烧结方法对CP-Ti粉末烧结块显微组织和力学性能的影响

来源期刊:中国有色金属学报(英文版)2014年第z1期

论文作者:Je-ha SHON Jong-moon PARK Kyeong-sik CHO Jae-keun HONG Nho-kwang PARK Myung-hoon OH

文章页码:59 - 67

关键词:CP-Ti粉末;烧结方法;放电等离子体烧结;热压;电阻烧结

Key words:CP-Ti powders; sintering method; spark plasma sintering; hot pressing; electrical resistance sintering

摘 要:研究不同烧结方法,包括放电等离子体烧结(SPS)、热压(HP)和电阻烧结(ERS),对商用纯钛(CP-Ti)粉末固结后显微组织和力学性能的影响。选用的粉末粒度分别为<147 μm, <74 μm 和<43 μm,粉末粒度越小,其致密化过程越快。在850 °C、 30 MPa条件下进行SPS和HP,获得烧结体的相对密度高达99%。而通过ERS,则在950 °C、30 MPa条件下才发生CP-Ti粉末的致密化。在850~950 °C获得烧结钛的显微组织由等轴晶构成。对于粒度<43 μm粉末,在 850 °C、30 MPa条件下通过SPS制备烧结体,其屈服强度为868 MPa。随着小尺寸颗粒含量的升高,通过SPS 和 HP制备烧结体的屈服强度得到提高。然而在950 °C、30MPa条件下,通过ERS制备样品的最高屈服强度仅为441 MPa,比SPS 和 HP样品的低。与SPS 和 HP相比,ERS需要较短的烧结时间,但较高的烧结温度导致材料的脆性断裂,使其强度和伸长率降低。

Abstract: Effects of various sintering methods such as spark plasma sintering (SPS), hot pressing (HP) and electric resistance sintering (ERS) on the microstructure and mechanical properties of commercial pure titanium (CP-Ti) powder consolidations with particle size of <147 μm, <74 μm and <43 μm were studied. The smaller particle powders are densified to proceed at a higher rate. Dense titanium with relative density up to 99% is found to take place at 850 °C under 30 MPa of SPS and HP condition. However, in case of ERS, CP-Ti powders were densified almost at 950 °C under 30 MPa. The microstructure of sintered titanium is composed of equiaxed grains at 850-950 °C. The yield strength of sintered body composed of <43 μm powder is 858 MPa by using SPS at 850 °C under 30 MPa. When there is a higher content of small particle, the higher yield strength value is obtained both by using SPS and HP. However, when ERS is introduced, the highest yield strength is 441 MPa at 950 °C under 30 MPa, which shows much lower values than those by SPS and HP methods. ERS method takes much less sintering time compared with SPS and HP. Nevertheless, higher sintering temperature results in lower strength and elongation because of brittle fracture.

Trans. Nonferrous Met. Soc. China 24(2014) s59-s67

Je-ha SHON1, 2, Jong-moon PARK1, Kyeong-sik CHO1, Jae-keun HONG3, Nho-kwang PARK3, Myung-hoon OH1

1. Department of Advanced Materials Engineering, Kumoh National Institute of Technology, Gumi, Gyeongbuk 730-701, Korea;

2. Advanced Technology Team, Pohang Institute of Metal Industry Advancement, Pohang, Gyeongbuk 790-834, Korea;

3. Titanium Department, Korea Institute of Materials Science (KIMS), Changwon, Gyeongnam 642-831, Korea

Received 18 June 2013; accepted 13 November 2013

Abstract: Effects of various sintering methods such as spark plasma sintering (SPS), hot pressing (HP) and electric resistance sintering (ERS) on the microstructure and mechanical properties of commercial pure titanium (CP-Ti) powder consolidations with particle size of <147 μm, <74 μm and <43 μm were studied. The smaller particle powders are densified to proceed at a higher rate. Dense titanium with relative density up to 99% is found to take place at 850 °C under 30 MPa of SPS and HP condition. However, in case of ERS, CP-Ti powders were densified almost at 950 °C under 30 MPa. The microstructure of sintered titanium is composed of equiaxed grains at 850-950 °C. The yield strength of sintered body composed of <43 μm powder is 858 MPa by using SPS at 850 °C under 30 MPa. When there is a higher content of small particle, the higher yield strength value is obtained both by using SPS and HP. However, when ERS is introduced, the highest yield strength is 441 MPa at 950 °C under 30 MPa, which shows much lower values than those by SPS and HP methods. ERS method takes much less sintering time compared with SPS and HP. Nevertheless, higher sintering temperature results in lower strength and elongation because of brittle fracture.

Key words: CP-Ti powders; sintering method; spark plasma sintering; hot pressing; electrical resistance sintering

1 Introduction

Titanium, the fourth most abundant metal on the Earth, has been widely researched over the past 50 years, and has become an important material with extensive commercial applications. This is due to its excellent specific strength, corrosion resistance and biocompatibility; such properties make titanium a popular material for a wide variety of applications in aerospace, military defense, chemical, petrochemical and marine industries, with constantly increasing production and consumption quantities [1-6]. The demand for titanium is increasing accordingly, and the interest in its production by molding processes such as plate rolling and precision casting is gradually growing. This increase in demand is fulfilled by increased production of titanium ingots.

Kroll, Hunter, Armstrong and Cambridge processes have been employed to extract titanium from its ores and to convert it into a sponge-like metal, which is finally re- dissolved to produce bulk titanium [7]. In general, bulk titanium production involves complex processes such as refining, distillation and dissolution performed using specific devices in a vacuum environment. This is due to its high melting point (1668 °C) and high solid solubility in the gas phase (such as O2, N2 and H2). The requirement of such specific processing conditions boosts the titanium material prices, as a result, titanium has not been widely used despite its superior properties [8,9]. Therefore, the production of titanium plates by the plate rolling method would enable continuous large-scale titanium production at the industrial level, and would widen its range of applications.

According to a study on the sintering of titanium powders, production of sintered materials exhibiting full densification is possible only at high temperatures ranging from 1100 to 1400 °C in a vacuum environment [10,11]. A phase transformation from α-Ti (HCP) to β-Ti (BCC) occurs at 882 °C, and this induces an abnormal diffusion behavior due to α- and β-phases manifesting different crystal structures [12]. Additionally, the oxide film that is always present on the surface of pure titanium powder inhibits diffusion, making the densification of pure titanium difficult [13,14].

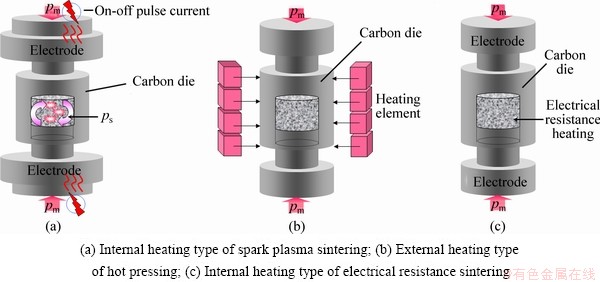

On the other hand, spark plasma sintering (SPS) has the advantage of rapidly achieving perfect sintering at low temperatures, which is unlike conventional sintering techniques through quick temperature control over a broad range from low temperatures up to over 2000 °C, as well as through thermal and electronic effects due to spark plasma generation. SPS is a technique applicable to a wide variety of materials such as oxides, non-oxides, metals and composites [15-20]. Hot-pressing (HP) is a representative conventional pressure sintering method that involves loading powder into a graphite mold as in SPS, followed by the application of mechanical pressure (pm) with heating to accelerate densification. HP involves indirectly heating the pressurized powder in the mold via resistive heating units outside the graphite mold while uniaxially pressurizing the powder within the graphite mold. Therefore, the main sintering reaction is thermal diffusion plastic deformation. In contrast, SPS is a direct- heat sintering technology capable of ultra-fast densification; since it involves simultaneous application of spark impact pressure (ps), external mechanical pressure and heat generated by passing a high energy pulse current through pulverized particles, its main sintering reaction is a combination of ion diffusion in an electric field and thermal diffusion plastic deformation [17]. Both SPS and HP are known to generate superior mechanical properties because uniform and fine crystalline particles are formed. Electrical resistance sintering (ERS) is a sintering method that is most frequently used in industry to produce diamond-tool tips. It also uses a direct heating method similar to SPS, but the main sintering reaction is thermal diffusion plastic deformation. Schematic diagrams of the three sintering methods are shown in Fig. 1.

To overcome the poor sintering ability of titanium, which usually requires complex and uneconomical preparation, various sintering methods have been used to apply powder metallurgy to the preparation of bulk titanium by sintering commercial pure titanium (CP-Ti) powder. Among the three sintering methods, SPS is believed to be the most effective method for sintering crystalline pure titanium, because the pressurized impact of the plasma from the high energy pulse of current locally melts and removes the oxidized layer on the contacted surface of the particles [15, 20-22].

The temperature-dependent sintering properties of CP-Ti powder using SPS with a low pressing force [19] and the pressing-force-dependent sintering properties of CP-Ti using SPS at low temperature [23] were previously reported. In the present study, the properties of the sintered body prepared by applying various sintering methods to three kinds of CP-Ti powders with different particle sizes and particle size distributions are investigated to determine the effect of the sintering method on the microstructure and mechanical properties.

2 Experimental

2.1 Materials

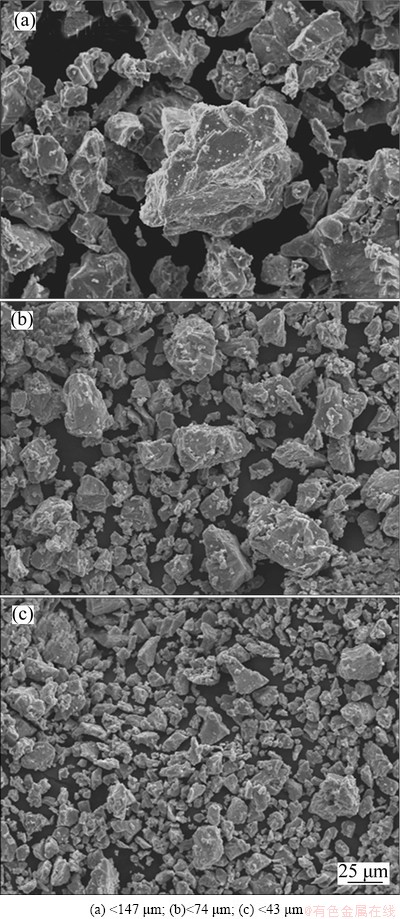

CP-Ti powders with different mean particle sizes and particle size distributions obtained by passing the powder through 100-mesh, 200-mesh, and 325-mesh sieves (Sejong Materials Co., LTD. Korea) were used to investigate the effects of the particle size distribution on the sintering properties. As shown in Fig. 2, the particles were irregular polyhedrons and the powders were at least 99.5% pure with trace amounts of Fe, Ni, Cr, Mn, and C.

Fig. 1 Assisted effects of sintering for pressure sintering

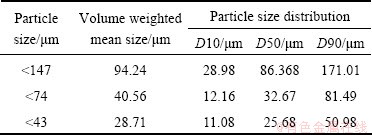

The particle sizes and particle size distributions of the three CP-Ti powders are listed in Table 1. There is a substantial difference in the mean particle size and particle size distribution. Each CP-Ti powder was loaded in a graphite die with an inner diameter of 20 mm, and 3 to 5 mm thick titanium specimens were prepared using each sintering method.

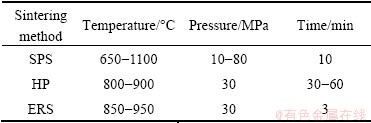

2.2 Sintering methods

The properties of the sintered bodies generated using the various sintering methods (SPS, HP and ERS) were assessed. Sintering was performed with different temperatures and pressures for SPS, with different temperatures and times for HP, and with different temperatures for ERS. Since the exposure of Ti powder to oxygen results in the formation of an oxide layer which interferes with sintering, SPS was performed under an Ar+H2 gas atmosphere, which is the most effective for de-oxidation [24], while HP and ERS were conducted under vacuum. The experimental conditions for each sintering method are summarized in Table 2.

Fig. 2 SEM micrographs of CP-Ti powders with different sizes

Table 1 Particle size characters of <147 μm, <74 μm and <43 μm CP-Ti powders

Table 2 Experimental conditions for each sintering method

2.3 Analysis and measurement

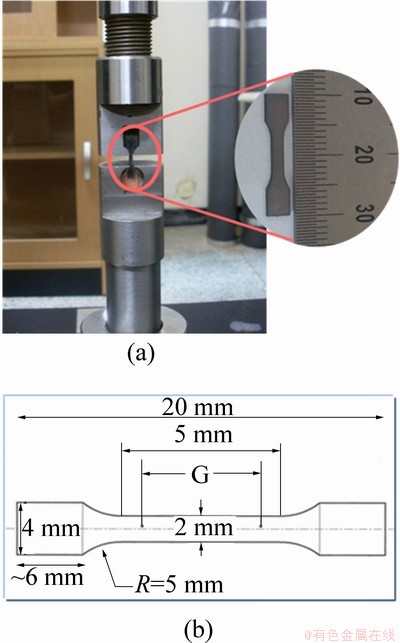

To determine the particle sizes of the raw material powders, the particle size distribution was measured via a wet process using a Mastersizer 2000 (Marvern Inc.). The produced titanium sinters were assessed by measuring their bulk density using the Archimedes’ principle and comparing it with the theoretical density (4.507 g/cm3) to deduce their sinterability. Moreover, the sinters were phase analyzed by X-ray diffraction (AXSD5005, Bruker, Germany) under the conditions of Co Kα, with 2θ range of 20°-100°. The fine structure of the sinters was examined by polishing them with 1 mm diamond paste, corroding them in a 5 mL KOH (40%) + 5 mL H2O2 + 20 mL H2O solution at 60 °C for 30 min, and observing the crystal grain sizes and shapes under a field-emission scanning electron microscope (FE-SEM, JEOL, 6500F, Japan). The hardness of the sinters was calculated using a Vickers microhardness tester (AVK-CO, Akashi, Japan) by indenting the polished specimen surface with a 9.8 N load and measuring the diagonal length of the indent. A small jig was fabricated to accommodate the specimen, and the measurements were conducted using a universal testing machine (Model 4468, Instron Corporation, USA). A disc-shaped specimen with a width of 20 mm was polished down to a thickness of 1.5-2.0 mm, and a tensile test was conducted with a load speed of 0.5 mm/min using a universal testing machine (Model 4468, Instron Corporation, USA) with the small jig, as shown in Fig. 3.

3 Results and discussion

3.1 Sintered density

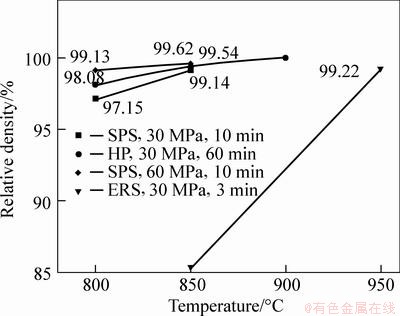

To determine the sintering conditions that result in the best sintered density for each sintering method, a sintered body was prepared using the <147 μm powder, which has the largest mean particle size among the three CP-Ti powders. The sintered densities of the <147 μm CP-Ti powder with respect to sintering method and conditions are outlined in Fig. 4.

Fig. 3 Photo (a) and dimensions (b) of specimen for tensile test

Fig. 4 Changes of relative density from <147 μm CP-Ti powders by various sintering methods

Using SPS, the sintered body has a relative density of about 97% when pressed under 30 MPa at 800 °C and at least 99% when the pressing force is increased to 60 MPa. Using HP, a relative density of about 97% is achieved after 30 MPa pressure for 30 min at 850 °C, while a relative density of 98% is obtained after treatment at 800 °C for 60 min, and 99% or greater density, i.e., complete densification, is obtained from treatment at 850 °C. ERS is a commercial sintering method widely used in industry because it can yield multiple sintered bodies at a time and requires only a short sintering time. In order to compare ERS with other sintering methods, the pressing force was fixed at 30 MPa for 3 min at 850 °C and 950 °C, respectively. A sintered density of about 85% is obtained at 850 °C. To obtain 99% densification, the sintering temperature is required to be higher than 950 °C.

For SPS and HP, complete densification of at least 99% is achieved under pressure of 30 MPa at 850 °C, whereas, for ERS, complete densification of at least 99% occurs under pressure of 30 MPa at 950 °C due to the differences in the sintering process. Diminished mechanical properties are expected, as a prior study reported coarsening of the fine structures (epitaxial growth) at higher temperatures [19].

In general, the powder sintering of titanium is performed in vacuum or an inert atmosphere due to its high reactivity. When sintered in vacuum at 1100-1350 °C for 100-200 min, titanium sintered with full densification can be obtained [10, 11]. However, in current research titanium powders were densified by SPS under 10 MPa at 950 °C, thus reducing the sintering temperature by about 200 °C [19]. Furthermore, in SPS performed under a targeted pressure effect by applying 60 MPa pressure, the full densification of titanium was achieved at 700 °C, lowering the sintering temperature by 250 °C [23].

MUNIR et al [20] outlined the effect of applied pressure on the densification obtained by SPS. They categorized the effect of pressure on sintering into intrinsic and extrinsic effects. The former is associated with an increase in the chemical potential as

(1)

(1)

where μI is the chemical potential on a particle interface under stress;  is the standard chemical potential; σn is the vertical stress on the interface and ΩI is the atomic volume of diffusing chemical species.

is the standard chemical potential; σn is the vertical stress on the interface and ΩI is the atomic volume of diffusing chemical species.

The intrinsic effect of pressure involves diffusion-related material transport, viscosity flow, plasticity transformation, and creep process. However, the extrinsic effect of pressure is particle rearrangement and collapse of particle agglomerates. In particular, the collapse of particle agglomerates has a crucial effect on nanoparticle sintering.

Pulse-current-activated sintering, a sintering technique in which pulse current and pressure are simultaneously applied, has many similarities with SPS. In this technique, sintering is reportedly facilitated at low temperatures owing to the rapid atomic diffusion accelerated by high Joule heat generated at powder contact points due to induced current, as well as accelerated by the applied electric field [25-27].

In the present study, concerning the sintering of Ti, SPS results in faster densification than HP because of the heat generated at the contact points of the powders due to the simultaneous application of current and pressure, increased chemical potential due to activation of the surface of the Ti particles, accelerated movement of the external materials relative to the inside, increased plastic deformation, and accelerated rearrangement of the pressurized powders. ERS requires a higher temperature to achieve densification because the sintering time is short.

3.2 Microstructure

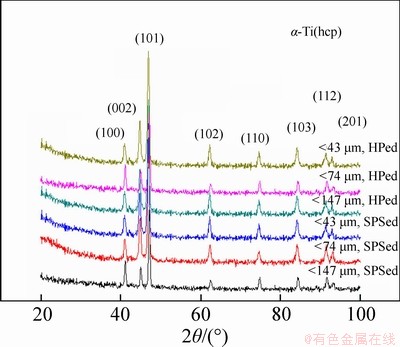

Figure 5 shows the XRD patterns of the specimens sintered via SPS and HP with a pressing force of 30 MPa at 850 °C using the <147 μm, <74 μm, and <43 μm CP-Ti raw material powders. The crystalline phase of the raw material powder is α-Ti, and only α-Ti phase is observed in the sintered body that is completely densified at 850 °C, which confirms that it does not undergo a phase change.

Fig. 5 XRD patterns of sintered titanium at 850 °C and 30 MPa

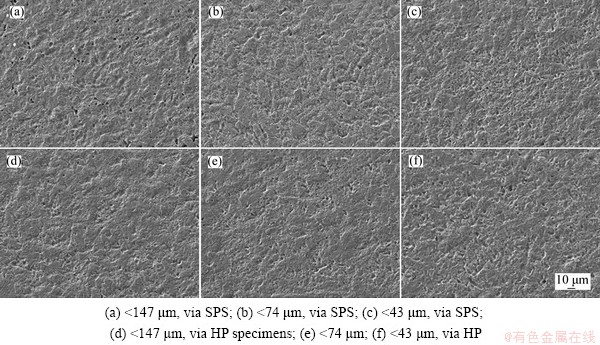

Figure 6 shows the microstructure of each titanium specimen prepared by SPS and HP at 30 MPa and 850 °C from the three particle size CP-Ti powders. A grain of the sintered titanium specimen comprises a polyhedron of about 10–20 mm, and densification occurrs without significant growth of the grain as the initial size and shape of the CP-Ti powder are maintained. In addition, the specimen sintered at high temperature and high pressure shows a microstructure in which equiaxed grains grow longitudinally with a certain orientation to form elongated grains; in contrast, specimens sintered at 850 °C and 30 MPa have an equiaxed grain structure with a uniform microstructure where no grain growth or elongated grain is observed.

A study reported that a comparison between the general densification method involving vacuum or high- pressure sintering and SPS at temperatures lower by 300-400 °C revealed that low-temperature (SPS) sintering is more effective than high-temperature (vacuum) sintering. Moreover, in SPS, high pressure is more effective in grain growth suppression [28].

3. 3 Mechanical properties

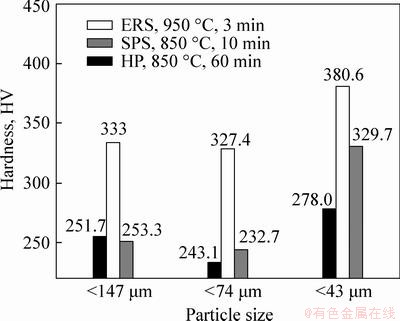

Figure 7 shows the hardness of the completely densified sintered bodies obtained from the three kinds of CP-Ti powders using each sintering method. The Vickers hardness is the highest for the <43 μm powder due to its small mean particle size, and the <147 μm and <74 μm powders follow the corresponding trend. With respect to the sintering method, the sintered body prepared by ERS, which requires the highest sintering temperature, shows a high hardness value of at least HV 300 and results in the highest hardness value of HV 380 for the <43 μm powder. It is believed that the hardness value increases with decreasing mean particle size because the specific surface area is large and the sintering temperature is high, which leads to a higher content of dissolved interstitial elements even with the short treatment time. The hardness values of the sintered bodies prepared by SPS and HP show a similar tendency, although the bodies sintered by HP have slightly lower hardness values. This is likely because the decrease in hardness due to grain growth during the relatively long sintering time in HP is larger than the increase achieved by the higher content of interstitial elements at the same sintering temperature.

Fig. 6 SEM microstructures of specimens sintered at 850 °C under 30 MPa with different sized titanium powder by different methods

Fig. 7 Hardness of CP-Ti powders with different particle sizes by various sintering methods

CP-Ti (Grade 3) prepared by the melting has a hardness of HV 180-220 [26]. In contrast, the hardness of the specimens sintered in the present study is higher by about HV 50 to HV 150. The initial powder is comminuted by planetary mill and subjected to SPS sintering under 80 MPa at 700 °C resulting in Ti with a hardness value of about HV 250 [18]. The CP-Ti powder sintered in SPS under 10 MPa at 1100 °C results in Ti with a hardness value of about HV 280 [19]. This increase is attributed to the formation of uniform and fine grains due to the fast densification achieved using SPS [14]. For comparison, CP-Ti powders sintered via SPS at 10 MPa and 1100 °C have hardness of HV 276 and HV 288 [19]. Further, Vickers hardness testing via indentation is known to be affected by the density, porosity, and distribution of the sintered body. In addition, CHOE et al [29] reported that the hardness of the sintered body increases as the oxygen content increases.

In the present study, there are not significant differences in the overall density, porosity, and distribution of the sintered bodies; however, the oxygen content of the raw material varies between 2.93×10-3 for the <147 μm powder and 4.3×10-3 for the <43 μm powder. Thus, it is believed that the oxygen content also affects the hardness.

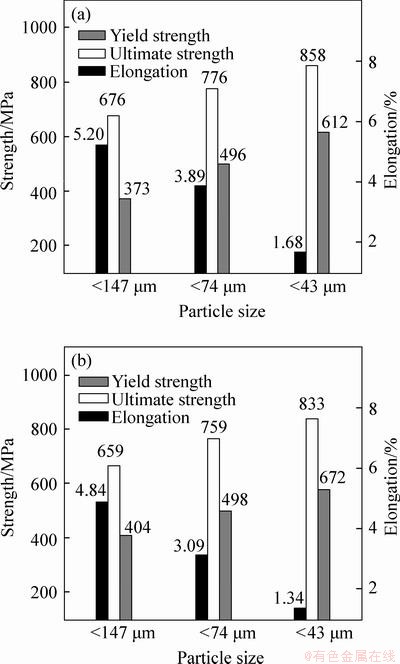

Figure 8 shows the tensile strength and elongation of a titanium body sintered by SPS and HP at a pressure of 30 MPa at 850 °C. It is difficult to obtain an exact value to compare with a standard-sized tensile specimen because the specimen is small, i.e., 20 mm long overall with a gage length less than 5 mm, but the result is sufficient and thus the measured values are compared. The tensile strength of CP-Ti (Grade 3) is known to be between 380 and 550 MPa [11]; however, the present specimen has a tensile strength of almost twice that value. This is likely due to the increase of tensile strength with size, the formation of uniform and fine grains by fast densification with SPS and HP sintering, and increased content of interstitial solids upon sintering. Comparison of the tensile properties of the sintered bodies obtained via different sintering methods reveals that the tensile strength, yield strength, and elongation show very similar tendencies for SPS and HP. The strength and elongation of the sintered body prepared by SPS are slightly higher than those of the specimen prepared by HP; this is ascribed to the fact that sintering is achieved in a shorter time period via SPS resulting in increased contents of interstitial elements and a finer microstructure, which improves the strength and elongation. In both SPS and HP methods, the elongation is about 5% for the <147 μm powder and about 1% for the <43 μm powder. This is explained by the experimental results of WANHILL [30] that, with increased oxygen content, twinning deformation is suppressed, which decreases the ductility, and when the oxygen content exceeds a certain level, the fracture of the specimen changes from a ductile fracture to a brittle fracture.

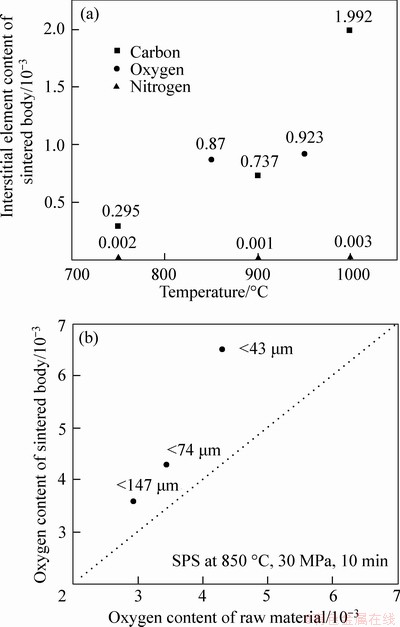

Fig. 8 Changes in strength and elongation of a titanium body sintered by SPS (a) and HP (b) at 850 °C and 30 MPa

In Fig. 9, the increased content of interstitial elements and oxygen content in the raw material powder and sintered body are shown with respect to the sintering temperature during SPS. The change of amount of the interstitial elements, after accounting for the increased carbon due to the use of a graphite mold, is not large with respect to changing pressure, but drastically increases with increasing temperature. Accordingly, in order to decrease the content of interstitial elements, it is advantageous to sinter at the lowest possible temperature. The comparison of the oxygen contents of the raw material powder and sintered body reveals that an increased amount of oxygen in the sintered body is caused by an increase of the specific surface area; accordingly, smaller mean particle sizes lead to increased oxygen content after sintering, and the larger specific surface areas of the raw material powder lead to higher oxygen content after sintering. CHOE et al [29] explained the fracture transitions from ductile to brittle when the oxygen content of the sintered body is between 3×10-3 and 5.5×10-3 [29]. The oxygen content of the CP-Ti powder that is used as the raw material powder is between 2.93×10-3 and 4.3×10-3 and the oxygen content of the final sintered body is between 3.6×10-3 and 6.5×10-3, which is in the range of the ductile–brittle transition.

Fig. 9 Contents of interstitial elements after sintering (a) and oxygen content (b) in raw material powder and sintered body

Using ERS, it is impossible to compare the tensile properties with those of other sintering methods as the fractures are generally brittle fractures due to the higher content of interstitial elements and increased grain coarsening under the high-temperature sintering conditions.

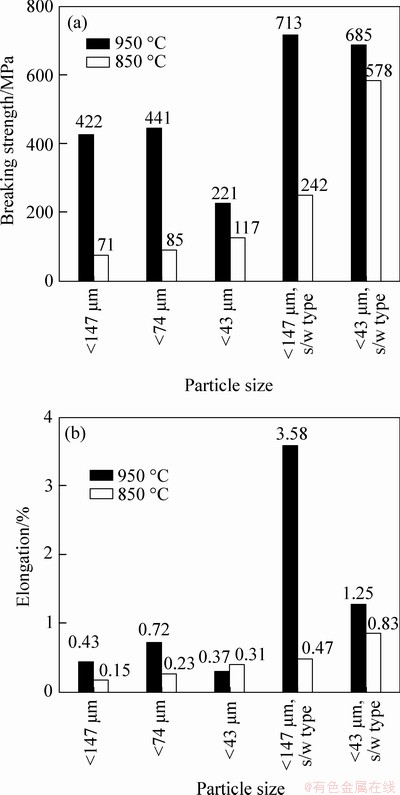

Fig. 10 Breaking strength (a) and elongation (b) of titanium sintered body prepared by ERS under 30 MPa at 850 °C and 950 °C

Figure 10 shows the breaking strength and the elongation of the titanium sintered body prepared by ERS under 30 MPa at 850 °C and 950 °C. For ERS, 850 °C is a non-sintering temperature, and at a high sintering temperature of 950 °C, the fracture occurs mostly in the elastic region due to an increased content of interstitial elements and increased grain coarsening. However, these results are compared to a sandwich panel structure (s/w type) in order to see the property changes with respect to the increased carbon content due to the graphite mold upon sintering (<147 μm and <43 μm, s/w type). A higher breaking strength is evident and the elongation is not affected in the case of the <43 μm powder. However, in the case of the <147 μm powder, the elongation increases to 3.5%. It is hence confirmed that the drastic increase in the carbon content in accordance with the increase in temperature results in poorer properties. This is evident in the analytical result, which shows an increased amount of interstitial elements with increased sintering temperature (Fig. 9).

Accordingly, in the present study, the sintered bodies are prepared by three kinds of sintering methods that shorten the sintering time while maintaining the intrinsic microstructure and purity of the three commercially available CP-Ti powders, which have different particle size distributions. Further, via SPS and HP, densification is achieved while suppressing the grain growth, resulting in titanium consolidation with superior mechanical properties, such as hardness and strength.

4 Conclusions

1) The hardness values of the sintered bodies obtained via SPS and HP are similar, while the highest hardness value is obtained via ERS, which has the highest sintering temperature. The tensile properties, i.e., tensile strength, yield strength, and elongation, of the sintered bodies obtained via SPS and HP are very similar; however, it is difficult to compare with those obtained via ERS, because fracture occurs in the elastic region.

2) The completely densified sintered bodies obtained via SPS and HP show higher strength values with smaller particle size due to the formation of uniform and fine grains by fast densification and an increased content of interstitial solids. The elongation, however, is about 5% for the <147 μm powder, about 3% for the <74 μm powder, and negligible for the <43 μm powder, which has the smallest mean particle size. The low elongation is found to be due to a transition from ductile to brittle fracture when the oxygen content in titanium exceeds a certain level. When the mean particles sizes of the raw material powder are small, the oxygen content is higher. This results in a higher oxygen content of the sintered body due to an increase of the oxygen content during sintering with smaller mean particle size. Thus, the sintered body is embrittled.

3) As to the increase of the carbon content due to the use of a graphite mold during sintering, it is determined that the interstitial elements have a significant impact on the degradation of the physical properties. This is shown by the elongation, which increases to 3.5% for the <147 μm powder as revealed by comparing the results of sintering to a sandwich-panel structure.

References

[1] DONG H, BELL T. Enhanced wear resistance of titanium surfaces by a new thermal oxidation treatment [J]. Wear, 2000, 238: 131-137.

[2] CHEN F K, CHIU K H. Stamping formability of pure titanium sheets [J]. Journal of Materials Processing Technology, 2005, 170: 181-186.

[3] HUSSAINA G, GAOA L, HAYATB N, CUI Z, PANG Y C, DARD N U. Tool and lubrication for negative incremental forming of a commercially pure titanium sheet [J]. Journal of Materials Processing Technology, 2008, 203: 193-201.

[4] YAPICI G G, KARAMAN I, MAIER H J. Mechanical flow anisotropy in severely deformed pure titanium [J]. Mater Sci & Eng A, 2006, 434: 294-302.

[5] NIINOMI M. Mechanical properties of biomedical titanium alloys [J]. Mater Sci & Eng A, 1998, 243: 231-236.

[6] WANG Zhong-jin, SONG Hui. Effect of electropulsing on anisotropy behaviour of cold-rolled commercially pure titanium sheet [J]. Transactions Nonferrous Metals Society of China, 2009, 19: 409-413.

[7]  G, WILLIAMS J C. Titanium [M]// Engineering Materials and Processes, 2nd ed. New York: Springer, 2007: 53-174.

G, WILLIAMS J C. Titanium [M]// Engineering Materials and Processes, 2nd ed. New York: Springer, 2007: 53-174.

[8] MACHADO A R, WALLBANK J. Machining of titanium and its alloys—A review [J]. Proc Inst Mech Eng, 1990, 204: 53-60.

[9] KNIGHT R, SMITH R W, APELIAN D. Application of plasma arc melting technology to processing of reactive metals [J]. Inter Mater Rev, 1991, 36: 221-252.

[10] GAI G, YANG Y, JIN L, ZOU X, WU Y. Particle shape modification and related property improvements [J]. Powder Tech, 2008, 183: 115-121.

[11] LOW R J, ROBERTSON I M, SCHAFFER G B. Excessive porosity after liquid-phase sintering of elemental titanium powder blends [J]. Scripta Mater, 2007, 56: 895-898.

[12] MISHIN Y, HERZIG C. Diffusion in the Ti–Al system [J]. Acta Mater, 2000, 48: 589-623.

[13] SEEBER A, KLEIN A N, SPELLER C V, EGERT P, WEBER F A, LAGO A. Sintering unalloyed titanium in DC electrical abnormal glow discharge [J]. Mat Res, 2010, 13: 99-106.

[14] PANIGRAHI B B, GODKHINDI M M, DAS K, MUKUNDA P G, RAMAKRISHNAN P. Sintering kinetics of micrometric titanium powder [J]. Mater Sic & Eng A, 2005, 396: 255-262.

[15] TOKITA M. Trends in advanced spark plasma sintering systems and technology [J]. J Soc Powder Tech Japan, 1993, 30: 790-804.

[16] TAMARI N, TANAKA T, TANAKA K, KONDOH I, KAWAHARA M, TOKITA M. Effect of spark plasma sintering on densification and mechanical properties of silicon carbide [J]. J Ceram Soc Japan, 1995, 103: 740-742.

[17] CHO K S, LEE K S, LEE H K, LEE S J, CHOI H J. Microstructure development of spark plasma sintered silicon carbide with Al-B-C [J]. J Kor Ceram Soc, 2005, 42: 567-574.

[18] HANDTRACK D, DESPANG F, SAUER C, KIEBACK B, REINFRIED N, GRIN Y. Fabrication of ultra-fine grained and dispersion-strengthened titanium materials by spark plasma sintering [J]. Mater Sic & Eng A, 2006, 437: 423-429.

[19] CHO K S, SONG I B, JANG M H, YOON J H, OH M H, HONG J K, PARK N K. Effect of sintering temperature on microstructure and mechanical properties for the spark plasma sintered titanium from CP-Ti Powders [J]. J Kor Powder Metall Inst, 2010, 17: 365-372.

[20] MUNIR Z A, QUACH D V, OHYANAGI M. Electric current activation of sintering: Review of PECS [J]. J Am Ceram Soc, 2011, 94: 1-19.

[21] SRIVATSAN T S, RAVI B G, PETRAROLI M. The microhardness and microstructural characteristics of bulk molybdenum samples obtained by consolidating nanopowders by plasma pressure compaction [J]. Int J Refract Met Hard Mater, 2002, 20: 181-186.

[22] MA Yao, ZHOU Zhang-jian, TAN Jun, LI Ming. Fabrication of ultra-fine grain tungsten by combining spark plasma sintering with resistance sintering under ultra high pressure [J]. Rare Metal Mater Eng, 2011, 40: 4-8.

[23] CHO K S, SONG I B, KIM J, OH M H, HONG N J K, PARK K. Effect of applied pressure on microstructure and mechanical properties for spark plasma sintered titanium from CP-Ti powders [J]. Kor J Met Mater, 2011, 49: 678-685.

[24] SU Y, WANG L, LUO L, JIANG X, GUO J, FU H. Deoxidation of titanium alloy using hydrogen [J]. Int J Hydrogen Energy, 2009, 34(21): 8958-8963.

[25] WOO K D, KANG D S, KWON E P, MOON M S, SHON I J, LIU Z. Fabrication and properties of Ti-Ha composites produced by pulsed current activated sintering for biomaterials [J]. Kor J Met Mater, 2009, 47: 508-515.

[26] DU S L, KIM N R, KIM W, CHO S W, SHON I J. Rapid sintering of TiCu by pulsed current activated heating and its mechanical properties [J]. Kor J Met Mater, 2010, 48: 922-928.

[27] KIM J Y, WOO K D, KANG D S, KIM S H, PARK S H, ZHANG D. Effect of high-energy mechanical milling time on microstructure and mechanical properties of the nano-sized TiAl intermetallic compounds fabricated by pulse current activated sintering [J]. Kor J Met Mater, 2011, 49: 161-166.

[28] QUACH D V, AVILA-PAREDES H, KIM S, MARTIN M, MUNIR Z A. Pressure effects and grain growth kinetics in the consolidation of nanostructured fully stabilized zirconia by pulsed electric current sintering [J]. Acta Mater, 2010, 58: 5022-5030.

[29] CHOE J S, LEE D H, CHOI G S, KIL D S, SUH C Y, KIM W, HA H. The effect of oxygen on the sintering of titanium powder [J]. Kor J Mater Res, 2000, 10: 464-470.

[30] WANHILL R J H. A consideration of cleavage in alpha titanium [J]. Acta Metallurgica, 1973, 21: 1253-1258.

Je-ha SHON1, 2, Jong-moon PARK1, Kyeong-sik CHO1, Jae-keun HONG3, Nho-kwang PARK3, Myung-hoon OH1

1. Department of Advanced Materials Engineering, Kumoh National Institute of Technology, Gumi, Gyeongbuk 730-701, Korea;

2. Advanced Technology Team, Pohang Institute of Metal Industry Advancement, Pohang, Gyeongbuk 790-834, Korea;

3. Titanium Department, Korea Institute of Materials Science (KIMS), Changwon, Gyeongnam 642-831, Korea

摘 要:研究不同烧结方法,包括放电等离子体烧结(SPS)、热压(HP)和电阻烧结(ERS),对商用纯钛(CP-Ti)粉末固结后显微组织和力学性能的影响。选用的粉末粒度分别为<147 μm, <74 μm 和 <43 μm,粉末粒度越小,其致密化过程越快。在850 °C、 30 MPa条件下进行SPS和HP,获得烧结体的相对密度高达99%。而通过ERS,则在950 °C、30 MPa条件下才发生CP-Ti粉末的致密化。在850~950 °C获得烧结钛的显微组织由等轴晶构成。对于粒度<43 μm粉末,在 850 °C、30 MPa条件下通过SPS制备烧结体,其屈服强度为868 MPa。随着小尺寸颗粒含量的升高,通过SPS 和 HP制备烧结体的屈服强度得到提高。然而在950 °C、30MPa条件下,通过ERS制备样品的最高屈服强度仅为441 MPa,比SPS 和 HP样品的低。与SPS 和 HP相比,ERS需要较短的烧结时间,但较高的烧结温度导致材料的脆性断裂,使其强度和伸长率降低。

关键词:CP-Ti粉末;烧结方法;放电等离子体烧结;热压;电阻烧结

(Edited by Jing-hua FANG)

Foundation item: Project (K0004130) supported by the Fundamental R&D Program for Core Technology of Materials funded by the Ministry of Knowledge Economy, Korea

Corresponding author: Myung-hoon OH; Tel: +82-54-478-7735; Fax: +82-54-478-7769; E-mail: ohmyung@kumoh.ac.kr

DOI: 10.1016/S1003-6326(14)63289-1