文章编号:1004-0609(2009)04-0670-07

硬质合金刀片切削过程中自润滑功能稀土氧硫化物的原位形成

吴厚平1,张 立1,余贤旺1,陈 述2,熊湘君1

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 长沙矿冶研究院,长沙 410012)

摘 要:考察了高活性混合稀土(RE)掺杂的WC-8%Co-0.07%RE(质量分数)硬质合金刀片对铸铁的切削试验。采用扫描电镜、能谱分析以及X射线衍射等分析方法对硬质合金烧结体表面、切削试验后刀片的前刀面、后刀面以及切削刃进行观察与分析。结果表明,在稀土硬质合金刀片切削过程中发生了La、Ce从合金内部至刀片工作表面的非同步迁移现象,在刀具工作表面原位形成了具有自润滑功能的稀土氧硫化物。在实验观察与分析基础上,对La、Ce的定向迁移机制与稀土氧硫化物的形成机制进行了探讨。

关键词:硬质合金;稀土;切削;非同步迁移;自润滑

中图分类号:TF 125.3; TG 711⊙ 文献标识码: A

1In-situ formation of RE oxysulfide with self lubricating function during cutting process of cemented carbide tool

2WU Hou-ping1, Zhang Li 1, Yu Xian-wang 1, Chen Shu 2, Xiong Xiang-jun 1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Changsha Mining and Metallurgy Research Institute, Changsha 410012, China)

Abstract: As-sintered high activity mischmetal (RE, with lanthanum and cerium) doped WC-8%Co-0.07%RE (mass fraction) cemented carbide inserts were tested for the turning of cast iron. The sinter skin, flank face, rake face and cutting edge of the inserts after testing were observed and analyzed by scanning electron microscopy, energy dispersive X-ray spectroscopy and X-ray diffractometry. Asynchronous migration phenomenon of lanthanum and cerium from the inside to the working faces of the as-sintered insert during the turning process was observed. The results show that a rare earth oxysulfide phase with self lubricating function forms in-situ on the working faces of cemented carbide cutting tool. The mechanisms for the directional migration and formation of rare earth oxysulfide were discussed.

Key words: cemented carbide; rare earth; cutting; asynchronous migration; self lubricating

高活性混合稀土掺杂的硬质合金烧结过程中稀土的定向迁移能力与在合金烧结体表面的富集现象已有报道[1-4]。研究结果表明,烧结过程中稀土在合金中的作用行为与合金的碳含量有关,并具有尺寸效应。对WC+β (Co基固溶体粘结相)两相结构的合金,稀土在烧结过程中处于稳定状态,不会向合金烧结体表面产生定向迁移与表面富集。

从硬质合金烧结过程中[1-4]、Ni基合金[5]与Au基合金丝刷[6]摩擦试验过程中,以及碳化处理的Mo合金阴极材料热电子发射过程中[7-8]稀土的定向迁移现象可以推断,在稀土硬质合金工具服役过程中,合金中的稀土可能向工具工作表面产生定向迁移与表面富集。为了证实这一设想,对稀土硬质合金切削刀片进行了切削试验,并对试验后刀片的工作表面进行了观察与分析。

尽管在某些稀土掺杂材料的服役过程中,稀土由合金内部向合金工作表面迁移、富集的现象已有报 道[5-8],但是未见固态稀土原子迁移、富集机理的报道。因为稀土原子La/Ce与W/Co原子的原子半径相差40%以上,关于稀土在全致密的硬质合金工具服役过程中定向迁移能力的证实以及稀土迁移机制的研究不仅具有重要的科学价值,而且对稀土硬质合金使用性能改善机理的认识以及稀土掺杂材料服役过程中稀土迁移行为的认识均具有重要意义。

1 实验

硬质合金刀片型号为31303C,基本成分为WC-8%Co-0.07%RE(质量分数)。混合稀土中La、Ce的质量分数分别为29.91%和45.84%。合金为WC+β两相结构,碳含量为5.65%。

采用JEOL JSM-6360 LV 扫描电镜(SEM)与EDAX Genesis 2000 能谱分析仪(EDXS)进行表面观察与分析。采用Rigaku Dmax /2550VB X射线衍射仪(XRD)对切削试验后刀片后刀面进行物相分析。

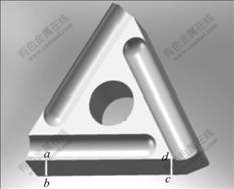

刀片的几何形状如图1所示。切削试验在传统的车床上进行,采用干切削方式,工件材料为铸铁。为了便于观察分析,仅对刀片3个切削刃中的一个刀刃进行切削试验。对铸铁的粗加工,每个切削刃的切削试验一直持续到被加工件的表面粗糙度超标为止。

图1 切削试验用31303C型可转位刀片的几何示意图

Fig.1 Geometry of indexable inserts for turning experiment (Flank face zone marked by abcd is observation and analysis zone by SEM and EDXS)

2 结果及分析

2.1 粗车削试验结果

采用5片刀片对铸铁棒材进行切削试验。棒材的平均长度与平均原始直径分别为350和50 mm。对每件棒材进行两道加工,切削参数如下:转速360 r/min,棒材原始态(第一道)与第二道加工的背吃刀量分别为7和5 mm。切削过程中未出现切削刃的异常破损,刀片单切削刃平均切削寿命为33 min。

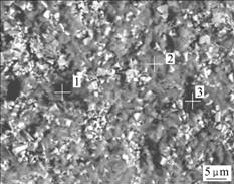

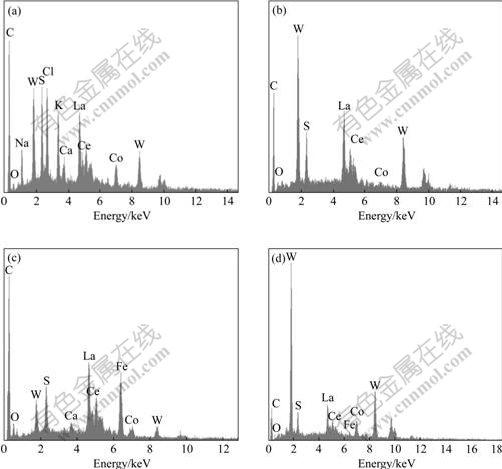

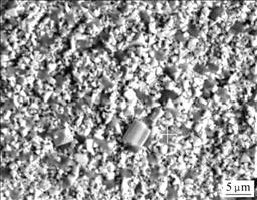

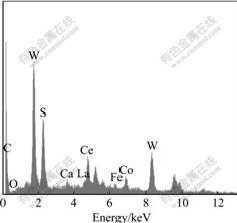

对切削试验后刀片表面进行观察,发现在图1所示的abcd所包围的后刀面区域出现了明显的表面颜色改变。图2所示为35 min切削试验后一刀片后刀面的SEM像。图2中相应位置的EDXS分析谱与定量分析结果分别见图3与表1。

图2 铸铁粗车削试验后刀片后刀面的BSE像

Fig.2 BSE image of flank face after rough turning of cast iron

图3 图2中相应位置的EDXS谱

Fig.3 EDXS spectra of positions in Fig.2: (a), (b), (c) Corresponding to positions 1, 2 and 3, respectively; (d) whole surface

表1 铸铁的粗车削EDXS分析结果

Table 1 EDXS analysis results of different points of cast iron by rough turning

由EDXS分析结果可知,图2中含La、Ce深色区域的存在是由于Na、K、Ca等低原子序数杂质元素的存在以及高C含量所致。因铸铁中C含量(质量分数)>2.11%,含La、Ce区域中高C含量的存在是由于铸铁中C向合金刀片工作面扩散所致。

通常铸铁中的Si与S含量分别在1.0%~3.0%之间与0.02%~0.2%之间。然而,在切削试验后的刀片后刀面没有检测到Si的存在;与此同时,尽管后刀面中存在Fe含量相对较高的个别微区,但Fe、O平均含量却较低,分别为0.93%与1.35%。因此,从EDXS分析结果可以推断,切削过程中,工件中的Fe、Si至刀片工作表面的扩散以及刀片工作面的氧化得到了有效的抑制。

为了确定刀片后刀面形成的如图2所示的含La、Ce、S和O的灰色和黑色网状薄膜的物相成分,对刀片后刀面整个表面进行了XRD物相分析,XRD谱如图4所示。由XRD分析结果可知,后刀面除存在WC硬质相、面心立方结构(fcc)的Co基固溶体粘结相外,还存在一种第三相,即一种与La2O2S(PDF 27—0263)非常类似的物相。因晶格畸变可导致XRD衍射峰宽化现象的产生[9],从图4所示的衍射峰宽化现象以及EDXS分析结果可以判断,切削过程中在后刀面形成的第三相为一种六方结构的(La、Ce)2O2S复杂形式化合物。La2O2S与Ce2O2S(PDF 26—1085) 均为六方结构,c/a分别为1.714和1.718。因(0001)晶面间距较大,容易产生滑移,La2O2S和Ce2O2S均具有润滑剂的功能。因晶体结构与La2O2S类似,可以推断,(La、Ce)2O2S复杂形式化合物也具有润滑剂功能。正是由于切削过程中硬质合金中稀土La、Ce的定向迁移以及工件材料中S向刀具表面的定向扩散,导致稀土氧硫化物在刀具表面的原位形成,赋予了刀具在切削过程中的自润滑功能。事实上,关于稀土硬质合金刀具切削性能的改善,如切削寿命的提高、刀片工作面与工件表面之间摩擦因数的降低以及切削力的降低早有报道[10-12]。

图4 铸铁粗车削试验后刀片整个后刀面的XRD谱

Fig.4 XRD pattern of whole flank face after rough turning of cast iron

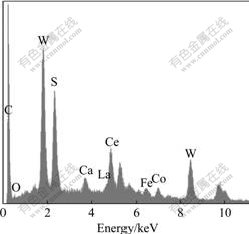

2.2 精车削试验结果

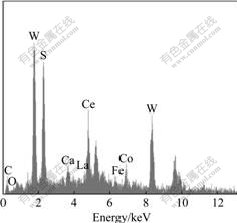

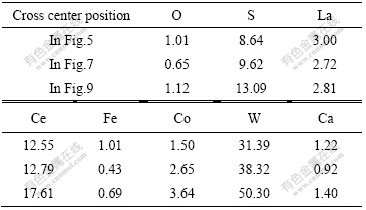

粗加工后用一片新合金刀片继续对铸铁棒材进行精加工。切削参数如下:转速560 r/min,进给量0.26 mm/r。单刃切削时间为60 min,铸铁的切削量为180 cm3。切削结束后刀片的切削刃依然锋利,未见明显磨损。采用SEM与EDXS对刀片切削刃、后刀面以及前刀面进行观察与分析,结果见图5~10与表2。由图5、7和9可知,稀土富集相在刀片切削刃、后刀面以及前刀面的分布状态非常类似,呈弥散分布状态。对比图5、7和9与图2可知,铸铁精车削试验后稀土在刀片工作表面单位面积的富集数量较粗加工时少;更重要的是, La与Ce的平均质量比与粗车削时的完全不同(见表3)。

图5 铸铁精车削试验后刀片切削刃的BSE照片

Fig.5 BSE image of cutting edge after finish turning of cast iron

图6 图5中十字中心部位的EDXS谱

Fig.6 EDXS spectrum of cross center in Fig.5

图7 铸铁精车削试验后刀片后刀面的BSE照片

Fig.7 BSE image of flank face after finish turning of cast iron

图8 图7中十字中心部位的EDXS谱

Fig.8 EDXS spectrum of cross center in Fig.7

图9 铸铁精车削试验后刀片前刀面的BSE照片

Fig9 BSE image of rake face after finish turning of cast iron

图10 图9中十字中心部位的EDXS谱

Fig.10 EDXS spectrum of cross center in Fig.9

表2 铸铁的精车削EDXS分析结果

Table 2 EDXS analysis results of finish turning of cast iron (mass fraction, %)

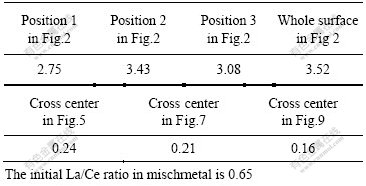

表3 各种工况条件下刀片工作表面相应位置La与Ce 质量比

Table 3 Mass fraction ratios of La/Ce under different working conditions

3 关于La、Ce非同步迁移的讨论

尽管EDXS成分分析方法的分析误差较大,特别是在C存在的情况下,但是它依然是一种比较可靠的成分相对比较方法。不同工况条件下刀片工作表面相应位置的La与Ce质量比见表3。由表3可知,刀片工作表面的La与Ce质量比随加工工况的变化而变化,已完全不同于原始混合稀土中La与Ce的质量比。

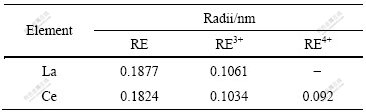

S、C、La和Ce的电负性参数分别为2.58、2.55、1.11和1.12。当稀土原子和与其电负性相差较大的非金属原子之间发生强烈交互作用时,因稀土原子的电子结构特殊,稀土原子会产生极化或离子化,使其原子半径显著减小[13]。事实上,戢景文等[14]用内耗研究方法已经证实了在钢铁中稀土原子的固溶现象。La、Ce的原子半径与离子半径见表4。由表4可知,由于Ce4+的存在,在La、Ce原子存在原子极化的条件下,Ce的原子半径可能会变得较La的原子半径更小,更有利于Ce的迁移。

表4 La和Ce的原子半径与离子半径

Table 4 Atomic and ionic radius of La and Ce

铸铁的精车削试验以及稀土硬质合金的烧结试验结果[1, 3]已经证实了Ce的优先迁移现象。由于金属Ce的熔点仅为799 ℃,较金属La的熔点低122 ℃,因此,出现La/Ce比超过混合稀土中原始比例的情况,这很可能是长时间非连续重切削过程中Ce的流失所致。实际上,Ce的流失现象在球粒状硬质合金烧结过程中早已被发现[2]。重切削所导致的局部高温可能导致先期到达刀片工作表面的Ce部分流失。WANG等[15]通过X射线光电子能谱分析方法发现:通过稀土氧化物的高温碳还原反应,La2O3-Mo 阴极材料表面有金属La的存在,即证实了在特殊条件下稀土氧化物与碳之间发生还原反应的可能性。周文元等[16]甚至认为,阴极表面的Mo2C 可作为还原剂直接使La2O3-Mo阴极材料表面区域的La2O3得到还原。由此可以推断,即使早期迁移至刀片工作表面的Ce不是以金属态存在,也可以通过重切削过程中碳的还原使其转变为金属态。正是由于切削过程是非连续的,Ce的还原反应在切削间断过程中会被中止,金属态Ce又可能进一步与S、O反应,生成稀土氧硫化合物。

由于硬质合金中的孔隙度(体积分数)通常小于0.02%(A02),金属元素在WC-Co硬质合金中的主扩散通道通常只有WC晶粒间的晶界与WC/β相界。即使在存在Ce的原子极化或离子化的条件下,Ce在全致密硬质合金中扩散的激活能也必定是较高的,因此,Ce原子先期到达刀片工作表面必然需要一定的时间。然而,因Ce原子扩散、迁移可导致晶界、相界等界面中空位与位错数量的增加,随着Ce原子的先期到达,随后继续扩散、迁移的Ce原子以及La原子的扩散激活能降低,因此,后期的Ce、La原子的扩散、迁移速度会加快。显然,La、Ce的分离与La、Ce的非同步迁移以及随后Ce的部分流失与La、Ce、S、O原子之间的化合反应的整个过程是非常复杂的。

4 结论

1) 在C、S含量适中的金属材料加工过程中,稀土硬质合金工具中的La、Ce原子可以扩散迁移至其工作表面,形成一种La、Ce、S、O复杂形式化合物。然而,硬质合金工具工作表面的这种稀土化合物第三相的数量与分布状态与实际加工工况密切相关。

2) La、Ce原子扩散迁移至硬质合金工具工作表面是非同步的。硬质合金工具工作表面La与Ce质量比可随加工工况的变化发生实质性的改变,通常La与Ce的平均质量比远偏离混合稀土中La与Ce的原始质量比。

3) 在稀土硬质合金工具使用过程中,其工作表面原位形成的具有六方结构、c/a>1.633的 La、Ce、S、O复杂形式化合物可赋予刀具自润滑功能,有利于硬质合金工具使用性能的改善与工作寿命的提高。

REFERENCES

[1] Zhang Li, Chen Shu, Xiong Xiang-jun, Yu Xian-wang, Wang Yuan-jie. Directional migration behavior of cerium during the sintering process of mischmetal doped cemented carbide[J]. Journal of Central South University of Technology, 2008, 15(1): 6-10.

[2] Zhang Li, SCHUBERT W D, Chen Shu, Zhang Chuan-fu, Huang Bai-yun. Rare earth enrichment phenomenon during the sintering process of grainy hardmetal[J]. Mater Sci Eng A, 2004, 384 (1/2): 395-401.

[3] 张 立, SCHUBERT W D, 黄伯云, 吴恩熙. 含稀土硬质合金的表面观察[J]. 中南工业大学学报(自然科学版), 2003, 34(5): 467-471.

Zhang Li, SCHUBERT W D, Huang Bai-yun, Wu En-xi. Surface observation of rare earth doped cemented carbide[J]. Journal of Central South University of Technology, 2003, 34(5): 467-471.

[4] 张 立, 陈 述, SCHUBERT W D, 黄伯云. Ce在混合稀土掺杂的硬质合金烧结体表面富集现象的热力学分析[J]. 硬质合金, 2004, 21(2): 70-76.

Zhang Li, Chen Shu, SCHUBERT W D, Huang Bai-yun. Thermodynamic analysis on the phenomenon of the enrichment of Ce on the sinter skin during the sintering of mischmetal doped cemented carbide [J]. Cemented Carbide, 2004, 21(2): 70-76.

[5] 翟光杰, 刘家浚, 朱宝亮. 稀土元素对镍基喷焊合金层摩擦表面形成氧化物膜的影响[J]. 摩擦学学报, 1996, 16(1): 21-27.

Zhai Guang-jie, Liu Jia-jun, Zhu Bao-liang. Effect of rare earth on oxide film formed on the friction surface of spray-welding Ni-base alloy coating[J]. Tribology, 1996, 16(1): 21-27.

[6] 虞 澜. 金-稀土合金电刷丝的磨损机理研究[J]. 摩擦学学报, 2002, 22(4): 282-285.

Yu Lan. Study on the wear mechanism of Au-rare earth alloy wires[J]. Tribology, 2002, 22(4): 282-285.

[7] SADEK ALBER A, MASAO U, FUKUHISA M. Effect of rare earth metal oxide additions to tungsten electrodes[J]. Metallurgical Transactions A, 1990, 21 (12): 3221-3236.

[8] Wang Jin-shu, Liu Juan, Zhou Mei-ling, Li Hong-yi, Zhang Jiu-xing, Zuo Tie-yong. La2O3-Gd2O3-Mo emission material[J]. Trans Nonferrous Met Soc China, 2003, 13(1): 38-41.

[9] UNG?R T. Microstructural parameters from X-ray diffraction peak broadening [J]. Scripta Materialia, 2004, 51(8): 777-781.

[10] 李规华, 严兰英, 张鸿绪. YG6R系与硬质合金的研究[J]. 粉末冶金技术, 1994, 12(3): 206-209.

Li Gui-hua, Yan Lan-yin, Zhang Hong-xu. Research on rare earth hard metal YG6R[J]. Powder Metallurgy Technology, 1994, 12(3): 206-209.

[11] 阎开印, 孟廷会, 于军慧. 添加稀土元素对硬质合金物理机械性能和切削性能的影响[J]. 西南交通大学学报, 1995, 30(1): 46-51.

Yan Kai-yin, Meng Ting-hui, Yu Jun-hui. The effect on mechanical properties and cutting performances of hard metal inserted with rare earth metal elements[J]. Journal of Southwest Jiaotong University, 1995, 30(1): 46-51.

[12] 李斌书. 稀土添加方法对硬质合金物理力学性能和使用寿命的影响[J]. 硬质合金, 1996, 13(1): 15-19.

Li Bin-shu. The influence of addition method of RE on the physical-mechanical properties and service properties of cemented carbide[J]. Cemented Carbide, 1996, 13(1): 15-19.

[13] 吉泽升, 夏立芳, 王海波. 稀土硼铝共渗初期渗层的相组成[J]. 中国有色金属学报, 1998, 8(S1): 66-69.

Ji Zhe-sheng, Xia Li-fang, WanG Hai-bo. Phase composition of initial rare earth-B-Al permeation layer[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(S1): 66-69.

[14] 戢景文, 车韵怡, 刘爱生. 钢铁中稀土合金化的内耗研究及其理论[J]. 中国稀土学报, 1996, 14(4): 350-359.

Ji Jing-wen, Che Yun-yi, Liu Ai-sheng. Research and theory in internal friction of alloying of rear earth in iron and steel[J]. Journal of the Chinese Rare Earth Society, 1996, 14(4): 350-359.

[15] Wang Jin-shu, Liu Wei, Liu Yan-qin, Zhou Mei-ling. Emission efficiency optimization of RE2O3 doped molybdenum thermionic cathode by application of pattern recognition method[J]. Applied Surface Science, 2005, 251(1/4): 89-96.

[16] 周文元, 张久兴, 刘燕琴, 万小峰, 周美玲, 左铁镛. 稀土镧钼热阴极材料稳定发射机理—碳化及发射寿命[J]. 中国有色金属学报, 2004, 14(6): 985-989.

ZHOU Wen-yuan, ZHANG Jiu-xing, LIU Yan-qin, WAN Xiao-feng, ZHOU Mei-ling, ZUO Tie-yong. Stable emission mechanism of Mo-La2O3 cathode—Carbonization and emission lifetime[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 985-989.

基金项目:国家自然科学基金资助项目(50574104;50823006)

收稿日期:2008-06-20;修订日期:2008-09-18

通讯作者:张 立,教授,博士;电话:0731-8876424;E-mail: zhangli@mail.csu.edu.cn

(编辑 何学锋)