Trans. Nonferrous Met. Soc. China 22(2012) 275-280

Characterization of cast A356 alloy reinforced with nano SiC composites

Ali MAZAHERY, Mohsen Ostad SHABANI

Hashtgerd Branch, Islamic Azad University, Hashtgerd, Iran

Received 25 May 2011; accepted 23 August 2011

Abstract: The microstructure and mechanical properties of nano composites processed via stir casting were studied. The composites were based on the A356 aluminum alloy reinforced with nano SiC particles. The density measurements show that the samples contain little porosity and the amount of porosity in the composites increases with increasing volume fraction of SiC. The microstructures of the composites were examined using optical microscope and transmission electron microscope. Microscopic observations of the microstructures reveal that the dispersion of the particles is uniform. The yield strength, ultimate tensile strength and the elastic modulus are improved with the addition of nano particles although some reduction in ductility is observed. The highest yield strength and ultimate tensile strength are obtained with the addition of 3.5% SiC nano-particles. A relatively ductile fracture in tensile fractured samples was observed by fractography examination.

Key words: aluminum matrix composites; SiC; strength; nano

1 Introduction

During the last two decades, a lot of research has been conducted on aluminium matrix composites (AMCs) in commercial laboratories and small businesses. As a result of these activities, many new AMCs applications have been established, and most of these have found insertion within the commercial sector. Important AMCs applications in aerospace and infrastructure industries are enabled by functional properties including high structural efficiency, excellent wear resistance, and attractive thermal and electrical characteristics. Challenging technical issues are overcome including compatibility between reinforcement and matrix, affordable primary and secondary processing techniques capable of adequately controlling reinforcement distribution, engineering design methodologies, and characterization and control of interfacial properties [1-8].

Recent investigations find that the incorporation of nano-particles into the aluminum matrix could enhance the hardness, the yield and ultimate tensile strength considerably, while the ductility is retained [9, 10]. The great enhancement in strength values of these composites is attributed to grain refinement, strong multidirectional thermal stress at the matrix/nano particle interface, small size of nano particles, good distribution of the nano particles and low degree of porosity which leads to effective transfer of applied tensile load to the uniformly distributed strong nano particulates. The strength of composites is expected to be influenced by the dislocation density, dislocation-to-dislocation interaction and constraint of plastic flow due to the resistance offered by particles. It is reported that due to the thermal mismatch stress, there is a possibility of increased dislocation density within the matrix which leads to local stress and increasing strength of the matrix and the composite. More than 50% improvement in yield strength of A356 alloy was observed with only 2.0% (mass fraction) nano-sized SiC particles [8]. ZHAO et al [2] characterized the properties and deformation behavior of aluminum matrix nano-composites. It was reported that the elongation, ultimate tensile strength and yield strength of nano-composites are enhanced with increasing the particulate volume fraction, which are markedly higher than those of Al composites synthesized by micro size particles.

This study is aimed at the characterization of microstructure and mechanical properties in commercial Al-Si casting alloys reinforced with nano SiC composites.

2 Experimental

Due to its good castability, the aluminium alloy A359 was used as matrix material. The chemical composition is listed in Table 1.

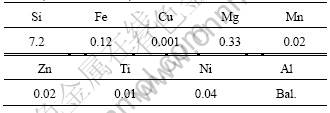

Table 1 Chemical composition of aluminium alloy used as matrix (mass fraction, %)

A mixture of nano-SiC and aluminum particles with average particle size of 50 nm and 16 μm respectively was used as the reinforcement. The powders were mixed in the mass ratio of Al/SiC being 1.67 and ball milled in isopropyl alcohol for 20 min using WC/Co balls. The mixture was then dried in a rotary vacuum evaporator and passed through a 60 mesh screen. The powder mixtures were cold pressed under 200 MPa into samples with dimensions of 60 mm×60 mm×60 mm. The compacted samples were crushed and then passed through a 60 mesh screen. The required amount of SiC was calculated according to the ratio of Al/SiC. Aluminum 356 alloy was selected as the matrix and 1% (mass fraction) magnesium additive in powder form was also used as wetting agent. Experiments were carried out using a relatively simple experimental set-up consisted of several parts. The main part allows temperatures up to 1000 °C, This is surrounded by a 50 mm thick layer of kaowool insulator to minimize heat loss. Inside the heater band is a graphite crucible with a lid for holding the materials. Weighed Al 356 alloy was charged into the crucible and heated up to 750 °C (above the alloy liquidus temperature) for melting. There was a nitrogen supply to the crucible in order to minimize the oxidation of molten aluminum, and a graphite stirrer mounted on a graphite shaft passed through small holes out of the crucible lid. This hole also acted as the outlet for the nitrogen gas. The shaft was connected to a digital DC motor to stir the slurry. The end of the shaft was used to facilitate the bottom pouring of the composite melt. During stirring, the shaft acted as a plug at the bottom of the crucible and the stirring rod assembly was lifted at a distance of 5-10 mm from the bottom during pouring, thus opening the stopper and allowing the slurry to flow into a mould beneath the set-up. This feature was to ensure that the impurities floating on the surface of the melt were not mixed into it.

The powder mixture was inserted into an aluminium foil by forming a packet and added into molten metal of crucible when the vortex was formed. The packet of mixture melted and the particles started to distribute around the alloy sample.

Microstructural evaluations were carried out using optical microscope (OM), scanning electron microscope (SEM) and transmission electron microscope (TEM). The OM and SEM specimens were ground through grit papers and etched with Keller’s reagent (2 mL HF, 3 mL HCl, 5 mL HNO3 and 190 mL water). The TEM specimens were machined to thickness of 0.5 mm and cut using a wire electro discharge machine. The samples were then ground down (from 350 to 1200 grit) and perforated using double spew with methanol solution. The experimental density of the composites was obtained by the Archimedian method of weighing small pieces cut from the composite cylinder first in air and then in water, while the theoretical density was calculated using the mixture rule according to the mass fraction of the nano particles. The porosities of the produced composites were evaluated from the difference between the expected and the observed density of each sample.

The tension tests were used to assess the mechanical behavior of the composites. The tensile specimens were machined from composite rods according to ASTM.B 557 standard. For each volume fraction of SiC particles, three samples were tested. In order to study the effect of nano particles on the fracture mechanisms during tensile loading of the samples, fractography was performed on the fractured surfaces of composite specimens. Brinell hardness values of the samples were measured on the polished samples using a ball with diameter of 2.5 mm under a load of 306 N.

3 Results and discussion

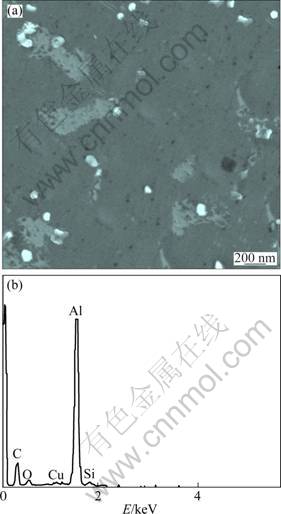

Optical micrographs of unreinforced Al alloy and composites reinforced with SiC particles are shown in Fig. 1. Dendritic microstructure resulting from casting process is clearly revealed. This trend was observed in previous works [9, 10]. Further study of the composites with high magnification bright field TEM shows uniform distribution of SiC particles through the matrix alloy (see Fig. 2). It is assumed that the uniform dispersion of nano-particles provides some heterogeneous nucleation sites during solidification, resulting in a more refined microstructure. Figure 3 shows the grain size of the composites.

Energy dispersion spectrum (EDS) analysis was utilized to determine the composition of the nano-composite (see Fig. 4). The detected zone of EDS beam is bigger than the average size of SiC, therefore, the EDS peaks for SiC nano particles inevitably include compositional information of Al matrix near particles. However, according to the compositional information of matrix, it is evident that Si and C peaks correspond to the composition of nano particles.

Fig. 1 Optical micrographs of unreinforced A356 alloy (a) and A356 alloy reinforced with 1.5% SiC (b)

Fig. 2 TEM image of composites with 3.5% nano SiC particles

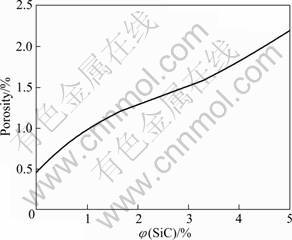

Comparison of the measured density of the cast alloy and the composites with theoretical density determines the amount of porosity. Figure 5 shows the variation of porosity with the volume fraction of nano SiC particles. Higher degree of defects and micro- porosity is observed at higher SiC fraction, which is the result of increased amount of interface area [11, 12].

Fig. 3 Relationship of grain size and volume fraction of SiC

Fig. 4 SEM micrograph (a) and EDS spectrum (b) of sample with 2.5% SiC

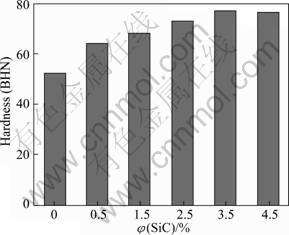

Hardness tests were performed using a Brinell hardness machine. In order to obtain the average values of hardness, areas predominant in the soft matrix or the hard reinforcing phase should be avoided so that the average values of hardness are attained from these measurements. The variation in hardness with volume fraction of SiC is shown in Fig. 6.

It is clear from the graph that the hardness of the composites is higher than that of the non-reinforced alloy. The higher hardness of the composites could be attributed to the fact that SiC particles act as obstacles to the motion of dislocation. The hardness increment can also be attributed to the reduced grain size. As shown, hardness increases with the amount of SiC particles. It is believed that since SiC particles are harder than aluminum alloy, the inherent property of hardness is rendered to the soft matrix [13, 14].

Fig. 5 Variation of porosity with volume fraction of nano SiC

Fig. 6 Variation of hardness as function of volume fraction of SiC particulates

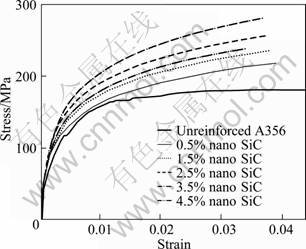

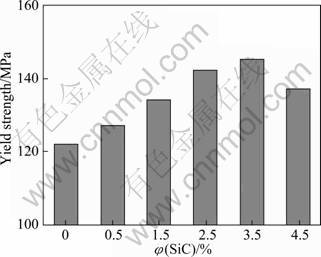

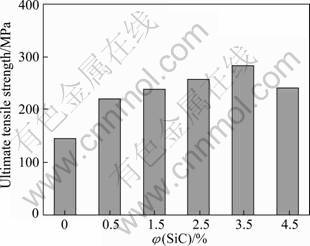

Figures 7, 8 and 9 display the tensile flow curves, yield strength and ultimate tensile strength of the composites, respectively. It could be noted that the flow curves do not show any sharp yield point irrespective of the material, and the strength values increase with the addition of nano SiC particles. It is believed that the great enhancement in tensile flow stress observed in these composites is due to good distribution of the nano-SiC particles and low degree of porosity, which leads to effective transfer of applied tensile load to the uniformly distributed strong SiC particulates. The grain refinement and strong multidirectional thermal stress at the Al/SiC interface are also important factors which play a significant role in the high strength of the composites. SiC particles have grain-refined strengthening effect, which is improved with increasing volume fraction since they act as the heterogeneous nucleation catalyst for aluminum [9-15].

Fig. 7 Flow curves in tensile deformation of composites

Fig. 8 Variations of yield strength as function of volume fraction of nano SiC particulates

Fig. 9 Variation of ultimate tensile strength as function of volume fraction of nano SiC particulates

The difference between the coefficient of thermal expansion (CTE) values of matrix and ceramic particles generates thermally induced residual stresses and increases dislocations density upon rapid solidification during the fabrication process. The interaction of dislocations with the non-shearable nano particles increases the strength level of the composite samples. According to the Orowan mechanism, the nano-SiC particles act as obstacles to hinder the motion of dislocations near the particles in the matrix. This effect of particles on the matrix is enhanced gradually with the increase of particulate volume fraction [2, 10].

Quite significant improvement in strength is noted initially when particles are added; however, further increase in SiC content leads to the reduction in strength values. The weakening factors of mechanical properties might be responsible for the included particles clusters and porosity. Hereby, it is believed that strengthening and weakening factors of mechanical properties could neutralize the effect of each other and thus, the composite containing 3.5% (volume fraction) SiC exhibits the maximum tensile flow stress. Normally, micron-sized particles are used to improve the ultimate tensile and the yield strength of the metal. However, the ductility of the MMCs deteriorates significantly with high ceramic particle concentration [16-18].

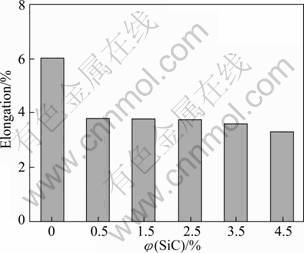

It is of interest to use nano-sized ceramic particles to strengthen the metal matrix while maintaining good ductility [6, 19]. It is inferred from Fig. 10 that the added nano particles deteriorate the ductility of A356 alloy. The stir casting method used in the present work is to produce the nano-composites which can most probably create different interfaces between nano particles and matrices and thus encourage crack initiation and propagation [10]. It is also noted that the elongation remains rather constant with the addition of nano particles. This is consistent with the findings by HASSAN and GUPTA [20, 21].

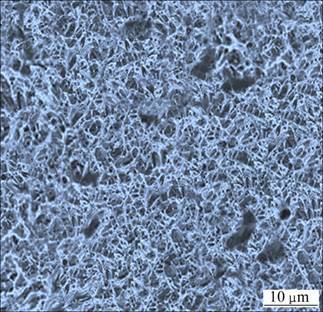

Typical SEM micrograph of tensile fracture surface for composite is shown in Fig. 11. The tensile fracture surface of the sample is clearly indicative of lots of dispersed shallow and small dimples with varying sizes in the matrix, confirming the high ductility observed in the tensile studies. However, there is a number of larger dimples linked together along the boundaries, showing increased degree of clustering along the grain boundaries (see Fig. 11).

Fig. 10 Variation of elongation as function of volume fraction of nano-SiC particulates

Fig. 11 SEM fractograph of tensile fracture surface of composites with 3.5% nano SiC particles

4 Conclusions

1) Nano-sized SiC particles are successfully incorporated into the aluminum matrix. Optical microscope examination reveals the grain refining effect of nano particles. A reasonably uniform distribution of SiC nano particles in the Al matrix is observed. Porosity level increases slightly with increasing particulate content which can be attributed to the increased surface area of the nano SiC particles.

2) The addition of nano particles results in significant improvement in hardness, yield strength and ultimate tensile strength of the composites. Different strengthening mechanisms contribute to the obtained strength improvement including Orowan strengthening, grain refinement, accommodation of CTE mismatch between the matrix and the particles, and the load bearing effects. The dispersed dimples with varying sizes are observed in the fractured surface of tensile specimens, confirming the high ductility of the nano composites.

References

[1] TU J P, WANG N Y, YANG Y Z, QI W X, LIU F, ZHANG X B. Preparation and properties of TiB2 nanoparticle reinforced copper matrix composites by in situ processing [J]. Mater Lett, 2002, 52(6): 448-452.

[2] ZHAO Y T, ZHANG S L, CHEN G, CHENG X N, WANG C Q. In situ (Al2O3+Al3Zr)np/Al nanocomposites synthesized by magneto-chemical melt reaction [J]. Compos Sci Technol, 2008, 68: 1463-1470.

[3] SHABANI M O, MAZAHERY A. Prediction of wear properties in A356 matrix composite reinforced with B4C particulates [J]. Synthetic Metals, 2011(161): 1226-1231.

[4] FERKEL H, MORDIKE B L. Magnesium strengthened by SiC nano particles [J]. Mater Sci Eng A, 2001, 298: 193-199.

[5] AKIO K, ATSUSHI O, TOSHIRO K, HIROYUKI T. Fabrication, process of metal matrix composite with nano-size SiC particle produced by vortex method [J]. J Jpn Inst Light Met, 1999, 49: 149-154.

[6] SHABANI M O, MAZAHERY A. Modeling of the wear behavior in A356–B4C composites [J]. J Mater Sci, 2011, 46: 6700-6708.

[7] LAN J, YANG Y, LI X. Microstructure and microhardness of SiC nanoparticles reinforced magnesium composites fabricated by ultrasonic method [J]. Mater Sci Eng A, 2004, 386: 284-290.

[8] LAN J, YANG Y, LI X. Study on bulk aluminum matrix nano-composite fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminum alloy [J]. Mater Sci Eng A, 2004, 380: 378-383.

[9] MAZAHERY A, ABDIZADEH H, BAHARVANDI H R. Development of high-performance A356/nano-Al2O3 composites [J]. Mater Sci Eng A, 2009, 518: 61-64.

[10] HABIBNEJAD-KORAYEMA M, MAHMUDIA R, POOLEB W J. Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nano-particles [J]. Mater Sci Eng A, 2009, 519(1-2): 198-203.

[11] SURESH K R, NIRANJAN H B, JEBARAJ P M, CHOWDIAH M P. Tensile and wear properties of aluminum composites. Proceedings of the 14th International Conference on Wear of Materials [J]. Wear, 2003, 255(1-6): 638-642.

[12] HASSAN S F, GUPTA M. Enhancing physical and mechanical properties of Mg using nano-sized Al2O3 particulates as reinforcement [J]. Metall Mater Trans A, 2005, 36: 2253-2258.

[13] COOKE P S, WERNER P S. Pressure infiltration casting of metal matrix composites [J]. Mater Sci Eng A, 1991, 144: 189-193.

[14] MONDAL D P, GANESH N V, MUNESHWAR V S. Effect of SiC concentration and strain rate on the compressive deformation behaviour of 2014Al-SiCp composite [J]. Mater Sci Eng A, 2006, 433: 18-31.

[15] WATSON M C, CLINE T W. The use of single fibre pushout testing to explore interfacial mechanics in SiC monofilament-reinforced Ti-I. A photoelastic study of the test [J]. Acta Metall Mater, 1992, 40: 131-139.

[16] REDDY R G. Processing of nanoscale materials [J]. Rev Adv Mater Sci, 2003, 5: 121-133.

[17] KANG Y C, CHEN S L I. Tensile properties of nanometric Al2O3 particulate-reinforced aluminum matrix composites [J]. Mater Chem Phys, 2004, 85(2-3): 438–443.

[18] HIRATA Y, SUZUE N, MATSUNAGA N, SAMESHIMA S. Particle size effect of starting SiC on processing, microstructures and mechanical properties of liquid phase-sintered SiC [J]. Journal of the European Ceramic Society, 2010, 30(9): 1945-1954.

[19] MUSSERT K M, VELLINGA W P, BAKKER A, Van der ZWAAG S. A nano-indentation study on the mechanical behavior of the matrix material in an AA6061-Al2O3 MMC [J]. J Mater Sci, 2002, 37: 789–794.

[20] HASSAN S F, GUPTA M. Effect of different types of nano-size oxide particulates on microstructural and mechanical properties of elemental Mg [J]. J Mater Sci, 2006, 41: 2229–2236.

[21] HASSAN S F, GUPTA M. Development of high performance Mg nanocomposites using nano-Al2O3 as reinforcement [J]. Mater Sci Eng A, 2005, 392: 163–168.

SiC纳米颗粒增强A356铸造合金的表征

Ali MAZAHERY, Mohsen Ostad SHABANI

Hashtgerd Branch, Islamic Azad University, Hashtgerd, Iran

摘 要:通过搅拌铸造制备SiC纳米颗粒增强A356铝合金复合材料,并研究其显微组织和力学性能。密度测量发现试样的孔隙度较低,且孔隙度随SiC颗粒体积分数的增加而增加。通过光学显微镜和透射电镜观察材料的显微组织,发现弥散的颗粒分布均匀。材料的拉伸强度和弹性模量随加入纳米SiC颗粒的增加而提高,而延展性有所降低。当SiC纳米颗粒的加入量为3.5%时,复合材料的屈服强度和极限抗拉强度达到最高。断口分析表明,拉伸断裂试样为相对韧性断裂。

关键词:铝基复合材料;SiC;强度;纳米

(Edited by FANG Jing-hua)

Corresponding author: Mohsen Ostad SHABANI; Tel: +98-912-563-6709; Fax: +98-261-6201888; E-mail: vahid_ostadshabany@yahoo.com

DOI: 10.1016/S1003-6326(11)61171-0