V C, MANDAL R K, OJHA S N. Microstructure and mechanical properties of Al-Si alloys produced by spray forming process[J].Materials Science and Engineering A, 2001, 304/306: 555-558.

[8] CUI C, SHULZ A, SCHIMANSKI K, ZOCH H W. Spray forming of hypereutectic Al-Si alloys[J]. Journal of Materials Processing Technology, 2009, 209(11): 5220-5228.

[9] LIU Jun, XIU Zi-yang, LIANG Xue, LI Qiang, HUSSAIN M, QIAO Jing, JIANG Long-tao. Microstructure and properties of Sip/Al-20 wt% Si composite prepared by hot-pressed sintering technology[J]. Journal of Materials Science, 2014, 49(3): 1368-1375.

[10] NICOLETTO G, KONECNA R, FINTOVA S. Characterization of microshrinkage casting defects of Al-Si alloys by X-ray computed tomography and metallography[J]. International Journal of Fatigue, 2012, 41: 39-46.

[11] LIU Y Q, WEI S H, FAN J Z, MA Z L, ZUO T. Mechanical properties of a low-thermal-expansion aluminum/silicon composite produced by powder metallurgy[J]. Journal of Materials Science & Technology, 2014, 30(4): 417-422.

[12] FEVZI B. Characteristic properties of Al-Cu-SiCp and Al-Cu-B4Cp composites produced by hot pressing method under nitrogen atmosphere[J]. Materials & Design, 2007, 28(4): 1238-1244.

[13] YOON B K, LEE B A, KANG S J L. Growth behavior of rounded (Ti,W) C and faceted WC grains in a Co matrix during liquid phase sintering[J]. Acta Mater. 2005, 53(17): 4677-4685.

[14] KANG S J L, HAN S M. Grain growth in Si3N4-based materials[J]. Mrs Bulletin, 1995, 20(2): 33-37.

[15] 孙兰, 贾成厂, 曹瑞军, 刘总. WC-Co硬质合金烧结过程中的晶粒长大现象研究[J]. 稀有金属与硬质合金, 2007, 35(1): 44-47.

SUN Lan, JIA Cheng-chang, CAO Rui-jun, LIU Zong. Research on the phenomena of grain growth during the sintering of WC-Co hard alloy[J]. Rare Metals and Cemented Carbides, 2007, 35(1): 44-47.

[16] OGEL B, GURBUZ R. Microstructural characterization and tensile properties of hot pressed Al-SiC composites prepared from pure Al and Cu powders[J]. Materials Science and Engineering A, 2001, 301(2): 213-220.

[17] ZHANG Q, XIAO B L, LIU Z Y, MA Z Y. Microstructure evolution and elemental diffusion of SiCp/Al-Cu-Mg composites prepared from elemental powder during hot pressing[J]. Journal of Materials Science, 2011, 46(21): 6783-6793.

[18] 刘孝飞, 刘彦强, 樊建中, 魏少华, 马自力, 左 涛. 热等静压制备Sip/Al-Cu复合材料的组织与性能[J]. 中国有色金属学报, 2012, 22(11): 3059-3065.

LIU Xiao-fei, LIU Yan-qiang, FAN Jian-zhong, WEI Shao-hua, MA Zi-li, ZUO Tao. Microstructure and properties of Sip/Al-Cu composites fabricated by hot isostatic pressing[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3059-3065.

[19] 郦定强, 洪淳亨. 增强体颗粒尺寸对SiCp/2124Al复合材料变形行为的影响[J]. 上海交通大学学报, 2000, 34(3): 342-346.

LI Ding-qiang, HONG Chun-heng. Effects of particle reinforcement size on deformation behavior of SiCp/2124Al composites[J]. Journal of Shanghai Jiao Tong University, 2000, 34(3): 342-346.

[20] TSZENG T C. The effects of particle clustering on the mechanical behavior of particle reinforced composites[J]. Composites Part B:Engineering, 1998, 29(3): 299-308.

Effects of Cu content on microstructures and mechanical properties of Al-50%Sip composite

WU Xiang, WANG Ri-chu, PENG Chao-qun, CAI Zhi-yong

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The Al alloy matrix composites reinforced by 50% silicon (mass fraction) with various amounts of Cu (0-6%, mass fraction) were prepared by hot pressing. The effect of Cu content on microstructure and mechanical property of the composite was studied. The mixed powder was analyzed by DSC. The microstructure and phase composition of the composites were analyzed by SEM and XRD, and the mechanical properties of each sample were tested. The results show that Cu addition lowers the melting point of alloy powder, which is beneficial to the densification of the materials at relatively low temperatures. The microstructure of the composites is uniform and the coarsening behavior of Si particles does not appear when the Cu content is below 2%, and its distribution uniformity decreases when the Cu content is more than 2%. The tensile strength and bending strength of the samples rise at first and go down latter with the increase of the Cu. When Cu content is 2%, the tensile strength and bending strength of composite materials reach maximum values (268 MPa and 423 MPa), which increase by 66.5% and 46.9%, respectively, compared to the unalloyed reference composite. With the increase of the content of Cu, the elastic modulus and Brinell hardness increase gradually.

Key words: aluminum-silicon composite; Al-50%Sip alloy; hot pressing; microstructure; tensile strength; bending strength; elastic modulus; hardness

Foundation item: Project (JPPT-125-GJGG-14-016) supported by Military Industry Cooperative Program of COSTIND

Received date: 2015-07-08; Accepted data: 2015-10-20

Corresponding author: WANG Ri-chu; Tel: +86-731-88836638; E-mail: rcwcsu@163.com

(编辑 王 超)

基金项目:国防科学技术工业委员会军工配套项目(JPPT-125-GJGG-14-016)

收稿日期:2015-07-08;修订日期:2015-10-20

通信作者:王日初,教授,博士;电话:0731-88836638;E-mail:rcwcsu@163.com