文章编号:1004-0609(2016)-07-1466-07

超高强导电Cu-Ni-Si-Al合金的TTP曲线

王 晶1,李 周 1, 2,李 思1,邢 岩1,申镭诺1,雷 前3

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程湖南省重点实验室,长沙 410083;

3. 中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:设计并制备一种超高强导电Cu-6.0Ni-1.0Si-0.5Al-0.15Mg-0.1Cr(质量分数,%)合金。通过测量合金的硬度,分析经固溶处理并分别经600~850 ℃等温处理后再在450 ℃时效处理1 h的合金力学性能的变化规律,建立合金的时间-温度-性能(TTP)曲线。通过透射电镜观察,研究合金在等温处理过程中的第二相的析出规律。结果表明:合金的鼻尖温度约为725 ℃,淬火敏感区域为675~775 ℃。合金在淬火敏感区进行等温处理时,晶内析出的δ-Ni2Si和Ni3Al迅速形核和长大;延长等温时间,析出相粗化,合金的硬度随之降低。合金在鼻尖温度附近表现出高的淬火敏感性。

关键词:CuNiSiAl合金;等温处理;淬火敏感性;力学性能

中图分类号:TG146.1 文献标志码:A

铍青铜因具有高强度、高弹性、高硬度、高耐磨性和良好的导电性能而成为应用广泛、综合性能优异的弹性铜基合金之一[1-3]。但该合金在生产过程中,由于铍的氧化物和粉尘严重危害人体健康[4-5],而且,当合金在高于200℃环境下服役时,合金弹性急剧降低,应力松弛率高达30%以上,难以满足现代电子工业的需求[6]。目前,开发的用于替代铍青铜的Cu-Ni-Sn[7]、Cu-Ni-Al和Cu-Ti[8-9]等合金的强度虽然已经超过1000 MPa,但是其电导率则小于15%(IACS),远低于 Cu-Be合金的(≥22%(IACS))[10-11],使用范围受到制约。

Cu-Ni-Si 合金作为一种典型的时效硬化合金,利用时效处理可以在合金中产生高密度纳米强化粒子,获得时效强化效果的同时能够大幅度提高合金的电导率,是铍青铜合金的潜在替代材料[12-13]。国内一些学者对其热变形行为及动态再结晶、热压缩流变行为以及较低温度下时效相变行为进行了研究[14-16]。合金淬火敏感性对合金产业化生产具有十分重要的实用价值,但目前该方面研究工作鲜见报道。本课题组通过调整Ni与Si元素的含量和比例,设计了一种Cu-6.0Ni-1.0Si-0.5Al-0.15Mg-0.1Cr合金,通过形变热处理,其硬度可达341HV,电导率26.5%(IACS),抗拉强度 1090 MPa,屈服强度 940MPa[17]。因温度和淬火速率对该合金随后时效过程中析出相的体积分数、尺寸及种类有很大影响,使合金表现出淬火敏感性,并影响合金的最终性能[18-19]。为了避免合金在热处理过程中析出粗大的第二相粒子,保证合金获得优良的综合性能,本文作者对该合金的淬火敏感性进行了研究,建立了该合金的TTP曲线,并对其结构演变过程进行了表征,旨在为建立该合金合适的淬火工艺提供参考。

1 实验

Cu-6.0Ni-1.0Si-0.5Al-0.15Mg-0.1Cr合金经中频感应炉中熔炼扣铸锭,利用铣床铣去铸锭表面缺陷,在940 ℃下均匀化处理4 h,再在900 ℃下热轧,将所得合金板材线切割成15 mm×15 mm×2 mm片状样品,于980 ℃固溶4 h后迅速转移入不同温度的等温炉内等温设定的时间后水淬,然后在450 ℃温度下时效1 h并测量其硬度和电导率。等温处理温度分别设为600、650、700、750、800和850 ℃,等温时间分别为0、1、5、10、15和30 min。

合金的固溶和等温处理都在 RJX-2.5-10 型箱式电阻炉中进行,为防止氧化,用铜箔包裹样品,并在电阻炉中加入木炭进行保护。等温处理过程中,使用质量比为1:1的KNO3和NaNO3混合盐作为盐浴介质。样品的显微硬度在 HV-5 型硬度计上进行测量,载荷为30 N,加载时间为10s,测量5个点的硬度值并取其平均值。合金经等温和时效处理后,采用硬度峰值10%、15%、20%、23%和25%所对应的等温温度和等温时间绘制合金的TTP曲线。透射电镜样品经过机械减薄至80 μm后,利用离子减薄仪减薄,氩离子能量为3 eV,束电流为1~1.5 mA。透射电镜观察在JEM-2100F型透射电镜上进行,操作电压为 200 kV。

2 结果与讨论

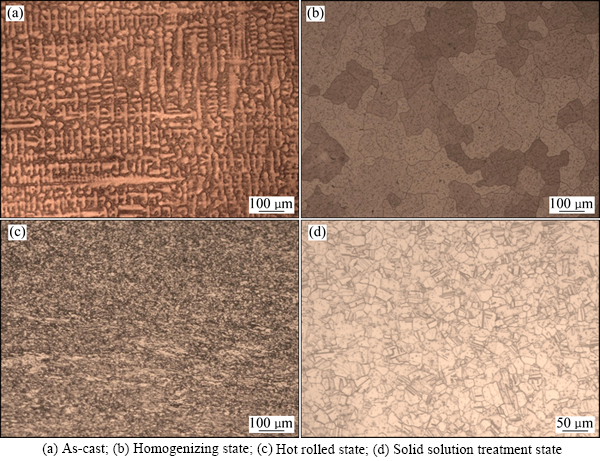

2.1 铸态、均匀化、热轧和固溶态组织结构

图1所示为合金铸态、均匀化、热轧和固溶态的典型金相组织。合金的铸态组织为均匀、细小的枝晶组织(见图1(a))。合金铸锭在940℃均匀化处理4 h后的组织如图1(b)所示,经过均匀化处理后,合金的枝晶组织已经基本消除,但仍存在第二相。图1(c)所示为合金在900 ℃下热轧80%后板材的轧面金相显微组织,合金晶粒沿热轧方向拉长,完全再结晶,尺寸非常细小。合金经过980 ℃固溶处理4 h并淬火的金相组织如图1(d)所示,析出相已经全部固溶入铜基体中,形成过饱和固溶体,晶粒有所长大,平均尺寸约为40 μm。

2.2 等温处理对合金性能的影响

将合金于 980 ℃固溶处理4 h, 然后迅速转移入不同温度的等温炉内等温处理不同时间后水淬,然后在 450 ℃下时效1 h,淬火后测量其硬度。合金硬度随等温时间的变化规律如图2所示。由图2(a)可知,在等温温度保持不变的条件下,合金的硬度均随等温时间的延长急剧下降,其中,合金在700~800 ℃等温时,硬度下降较快,而在高于800 ℃和低于700 ℃时合金硬度下降较缓慢。

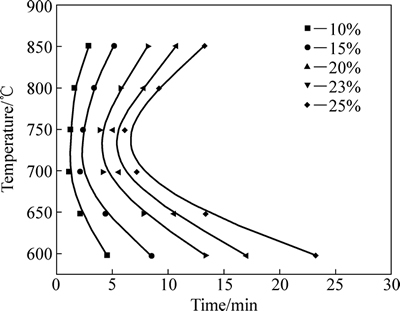

2.3 合金的TTP曲线和淬火敏感性

图3所示为根据图2(a)硬度曲线绘出的合金的TTP曲线,为典型的“C型”曲线,TTP 曲线可按孕育期所需时间的不同分为3个区间:高温区(>775 ℃)、鼻尖区(675~775 ℃)和低温区(<675 ℃)。采用不同硬度值拟合后所得的鼻尖温度基本一致,约为725 ℃。合金在750 ℃等温5 min后硬度急剧下降至184.79 HV,表明TTP曲线鼻尖温度附近第二相孕育期很短,合金在鼻尖区的淬火敏感性较大。而合金在775 ℃以上和低于675 ℃时,硬度降低的幅度不大,说明合金在高温区和低温区第二相的孕育期相对较长,淬火敏感性有所降低。

图1 Cu-6.0Ni-1.0Si-0.5Al-0.15Mg-0.1Cr合金典型金相组织

Fig. 1 Typical metallurgical microstructures of Cu-6.0Ni-1.0Si-0.5Al- 0.15Mg-0.1Cr alloy:

图2 等温处理对合金硬度的影响

Fig. 2 Influence of isothermal treatment on hardness of alloy

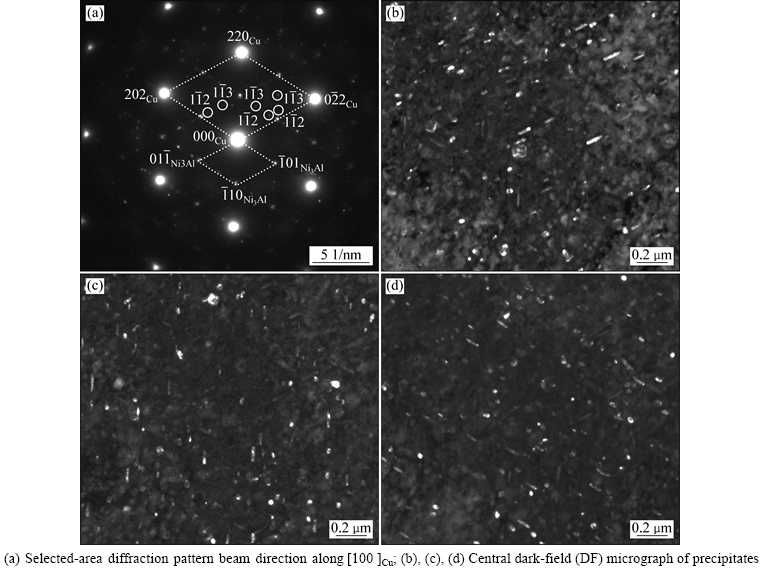

2.4 合金显微组织的TEM观察

合金力学性能的差异必然与其显微组织的变化相对应,本实验中分别对650 ℃以及700 ℃等温处理的样品进行透射电镜观察。图4所示为合金在980 ℃固溶处理4 h后、在650 ℃等温处理1 min的TEM明场像和相应的电子衍射花样。由图4(a)和4(b)可知,经650 ℃等温1 min后,合金基体中析出了大量的第二相,第二相的形貌差异较大,部分析出相呈球形,另一部分析出相呈棒状。这些棒状的析出相粒子呈现两种取向,两种取向之间的夹角约90 ℃。图4(c)和4(d)所示为选区电子衍射花样。由选区电子衍射花样可知,合金的析出相主要是 Ni2Si,Ni3Al粒子,棒状的第二相为δ-Ni2Si[20]。呈球状的第二相为Ni3Al[21]。

图3 合金的TTP曲线

Fig. 3 TTP curves of alloy

图4 合金经650 ℃等温处理1 min后的TEM像及相应选区电子衍射花样

Fig. 4 TEM images of alloys after isothermally treated at 650 ℃ for 1 min and selected-area diffraction pattern:

图5(a)所示为650 ℃等温处理1 min后合金另一选区电子衍射花样,衍射斑点主要来自δ-Ni2Si相、Ni3Al相和其体。对粒子进行中心暗场像观察的结果如图5(b)~(d)所示。3个方向的中心暗场相粒子尺寸均约为100~200 nm。第二相粒子具有两种不同的形貌:一种为球形的析出相,另一种为棒状的析出相。且棒状析出相的生长方向上存在3种变体,3种变体相互之间夹角近120°,这些棒状析出相的粒子尺寸约为100 nm,呈球状的Ni3Al粒子尺寸较小,约为50 nm。

图6所示为Cu-6.0Ni-1.0Si-0.5Al-0.15Mg-0.1Cr合金在980 ℃固溶处理4 h后,在700 ℃等温处理不同时间后透射电镜明场像。合金经等温处理1 min后,近球形的第二相尺寸约为80~150 nm(见图6(a))。合金经5 min后,第二相粒子约为100~200 nm(见图6(b))。等温处理10 min后(见图6(c)),较粗大的呈棒状分布的第二相δ-Ni2Si,粒径约为200 nm,球形的Ni3Al粒子尺寸大约为100 nm;合金经等温处理30 min后,Ni3Al粒子的尺寸约为 150 nm,δ-Ni2Si相的粒径约为250 nm。根据奥罗万强化机制,随着析出相尺寸的长大,合金的硬度和强度将降低,故合金的时效硬化曲线呈现出下降的趋势。

3 结论

1) Cu-6.0Ni-1.0Si-0.5Al-0.15Mg-0.1Cr合金的硬度在等温处理的过程中随着等温时间的延长而下降。等温时间相同的条件下,合金在600 ℃等温处理的硬度最高。

图5 合金经650 ℃等温处理1 min后的透射电镜暗场像

Fig. 5 TEM images of alloy isothermally treated at 650 ℃ for 1 min:

图6 合金经700 ℃等温处理不同时间的透射电镜明场像

Fig. 6 TEM bright field images of alloy isothermally treated at 750 ℃ for different time:

2) 等温处理过程合金的析出相为δ-Ni2Si和Ni3Al,等温温度越高,析出相尺寸越大。

3) 合金的TTP曲线为典型的“C型”曲线,鼻尖温度约为725 ℃,淬火敏感区间为675~775 ℃。合金在鼻尖区形核率和长大速率均很大,导致合金具有很高的淬火敏感性。

REFERENCES

[1] CHEN Jian, YAN Wen, LIU Chen-xin, DING Rong-gu, FAN Xu-he. Dependence of texture evolution on initial orientation in drawn single crystal copper[J]. Materials Characterization, 2011, 62(2): 237-242.

[2] XIE Hui, JIA Lei, LU Zhen-lin. Microstructure and solidification behavior of Cu-Ni-Si alloys[J]. Materials Characterization, 2009, 60(2): 114-118.

[3] ZHANG Yi, LIU Ping, TIAN Bao-hong, LIU Yong, LI Rui-qin, XU Qian-qian. Hot deformation behavior and processing map of Cu-Ni-Si-P alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(8): 2341-2347.

[4] XIE Guo-liang, WANG Qiang-song, MI Xu-jun, XIONG Bai-qing, PENG Li-jun. The precipitation behavior and strengthening of a Cu-2.0 wt% Be alloy[J]. Materials Science and Engineering A, 2012, 558(15): 326-330.

[5] YAGMUR L, DUYGULU O, AYDEMIR B. Investigation of metastable γ′ precipitate using HRTEM in aged Cu-Be alloy[J]. Materials Science and Engineering A, 2011, 528(12): 4147-4151.

[6] YAGMUR L. Effect of microstructure on internal friction and Young’s modulus of aged Cu-Be alloy[J]. Materials Science and Engineering A, 2009, 523(1/2): 6569.

[7] KRATOCHVIL P, MENCL J,  J, KOMNIK S N. The structure and low temperature strength of the age hardened Cu-Ni-Sn alloys[J]. Acta Metallurgica, 1984, 32(9): 1493-1497.

J, KOMNIK S N. The structure and low temperature strength of the age hardened Cu-Ni-Sn alloys[J]. Acta Metallurgica, 1984, 32(9): 1493-1497.

[8] MANGAN M A, SHIFLET G J. Three dimensional investigation of Cu-Ti discontinuous precipitation[J]. Scripta Materialia, 1997, 37(4): 517-522.

[9] DATTA A, SOFFA W A. The structure and properties of age hardened Cu-Ti alloys[J]. Acta Metallurgica, 1976, 24(11): 987-1001.

[10] PANG J C, DUAN Q Q, WU S D, LI S X, ZHANG Z F. Fatigue strengths of Cu-Be alloy with high tensile strengths[J]. Scripta Materialia, 2010, 63(11): 1085-1088.

[11] DJURI B, JOVANOVI

B, JOVANOVI M, DROBNJAK D J. A study of precipitation in Cu-Be alloys[J]. Metallography, 1980, 13(3): 235-247.

M, DROBNJAK D J. A study of precipitation in Cu-Be alloys[J]. Metallography, 1980, 13(3): 235-247.

[12] LEI Qian, LI Zhou, DAI Chen, WANG Ji, CHEN Xi, XIE Jia-min, YANG Wan-wan, CHEN Deng-lei. Effect of aluminum on microstructure and property of Cu-Ni-Si alloys[J]. Materials Science and Engineering A, 2013, 572: 65-74.

[13] LEI Qian, LI Zhou, ZHU An-yin, QIU Wen-ting, LIANG Shu-quan. The transformation behavior of Cu-8.0Ni-1.8Si- 0.6Sn-0.15Mg alloy during isothermal heat treatment[J]. Materials Characterization, 2011, 62(9): 904-911.

[14] 王俊峰, 贾淑果, 陈少华, 刘 平, 宋克兴, 刘红勋. 固溶态Cu-Ni-Si合金时效过程的相变动力学[J]. 中国有色金属学报, 2012, 22(10): 2862-2867.

WANG Jun-feng, JIA Shu-guo, CHEN Shao-hua, LIU Ping, SONG Ke-xing, LIU Hong-xun. Kinetics of phase transformation of solution-treated Cu-Ni-Si alloy during aging treatment[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2862-2867.

[15] 张凌峰, 刘 平, 康布熙, 赵冬梅, 田保红, 董企铭. Cu-3.2Ni-0.75Si-0.30Zn合金时效过程的动力学分析[J]. 中国有色金属学报, 2003,13 (3): 717-721.

ZHANG Ling-feng, LIU Ping, KANG Bu-xi, ZHAO Dong-mei, TIAN Bao-hong, DONG Qi-ming. Kinetics of aging process of Cu-3. 2Ni-0. 75Si-0.30Zn alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 717-721.

[16] 张 毅, 刘 平, 田保红, 陈小红, 刘 勇. Cu-Ni-Si-P-Cr合金高温热变形行为及动态再结晶[J]. 中国有色金属学报, 2013, 23(4): 970-976.

ZHANG Yi, LIU Ping, TIAN Bao-hong, CHEN Xiao-hong, LIU Yong. Hot deformation behaviors and dynamic recrystallization of CuNiSiPCr alloy at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 970-976.

[17] 雷 前. 超高强CuNiSi系弹性导电铜合金制备及相关基础研究[D]. 长沙: 中南大学, 2014: 1-5.

LEI Qian. Fundamental research and preparation of an ultrahigh strength, elastic and conductive CuNiSi alloy[D]. Changsha: Central South University, 2014: 1-5.

[18] 刘文军, 张新明, 刘胜胆, 周新伟. 均匀化对 7050 铝合金板材淬火敏感性的影响[J]. 中国有色金属学报, 2010, 20(6): 1102-1109.

LIU Wen-jun, ZHANG Xin-ming, LIU Sheng-dan, ZHOU Xin-wei. Effect of homogenization on quenching sensitivity of 7050 aluminum alloy plates[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1102-1109.

[19] LIU Sheng-dan, ZHONG Qi-min, ZHANG Yong, LIU Wen-jun, ZHANG Xin-ming, DENG Yun-lai. Investigation of quench sensitivity of high strength Al-Zn-Mg-Cu alloys by time-temperature-properties diagrams[J]. Materials & Design, 2010, 31(6): 3116-3120.

[20] LEI Qian, LI Zhou, XIAO Tao, PANG Yong, XIANG Zhou-qi, QIU Wen-ting, XIAO Zhu. A new ultrahigh strength Cu-Ni-Si alloy[J]. Intermetallics, 2013, 42: 77-84.

[21] SHEN Lei-nuo, LI Zhou, DONG Qi-yi, XIAO Zhu, LI Si, LEI Qian. Microstructure evolution and quench sensitivity of Cu-10Ni-3Al-0.8 Si alloy during isothermal treatment[J]. Journal of Materials Research, 2015, 30(5): 736-744.

TTP diagrams of Cu-6.0Ni-1.0Si-0.5Al-0.15Mg-0.1Cr alloy with super high strength and good conductivity

WANG Jing1, LI Zhou1, 2, LI Si1, XING Yan1, SHEN Lei-nuo1, LEI Qian3

(1. School of Material Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering of

Hunan Province, Central South University, Changsha 410083, China;

3. Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: A novel Cu-6.0Ni-1.0Si-0.5Al-0.15Mg-0.1Cr (mass fraction, %) alloy was designed and prepared. The changes of mechanical properties of the alloy under different isothermal conditions(600-850 ℃) after solution treated with 980 ℃ were studied, and on the basis of micro-hardness measurement, time-temperature-property (TTP) curves of the alloy were established. The transformation behavior during isothermal heat treatment was studied by transmission electron microscopy. The results show that the nose-temperatures of the curve is about 725 ℃, and quenching sensitivity region ranges from 675 ℃ to 775 ℃. As the alloy is isothermally treated in the quenching sensitivity region, the nucleation rate and growth rate of δ-Ni2Si and Ni3Al particles are high. With the isothermal holding time, the precipitated phases are coarsened rapidly, and the micro-hardness decreases. The alloy shows high quench sensitivity as it is treated around the nose-temperature.

Key words: CuNiAlSi alloy; isothermal treatment; quenching sensitivity

Foundation item: Project(51271203) supported by the National Natural Science Foundation of China

Received date: 2015-08-11; Accepted date: 2016-01-16

Corresponding author: LI Zhou; Tel: +86-731-88830264; E-mail: lizhou6931@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51271203);中南大学创新驱动计划资助项目

收稿日期:2015-08-11;修订日期:2016-01-16

通信作者:李 周,教授,博士;电话:0731-88830264;E-mail:lizhou6931@163.com