DOI: 10.11817/j.ysxb.1004.0609.2020-39524

全尾砂膏体管道输送壁面滑移减阻模型

王小林1, 2,王洪江1, 2,吴爱祥1, 2,彭青松1, 2

(1. 北京科技大学 土木与资源工程学院,北京 100083;

2. 北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京 100083)

摘 要:为定量表征全尾砂膏体管道输送过程中壁面滑移效应的减阻效果,基于膏体柱塞流动模型和H-B流变模型推导出考虑壁面滑移效应的管道阻力公式。滑移层厚度可根据尾砂平均粒径、膏体体积浓度和极限体积浓度进行计算。当H-B流变模型退变为宾汉流变模型时,考虑壁面滑移效应的管道阻力公式由小于1的无量纲系数对目前广泛使用的白金汉公式进行修正得到,修正系数与管道直径和滑移层黏度正相关,与滑移层厚度和膏体黏度负相关。工业环管试验结果表明,白金汉公式的压降预测值比实测值平均大36.6%,壁面滑移减阻模型的压降预测值比实测值平均大14.4%,壁面滑移减阻模型预测结果偏保守的原因是未考虑膏体触变性的影响。

关键词:全尾砂膏体;管道阻力;柱塞流动;壁面滑移;H-B流变模型

文章编号:1004-0609(2020)-09-2201-05 中图分类号:X753 文献标志码:A

尾砂是矿山产出量最大、综合利用率最低的大宗固体废弃物,我国现有尾砂堆存量超过150亿t,并且每年以12亿t的速度递增,成为潜在的地质灾害和环境污染源头[1]。因此,进行尾砂利用是矿山安全、绿色开采的必然要求。全尾砂制成的膏体具有不离析、不沉淀、不泌水的特点,用于井下采空区充填可以达到“一废(尾砂)治两害(采空区、尾矿库)”的效果[2]。对于无充填需求的矿山,全尾砂膏体堆存技术则具有安全、环保、省水、节能和占地少的优点[3],我国已有乌山铜矿和巴润铁矿进行使用。

不管是井下充填还是尾矿库堆存,管道输送均是膏体运输的主要方式。壁面滑移是全尾砂膏体管道输送过程中的重要现象,并已被实验证实有助于降低管道输送阻力[4-5]。壁面滑移的形成机理尚未形成统一认识,有观点认为膏体为了降低体系的自由能,尾砂颗粒自发地向管道中心迁移,而水分向管壁处迁移,从而在管壁处形成黏度很低的稀薄的滑移层[6]。目前,主要通过图像扫描[6]、流变测试[7]和环管测试[8]等实验方法,研究壁面滑移的形成机理、影响因素和对具体工程的减阻效果,尚未将壁面滑移减阻效应用于膏体管道输送阻力计算的理论模型修正[6]。

膏体浓度高、黏度大,其管道输送阻力计算是重要的研究课题,目前普遍采用基于宾汉流变模型推导的白金汉公式[9]进行管道阻力计算。而现有的其他膏体管道输送阻力计算公式虽然预测精度较高,但大多是对特定材料实验结果的回归拟合,公式中的相关参数均与特定材料有关,因而推广应用较难。白金汉公式的缺点是未考虑膏体壁面滑移对管道阻力的影响,因此需进行修正。此外人们逐渐认识到,具有三个参数的H-B流变模型描述全尾砂膏体的流变参数时适应性更广[10],而宾汉流变模型仅是H-B流变模型的特例,显然基于宾汉流变模型推导的白金汉公式也有一定的局限性。因此,基于适应性更广的H-B流变模型,并考虑壁面滑移效应的减阻作用,建立膏体的管道阻力计算模型更有意义。

1 考虑壁面滑移效应的膏体管道输送阻力模型

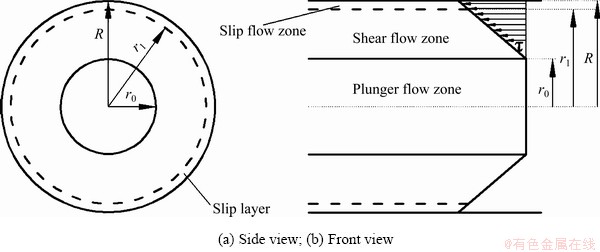

全尾砂膏体因浓度高、黏度大,即使在静置条件下也基本不沉淀,一般视为均质流,在管道中呈柱塞状流动。如图1所示,膏体在管道中的流动被划分为滑移流动区、剪切流动区和柱塞流动区[11]。

图1 膏体在管道中的柱塞流动模型

Fig. 1 Plug flow model of paste in pipeline

在柱塞流动模型中,剪切应力和剪切速率沿半径呈线性分布,在管道中心处为零,在管壁处达到最大。管道中的总剪切速率由两部分组成[12]:

(1)

(1)

式中: 为管道总剪切速率;v为管道中的平均流速;

为管道总剪切速率;v为管道中的平均流速; 为滑移剪切速率;

为滑移剪切速率; 为滑移速度;

为滑移速度; 是主流区的剪切速率;

是主流区的剪切速率; 是管壁处的剪切应力;

是管壁处的剪切应力; 是剪切流动区的剪切应力。

是剪切流动区的剪切应力。

在管道中取一半径为r、长为L的膏体微元进行分析,根据受力平衡可得到如下公式:

(2)

(2)

式中:Δp是微元体两端的压力差。当r=R时, ,因此,有如下关系:

,因此,有如下关系:

(3)

(3)

由于滑移区流体的黏度很低,可以视为牛顿流体(清水)。根据牛顿流体的剪切速率与黏度的关系,可将滑移速度表示为

(4)

(4)

积分后的结果为

(5)

(5)

滑移区厚度 ,由于

,由于 远小于管道半径,因此有

远小于管道半径,因此有 ,滑移速度可表示为

,滑移速度可表示为

(6)

(6)

或者

(7)

(7)

式(1)积分部分中的剪切速率 取决于流变模型。H-B流变模型如下:

取决于流变模型。H-B流变模型如下:

(8)

(8)

式中: 是剪切应力;

是剪切应力; 是膏体屈服应力;

是膏体屈服应力; 是膏体黏度系数;

是膏体黏度系数; 和n分别是剪切速率和无量纲流动指数。n<1时,膏体表现为伪塑性(剪切稀化);n>1时,膏体表现为膨胀性(剪切稠化);n=1时,H-B流变模型退化为宾汉流变模型。

和n分别是剪切速率和无量纲流动指数。n<1时,膏体表现为伪塑性(剪切稀化);n>1时,膏体表现为膨胀性(剪切稠化);n=1时,H-B流变模型退化为宾汉流变模型。

对于H-B流变模型, 。对于具有屈服应力的流体,式(1)中积分下限需替换为

。对于具有屈服应力的流体,式(1)中积分下限需替换为 。假设

。假设 ,因此,

,因此,

,最终积分结果如下:

,最终积分结果如下:

(9)

(9)

将式(7)和式(9)代入式(1),结果如下:

(10)

(10)

式(10)即是基于H-B流变模型并考虑壁面滑移效应的管道阻力计算公式,因其是一个隐式表达式,很难直接写成 的形式,可以借助MATLAB等数学软件先求得

的形式,可以借助MATLAB等数学软件先求得 ,然后根据式(3)求得

,然后根据式(3)求得 。

。

显然,不考虑壁面滑移效应时,式(10)可变换为

(11)

(11)

式(11)即为符合H-B流变模型、不考虑壁面滑移效应的柱塞流管道阻力计算公式。

对于n=1的特殊情况(宾汉流变模型),式(10)可简化为

(12)

(12)

将式(3)代入式(12)并忽略四次项,结果如下:

(13)

(13)

式(13)即为基于宾汉流变模型并考虑壁面滑移效应的管道阻力计算公式,显然其是对目前广泛使用的计算膏体管道输送阻力的白金汉公式的修正。

令 ,分析可知

,分析可知 无量纲,且

无量纲,且 小于1,因此考虑壁面滑移效应时管道压降比白金汉公式计算值要小。

小于1,因此考虑壁面滑移效应时管道压降比白金汉公式计算值要小。

可将 称作壁面滑移阻力修正系数,显然

称作壁面滑移阻力修正系数,显然 与管道直径和滑移层黏度正相关,与滑移层厚度和膏体黏度负相关。

与管道直径和滑移层黏度正相关,与滑移层厚度和膏体黏度负相关。

由式(10)和式(13)可知,滑移层厚度δ的计算是管道阻力预测的基础之一。YARAS等[12]和KALYON[5]通过大量的实验研究建立了计算滑移层厚度的经验公式,如式(14)所示:

(14)

(14)

式中:dp是尾砂颗粒的平均直径;cV是膏体的体积浓度;cVM是膏体的极限体积浓度。体积浓度可通过质量浓度和尾砂比重换算,极限体积浓度可通过沉降法或流变测试[13]等方法进行确定。

2 膏体管道阻力模型可靠性验证

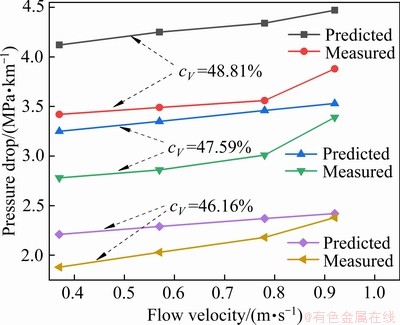

采用文献[14]的工业级环管试验数据对考虑壁面滑移效应的膏体管道输送阻力计算公式进行验证。环管直径150 mm,尾砂平均粒径64.2 μm,均添加有11%的水泥,实验得到的极限体积浓度为55.7%。三组浓度的全尾砂膏体均属于宾汉流体,体积浓度48.81%时屈服应力为132.4 Pa,黏度为0.48 Pa·s;体积浓度47.59%时屈服应力为104.2 Pa,黏度为0.405 Pa·s;体积浓度46.16%时屈服应力为68.18 Pa,黏度为0.323 Pa·s。采用公式(13)对管道压降进行计算,壁面滑移减阻模型预测压降与环管试验的实测压降对比见图2。

图2 壁面滑移减阻模型预测压降与实测值对比

Fig. 2 Comparison of pressure drop between predicted by wall slip drag reduction model and measured value

由图2可知,本文推导的考虑壁面滑移效应的管道阻力模型计算值比实测值要大,当体积浓度48.81%时误差为15.2%~20.5%(平均19.8%);当体积浓度47.59%时误差为4.2%~16.9%(平均13.3%);当体积浓度46.16%时误差为1.9%~17.5%(平均10.2%);模型的总体误差在1.9%~20.5%之间,平均误差为14.4%。体积浓度48.81%、47.59%和46.16%对应的修正系数λ的值分别为0.831、0.832和0.852,因此,考虑壁面滑移效应的全尾砂膏体管道压降分别比白金汉公式计算值小16.9%、16.8%和14.8%。若不考虑修正系数λ,则三组膏体浓度下白金汉公式压降计算值分别比实测值大44.2%、36.2%和29.4%,平均大36.6%。

总的看来,白金汉公式计算值明显偏大,论文推导的考虑壁面滑移效应的膏体管道输送阻力计算模型也偏保守。出现这种现象的原因是膏体在管道输送过程中不仅存在壁面滑移效应,还存在触变性[15],即膏体流变参数随输送时间的增加而逐渐减小至稳定值,管道压降也会有所降低[16-17],并且膏体浓度越高触变性越强[15],这也能很好地解释膏体体积浓度由48.81%降低至46.16%时壁面滑移减阻模型预测压降的误差也相应地由19.8%减小至10.2%。一般的流变测试并未考虑膏体触变性影响,所以考虑壁面滑移的压降预测值仍然比环管试验的实测值偏大。而白金汉公式既未考虑壁面滑移又没有考虑膏体触变性的影响,因此预测的管道压降值明显大于实测值。

3 结论

1) 基于H-B流变模型推导了考虑壁面滑移效应的全尾砂膏体管道输送阻力计算模型,实现壁面滑移减阻的定量表征,且模型具有较高的可靠度,可通过测量膏体基本物理参数来进行计算,实际操作比较简单。

2) 白金汉公式预测的膏体管道输送阻力明显偏大,可通过考虑壁面滑移效应的无量纲系数进行修正,修正系数小于1,与管径和滑移层黏度正相关,与滑移层厚度和膏体黏度负相关。

3) 考虑壁面滑移效应的膏体管道输送阻力预测模型仍然偏保守,主要是未考虑膏体触变性的影响。建立同时考虑膏体壁面滑移和触变特性的阻力计算模型,将使膏体管道输送阻力预测结果更为准确。

REFERENCES

[1] 孟跃辉, 倪 文, 张玉燕. 我国尾矿综合利用发展现状及前景[J]. 中国矿山工程, 2010, 39(5): 4-9.

MENG Yue-hui, NI Wen, ZHANG Yu-yan. Current state of ore tailings reusing and its future development in China[J]. China Mine Engineering, 2010, 39(5): 4-9.

[2] 吴爱祥, 杨 莹, 程海勇, 陈顺满, 韩 悦. 中国膏体技术发展现状与趋势[J]. 工程科学学报, 2018, 40(5): 517-525.

WU Ai-xiang, YANG Ying, CHENG Hai-yong, CHEN Shun-man, HAN Yue. Status and prospects of paste technology in China[J]. Chinese Journal of Engineering, 2018, 40(5): 517-525.

[3] 印万忠. 尾矿堆存技术的最新进展[J]. 金属矿山, 2016(7): 10-19.

YIN Wan-zhong. Latest progress of tailings stockpiling technology[J]. Metal Mine, 2016(7): 10-19.

[4] CHEN Dan-dan, JIANG Xu-guang, Lü Shuai, Lü Guo-jun, MA Zeng-yi, YAN Jian-hua, YU Xue-hai, LIAO Hai-yan, ZHAO Hua. Rheological properties and stability of lignite washery tailing suspensions[J]. Fuel, 2015, 141: 214-221.

[5] KALYON D M. Apparent slip and viscoplasticity of concentrated suspensions[J]. Journal of Rheology, 2005, 49(3): 621-640.

[6] 张 磊, 王洪江, 李公成, 吴爱祥, 刘晓辉. 膏体管道壁面滑移特性研究进展及趋势[J]. 金属矿山, 2015(10): 1-5.

ZHANG Lei, WANG Hong-jiang, LI Gong-cheng, WU Ai-xiang, LIU Xiao-hui. Research progress and trend of characteristics about wall slip in paste pipeline[J]. Metal Mine, 2015(10): 1-5.

[7] LYU Fu-yan, QU Yuan-yuan, ZHANG Ning-xiao, GAO Jie, HAO Xue-di, WU Miao. Yield stress measurement of dense pastes with pipe transport and vane[J]. Journal of Dispersion Science and Technology, 2016, 37(11): 1563-1569.

[8] CHEN Liang-yong, DUAN Yu-feng, LIU Meng, ZHAO Chang-sui. Slip flow of coal water slurries in pipelines[J]. Fuel, 2010, 89(5): 1119-1126.

[9] YANEZ R, TAPIA C. Tailings transport on high yield stress requirements: turbulent or laminar flow?[C]//Proceedings of the 21st International Seminar on Paste and Thickened Tailings. Perth: Australian Centre for Geomechanics, 2018: 217-226.

[10] BHARGAV B, MAUREEN M, SHARUN K, KERMANIA M. Pressure loss and friction factor in non-Newtonian mine paste backfill: modelling, loop test and mine field data[J]. Powder Technology, 2019, 344: 443-453.

[11] 吴爱祥, 程海勇, 王贻明, 王洪江, 刘晓辉, 李公成. 考虑管壁滑移效应膏体管道的输送阻力特性[J]. 中国有色金属学报, 2016, 26(1): 180-187.

WU Ai-xiang, CHENG Hai-yong, WANG Yi-ming, WANG Hong-jiang, LIU Xiao-hui, LI Gong-cheng. Transport resistance characteristic of paste pipeline considering effect of wall slip[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 180-187.

[12] YARAS P, KALYON D M, YILMAZER U. Flow instabilities in capillary flow of concentrated suspensions[J]. Rheologica Acta, 1994, 33(1): 48-59.

[13] 陈 立. 高含沙水流流变参数的试验研究[J]. 武汉水利电力学院学报, 1992, 25(4): 384-392.

CHEN Li. Research on the rheological parameters of high sediment-laden flow[J]. Journal of the Wuhan Institute of Hydraulic and Electric Engineering, 1992, 25(4): 384-392.

[14] 杨清平, 王贻明, 王 勇, 吴国珉, 岑佑华, 沈家华. 谦比希铜矿膏体充填环管实验研究[J]. 采矿技术, 2016, 16(5): 21-22, 31.

YANG Qing-ping, WANG Yi-ming, WANG Yong, WU Guo-min, CEN You-hua, SHEN Jia-hua. Experimental study on paste filling loop of chambishi copper mine[J]. Mining Technology, 2016, 16(5): 21-22, 31.

[15] 杨柳华, 王洪江, 吴爱祥, 邢 鹏, 高维鸿. 全尾砂膏体搅拌剪切过程的触变性[J]. 工程科学学报, 2016, 38(10): 1343-1349.

YANG Liu-hua, WANG Hong-jiang, WU Ai-xiang, XING Peng, GAO Wei-hong. Thixotropy of unclassified pastes in the process of stirring and shearing[J]. Chinese Journal of Engineering, 2016, 38(10): 1343-1349.

[16] 吴爱祥, 刘晓辉, 王洪江, 王贻明, 焦华喆, 刘斯忠. 结构流充填料浆管道输送阻力特性[J]. 中南大学学报(自然科学版), 2014, 45(12): 4325-4330.

WU Ai-xiang, LIU Xiao-hui, WANG Hong-jiang, WANG Yi-ming, JIAO Hua-zhe, LIU Si-zhong. Resistance characteristics of structure fluid backfilling slurry in pipeline transport[J]. Journal of Central South University (Science and Technology), 2014, 45(12): 4325-4330.

[17] 李 俊, 肖崇春, 姜 寄, 李书生. 泵送膏体触变特性对管道阻力的影响[J]. 中国矿业, 2017, 26(S2): 283-287.

LI Jun, XIAO Chong-chun, JIANG Ji, LI Shu-sheng. Thixotropic properties of paste pumping effect on pipeline resistance[J]. China Mining magazine, 2017, 26(S2): 283-287.

Wall slip drag reduction model of full tailings paste in pipeline transportation

WANG Xiao-lin1, 2, WANG Hong-jiang1, 2, WU Ai-xiang1, 2, PENG Qing-song1, 2

(1. School of Civil and Resource Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Key Laboratory of High-Efficient Mining and Safety of Metal, Ministry of Education, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: To quantitatively characterize the drag reduction effect of the wall slip effect during pipeline transportation of full tailings paste, a pipe resistance formula considering the wall slip effect is derived, based on the paste plug flow model and the H-B rheological model. The slip layer thickness can be calculated according to the average tailings particle size, the volume concentration and ultimate volume concentration of paste. When the H-B rheological model is degenerated into the Bingham rheological model, the pipe resistance formula considering the wall slip effect is composed of the widely used Buckingham formula and a dimensionless coefficient less than 1. The correction coefficient is positively with the pipeline diameter and the viscosity of the slip layer, while negatively with the thickness of the slip layer and paste viscosity. The results of industrial loop test show that the predicted pressure drop by the Buckingham formula is 36.6% larger than the measured value, and the predicted pressure drop by the wall slip drag reduction model is 14.4% larger than the measured value. The wall slip drag reduction model is conservative than the measured value, because the influence of paste thixotropy is not considered.

Key words: full tailings paste; pipeline resistance; plug flow; wall slip; H-B rheological model

Foundation item: Project(2017YFC0602903) supported by the National Key Research Development Program of China; Project(51834001) supported by the National Natural Science Foundation of China

Received date: 2019-09-20; Accepted date: 2020-05-10

Corresponding author: WANG Hong-jiang; Tel: 15901196527; E-mail: wanghj1988@126.com

(编辑 龙怀中)

基金项目:国家重点研发计划项目(2017YFC0602903);国家自然科学基金重点资助项目(51834001)

收稿日期:2019-09-20;修订日期:2020-05-10

通信作者:王洪江,教授,博士;电话:15901196527;E-mail:wanghj1988@126.com