文章编号:1004-0609(2015)-04-1005-07

新型Hg3In2Te6芯片引线的键合机制

王晓珍,傅 莉,李亚鹏,李林峰

(西北工业大学 材料学院 凝固技术国家重点实验室,西安710072)

摘 要:Hg3In2Te6(MIT)晶体是一种新型的短波红外光电探测材料,采用热压超声球焊的方法实现MIT红外探测器与外电路的引线连接,探讨MIT复合电极厚度及结构对键合率的影响规律,研究超声功率和键合压力对第一焊点的外观形貌和键合强度的影响机理。结果表明:在化学抛光后的MIT晶片表面蒸镀0.2 μm In、1.0 μm Au制备In/Au复合电极时,键合率显著提高,达到100%;MIT与In/Au复合电极间存在一定的互扩散,促进了键合过程的形成;超声功率与键合压力对焊点形貌和键合强度影响最大,当超声功率为0.45~0.55 W、键合压力为0.5~0.6 N时,焊球与引线的直径比约为3.5,焊点变形适中,有效键合面积较大,90%以上的断裂发生在引线位置,表明此种工艺参数下形成的键合强度高、可靠性好。

关键词:Hg3In2Te6芯片;热压超声键合;Au 电极;In中间层

中图分类号:TM23;TN36 文献标志码:A

Bonding mechanism of Hg3In2Te6 new chip wire

WANG Xiao-zhen, FU Li, LI Ya-peng, LI Lin-feng

(Northwestern Polytechnical University, School of Materials Science and Engineering,

State Key Laboratory of Solidification Processing, Xi’an 710072, China)

Abstract: In order to realize the connection of Hg3In2Te6 (short for MIT), a new type of near-infrared photoelectric material, with outer circuits, the thermo-sonic bonding technology between MIT electrode and down-lead wire was used, and the influence of the electrode thickness and structure on the bonding ratio was studied. Furthermore, the effects of ultrasonic power and bonding pressure on the first joint morphology and bonding strength were also analyzed. The results show that the bonding rate increases (reaching 100%) when 0.2 μm In interlayer was inserted between MIT wafer after chemical polish and the Au electrode with thickness of 1 μm. XPS analysis results show that inter-diffusion between MIT and In/Au composite electrode promotes the bonding process. The welding ball morphology and bonding quality are mainly affected by the ultrasonic power and bonding pressure. When the ultrasonic power and the bonding pressure are about 0.45-0.55 W and 0.5-0.6 N, respectively, the diameter ratio between the ball and wire is about 3.5, and more than 90 % failure position occurs at wire by tensile test, indicating the perfect shape of welding ball and good bonding strength and reliability can be reached.

Key words: Hg3In2Te6 chip; thermo-sonic bonding; Au electrode; In interlayer

随着集成电路的发展,先进封装技术不断发展变化以适应各种半导体新工艺和新材料的要求和挑战。半导体封装内部芯片和外部管脚以及芯片之间的引线键合,决定了器件信号传输的可靠性,成为整个封装过程中的关键[1]。引线键合以工艺实现简单、成本低廉、适用多种封装形式而在连接方式中占主导地位,目前所有封装管脚的90%以上都采用引线键合连接[2-3]。引线键合工艺主要分为3种:热压键合、超声波键合与热压超声波键合;键合的基本形式有两种:球键合和楔键合,其中应用最为广泛的是热压超声Au丝球键合[4-5]。由于键合技术所涉及的学科非常广泛,且键合过程速度快、时间短、键合面小,国内外关于其机理的研究结论并不统一,主要包括摩擦热键合机理[6]、位错与变形机理[7]和微观滑移机理[8]等。目前,研究人员已经将微动力学理论应用在引线键合机理解释方面,试图找出它们之间的关联,推动了引线键合技术的发展[9]。

MIT是一种新型的用于近红外光电探测的Ⅱ-Ⅵ/Ⅲ-Ⅵ 族化合物半导体材料,它具有较高的光导量子效率、良好的温度稳定性和抗辐射性能。基于金属/MIT接触特性制备出的非制冷短波红外探测器,在航空制导技术、太空与航天探测技术等国防领域,以及光纤通信、核电站安全监测等民用领域都具有广阔的应用前景[10-12]。MIT红外探测器芯片与外部管脚的引线键合质量直接决定着光电信号输出的可靠性。影响引线键合可焊性与可靠性的因素很多,从焊接设备来看,它与超声功率、键合压力和键合时间等有关;从芯片焊接表面来看,它与被键合表面清洁度、材料性质和处理工艺等有关[13]。超声功率和键合压力对键合质量和外观影响最大,而半导体与金属电极接触界面特性差、电极强度低、均匀性不好、表面有污染等也会造成可焊性与可靠性严重降低[14]。由于MIT晶体具有强度低、脆性大的特点,使其接触电极与外引线很难实现可靠性的连接,目前尚未见到有关的研究报道。本文作者拟通过改变金属电极厚度和组成来提高MIT接触电极与外引线的键合成功率,同时探索了键合工艺参数对第一焊点外观形貌和键合强度的影响规律,优化MIT芯片引线连接工艺方案,可为实现MIT芯片引线键合的可靠性和红外探测器的制备提供理论和实践的依据。

1 实验

1.1 MIT晶片的表面处理与电极制备

本实验中所采用的MIT晶体由垂直布里奇曼法生长,将生长好的晶锭沿着垂直于轴向切割成5 mm×5 mm×1 mm的晶片,并对其进行机械抛光以获得光滑洁净的表面,然后用2% Br2-C3H7NO(体积分数)溶液化学抛光2 min去除表面的机械损伤层,减少表面粗糙度。实验采用Dimension Icon型原子力显微镜(Atomic force microscope, AFM)观察晶片化学抛光前后的表面形貌。对抛光后的晶片依次采用丙酮、去离子水超声清洗,氮气吹干后获得干净无污染的晶片表面。采用HHV Auto 306型真空热阻蒸发镀膜仪制备金属电极,电极镀层制备过程中真空度优于1×10-5 mbar,蒸发速率约为1.4  /s,制备的金属化层致密且均匀,膜层厚度由镀膜仪所配制的晶振片监测。本实验中通过金属电极厚度及结构的优化来提高键合率,实验中所设计电极分别是:0.7、0.8和1.0 μm 的Au电极及0.2 μm In+1.0 μm Au组成的复合电极。

/s,制备的金属化层致密且均匀,膜层厚度由镀膜仪所配制的晶振片监测。本实验中通过金属电极厚度及结构的优化来提高键合率,实验中所设计电极分别是:0.7、0.8和1.0 μm 的Au电极及0.2 μm In+1.0 μm Au组成的复合电极。

1.2 MIT金属电极与引线的键合

采用F&K公司5310热压超声焊机实现MIT金属电极与金引线的球-楔键合,本实验中,采用为直径25 μm加入微量合金元素的金丝,键合过程中,先用高压电火花使金丝在劈刀外的伸出部分熔化,同时在表面张力作用下熔融金属凝固形成标准球形。通过劈刀向金属球施加压力,同时在超声波的作用下,在金球和芯片电极金属之间发生塑性变形,且伴随着原子间互扩散,完成第一焊点的键合[15-20]。然后劈刀运动到第二键合位置,通过劈刀外壁对金属线施加压力以楔焊的方式完成第二焊点的键合。本实验中对制备的不同厚度和结构的电极表面分别键合20次,并记录键合成功次数,计算出键合率。通过ESCALAB 250Xi 型X射线光电子能谱(X-ray photoelectron spectroscopy, XPS)仪分析了In/Au复合电极与MIT界面元素间的互扩散现象,推测促进键合过程形成的原因。

1.3 MIT焊点形貌及键合强度的表征

通过ZEISS SUPRA场发射扫描电子显微镜(Field emission scanning electron microscopy, SEM)观察MIT金属电极与引线热压超声键合第一焊点的微观形貌,通过观察焊球变形的大小和计算焊球与引线的直径比表征键合质量的优劣。对键合成功的试样用引线键合拉力测试仪进行拉力测试,通过引线断裂的位置评价外引线与金属电极的结合强度。

2 结果与分析

2.1 化学抛光对表面形貌的影响

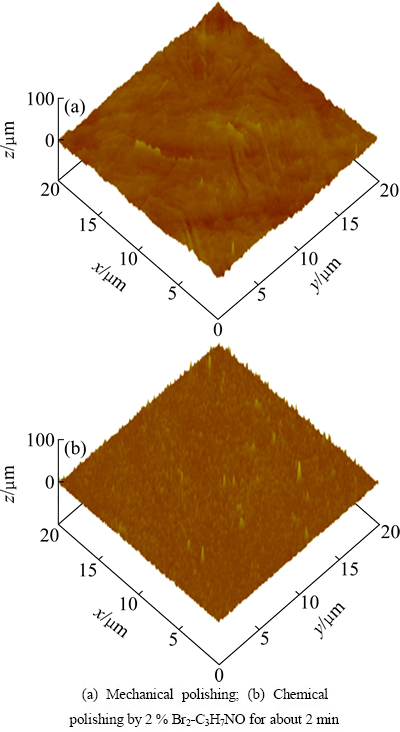

图1所示为机械抛光和化学抛光后MIT晶片的表面形貌。由图1(a)可见,机械抛光后晶片表面存在一些细微的划痕和较多的机械损伤层,这些机械损伤会造成晶格畸变和应力集中,导致金属与半导体间结合性变差,从而使键合率降低、可靠性减小。而采用2% Br2-C3H7ON 化学抛光2 min后表面粗糙度由机械抛光后的3.80 nm降低为2.41 nm,如图1(b)所示。实验结果表明:化学抛光可以有效地去除MIT晶体表面的机械损伤层,降低MIT晶体表面的粗糙度,从而使蒸镀的金属电极表面平整且均匀性好,同时,改善金属电极与半导体间的接触特性,减少焊接表面对键合质量的影响。

图1 不同表面处理状态下MIT晶片的表面形貌

Fig. 1 Surface morphologies of MIT wafer under different surface treatments

2.2 复合电极设计对键合率的影响

金属电极的强度、厚度、金属电极与芯片及引线间的结合强度、金属间化合物的形成等对连接的可焊性和可靠性都会产生重要影响。在引线键合过程中,如果金属电极的强度低且厚度较薄将会对电极下面的半导体材料造成一定的损伤,即焊盘出坑。据文献[15],0.6 μm以下厚度的金属电极可能存在问题,1~3 μm厚的金属电极焊盘损伤比较小,这是因为随镀层厚度的增加,芯片受到的压应力和剪切力逐渐减小[15, 21]。通常,芯片与金属电极、金属电极与引线间结合力差会使金属电极与引线间难以实现完整的键合;即使键合成功后也会在器件使用过程中因结合力差而使引线与金属电极间脱焊;焊盘金属间化合物的形成使键合强度降低、变脆,易造成碎裂而脱键,同时它使导电性能下降、接触电阻增大,从而造成器件的光电性能退化。

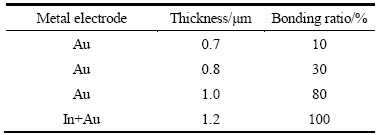

由于Au-Au系统可靠性非常好,不存在界面腐蚀和金属间化合物形成等问题,因而,本实验中选用Au电极。另外,考虑金属电极厚度和经济实用性两方面的因素,Au电极厚度从0.7 μm开始热压超声键合。实验中MIT芯片金属电极与金丝引线键合的工艺参数为:键合压力0.6 N,超声功率0.6 W,超声时间30 ms,弧高895 μm,弧长1085.6 μm,室温下键合。在此工艺参数下,0.7、0.8和1.0 μm的Au电极和1.2 μm In/Au复合电极的键合率如表1所列。

表1 MIT金属电极厚度和结构对其引线间键合率的影响

Table 1 Influences of MIT metal electrode thickness and structure on bonding ratio

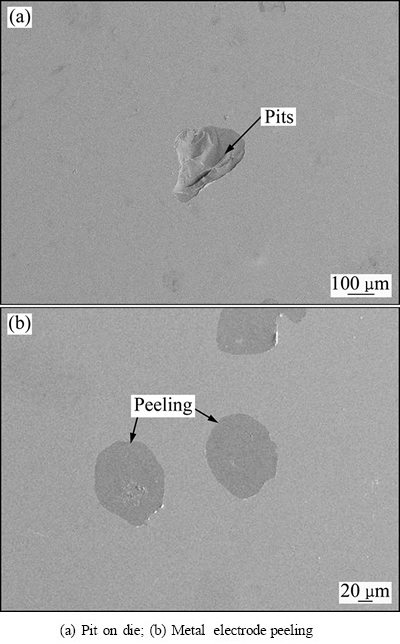

当Au电极厚度为0.7 μm时,未键合成功的焊点失效形貌如图2(a)所示,由于金属电极层过薄,劈刀下压过程中膜层被破坏,且由于MIT属于脆性材料,因而会对MIT芯片造成损伤,出现焊盘出坑现象。当Au电极厚度为1.0 μm时,未键合点形貌出现如图2(b)所示的现象,即Au电极被金球剥离。引起这种现象的主要原因是Au电极与MIT晶体间的热膨胀系数相差很大,20 ℃时MIT热膨胀系数为-2.6×10-6 K;而Au的热膨胀系数为14.7×10-6 K,Au电极层与MIT晶片间产生的内应力,降低了Au与MIT间的结合力。因此,在引线键合的过程中,极易使引线与金属电极间脱焊。为了提高金属电极与MIT芯片间的结合力,实验中以蒸镀0.2 μm In作为中间过渡层制备In/Au复合电极。为了进一步研究作为过渡层的In与Au电极相互作用机制,通过XPS深度剖析对Au/In/MIT接触的金属电极界面Au和In的芯能级进行测试,其结果如图3所示。从图3可以看出:随着刻蚀时间递增,Au 4f峰值急剧递减,而In 3d峰值缓慢降低,且Hg 4f、Te 3d峰值出现。另外,从图3可以得知,In/Au界面处所有元素的结合能并未发生偏移,因而可以推测在In/Au界面处并未形成金属间化合物。综合上述分析可以推测In在Au电极和MIT界面都存在显著的扩散,这种扩散现象不仅提高了In/Au复合电极与MIT芯片间的结合力,而且有利于使键合过程中所施加的键合压力在In过渡层中缓冲,减小内应力,从而使键合率和键合质量大大提高[22]。因此,In/Au复合电极是较佳的金属电极组成,在本实验条件下,其复合电极的键合率可达到100 %(见表1)。

图2 MIT金属电极与引线未键合的焊点形貌

Fig. 2 SEM morphologies of failure joints between MIT metal electrode and down-lead wire

图3 Au/In/MIT界面的XPS全谱

Fig. 3 Survey XPS spectra of Au/In/MIT interface (Black line representing Ar+ etching at interface about 30 s and red line representing etching about 120 s)

2.3 键合工艺参数对第一焊点形貌及键合强度的影响

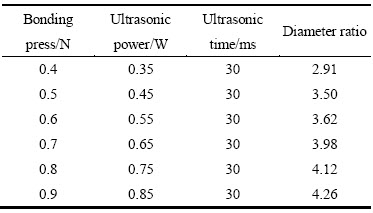

通常超声功率和键合压力对键合质量和焊球外观形貌影响最大,过小会导致金球小,使引线与金属电极间无连接,过大容易导致芯片破裂或内部出现裂纹。一般超声功率和键合压力是一对相互关联的参数,增大超声功率需要增大键合压力使超声能量通过键合工具传递到键合点处,过大的键合压力会阻碍键合工具的运动,抑制超声能量的传导,导致污染物和氧化物被推到键合区域的中心,形成中心未键合区域[23-24]。焊点的外观是评价键合质量最简单直接的定性方法,对于球键合,标准且形态良好的球一般键合质量较好,可靠性较高,通过SEM观测焊点外形,可初步判断键合质量的优劣。标准且形态良好的球应具有以下特点:第一焊点焊球直径为引线直径的3~3.5倍,厚度适中且焊球与线弧过渡平滑[5, 23]。本实验在超声时间为30 ms条件下,获得超声功率和键合压力对MIT复合电极表面焊球与引线的直径比的影响规律如表2所列。

表2 不同键合工艺参数下MIT复合电极表面焊球与引线的直径比

Table 2 Diameter ratio of golden ball and wire on surface of MIT composite electrode with different bonding parameters

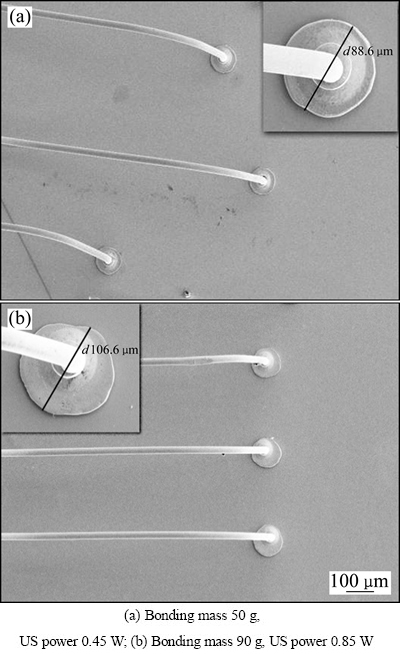

从表2可以看出,随着超声功率和键合压力的增加,焊球与引线的直径比逐渐增大。这是由于随着超声功率和键合压力的增加,金球和MIT芯片电极金属间塑性变形增大,使得焊球与引线的直径比略有增加。另外,超声功率与键合压力对第一焊点焊球的外观形貌也会产生一定的影响,当键合压力为0.5~0.6 N,超声功率为0.45~0.55 W时,焊球与引线的直径比约为3.5,焊球变形适中,饱满且层次分明,如图4(a)所示,说明此时有效键合面积较大,键合强度较高,焊点结合均匀牢固且产生的应力集中现象较小。当键合压力增加到0.8~0.9 N、超声功率增加到0.75~0.85 W时,焊接区域变大,焊球与引线的直径比达到4.2左右,焊球变形较大,金球坍塌且形状已偏离标准的半球状,如图4(b)所示,说明此时引线与金属电极间形成了过键合,局部产生了较大塑性变形与残余应力,导致键合强度降低。本实验预先选定键合压力为0.5 N,超声功率分别为0.35、0.45和0.55 W;在固定超声功率为0.45 W时,键合压力分别为:0.4、0.5和0.6 N,观察焊点外观形貌,计算焊球与引线的直径比。结果发现,在这两种键合工艺条件下,焊点形貌与直径比几乎没有变化,这说明超声功率和键合压力是一对相互关联的参数,两者需协调改变,才能达到最好键合的目的。

图4 键合工艺参数对键合点形貌及键合质量的影响

Fig. 4 Effects of bonding parameters on morphology and bonding quality of wire bonding joints

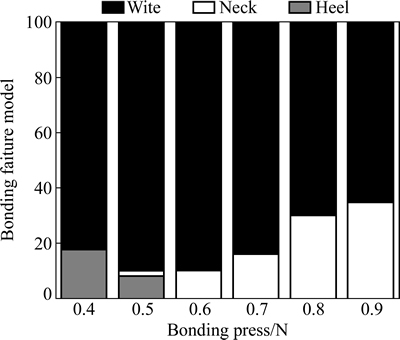

对不同工艺参数下的键合成功的试样进行拉力测试,通过观察键合失效位置可以分析出失效的原因如下。若失效位置断裂在引脚(Heel)处,说明键合过程中选用的焊接参数偏小,造成键合不充分;若失效位置断裂在引线颈部(Neck),说明键合过程中做球参数选择以及做球操作等不合适,或着参数偏大引起金丝损伤而导致失效;若断裂位置在引线(Wire)处,此处为拉力失效实验正常断裂的位置,说明键合过程中焊接参数选择较优,键合质量较好;若断裂位置在焊盘(Pad)上,说明焊接时参数选择偏大,使芯片焊盘损伤[13]。图5所示为采用表2所示键合工艺参数时,MIT复合电极与引线键合失效位置统计图。从图5可以看出:当键合压力和超声功率较小时,在Heel位置断裂的几率较大;当键合压力为0.5~0.6 N、超声功率为0.45~0.55 W时,键合失效位置约90 %以上断裂在引线位置处,表明此时焊球与金属电极间的结合力较强,键合强度较高,可靠性较好;当键合压力和超声功率分别大于0.7 N和0.65 W 时,在Neck位置断裂的几率增大,这跟选取的键合工艺参数偏大有关。

图5 MIT复合电极与引线键合失效位置统计图

Fig. 5 Bonding failure charts of MIT composite electrode and down-lead wire under bonding parameters of Table 2

3 结论

1) 经2 % Br2-C3H7NO化学抛光2 min后的MIT晶片,表面粗糙度由机械抛光后的3.80 nm降低为2.41 nm,表面机械损伤层被明显去除,化学抛光能有效地减小晶格畸变与应力集中,改善制备金属电极的平整度与均匀性,提高金属电极与MIT的接触特性。

2) 金属电极的厚度、金属电极与MIT间的结合力对键合率的影响至关重要。金属电极太薄,键合过程容易对MIT芯片造成损伤,使芯片破裂或暗裂;Au与MIT间的结合力较差,使得键合过程中Au电极容易被剥落,当加入0.2 μm In作为中间过渡层,同时Au膜厚度为1.0 μm制备In/Au复合电极(0.2 μm In+1.0 μm Au)时,键合率将显著提高,达到100%。Au/In/MIT界面XPS全谱分析结果表明,复合电极与MIT间存在一定的互扩散促进了键合过程的形成。

3) 超声功率和键合压力对键合质量和键合强度影响最大。若超声功率与键合压力过小,则在键合过程中无法产生足够的塑性变形,不能形成足够的键合强度,焊点不牢,易剥离脱键;若超声功率与键合压力过大,则焊点变形太大,会形成过键合,键合强度降低,易造成根部折断或焊盘损伤。对于MIT芯片金属电极与引线的热压超声键合,当键合压力为0.5~0.6 N、超声功率为0.45~0.55 W时,焊球与引线的直径比约为3.5,焊点变形适中,有效键合面积较大,拉力测试结果90% 以上断裂在引线位置处,表明此种工艺参数下形成的键合强度高、可靠性好。

REFERENCES

[1] 何 田. 引线键合技术的现状和发展趋势[J]. 电子工业专用设备, 2004, 33(10): 12-14.

HE Tian. Research state and progress on technology of wire bonding[J]. Special Equipment for the Electronics Industry, 2004, 33(10): 12-14.

[2] 晁宇晴, 杨兆健, 乔海灵. 引线键合技术进展[J]. 电子工艺技术, 2007, 28(4): 205-210.

CHAO Yu-qing, YANG Zhao-jian, QIAO Hai-ling. Progress on technology of wire bonding[J]. Electronics Process Technology, 2007, 28(4): 205-210.

[3] ZHONG Fei, WANG Zhi-jie, XU Yan-bo, YE De-hong, SHU Ai-peng, CHEN Quan. A review on wire bonding process in electronic manufacturing[J]. Electronic & Packaging, 2013, 13(1): 1-8.

[4] 董永谦. 热声焊机的研制与工艺研究[J]. 电子工艺技术, 2004, 25(2): 84-85.

DONG Yong-qian. Design and development of ultrasonic/thermosonic soldering equipment[J]. Electronics Process Technology, 2004, 25(2): 84-85.

[5] 李元升. 引线键合机工艺技术分析[J]. 电子工业专用设备, 2004, 33(2): 78-81.

LI Yuan-sheng. Technology analysis of wire bonder[J]. Special Equipment for the Electronics Industry, 2004, 33(2): 78-81.

[6] JELLISON J. Effect of surface contamination on the thermocompression bondability of gold[J]. IEEE transactions on parts, hybrids and packaging, 1975, 11(3): 206-211.

[7] TU K N. Irreversible processes of spontaneous whisker growth in bimetallic Cu-Sn thin-film reaction[J]. Physical Review B, 1994, 49(3): 2030-2034.

[8] CHEN G K C. The role of micro-sip ultrasonic bonding of micro-electronic dimensions[C]//1972 International Micro- electronic Symposium. Washington, DC, 1972: 5A11-5A19.

[9] MINDLIN R D. Compliance of elasticbodies in contact[J]. Journal of Applied Mechanics, 1949, 16: 259-268.

[10] GRUSHKA O G, BAKHTINOV A P, GRUSHKA Z M. Advanced semiconductor compound Hg3In2Te6[J]. Journal of Advanced Materials, 1997(4): 36-39.

[11] MALIK A, VIERA M, FERNANDES M, MAGARICO F, GRUSHKA Z M. Near-infrared photodetectors based on HgInTe-semiconductor compound[C]//Proceedings of SPIE Conference on Photodetectors: Materials and Devices IV. California: Society of Photo-optical Instrumentation Engineers, 1999: 433-442.

[12] SUN J, FU L, LIU H W, LI Y P, RINGER S P, LIU Z W. On the morphology and crystallography of Hg5In2Te8 precipitation in Hg3In2Te6[J]. Journal of Alloys and Compounds, 2014, 601: 298-306.

[13] 朱炳金, 林 磊, 宋开臣, 王 晶. InSb红外探测器芯片金丝引线键和工艺研究[J]. 红外与激光工程, 2013, 42(1): 46-50.

ZHU Bing-jin, LIN Lei, SONG Kai-chen, WANG Jing. InSb infrared detector chip gold wire bonding process study[J]. Infrared and Laser Engineering, 2013, 42(1): 46-50.

[14] 田立萍, 朱颖峰, 王 微, 徐世春, 董 黎, 熊 雄. 制冷型红外焦平面探测器引线键合质量优化研究[J]. 红外技术, 2012, 34(12): 699-703.

TIAN Li-ping, ZHU Ying-feng, WANG Wei, XU Shi-chun, DONG Li, XIONG Xiong. Study on optimum of wire bonding for the cooled infrared focal plane detector[J]. Infrared Technology, 2012, 34(12): 699-703.

[15] 马 鑫, 何小琦. 集成电路内引线键合工艺材料失效机制及可靠性[J]. 电子工艺技术, 2001, 22(5): 185-191.

MA Xin, HE Xiao-qi. Wire bonding for IC technology materials failure mechanism and reliability[J]. Electronics Process Technology, 2001, 22(5): 185-191.

[16] HARMAN G G, ALBERS J. The ultrasonic welding mechanism as applied to aluminum- and gold- wire bonding in microelectronics[J]. IEEE Transactions on Parts, Hybrids, and Packaging, 1977, 13(4): 406-412.

[17] JOSHI K C. The formation of ultrasonic bonds between metals[J]. Welding Journal, 1971, 50(12): 840-848.

[18] HARMAN G G, LEEDY K O. An experimental modal of the microelectronic wire bonding mechanism[C]// Proceeding 10th Annual on Reliability Physics Symposium. Las Vegas, 1972, 8(4): 49-56.

[19] LANGENECKER B. Effects on ultrasound on deformation characteristics of metals[J]. IEEE Transactions on Sonics and Ultrasonics, 1966, 13(1): 1-8.

[20] CHEVALIER J L, GIBBONS D F, LEONARD L. High frequency fatigue in aluminum[J]. Journal of Applied Physics, 1972, 43(1): 73-77.

[21] 姜 威, 常保华, 都 东, 黄 华, 周运鸿. 引线键合中材料参数对硅基板应力状态的影响[J].焊接学报, 2012, 33(3): 13-17.

JIANG Wei, CHANG Bao-hua, DOU Dong, HUANG Hua, ZHOU Yun-hong. Wire bonding material parameters in the effect of stress on silicon substrate[J]. Transactions of the China Welding Institution, 2012, 33(3): 13-17.

[22] KIM J, JEONG B, CHIAO M, LIN L W. Ultrasonic bonding for MEMS sealing and packaging[J]. IEEE Transactions on Advanced Packaging, 2002, 32(2): 461-466.

[23] 蔡伟智. 发光二极管引线键合可靠性探讨[J]. 可靠性分析与研究(质量工程卷), 2007(4): 34-36.

CAI Wei-zhi. Wire bonding reliability for light emitting diode[J]. Reliability Analysis and Research (Quality Engineering), 2007(4): 34-36.

[24] ROONEY D T, NAGER D P, GEIGER D, AHANGUAN D. Evaluation of wire bonding performance, process conditions and metallurgical integrity of chip on board wire bonds[J]. Microelectronics Reliability, 2005, 45(2): 379-390.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51172185);陕西省重点领域科技创新团队项目(2014KCT-12);西北工业大学博士点创新基金资助项目(20116102110013)

收稿日期:2014-07-13;修订日期:2014-11-05

通信作者:傅 莉,教授,博士;电话:029-88494083;E-mail:fuli@nwpu.edu.cn