DOI: 10.11817/j.ysxb.1004.0609.2020-39633

热处理对7056和7095铝合金力学性能和SCC的影响

韦士龙1, 2,冯 艳1, 2,王日初1, 2,任 建1, 2,彭超群1, 2,张 辉3,许春停3,吴 瑛3

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 电子封装与先进功能材料重点实验室,长沙 410083;

3. 中国电子科技集团公司 第三十八研究所,合肥 230088)

摘 要:采用扫描电镜(SEM)、电子背散射衍射技术(EBSD)和透射电镜(TEM)、慢应变速率拉伸和断裂韧性试验等对峰值时效和过时效的7056合金和7095合金组织、力学性能和应力腐蚀开裂敏感性进行研究。结果表明:两种合金固溶后都发生了明显的再结晶,且7095合金再结晶程度更高。两种合金经峰值时效晶内都存在尺寸细小、密度高的析出相,且7056合金晶内析出相平均尺寸更小(3.5 nm)、密度更高,表现出更高的强度(643MPa)。两种合金经过时效晶内析出相都发生明显粗化,尤其是7095合金晶内存在更多的粗大η相,导致7095-T74合金的强度降低8.5%。7056合金和7095合金经峰值时效断裂韧值分别是26.8 MPa·m1/2和28.2 MPa·m1/2,过时效后分别增加到29.6 MPa·m1/2和34.7 MPa·m1/2。过时效的7095合金较高的断裂韧性是由于晶内和晶界强度差减小、晶界存在粗大不连续的析出相和无沉淀析出带的共同作用。峰值时效后,晶界上呈连续分布的析出相使7056合金和7095合金应力腐蚀开裂敏感性较高;过时效后,晶界析出相呈粗大、不连续分布,使得合金的SCC敏感性降低。

关键词:7xxx系铝合金;时效析出;应力腐蚀开裂;断裂韧性

文章编号:1004-0609(2020)-08-1739-11 中图分类号:TG146.2 文献标志码:A

含铜的7xxx系铝合金广泛应用于航空航天领域,特别是先进飞机的大型结构件[1-2]。在过去的十几年里,主元素(Zn, Mg 和Cu)含量高,具有不同Zn/Mg比和Cu/Mg比的一系列高强铝合金被开发出来,如7056合金、7136合金和7095合金,通过成分优化使该合金在高强和耐蚀方面得到良好的匹配[3-4]。铝合金虽有保护性氧化膜的存在使其具有良好的耐蚀性,但仍对一些局部腐蚀比较敏感,如点蚀、晶间腐蚀和应力腐蚀开裂(Stress corrosion cracking, SCC),尤其是SCC造成的失效占比很大[5-7]。对于SCC而言,它是在特定的环境下(拉应力和特定的腐蚀液)由于被测合金表面钝化膜的塑性远小于金属基体引起的,在拉应力作用下,被测合金不断变形,钝化膜首先破裂,导致基体暴露在腐蚀介质中,从而造成SCC发生。随着人们对SCC机理认识的不断深入,经典的局部阳极腐蚀理论认为晶界上优先发生了η-Mg(Zn,Al,Cu)2相的腐蚀,而氢致开裂理论认为晶界附近的H原子浓度超过了临界值是发生SCC的主要原因,目前有学者提出Mg在晶界的偏析和Mg—H的相互作用也会影响SCC[8-11]。

HOU等[12]研究了Mg、Cu对7xxx系铝合金力学性能的影响,认为Mg和Cu都能提高7xxx系铝合金的力学性能,且Mg的作用比Cu强,但是没有考虑Mg、Cu对SCC的影响。CHEN等[13-14]在研究Cu含量对7xxx系铝合金力学性能的影响中,认为Cu对合金的SCC敏感性较高,含量在0.8%~1.8%(质量分数)时合金强度最高,但这都是在单级峰值时效下得到的结果,并未考虑不同热处理下强度的变化。也有文献表明较高的Cu含量(大于2.0%,质量分数)能提高抗SCC能力,但合金表现出较高的点蚀和淬火敏感性[15-17],使合金强度降低。

如何使7xxx铝合金在保证高强度的同时也具有优良的抗SCC能力一直是该合金研究的重点。一般通过调整合金成分和改变热处理工艺来提高7xxx铝合金的抗SCC能力,本文采用Zn含量相当、Mg、Cu含量差异较大的7056合金和7095合金,借助慢应变速率拉伸试验和透射电镜分析成分变化来研究热处理对7xxx系铝合金力学性能和SCC的影响。

1 实验

本论文所使用的是热轧态铝合金板材,其具体成分如表1所列。铸态试样采用双级均匀化((450 ℃、8 h)+(475 ℃、24 h))退火后空冷,在430 ℃下保温2.5 h热轧到4 mm,变形量在80%左右。轧制后的样品在480 ℃下保温2 h进行固溶处理,随后分别在120 ℃下时效24 h(T6态)和110 ℃时效8 h后再160 ℃时效14 h(T74态)。

室温拉伸试验在MTS-810型电子万能试验机上完成。采用紧凑型拉伸C(T)试样,按照ASTM E399标准进行断裂韧性试验。采用慢应变速率拉伸试验(Slow strain rate test, SSRT)来评估该试样对SCC的敏感性。SSRT样品测试时外加应力沿轧制方向,应变速率为6.6×10-6 s-1。TEM和EBSD样品先机械减薄到80 μm左右,随后冲片和双喷,其中双喷液是甲醇和硝酸的混合液。借助Image-Pro Plus (IPP) 软件统计析出相的平均尺寸,EBSD数据使用TSL OIM Analysis 7 软件进行分析,2°~15°的晶界错配度定义为低角度晶界(Low angle grain boundaries, LAGBs),大于15°的晶界错配度定义为高角度晶界(High angle grain boundaries, HAGBs)。

表1 合金成分

Table 1 Chemical compositions

2 分析与讨论

2.1 显微组织

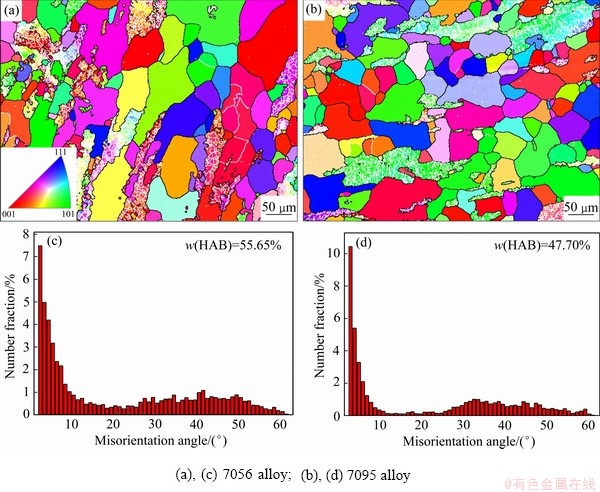

图1 7056合金和7095合金固溶后EBSD结果

Fig. 1 EBSD images((a), (b)) and distributions((c), (d)) of grain boundary misorientation after solid solution

图1所示为7056合金和7095合金固溶处理后的EBSD取向图。从图1(a)和(b)可知,两种合金都发生了明显的再结晶,7095合金晶粒结构趋向于等轴状,其中7056合金晶粒尺寸大约为62.4 μm,7095合金晶粒尺寸大约为54.8 μm,两者相差不大。从图1(c)和(d)可知,7056合金比7095合金的大角度晶界分数稍高,这意味7056合金发生的静态再结晶程度较低。这是由于7095合金中Cu含量较高,而Cu相较于Mg更易促使合金发生再结晶,这与HOU和JIN等[12, 18]的研究结论是一致的。

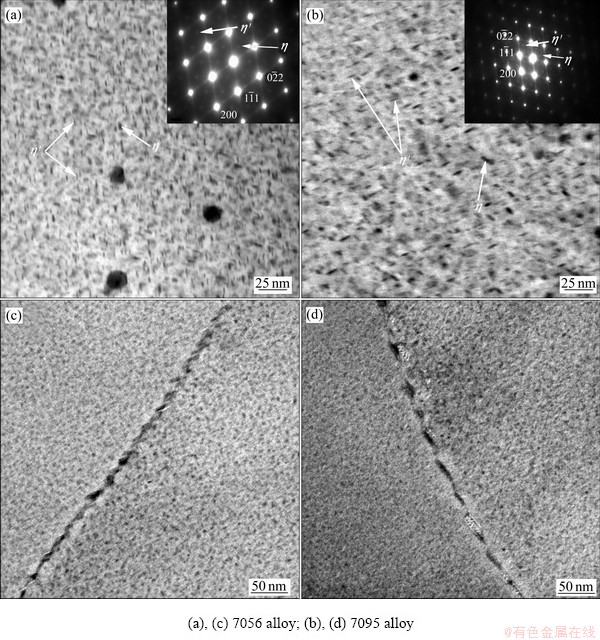

图2(a)和(b)所示为7056合金和7095合金T6时效后沿[110]晶带轴晶内析出相的明场像及电子衍射花样。由图可以清晰看到7056-T6合金和7095-T6合金晶内都存在细小的棒状η′和η析出相,其中7056-T6合金析出相的平均尺寸约为3.5 nm;而7095-T6合金析出相平均尺寸略大于7056-T6合金的,约4.3 nm,密度却显著小于7056-T6合金的。从图2(c)和(d)可看出,7056-T6合金和7095-T6合金晶界析出相(Grain boundary precipitates, GBPs)呈连续分布,无沉淀析出带(Precipitate free zones, PFZs)不明显。

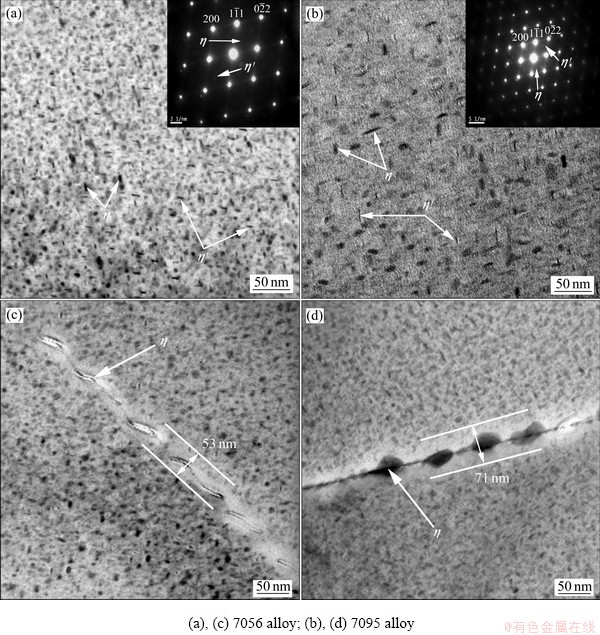

图3(a)和(b)所示为7056合金和7095合金T74时效后沿[110]晶带轴晶内析出相的明场像及电子衍射花样。由图可以看出,7056-T74合金和7095-T74合金晶内析出相相较于T6时效已发生明显粗化,7056-T74合金中η相数量开始增多,而7095-T74合金中η相尺寸可达20 nm,但7056-T74合金晶内析出相的密度仍然高于7095-T74合金的。此外,GBPs同样发生了粗化,其中7095-T74合金GBPs呈孤立、不连续的状态且间距比7056-T74合金的大。两种合金都出现了明显的PFZs,宽度值分别为53 nm和71 nm。

2.2 力学性能

图2 7056合金和7095合金T6时效后晶内和晶界TEM图像及相对应的电子衍射花样

Fig. 2 TEM images of intragranular((a), (b)) and grain boundary((c), (d)) under T6 aging

图3 7056合金和7095合金T74时效后晶内和晶界TEM图像及相对应的电子衍射花样

Fig. 3 TEM images of intragranular((a), (b)) and grain boundary((c), (d)) under T74 aging

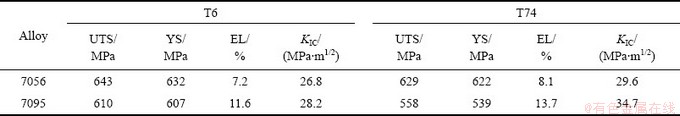

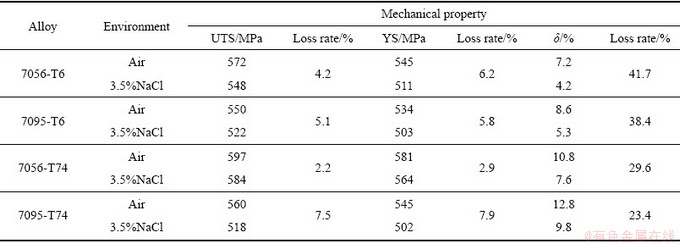

表2所列为两种合金在T6和T74时效后的力学性能值。7056-T6合金抗拉强度(Ultimate tensile strength, UTS)、屈服强度(Yield strength, YS)和伸长率(Elongation, EL)分别是643 MPa、632 MPa和7.2%,而7056-T74合金的抗拉强度和屈服强度分别降低2.2%和1.6%,但伸长率增加12.5%。7095-T6合金UTS 和EI分别是610 MPa和11.6%。7095合金从T6时效到T74时效强度值降低幅度更大(8.5%)。力学性能的变化往往与晶内析出相紧密相关,一般认为,7xxx系铝合金析出序列如下:过饱和固溶体(Supersaturated solid solution, SSS)→GP区→η′相→η相,其中GP区是与基体共格的原子团簇[19],半共格的亚稳η′相认为是7xxx系铝合金中最重要的时效析出强化相,该相的尺寸、密度和分布是影响析出强化的主要因素,η相是由η′相转变或从基体直接析出的尺寸较大、与基体不共格的平衡相[20-21]。研究表明:提高Mg含量可以增加析出相的体积分数,而Cu含量对析出相的稳定有重要的影响[12, 22]。从图2(a)和(b)可知,7056合金和7095合金经T6时效后晶内都存在高密度、纳米尺寸级别的析出相,这些析出相在塑性变形中可以有效阻碍位错的运动,因而两种合金都表现出较高的强度。但7095-T6合金晶内析出相的密度比7056-T6合金的要低,因此强度稍低于7056-T6合金。从T6到T74时效,两种合金晶内析出相都发生了明显的粗化,7095-T74合金出现的η析出相更多、粗化程度更深,而该相强化效果不如η′析出相[23],密度也降低的更多。7056-T74合金和7095-T74合金强度都出现了降低,但7095-T74合金的强度降低的幅度更大。因此,可以推出Mg元素的强化作用强于Cu元素,更高的Cu含量易使析出相发生粗化,这与HOU和CHINH等[12, 22]结论是一致的。

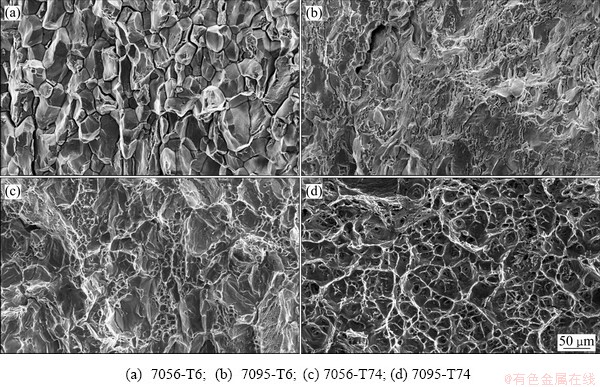

从表2也可知两种合金断裂韧性的变化规律,即T6时效下KIC值都较低(仅近30 MPa·m1/2),T74时效后KIC值明显增加,其中7095合金增加幅度最大,可达23.05%。断裂韧性与7xxx系铝合金的组织密切相关,主要包括难固溶的金属间化合物、晶粒结构、PFZs、GBPs和晶内析出相[24-25]。本论文所使用的材料Fe和Si的含量都在0.05%以下,因此可以忽略难溶相对断裂韧性的影响。从图1知两种合金固溶后晶粒结构相差不大,后续时效对晶粒结构和难固溶相基本无影响。因此重点研究合金成分和时效引起的晶内和晶界强度差对断裂韧性的影响。图4所示为7056合金和7095合金使用C(T)试样断裂后的断口形貌。7056-T6合金的断口呈冰糖状形貌,是典型的沿晶断裂,而7095-T6合金断口呈扁平状且有裂纹存在,是沿晶占主导的混合断裂模式。7056-T74合金的断口形貌虽有冰糖状形貌的特征,但已出现很多细小的韧窝,是混合断裂模式,而7095-T74合金断口形貌已由尺寸大且深的韧窝完全占据,是典型的穿晶断裂。因此,两种合金在T6和T74时效下共存在三种断裂模式:沿晶断裂模式、穿晶断裂模式和混合断裂模式。哪一种断裂模式占据主导地位,主要取决于晶内和晶界的强度差,影响因素包括:晶内析出相尺寸及密度、GBPs是否连续粗大和PFZs的宽度[26]。由图2可知7056-T6和7095-T6合金晶内析出相尺寸细小、密度高,造成晶界和晶内强度差较大。当合金发生塑性变形时,GBPs附近将出现严重的应力集中造成微裂纹或空洞,裂纹易沿连续的GBPs扩展,造成沿晶断裂[27]。因此,7056-T6合金和7095-T6合金拥有较低的KIC值,其图4(a)和(b)中典型的断裂模式也证实了这点。经T74时效后,两种合金晶内析出相的明显粗化会使晶内和晶界强度差减小,尤其是7095-T74合金晶内存在较多20 nm左右的η相会使强度差降低更多。因此,两种合金的KIC值都得到了提高。此外,孤立、不连续的GBPs也可延缓裂纹沿晶界的扩展,较软的PFZs也有利于变形的充分进行[26]。7095-T74合金拥有较低的晶内和晶界强度差,以及GBPs和PFZs独特的特征,从而拥有最高的KIC值,图4(d)的断口形貌也证实了这一点。

2.3 应力腐蚀开裂

表2 7056和7095合金的力学性能

Table 2 Mechanical properties of 7056 and 7095 alloys

图4 7056合金和7095合金在不同时效条件下断裂韧性断口形貌

Fig. 4 Fracture morphologies of 7056 alloy and 7095 alloy under different aging conditions

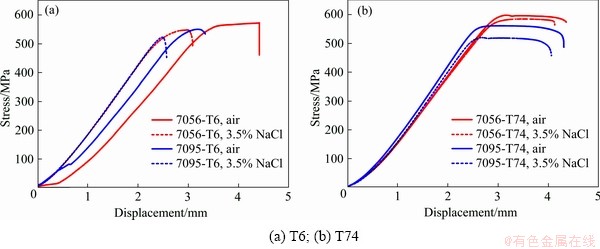

图5 7056合金和7095合金SSRT曲线

Fig. 5 Stress-displacement curves of 7056 alloy and 7095 alloy under different aging conditions

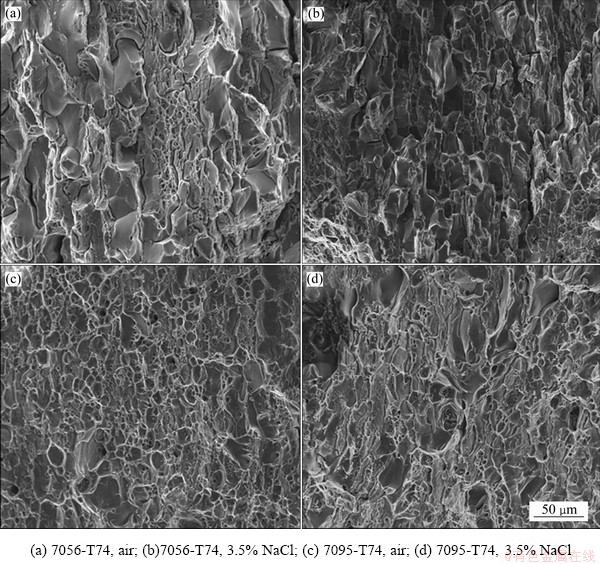

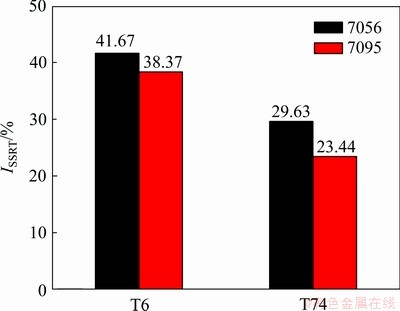

图5所示为7056合金和7095合金分别在室温和3.5% NaCl水溶液的SSRT应力-位移曲线。图6和图7所示为7056合金和7095合金分别在室温和3.5%NaCl水溶液SSRT试验后的断口形貌,可知断口形貌已发生明显改变,这也意味着发生了应力腐蚀开裂(SCC)。表3所列为两种合金SSRT试验后的力学性能值及损失量。结果表明:在3.5% NaCl溶液中测试的强度与室温测试后的强度相差不大,这意味着测试环境对强度的影响有限。然而,在3.5% NaCl溶液中测试的样品的伸长率远低于室温测试样品的,因此SCC的敏感性通过ISSRT值来评估,其值采用下面的式(1)计算[28]。

(1)

(1)

式中: 和

和 分别是3.5% NaCl溶液和室温下测试的伸长率。ISSRT值越大,耐SCC能力越差。图8所示为7056合金和7095合金的ISSRT结果,因此抗SCC能力由小到大的顺序为:7056-T6、7095-T6、 7056-T74、7095-T74。晶界上粗大的析出相一般认为是η-Mg(Zn,Al,Cu)2平衡相,该相和PFZs及邻近周围基体具有电势差,局部阳极腐蚀理论认为将优先发生该相的腐蚀,形成阳极腐蚀通道[29]。7056-T6合金和7095-T6合金GBPs呈链状连续分布,局部阳极腐蚀发生后会使腐蚀速率大大增加,这也是7056-T6合金和7095-T6合金SCC敏感性比较高的原因。图6所示为7056-T6合金和7095-T6合金SSRT失效后的断口形貌。从图6(a)和(c)中可以看出:7056-T6合金相貌由很多小且光滑的平面组成,是典型的沿晶断裂,而7095-T6合金断口相貌除沿晶特征外,已出现很多小韧窝区域,这是沿晶占主导的混合断裂。从图6(b)和(d)可知:除冰糖状的沿晶断裂特征外,还发现了沿晶界开裂的二次裂纹。这也是由于晶界上的η-Mg(Zn,Al,Cu)2相易腐蚀且呈连续分布,在SSRT试验时裂纹易在晶界处形成和扩展,从而表现出比较高的SCC敏感性。图7所示为过时效7056合金和7095合金SSRT失效的断口形貌。从图7(a)和(c)中可以看出:7056-T74合金已出现韧窝区,意味着开始从沿晶断裂向沿晶占主导的混合断裂转变,而7095-T74合金断口形貌已呈穿晶断裂模式。从图7(b)和(d)可知:7056和7095合金经T74时效已很难看到沿晶界的二次裂纹,这也表明发生氢致脆性开裂的可能性已大大降低。因此,7056-T74合金和7095-T74合金的SCC敏感性降低,尤其是7095-T74合金的SCC敏感性大大降低。这是由于7095-T74合金η-Mg(Zn,Al,Cu)2相粗化程度更深,GBPs间距更大,可减缓沿晶界的腐蚀速率和裂纹扩展速率。氢致开裂机制认为:SCC与晶界附近的原子H浓度有关,一旦超过临界值将会发生氢致脆性开裂,而粗大η-Mg(Zn,Al,Cu)2相可以作为捕获H原子的陷阱来降低SCC敏感性[10]。7056-T6合金和7095-T6合金的η-Mg(Zn,Al,Cu)2尺寸较小,不能有效的捕获H原子,同时应力易在η-Mg(Zn,Al,Cu)2相附近堆积,裂纹一旦在晶界萌生,将会沿着连续的GBPs快速扩展,导致氢致脆性开裂。7056合金和7095合金经T74时效,η-Mg(Zn,Al,Cu)2尺寸增加,能捕获更多的H原子来降低SCC敏感性,尤其是7095-T74合金GBPs不仅尺寸大且呈孤立、不连续分布,有利于延缓裂纹沿晶界扩展的速率,从而降低SCC敏感性。无论用局部阳极腐蚀理论还是氢致开裂理论来解释SCC敏感性,总之粗大、孤立不连续的GBPs对降低SCC敏感性总是有利的。因此,7095-T74合金GBPs的这种特点正是该合金具有出色的抗SCC能力的原因。此外,有学者认为晶界上Mg的偏析和Mg—H的相互作用将不可避免的影响SCC敏感性。晶界处Mg与H原子间的电负性差大于Al、H原子间的电负性差,Mg—H的相互作用增加了H原子在晶界的聚集,增加了氢致开裂的可能性[10-11, 16]。由于7056合金属于高Mg低Cu的高强铝合金,Cu原子在η-Mg(Zn,Al,Cu)2相中的含量较低,Mg元素又易在晶界偏析[30-31],造成7056合金SCC敏感性较高。低Mg高Cu含量的7095系合金在过时效状态具有更低的SCC敏感性。

分别是3.5% NaCl溶液和室温下测试的伸长率。ISSRT值越大,耐SCC能力越差。图8所示为7056合金和7095合金的ISSRT结果,因此抗SCC能力由小到大的顺序为:7056-T6、7095-T6、 7056-T74、7095-T74。晶界上粗大的析出相一般认为是η-Mg(Zn,Al,Cu)2平衡相,该相和PFZs及邻近周围基体具有电势差,局部阳极腐蚀理论认为将优先发生该相的腐蚀,形成阳极腐蚀通道[29]。7056-T6合金和7095-T6合金GBPs呈链状连续分布,局部阳极腐蚀发生后会使腐蚀速率大大增加,这也是7056-T6合金和7095-T6合金SCC敏感性比较高的原因。图6所示为7056-T6合金和7095-T6合金SSRT失效后的断口形貌。从图6(a)和(c)中可以看出:7056-T6合金相貌由很多小且光滑的平面组成,是典型的沿晶断裂,而7095-T6合金断口相貌除沿晶特征外,已出现很多小韧窝区域,这是沿晶占主导的混合断裂。从图6(b)和(d)可知:除冰糖状的沿晶断裂特征外,还发现了沿晶界开裂的二次裂纹。这也是由于晶界上的η-Mg(Zn,Al,Cu)2相易腐蚀且呈连续分布,在SSRT试验时裂纹易在晶界处形成和扩展,从而表现出比较高的SCC敏感性。图7所示为过时效7056合金和7095合金SSRT失效的断口形貌。从图7(a)和(c)中可以看出:7056-T74合金已出现韧窝区,意味着开始从沿晶断裂向沿晶占主导的混合断裂转变,而7095-T74合金断口形貌已呈穿晶断裂模式。从图7(b)和(d)可知:7056和7095合金经T74时效已很难看到沿晶界的二次裂纹,这也表明发生氢致脆性开裂的可能性已大大降低。因此,7056-T74合金和7095-T74合金的SCC敏感性降低,尤其是7095-T74合金的SCC敏感性大大降低。这是由于7095-T74合金η-Mg(Zn,Al,Cu)2相粗化程度更深,GBPs间距更大,可减缓沿晶界的腐蚀速率和裂纹扩展速率。氢致开裂机制认为:SCC与晶界附近的原子H浓度有关,一旦超过临界值将会发生氢致脆性开裂,而粗大η-Mg(Zn,Al,Cu)2相可以作为捕获H原子的陷阱来降低SCC敏感性[10]。7056-T6合金和7095-T6合金的η-Mg(Zn,Al,Cu)2尺寸较小,不能有效的捕获H原子,同时应力易在η-Mg(Zn,Al,Cu)2相附近堆积,裂纹一旦在晶界萌生,将会沿着连续的GBPs快速扩展,导致氢致脆性开裂。7056合金和7095合金经T74时效,η-Mg(Zn,Al,Cu)2尺寸增加,能捕获更多的H原子来降低SCC敏感性,尤其是7095-T74合金GBPs不仅尺寸大且呈孤立、不连续分布,有利于延缓裂纹沿晶界扩展的速率,从而降低SCC敏感性。无论用局部阳极腐蚀理论还是氢致开裂理论来解释SCC敏感性,总之粗大、孤立不连续的GBPs对降低SCC敏感性总是有利的。因此,7095-T74合金GBPs的这种特点正是该合金具有出色的抗SCC能力的原因。此外,有学者认为晶界上Mg的偏析和Mg—H的相互作用将不可避免的影响SCC敏感性。晶界处Mg与H原子间的电负性差大于Al、H原子间的电负性差,Mg—H的相互作用增加了H原子在晶界的聚集,增加了氢致开裂的可能性[10-11, 16]。由于7056合金属于高Mg低Cu的高强铝合金,Cu原子在η-Mg(Zn,Al,Cu)2相中的含量较低,Mg元素又易在晶界偏析[30-31],造成7056合金SCC敏感性较高。低Mg高Cu含量的7095系合金在过时效状态具有更低的SCC敏感性。

图6 7056合金和7095合金T6时效下SSRT断口形貌

Fig. 6 SEM fracture images of SSRT failed samples

表3 7056和7095合金慢应变速率试验结果

Table 3 SSRT results of 7056 and7095 alloys

图7 7056合金和7095合金T74时效下SSRT断口形貌

Fig. 7 SEM fracture images of SSRT samples failed

图8 7056合金和7095合金不同时效条件下ISSRT值

Fig. 8 SCC susceptibility index (ISSRT) of different aging conditions

3 结论

1) 7056合金和7095合金固溶中都发生了明显的再结晶,而7095合金再结晶程度更高。这是由于Cu元素相较于Mg元素更易使合金发生再结晶。

2) 7056合金和7095合金T6时效后强度分别是643 MPa和610 MPa,断裂韧性(KIC)分别是26.8 MPa·m1/2和28.2 MPa·m1/2。经T74时效后,合金强度下降,断裂韧性分别增加到29.6 MPa·m1/2和34.7 MPa·m1/2。析出相粗化使合金强度下降,Mg元素的强化效果强于Cu元素,Cu含量高更易使析出相粗化,因此7056合金强度高于7095合金。晶内与晶界强度差降低,晶界粗大、不连续的析出相和无沉淀析出带的共同作用使得合金的断裂韧性增加。

3) 7056合金和7095合金经T6时效后得到连续分布的晶界析出相(GBPs),易形成阳极腐蚀通道,造成沿晶开裂,使SCC敏感性较高(I7056-T6=41.67%,I7095-T6= 38.37%)。T74时效后,粗大、孤立不连续的GBPs降低了合金的腐蚀速率,SCC敏感性得到改善(I7056-T6= 29.63%,I7095-T6= 23.44%),尤其是7095-T74合金。

REFERENCES

[1] 刘 兵, 彭超群, 王日初, 王小锋, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

LIU Bin, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Research status and prospect of aluminum alloy for large aircraft[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1715.

[2] 袁丁玲, 陈送义, 周 亮, 昌江郁, 陈康华. 高Zn超强Al-Zn-Mg-Cu系合金的铸态及均匀化组织[J]. 中国有色金属学报, 2018, 28(12): 2394-2405.

YUAN Ding-lin, CHEN Song-yi, ZHOU Liang, CHANG Jiang-yu, CHEN Kuang-hua. The casting state and homogeneous microstructure of high-strength Al-Zn-Mg-Cu alloy with high Zn content[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(12): 2394-2405.

[3] ROMETSCH P A, ZHANG Yong, KNIGHT S. Heat treatment of 7xxx series aluminum alloys—Some recent developments[J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2003-2017.

[4] DURSUN T, SOUTI C. Recent developments in advanced aircraft aluminum alloys[J]. Material and Design, 2014, 56: 862-871.

[5] RAO A C U, VASU V, GOVINDARAJU M, SRINADH K V S. Stress corrosion cracking behaviour of 7xxx aluminum alloys: A literature review[J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1447-1471.

[6] TIAN Wen-ming, LI Song-mei, WANG Bo, LIU Jian-hua, YU Mei. Pitting corrosion of naturally aged AA7075 aluminum alloys with bimodal grain size[J]. Corrosion Science, 2016, 113: 1-16.

[7] SUN Yuan-wei, PAN Qing-lin, SUN Yu-qiao, WANG Wei-yi, HUANG Zhi-qi, WANG Xiang-dong, HU Quan. Localized corrosion behavior associated with Al7Cu2Fe intermetallic in Al-Zn-Mg-Cu alloy[J]. Journal of Alloys and Compounds, 2019, 783: 329-340.

[8] RAO A C U, VASU V, GOVINDARAJU M, SRINADH K V S. Stress corrosion cracking behaviour of 7xxx aluminum alloys: A literature review[J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1447-1471.

[9] CHEN Jun-feng, ZHANG Xing-feng, ZOU Lin-chi, YU Yan, LI Qiang. Effect of precipitate state on the stress corrosion behavior of 7050 aluminum alloy[J]. Materials Characterization, 2016, 114: 1-8.

[10] SONG R G, DIETZEl W, ZHANG B J, LIU W J, TSENG M K, ATRENS A. Stress corrosion cracking and hydrogen embrittlement of an Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2004, 52: 4727-4743.

[11] SU Hang, TODA H, MASUNAGA R, SHIMIZU K, GAO Hong-ye, SASAKI K, BHUIYAN M S, UESUGI K, TAKEUCHI A, WATANABE Y. Influence of hydrogen on strain localization and fracture behavior in Al-Zn-Mg-Cu aluminum alloys[J]. Acta Materialia, 2018, 159: 332-343.

[12] SHU Wen-xiang, HOU Long-gang, ZHANG Chuan, ZHANG Fan, LIU Jun-cheng, LIU Jun-tao, ZHUANG Lin-zhong, ZHANG Ji-shan. Tailed Mg and Cu contents affecting the microstructures and mechanical properyies of high-strength Al-Zn-Mg-Cu alloys[J]. Materials Science and Engineering A, 2016, 657: 269-283.

[13] YUAN Ding-ling, CHEN Kang-hua, CHEN Song-yi, ZHOU Liang, CHANG Jiang-yu, HUANG Lan-ping, YI You-ping. Enhancing stress corrosion cracking resistance of low Cu-containing Al-Zn-Mg-Cu alloys by slow quench rate[J]. Material and Design, 2019, 164: 107558.

[14] DONG Peng-xuan, CHEN Song-yi, CHEN Kang-hua. Effects of Cu content on microstructure and properties of super-high-strength Al-9.3Zn-2.4Mg-xCu-Zr alloy[J]. Journal of Alloys and Compounds, 2019, 788: 329-337.

[15] PENG Guo-sheng, CHEN Kang-hua, FANG Hua-chan, CHEN Song-yi. Effect of Cr and Yb additions on microstructure and properties of low copper Al-Zn-Mg-Cu-Zr alloy[J]. Materials and Design, 2012, 36: 279-283.

[16] KNIGHT S P, POHL K, HOLROYD N J H, BIRBILIS N, ROMETSCH P A, MUDDLE B C, GOSWANMI R, LYNCH S P. Some effects of alloy composition on stress corrosion cracking in Al-Zn-Mg-Cu alloys[J]. Corrosion Science, 2015, 98: 50-62.

[17] LIU Li, JIA Ying-ying, JIANG Jian-tang, ZHANG Bo, LI Guo-ai, SHAO Wen-zhu, ZHEN Liang. The effect of Cu and Sc on the localized corrosion resistance of Al-Zn-Mg-X alloys[J]. Journal of Alloys and Compounds, 2019, 799: 1-14.

[18] LIAO Yu-guo, HAN Xiao-qi, ZENG Miao-xia, JIN Man, Influence of Cu on microstructure and tensile properties of 7XXX series aluminum alloy[J]. Materials and Design, 2015, 66: 581-586.

[19] DAI Pan, LUO Xian, YANG Yan-qing, KOU Zong-de, HUANG Bin, WANG Chen, ZANG Jin-xin, RU Ji-gang. Nano-scale precipitate evolution and mechanical properties of 7085 aluminum alloy during thermal exposure[J]. Materials Science and Engineering A, 2018, 729: 411-422.

[20] STARINK M J, WANG S C. A model for the yield strength of overaged Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2003, 51: 5131-5150.

[21] DAI Pan, LUO Xian, YANG Yan-qing, KOU Zong-de, HUANG Bin, ZANG Jin-xin, RU Ji-gang. Thermal stability analysis of a lightweight Al-Zn-Mg-Cu alloy by TEM and tensile tests[J]. Materials Characterization, 2019, 153: 271-283.

[22] CHINH N Q, LENDVAI J, PING D H, HONO K. The effect of Cu on mechanical and precipitation properties of Al-Zn-Mg alloys[J]. Journal of Alloys and Compounds, 2004, 378: 52-60.

[23] LENG L, ZHANG Z J, DUAN Q Q, ZHANG P, ZHANG Z F. Improving the fatigue strength of 7075 alloy through aging[J]. Materials Science and Engineering A, 2018, 738: 24-30.

[24] DUMONT D, DESCHAMPS A, BRECHET Y. On the relationship between microstructure, strength and toughness in AA7050 aluminum alloy[J]. Materials Science and Engineering A, 2003, 356: 326-336.

[25] CHEN Song-yi, CHEN Kang-hua, DONG Peng-xuan, YE Sheng-ping, HUANG Lan-ping. Effect of heat treatment on stress corrosion cracking, fracture toughness and strength of 7085 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2320-2325.

[26] LI Bo, WANG Xiao-min, CHEN Hui, HU Jie, HUANG Cui, GOU Guo-qing. Influence of heat treatment on the strength and fracture toughness of 7N01 aluminum alloy[J]. Journal of Alloys and Compounds, 2016, 678: 160-166.

[27] HAN Nian-mei, ZHANG Xin-ming, LIU Sheng-dan, KE Bin, XIN Xing. Effects of pre-stretching and ageing on the strength and fracture toughness of aluminum alloy 7050[J]. Materials Science and Engineering A, 2011, 528: 3714-3721.

[28] LIU Zhi-yong, LI Xiao-gang, DU Cui-wei, ZHAI Guo-li, CHENG Yu. Stress corrosion cracking behavior of X70 pipe steel in an acidic[J]. Corrosion Science, 2008, 50: 2251-2257.

[29] LIU Ya-ru, PAN Qing-lin, LI Hang, HUANG Zhi-qi, YE Ji, LI Meng-jia. Revealing the evolution of microstructure, mechanical property and corrosion behavior of 7A46 aluminum alloy with different ageing[J]. Journal of Alloys and Compounds, 2019, 792: 32-45.

[30] MARLAUD T, DESCHAMPS A, BLEY F, LEFEBVRE W, BAROUX B. Influence of alloy composition and heat treatment on precipitate in Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2010, 58: 248-260.

[31] ZHAO H, GEUSER F D, SILVER A K D, SZCZEPANIAK A, GAULT B, PONGE D, RAABE D. Segregation assisted grain boundary precipitation in a model Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2018, 156: 318-329.

Effect of heat treatment on mechanical properties and SCC of 7056 and 7095 aluminum alloys

WEI Shi-long1, 2, FENG Yan1, 2, WANG Ri-chu1, 2, REN Jian1, 2, PENG Chao-qun1, 2, ZHANG Hui3, XU Chun-ting3, WU Ying3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Electronic Packaging and Advanced Functional Materials, Central South University, Changsha 410083, China;

3. The 38th Institute of China Electronics Technology Group Corporation, Hefei 230088, China)

Abstract: The microstructure, mechanical properties and stress corrosion cracking sensitivity of 7056 and 7095 alloys with peak aging and over aging treatments were studied by SEM, EBSD, TEM, slow strain rate tensile tests and fracture toughness tests. The results show that both alloys have obvious recrystallization after solid solution and the recrystallization degree of 7095 alloy is higher than 7056 alloy. After peak aging, fine precipitates with small size and high density in both alloys. 7056 alloy has smaller size (3.5 nm) and higher density than 7095 alloy, thus showing higher strength (643 MPa). After overaging, the precipitates of the two alloys obviously coarsen, leading to deteriorative strength. The 7095 alloy have lots of coarsening η phase after overaging, thus the strength of the 7095 alloy decreased 8.5%. The fracture toughness values of 7056 and 7095 alloys after peak aging are 26.8 MPa·m1/2 and 28.2 MPa·m1/2, respectively, and increase to 29.6 MPa·m1/2 and 34.7 MPa·m1/2, respectively, after overaging. The large fracture toughness of overaged 7095 alloy is due to the decrease of the strength difference between the grain and the grain boundary. The combined action of the precipitate free zones and the coarsening and discontinuous grain boundary precipitates is another reason. The continuous precipitates in the grain boundary in the two peak aging alloys result in high stress corrosion cracking (SCC) sensitivity. After overaging, the grain boundary precipitates (GBPs) in the two alloys turn to discontinuous distribution and obviously coarsen, decreasing the SCC sensitivity.

Key words: 7xxx series aluminum alloy; aging precipitation; stress corrosion cracking; fracture toughness

Foundation item: Project(2017GK2261) supported by the Hunan Science and Technology Program of China; Project(41423040204) supported by the Chinese National Pre-research Project, China

Received date: 2019-09-20; Accepted date: 2020-01-04

Corresponding author: WANG Ri-chu; Tel: +86-731-88836638; E-mail: wrc@csu.edu.cn

(编辑 龙怀中)

基金项目:湖南省科技计划资助项目(2017GK2261);中国国防预研项目(41423040204)

收稿日期:2019-09-20;修订日期:2020-01-04

通信作者:王日初,教授,博士:电话0731-88836638;E-mail:wrc@csu.edu.cn