DOI: 10.11817/j.ysxb.1004.0609.2020-39519

脆硫铅锑精矿富氧直接熔炼渣型理论研究

张忠堂,戴 曦

(中南大学 冶金与环境学院,长沙 410083)

摘 要:对脆硫铅锑精矿富氧直接熔炼渣型理论进行研究。根据富氧直接熔炼过程炉渣组成特性,选取FeO-SiO2-CaO-ZnO渣系为研究对象。采用热力学软件Factsage计算并绘制FeO-SiO2-CaO-ZnO渣系相图,考察CaO与SiO2质量比、Fe与SiO2质量比、ZnO含量及温度对该渣系熔化温度及黏度的作用规律,并在此理论基础上进行实验研究。理论研究表明,熔炼过程炉渣中Fe与SiO2质量比和CaO与SiO2质量比的增大均会提高炉渣的熔化温度。随着体系温度的升高,炉渣的黏度逐渐减小,1250 ℃时,炉渣的黏度均小于0.5 Pa·s。实验结果表明:熔炼过程产出合金品位为95.56%,合金直收率达到58.47%,渣中金属含量(Pb与Sb)小于1%(质量分数)。熔炼产物工艺矿物学研究发现,合金中主要物相为金属Pb、金属Sb以及少量Cu2Sb、FeSb2金属间化合物,炉渣主要由钙铁橄榄石、铁橄榄石组成,原料中锌主要以氧化锌形式进入渣相。

关键词:脆硫铅锑精矿;富氧直接熔炼;渣型;金属直收率

文章编号:1004-0609(2020)-06-1427-10 中图分类号:TF812 文献标志码:A

铅、锑是非常重要的金属元素,被广泛应用于蓄电池、阻燃剂、医药、冶金、射线防护等领域[1]。随着单一铅矿和锑矿资源的不断匮乏,含铅锑的复杂硫化矿逐渐成为生产铅锑的主要原料。我国广西河池地区蕴藏着丰富的脆硫铅锑矿,约占我国锑矿资源的30%~40%[2]。脆硫铅锑矿是一种多金属复杂硫化矿,除了含主金属Pb、Sb外,还含有Zn、Bi、Cu、Sn、Ag等多种有价金属,已成为生产铅锑的重要原料[3]。

工业上常采用传统工艺经沸腾焙烧-烧结-鼓风炉还原-吹炼-精炼处理脆硫铅锑精矿,但该工艺存在冶炼流程长、低浓度SO2污染、金属回收率低及能耗高等缺点[4]。目前,富氧直接熔炼工艺已成功应用于硫化矿的处理,与传统工艺相比,极大地缩短了冶炼流程,解决了低浓度SO2污染问题[5-7]。鉴于此,中南大学提出了脆硫铅锑精矿富氧直接熔炼新工艺,可实现铅锑硫化物一步氧化直接得到铅锑合金[8-10]。而富氧直接熔炼过程能否顺利进行并获取理想的技术经济指标,在一定程度上取决于与原料相适应的炉渣渣型,炉渣渣型决定了炉渣性质,进而影响熔炼过程金属直收率及渣含金属等重要参数[11]。尹飞等[12]结合铅富氧闪速熔炼的特点,研究了FeO与SiO2质量比、CaO与SiO2质量比及ZnO含量对炉渣性质的影响,结果发现,随着渣中FeO与SiO2质量比的改变,炉渣的性质变化较大,渣中氧化亚铁的含量适当增大可降低炉渣的熔化温度和黏度。付一鸣[13]提出采用高钙渣型可提高硫化铅精矿熔炼过程粗铅产量,同时渣含铅可降低至1.47%。崔雅茹等[14]采用Factsage热力学软件及相关实验对液态高铅渣还原过程炉渣熔化温度进行了研究,考察了各炉渣组分的变化对炉渣熔化性质的影响。杨斌[15]对QSL炼铅工艺中不同组成炉渣的熔度、黏度、密度及热焓进行分析,提出当精矿含铁5%左右时,选择中硅低铁渣有利于工艺控制,其渣型组成为FeO 30%、SiO2 25%~30%、CaO 15%~18%;当精矿含铁高于8%时,选择中硅中铁或中硅高铁渣型,熔剂配入少,产渣量少,其渣型组成为FeO 40%~50%、SiO2 25%~30%、CaO 15%~18%。周康洁[16]对辉锑矿富氧挥发熔炼合理渣系进行研究,确定了其合理渣系配比:Fe与SiO2质量比为0.7,CaO与SiO2质量比为0.5,此配比下渣中锑含量低至0.37%,粗锑率为2.2%。而目前有关脆硫铅锑精矿富氧直接熔炼过程炉渣渣型理论的研究报道较少,且渣型对富氧直接熔炼过程的影响机制尚不明确。

因此,本文作者采用热力学软件Factsage[17]计算并绘制了FeO-SiO2-CaO-ZnO渣系相图,考察了CaO与SiO2质量比、Fe与SiO2质量比、ZnO含量及温度对该渣系熔化温度及黏度的作用规律,并在此理论基础上进行了验证实验,为脆硫铅锑精矿富氧直接熔炼过程提供理论指导及技术支撑。

1 实验

1.1 实验原料

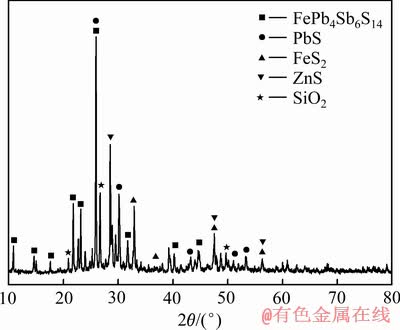

实验原料为广西某冶炼厂提供的脆硫铅锑精矿(Jamesonite concentrate,JC)和水淬渣(Antimony blast furnace slag,ABFS),其主要化学成分列于表1。图1所示为脆硫铅锑精矿XRD谱。由图1可见,脆硫铅锑精矿中主要元素Pb、Sb、Fe、Zn等均以金属硫化物的形式存在。

表1 实验原料主要化学成分

Table 1 Chemical composition of experimental raw materials

图1 脆硫铅锑精矿的XRD谱

Fig. 1 XRD pattern of jamesonite concentrate

1.2 实验设备

本实验在自行设计的通气式升降坩埚电阻炉中进行,采用铂-铑热电偶测温,多段式智能仪表控温,实验装置示意图见图2。

图2 实验装置示意图

Fig. 2 Schematic diagram of experimental apparatus

1.3 研究方法

1.3.1 热力学分析方法

根据熔炼过程炉渣组成特性,以FeO-SiO2- CaO-ZnO渣系为研究对象,采用热力学软件Factsage中Phase Diagram、Equilib、Viscosity模块和FToxid数据库计算并绘制了FeO-SiO2-CaO-ZnO渣系相图,探讨了CaO与SiO2质量比、Fe与SiO2质量比、ZnO含量及温度对该渣系熔化温度及黏度的作用规律。

1.3.2 验证实验

将称量的200 g脆硫铅锑精矿与1500 g水淬渣充分混合均匀后置入反应容器中,待炉温升至给定温度,将反应容器放入高温电炉中进行氧化熔炼,熔炼过程控制反应温度1250 ℃,CaO与SiO2质量比为0.6,Fe与SiO2质量比为1.1,富氧浓度为70%,气体压力为0.18 MPa,总气流量为0.2 m3/h,反应时间40 min,澄清时间40 min。反应结束后,待熔体冷却至室温,对熔炼产出的合金及炉渣进行称量并分析。合金直收率通过式(1)计算:

(1)

(1)

式中:RA为合金直收率;mJC,mABFS,malloy分别为精矿、水淬渣和产出合金的质量;w(Pb+Sb)JC、w(Pb+Sb)ABFS、w(Pb+Sb)alloy分别为精矿、水淬渣和产出合金中Pb和Sb质量分数。

1.3.3 分析测试

采用容量法对脆硫铅锑精矿富氧直接熔炼过程合金及炉渣中Pb、Sb含量进行分析;采用日本理学Rigaku-TTR Ⅲ型X射线衍射仪(Cu Kα靶,波长0.154056 nm)对富氧直接熔炼产出合金及炉渣进行物相分析(XRD);采用日本JSM-6360LV型扫描电镜(SEM)及X射线能谱仪(EDS,EDX-GENESIS 60S)对富氧直接熔炼过程产出合金及炉渣形貌特征进行表征。

2 理论分析

2.1 炉渣结构

由于本研究选取FeO-SiO2-CaO-ZnO渣系为研究对象,因此熔炼过程熔渣的结构与硅酸盐熔体的结构非常相似。根据共存理论模型[18-19],结合相关相图,对FeO-SiO2-CaO-ZnO渣系进行拆分,结构单元如下。

1) CaO-SiO2相图[20]

简单离子和分子:Ca2+,O2-,SiO2;复杂化合物:CaSiO3,Ca2SiO4和3CaO·2SiO2 (T≤1250 ℃)。

2) FeO-SiO2相图[20]

简单离子和分子:Fe2+,O2-,SiO2;复杂化合物:Fe2SiO4。

3) ZnO-SiO2相图[20]

简单离子和分子:ZnO,SiO2;复杂化合物:Zn2SiO4。

4) CaO-FeO-SiO2相图[20]

简单离子和分子:Ca2+,Fe2+,O2-,SiO2;复杂化合物:CaSiO3,Ca2SiO4,3CaO·2SiO2,Fe2SiO4,CaFeSiO4,Ca3SiO5。

根据上述相图分析可知,FeO-SiO2-CaO-ZnO渣系在温度低于1250 ℃时的结构单元包括:Ca2+,Fe2+,O2-,ZnO,SiO2,CaSiO3,Ca2SiO4,3CaO·2SiO2,Fe2SiO4,Zn2SiO4,CaFeSiO4。

硅酸盐熔体中硅和氧会形成稳定的硅氧四面体 结构,以及更为复杂的硅氧阴离子团,如

结构,以及更为复杂的硅氧阴离子团,如 、

、 、

、 等;这些硅氧阴离子团除了

等;这些硅氧阴离子团除了 是单体外,其他均为

是单体外,其他均为 的不同聚合程度的聚合体,而其中含有

的不同聚合程度的聚合体,而其中含有 的数目称为该聚合体的级数,级数越高其聚合程度也越大。

的数目称为该聚合体的级数,级数越高其聚合程度也越大。

最简单的硅氧阴离子为 ,nO/nSi=4,此硅氧四面体周围价键未饱和,当熔渣中SiO2含量较多时,就会进一步聚合,生成更为复杂的硅氧四面体,如:

,nO/nSi=4,此硅氧四面体周围价键未饱和,当熔渣中SiO2含量较多时,就会进一步聚合,生成更为复杂的硅氧四面体,如:

+

+

+ O2- (2)

+ O2- (2)

+

+

+ O2- (3)

+ O2- (3)

+

+

(4)

(4)

由式(2)~(4)反应可见,当反应从左向右进行时释放O2-,为聚合反应,可以认为熔渣中缺少自由O2-时,容易发生聚合反应;而当熔渣中O2-越多时,越有利于复杂硅氧阴离子解离。除了硅和氧外,硅酸盐熔体中还存在着各种金属离子,当MeO(碱性氧化物)引入硅酸盐熔体中时,由于Me—O键是以离子键为主,该键强度较以共价键为主的Si—O键强度弱,此时Si4+可以把Me—O键上的氧离子拉拢在自己周围;由此可知,熔渣中碱性氧化物(CaO、FeO等)会促使具有网状结构的复杂硅氧阴离子解离,熔渣中酸性氧化物(如SiO2)会与O2-结合成复杂硅氧阴离子,使熔渣中自由O2-减少,从而导致复杂硅氧阴离子的聚合[19]。由文献[21]可知,硅酸盐熔渣的物理化学性质(熔化温度、黏度、密度等)均取决于其聚合程度,当聚合程度较大时,将使熔渣的黏度增大,流动性变差,造成渣金分离困难;而硅酸盐熔体的聚合程度与熔体中的nO/nSi有关,nO/nSi越小,硅酸盐熔体的聚合程度越高;nO/nSi越大,硅酸盐熔体的聚合程度越低;由此可知,对于FeO-SiO2-CaO-ZnO渣系,熔渣中各组分的比例对该渣系的理化性质具有重要影响。

2.2 FeO-SiO2-CaO-ZnO渣系相图

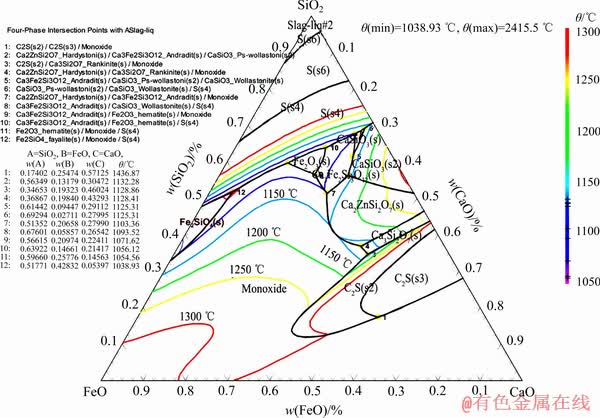

根据脆硫铅锑精矿富氧直接熔炼过程炉渣主要组成,采用热力学软件Factsage计算并绘制了FeO-SiO2- CaO-10%ZnO渣系相图,结果如图3所示。由图3可见,炉渣的液相区随着温度的升高逐渐增大,并且主要向着FeO顶点和CaO-SiO2边方向扩大,这是由于升高温度使生成的铁钙锌硅酸盐逐渐熔化形成液相所致。由此可知,熔炼过程温度的变化对炉渣液相区面积的大小及改变的方向具有重要影响。此外,由图3还可以看出,Fe与SiO2质量比以及CaO与SiO2质量比的变化对炉渣的液相线温度具有显著影响,特别是靠近SiO2和CaO顶点方向尤为明显,此时液相线温度分布较为密集。

3 结果与讨论

3.1 各因素对FeO-SiO2-CaO-ZnO渣系性质的影响

主要考察了CaO与SiO2质量比、Fe与SiO2质量比、ZnO含量及温度对该渣系熔化温度及黏度的作用规律。

图3 FeO-SiO2-CaO-10%ZnO渣系相图[10]

Fig. 3 Phase diagram of FeO-SiO2-CaO-10%ZnO slag system

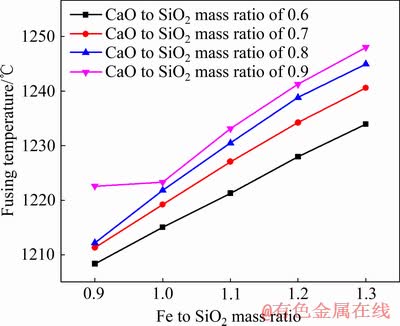

3.1.1 Fe与SiO2质量比及CaO与SiO2质量比对炉渣熔化温度的影响

固定ZnO含量为8%,考察了Fe与SiO2质量比(0.9~1.3)及CaO与SiO2质量比(0.6~0.9)对FeO-SiO2- CaO-8%ZnO渣系熔化温度的影响,结果如图4所示。由图4可见,当CaO与SiO2质量比一定时,随着体系中Fe与SiO2质量比的增大,炉渣的熔化温度逐渐增大。当CaO与SiO2质量比为0.6、Fe与SiO2质量比在0.9~1.3范围内增大时,炉渣的熔化温度从1208.35 ℃增大至1233.94 ℃,炉渣的熔化温度升高了25.59 ℃。当Fe与SiO2质量比一定时,随着体系CaO与SiO2质量比的不断增大,炉渣的熔化温度也逐渐升高。当Fe与SiO2质量比为1.1、CaO与SiO2质量比在0.6~0.9范围内增加时,炉渣的熔化温度从1221.27 ℃提高至1233.10 ℃,炉渣的熔化温度升高了11.83 ℃。由此可知,熔炼过程炉渣中Fe与SiO2质量比以及CaO与SiO2质量比的增大均会提高炉渣的熔化温度。因此,熔炼过程控制合理的Fe与SiO2质量比以及CaO与SiO2质量比对熔炼过程的顺行高产具有重要意义。

3.1.2 ZnO含量对炉渣熔化温度的影响

图4 Fe与SiO2质量比及CaO与SiO2质量比对炉渣熔化温度的影响

Fig. 4 Effect of Fe to SiO2 mass ratio and CaO to SiO2 mass ratio on fusing temperature of slag (w(ZnO)=8%)

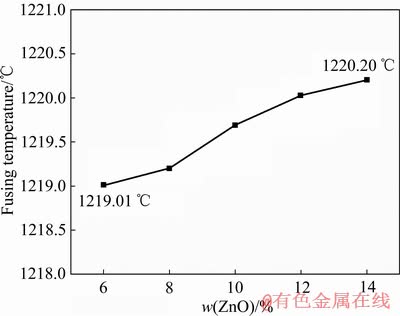

固定Fe与SiO2质量比为1.0、CaO与SiO2质量比为0.7、考察ZnO含量对FeO-SiO2-CaO-ZnO渣系熔化温度的影响,结果如图5所示。由图5可见,随着渣中ZnO含量的不断增加,炉渣的熔化温度呈逐渐升高的趋势,但ZnO含量在6%~14%范围内变化时,炉渣熔化温度最高为1220.20 ℃,最低为1219.01 ℃,炉渣熔化温度变化仅为1.19 ℃。由此可知,渣中ZnO含量的变化对炉渣熔化温度影响较小,即此时炉渣具有较好的热稳定性,根据这一结论,熔炼过程满足炉渣熔化温度适宜的情况下,可提高锌在渣中的富集。文献[12]对铅富氧闪速熔炼过程不同ZnO含量炉渣的熔化温度进行了测定,结果表明,当ZnO含量在6%~ 10%范围内变化时,炉渣熔化温度最高为1149 ℃,最低为1141 ℃,此条件下炉渣熔化温度变化较小。由此可知,本节理论计算所得结论与前人研究相一致。

图5 ZnO含量对炉渣熔化温度的影响

Fig. 5 Effect of ZnO content on fusing temperature of slag (Fe to SiO2 mass ratio of 1.0, CaO to SiO2 mass ratio of 0.7)

3.1.3 温度对炉渣黏度的影响

固定ZnO含量为8%、CaO与SiO2质量比为0.6、考察温度对FeO-SiO2-CaO-8%ZnO渣系黏度的影响,结果如图6所示。由图6可见,温度对炉渣的黏度影响较大,随着体系温度的升高,炉渣的黏度逐渐降低。当温度为1100 ℃,Fe与SiO2质量比在0.9~1.3范围内变化时炉渣的黏度均大于0.5 Pa·s,此时熔渣流动性较差,不利于熔炼过程的进行。当温度为1150 ℃,Fe与SiO2质量比在0.9~1.2范围内变化时炉渣的黏度均小于0.5 Pa·s,有利于熔炼过程的进行;但当Fe与SiO2质量比进一步增大到1.3时,此时炉渣的黏度大于0.5 Pa·s。当温度为1200 ℃和1250 ℃时,此时炉渣的黏度均小于0.5 Pa·s,熔渣流动性好,利于熔炼过程的进行。因此,熔炼过程控制反应温度高于1200 ℃为宜。

图6 温度对炉渣黏度的影响

Fig. 6 Effect of temperature on viscosity of slag (w(ZnO)= 8%, CaO to SiO2 mass ratio of 0.6)

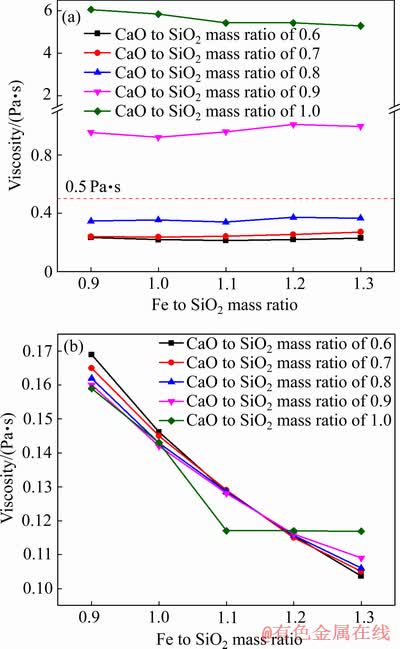

3.1.4 Fe与SiO2质量比及CaO与SiO2质量比对炉渣黏度的影响

固定ZnO含量为10%,考察1200和1250 ℃下Fe与SiO2质量比(0.9~1.3)及CaO与SiO2质量比(0.6~1.0)对FeO-SiO2-CaO-10%ZnO渣系黏度的影响,结果示于图7。由图7(a)可见,1200 ℃下,当CaO与SiO2质量比一定时,炉渣的黏度随着体系Fe与SiO2质量比的增加总体变化不大。当Fe与SiO2质量比一定时,随着体系CaO与SiO2质量比的增加炉渣的黏度逐渐增大。1200 ℃下,CaO与SiO2质量比在0.6~0.8范围内变化时,炉渣的黏度均小于0.5 Pa·s,此时熔渣流动性较好,利于熔炼过程的进行。但当CaO与SiO2质量比进一步增加至0.9~1.0时,此时炉渣的黏度快速增大,均大于0.5 Pa·s。由此可见,1200 ℃下,Fe与SiO2质量比在0.9~1.3范围内增加时,CaO与SiO2质量比对炉渣的黏度影响较大,且此条件下炉渣中CaO与SiO2质量比不宜超过0.8。由图7(b)可见,1250 ℃下,当Fe与SiO2质量比在0.9~1.3范围内变化,CaO与SiO2质量比在0.6~1.0范围内变化时,炉渣的黏度均小于0.5 Pa·s,此时熔渣具有较好的流动性,利于熔炼过程进行。

图7 1200 ℃和1250 ℃下Fe与SiO2质量比及CaO与SiO2质量比对炉渣黏度的影响

Fig. 7 Effects of Fe to SiO2 mass ratio and CaO to SiO2 mass ratio on viscosity of slag at 1200 ℃ (a) and 1250 ℃ (b) (w(ZnO)=10%)

3.1.5 ZnO含量对炉渣黏度的影响

固定Fe与SiO2质量比为1.1,CaO与SiO2质量比为0.7,考察ZnO含量对FeO-SiO2-CaO-ZnO渣系黏度的影响,结果示于图8。由图8可见,当温度低于1200 ℃时,随着渣中ZnO含量的增加,炉渣黏度逐渐增大,且黏度均大于0.5 Pa·s,此时熔渣流动性较差,不利于熔炼过程进行。当温度高于1200 ℃,ZnO含量在0~16%范围内变化时,炉渣黏度均小于0.5 Pa·s。由此可见,此条件下炉渣熔化温度高于1200 ℃对熔炼过程是有利的。

图8 ZnO含量对炉渣黏度的影响

Fig. 8 Effect of ZnO content on viscosity of slag (Fe to SiO2 mass ratio of 1.1, CaO to SiO2 mass ratio of 0.7)

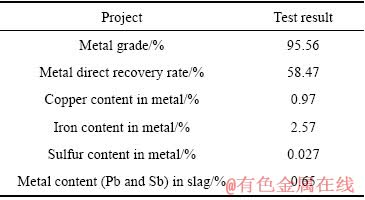

3.2 验证实验

根据前述理论计算可知,选取1250 ℃作为脆硫铅锑精矿富氧直接熔炼过程的反应温度是适合的,此时熔渣的黏度小于0.5 Pa·s,利于熔炼过程进行。验证实验条件包括熔炼温度1250 ℃,富氧浓度70%,气体压力0.18 MPa,总气流量0.2 m3/h,反应时间40 min,实验结果列于表2。由表2可知,富氧直接熔炼过程产出合金品位为95.56%,合金直收率达到58.47%,渣中金属含量(Pb与Sb)小于1%,合金中S含量较低为0.027%。

表2 脆硫铅锑精矿富氧直接熔炼试验结果

Table 2 Experimental results of oxygen-enriched direct smelting of jamesonite concentrate

3.3 熔炼产物微观分析

图9所示为合金及炉渣XRD谱。由图9可见,合金中可分辨的结晶相有金属Pb、金属Sb及Cu2Sb、FeSb2金属间化合物。炉渣中可分辨的结晶相有钙铁橄榄石、铁橄榄石、氧化锌及硫化锌等物相。

图9 合金及炉渣的XRD谱

Fig. 9 XRD patterns of alloy and slag

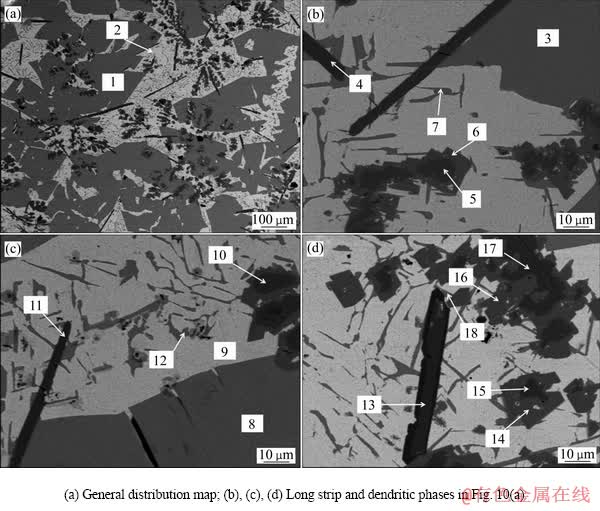

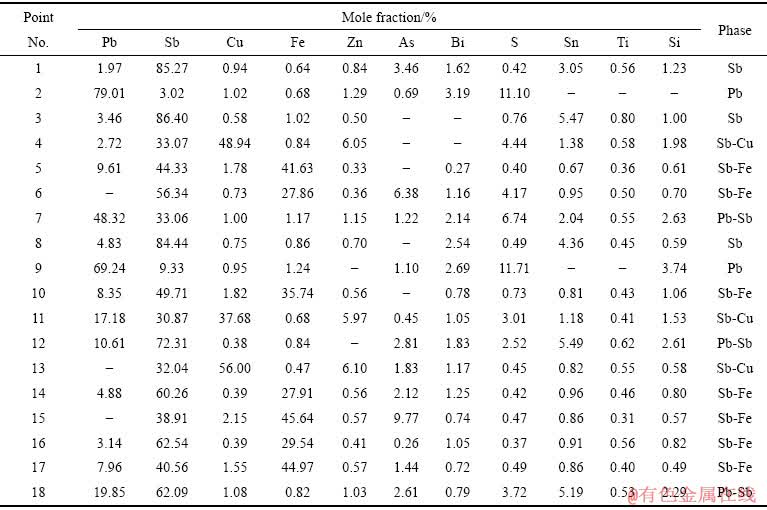

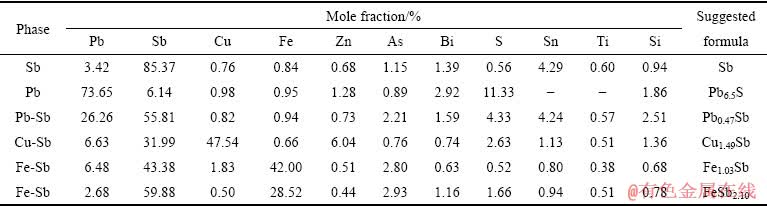

为了进一步明确合金中各结晶相区的物相组成,在背散射条件下对合金中不同形状及衬度的位置点采用EDS进行微区成分分析。图10所示为合金的BSE电子像,表3和表4所示分别为合金中不同衬度位置点的EDS分析结果及合金中各主要物相的平均组成。分析结果表明合金中主要物相为金属Pb相、金属Sb相、Pb-Sb合金相、Sb-Fe相及Sb-Cu相,与前述XRD分析结果相一致。

图10 合金的BSE电子像

Fig. 10 Backscattered electron images of alloy

表3 合金EDS分析结果

Table 3 Composition of main phase in alloy detected by EDS

表4 合金中各物相平均组成

Table 4 Average composition of main phase in alloy

表5 炉渣中主要相成分EDS分析结果

Table 5 Composition of main phase in slag detected by EDS

图11 炉渣的BSE电子像

Fig. 11 Backscattered electron images of alloy and slag

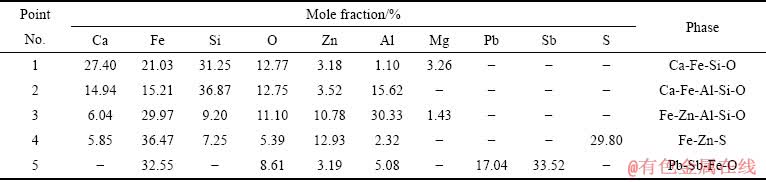

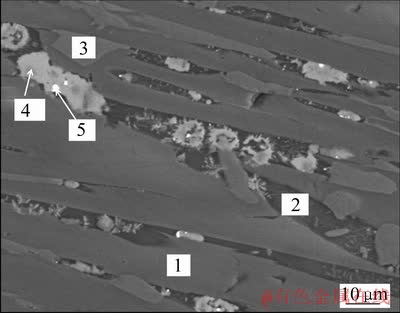

图11所示为炉渣的BSE电子像。对炉渣不同衬度的位置点(标记为1~5)采用EDS进行微区成分分析,结果列于表5。分析结果表明炉渣中赋存物相成分比较复杂,主要包括钙铁硅酸盐相、钙铁铝锌硅酸盐相、铁锌硫化物相及嵌于铁锌硫化物相中的铅锑铁氧化物相,与前述XRD分析结果相一致。但在前述XRD分析中未发现铅锑氧化物相,这可能是由于渣中铅锑含量(<1%)过低导致XRD分析未能分辨。

4 结论

1) 采用热力学软件Factsage计算并探讨了温度、Fe与SiO2质量比、CaO与SiO2质量比及ZnO含量对FeO-SiO2-CaO-ZnO渣系熔化温度及黏度的影响。结果表明,熔炼过程炉渣中Fe与SiO2质量比和CaO与SiO2质量比的增大均会提高炉渣的熔化温度。1250 ℃下,当Fe与SiO2质量比在0.9~1.3范围内变化、CaO与SiO2质量比在0.6~1.0范围内变化时,炉渣的黏度均小于0.5 Pa·s,利于熔炼过程进行。

2) 对脆硫铅锑精矿富氧直接熔炼过程进行实验研究,结果表明,熔炼过程产出合金品位为95.56%,合金直收率达到58.47%,渣中金属含量(Pb与Sb)小于1%,合金中S含量较低为0.027%。

3) 熔炼产物工艺矿物学研究发现,合金中主要物相为金属Pb、金属Sb以及少量Cu2Sb、FeSb2金属间化合物,炉渣主要由钙铁橄榄石、铁橄榄石组成,原料中锌主要以氧化锌形式进入渣相。

REFERENCES

[1] 胡 磊, 谷新建, 王仁元. 难处理脆硫锑铅矿综合利用技术研究[J]. 国土资源导刊, 2006, 3(3): 135-136.

HU Lei, GU Xin-jian, WANG Ren-yuan. Study on comprehensive utilization technology of jamesonite[J]. Land & Resources Herald, 2006, 3(3): 135-136.

[2] 熊 恒. 脆硫铅锑矿热分解及硫化物挥发规律研究[D]. 昆明: 昆明理工大学, 2016: 4-7.

XIONG Heng. Study on thermal decomposition and sulfide volatilization of jamesonite[D]. Kunming: Kunming University of Science and Technology, 2016: 4-7.

[3] 赵天从. 锑[M]. 北京: 冶金工业出版社, 1987: 20-22.

ZHAO Tian-cong. The metallurgy of antimony[M]. Beijing: Metallurgical Industry Press, 1987: 20-22.

[4] 韦万新. 脆硫锑铅矿火法流程生产高铅锑合金的实践[J]. 中国有色冶金, 1992(2): 42-44.

WEI Wan-xin. Practice of producing high lead-antimony alloy by jamesonit fire process[J]. China Nonferrous Metallurgy, 1992(2): 42-44.

[5] BARTLETT R W, MCCLINCY R J, WESELY R J. Smelting copper without converters[J]. JOM, 1985, 37(5): 17-19.

[6] ODLE R R, MORRIS A E, MCCLINCY R J. Investigation of direct smelting of copper concentrates[J]. Advances in Sulfide Smelting, 1983, 1: 57-72.

[7] LI Wei-feng, ZHAN Jing, Fan Yan-qing. Research and industrial application of a process for direct reduction of molten high-lead smelting slag[J]. JOM, 2017, 69(4): 784-789.

[8] 戴 曦, 蔡 勇, 廖春图, 宾万达, 安剑刚. 脆硫铅锑精矿富氧直接熔炼新工艺研究[C]// 全国“十二五”铅锌冶金技术发展论坛暨驰宏公司六十周年大庆学术交流会, 2010: 18-24.

DAI Xi, CAI Yong, LIAO Chun-tu, BIN Wan-da, AN Jian-gang. A new process for oxygen-enriched direct smelting of jamesonite concentrate[C]// Proceedings of Forum of the China “12th Five-Year” Lead and Zinc Metallurgical Technology Development and Symposium of the Sixty Anniversary of Chihong Company, Qujing, 2010: 18-24.

[9] ZHANG Zhong-tang, DAI Xi, ZHANG Wen-hai. Thermodynamic analysis of oxygen-enriched direct smelting of jamesonite concentrate[J]. JOM, 2017, 69(12): 2671-2676.

[10] 张忠堂, 戴 曦. FeO-SiO2-CaO-ZnO-5%Al2O3渣系熔化温度的研究[J]. 稀有金属, 2019, 43(2): 170-178.

ZHANG Zhong-tang, DAI Xi. Melting temperature of FeO-SiO2-CaO-ZnO-5%Al2O3 slag system[J]. Chinese Journal of Rare Metals, 2019, 43(2): 170-178.

[11] 甘雪萍. 金川镍闪速熔炼炉渣合理渣型的研究[D]. 长沙: 中南大学, 2002: 17-20.

GAN Xue-ping. Study of reasonable slag from of Jinchuan’s nickel flash smelting process[D]. Changsha: Central South University, 2002: 17-20.

[12] 尹 飞, 王成彦, 王 忠. 铅富氧闪速熔炼技术基础研 究[J]. 有色金属(冶炼部分), 2012(4): 11-14.

YIN Fei, WANG Cheng-yan, WANG Zhong. Basic research on lead oxygen-enriched flash smelting technology[J]. Nonferrous Metals(Extractive Metallurgy), 2012(4): 11-14.

[13] 付一鸣. 铅鼓风炉熔炼渣型的理论研究与生产实践[J]. 稀有金属与硬质合金, 1993, 113: 115-119.

FU Yi-ming. Theoretical study and production practice of smelting slag in lead-blast furnace[J]. Rare Metals and Cemented Carbides, 1993, 113: 115-119.

[14] 崔雅茹, 李凯茂, 何江山. 液态高铅渣还原过程炉渣熔化温度的研究[J]. 稀有金属, 2013, 37(3): 473-478.

CUI Ya-ru, LI Mao-shan, HE Jiang-shang. Melting point of molten high-lead slag in direct reduction process[J]. Chinese Journal of Rare Metals, 2013, 37(3): 473-478.

[15] 杨 斌. 浅析QSL炼铅工艺的渣型选择[J]. 中国有色冶金, 2004, 33(4): 27-28.

YANG Bin. Analysis on slag type selection of QSL lead smelting process[J]. China Nonferrous Metallurgy, 2004, 33(4): 27-28.

[16] 周康洁. 辉锑矿富氧挥发熔池熔炼工艺及渣型研究[D]. 长沙: 中南大学, 2014: 33-36.

ZHOU Kang-jie. Study on Oxygen-enriched Volatile Bath Smelting of stibnite concentrate and slag-type[D]. Changsha: Central South University, 2014: 33-36.

[17] BALE C W, CHARTRAND P, DEGTEROV S A. FactSage thermochemical software and databases[J]. Calphad- computer Coupling of Phase Diagrams & Thermochemistry, 2009, 33(2): 295-311.

[18] 汪金良. 重金属短流程冶金炉渣活度研究与过程数值模拟[D]. 长沙: 中南大学, 2009: 42-44.

WANG Jin-liang. Slag activity research and numerical simulation of heavy metal smelting process with short flow[D]. Changsha: Central South University, 2009: 42-44.

[19] 翟玉春. 冶金热力学[M]. 北京: 冶金工业出版社, 2018: 153-157.

ZHAI Yu-chun. Metallurgical thermodynamics[M]. Beijing: Metallurgical Industry Press, 2018: 153-157.

[20] 德国钢铁工程协会. 渣图集[M]. 北京: 冶金工业出版社, 1989: 345-350.

German Iron and Steel Engineering Association. Atlas of slag[M]. Beijing: Metallurgical Industry Press, 1989: 345-350.

[21] 李洪桂. 冶金原理[M]. 北京: 科学出版社, 2005: 83-87.

LI Hong-gui. Metallurgical principle[M]. Beijing: Science Press, 2005: 83-87.

Basic research of slag type in oxygen-enriched direct smelting of jamesonite concentrate

ZHANG Zhong-tang, DAI Xi

(School of Metallurgical and Environment, Central South University, Changsha 410083, China)

Abstract: Basic research of slag type in the oxygen-enriched direct smelting of the jamesonite concentrate was investigated. The FeO-SiO2-CaO-ZnO slag system was selected as the research object according to the composition characteristics of the slag. The phase diagram of FeO-SiO2-CaO-ZnO slag system was calculated and established through the thermodynamic software Factsage. The effects of temperature, Fe to SiO2 mass ratio, CaO to SiO2 mass ratio and ZnO content on the viscosity and fusing temperature of the FeO-SiO2-CaO-ZnOslag system were calculated. The results show that the fusing temperature of slag increases with increasing the Fe to SiO2 mass ratio and CaO to SiO2 mass ratio. The viscosity of the slag can be reduced with the increase of temperature. The viscosity of various slag composition is less than 0.5 Pa·s at 1250 ℃. According to the thermodynamics analysis results, the verification test is carried out, indicating that the metal grade is 95.56%, the metal recovery rate is 58.47%, and metal content (Pb and Sb) in slag is lower than 1% (mass fraction). The technological mineralogy of alloy and slag is studied and it is found that the main phases in the alloy contain metallic lead, metallic antimony and a small amount of Cu2Sb, FeSb2 intermetallic compounds. The slag is mainly composed of kirschsteinite and fayalite, zinc in the raw material is mainly oxidized into slag phase in the form of zinc oxide.

Key words: jamesonite concentrate; oxygen-enriched direct smelting; slag type; metal recovery rate

Foundation item: Project(51474248) supported by the National Natural Science Foundation of China

Received date: 2019-05-20; Accepted date: 2019-09-05

Corresponding author: DAI Xi; Tel: +86-13787265816; E-mail: luckcici1596@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51474248)

收稿日期:2019-05-20;修订日期:2019-09-05

通信作者:戴 曦,教授,博士;电话:13787265816;E-mail:luckcici1596@163.com