DOI: 10.11817/j.ysxb.1004.0609.2021-39721

铸造Al-Si合金表面粗糙度的高温演变机制

李 阳,李建平,刘 磊,郭永春,保 彤,高 宇,龚文健,王 缘

(西安工业大学 材料与化工学院,西安 710021)

摘 要:对经过T6处理的两种铸造Al-Si合金(Si含量为12%和18%,质量分数)进行不同温度(250、350、450、550 ℃)、时间2 h的热暴露试验。采用表面粗糙度仪、金相显微镜、扫描电子显微镜、专业型同步热分析仪等测试方法相互结合,对两种Al-Si合金在高温热暴露条件下表面状态的变化进行研究。结果表明:Al-x%Si二元合金的粗糙度变化基本遵循Ra, T6>Ra, thermal exposure>Ra, as-cast的规律;随着热暴露温度的升 高,Al-12%Si粗糙度呈现先降低后升高的趋势,Al-18%Si粗糙度呈现不断升高的趋势;合金表面粗糙度的变化与热暴露试验过程中的Al/Si相界开裂和稀土相的析出有关;对比粗糙度及表面微观形貌变化发现:Al-18%Si比Al-12%Si具有更加优良的高温稳定性,即在较低温度下,随着Si含量的增加,Al-x%Si合金发生开裂的趋势逐渐降低。

关键词:Al-Si合金;粗糙度;微观组织;热暴露

文章编号:1004-0609(2021)-08-2115-10 中图分类号:TG146.2 文献标志码:A

引文格式:李 阳, 李建平, 刘 磊, 等. 铸造Al-Si合金表面粗糙度在高温中的演变机制[J]. 中国有色金属学报, 2021, 31(8): 2115-2124. DOI: 10.11817/j.ysxb.1004.0609.2021-39721

LI Yang, LI Jian-ping, LIU Lei, et al. Evolution mechanism of cast Al-Si alloy surface roughness at high temperature[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(8): 2115-2124. DOI: 10.11817/j.ysxb.1004.0609.2021-39721

Al-Si系合金因其具有良好的铸造性能、热稳定性、耐磨性、低的热膨胀系数而被广泛用作活塞材料。当柴油发动机工作时,活塞合金会承受高温、高压、复杂摩擦和热机械耦合载荷等一系列因素[1]。随着发动机爆压与转速的提升,活塞顶部工作温度已经超过400 ℃,且各部位承受热量分布不均匀。已经有学者对Al-Si合金在工况环境中的力学性能、高温力学性能、高温蠕变性能以及Al-Si合金的热处理工艺进行了深入的研究,田璐莎等[2]在对Al-13%Si-4%Cu-2%Ni-1%Mg-0.25%Mn活塞合金进行不同温度和不同时间的时效处理,发现420 ℃时效所得合金的室温拉伸强度与高温拉伸强度均高于350 ℃时效所得合金,这是由于在420 ℃时效下合金内部析出的纳米强化相Al11Cu5Mn3;程峰等[3]对Al-12%Si-3.5%Cu-1%Mg-2%Ni在300 ℃、25~400 h环境中进行了长时间保温时,并且发现:随着保温时间的延长,合金抗拉强度、硬度逐渐降低,这主要是由于合金化合物相的析出和共晶Si尺寸由颗粒状→棒状→颗粒状的变化引起,合金中化合物的析出降低了固溶强化的作用。但这些研究较少涉及Si含量对Al-Si合金表面形态在高温下变化的影响,且未出现利用粗糙度表征合金表面特性的研究方法。

表面粗糙度是指加工表面具有的较小间距和微小峰谷的不平度,几乎所有的固体表面都是粗糙的。这种粗糙发生在长度尺度上包括13个数量级,即从千米尺度到原子尺度。不管对表面进行怎样的处理,粗糙度都会出现[4]。目前,针对粗糙度的研究主要集中在粗糙度对合金热交换的影响以及粗糙度对合金疲劳性能的影响等方面。活塞合金在工作时的散热主要以传导和对流换热为主,这对其热交换性能提出了较高要求,而表面粗糙度又是影响热交换的关键因素[5-6],表面粗糙度一方面影响材料的疲劳极限,粗糙度越大,越容易引起应力集中,从而导致疲劳极限越低[7-8];另一方面,大的表面粗糙度易于积聚更多的附壁燃油[9],从而容易形成更多的积碳,积碳厚度的增加会严重降低活塞的导热性能,使得燃烧室局部超温概率和频率提高,进而造成活塞的熔化烧蚀。因此,在一定程度内控制合金表面粗糙度对活塞合金的热交换性能及防止表面应力集中均有重要的作用。高度特性有关的表面粗糙度评定参数有轮廓算术平均差Ra、微观不平度十点高度Rz和轮廓最大高度Ry,实际生产实验中优先选用轮廓算术平均差Ra。所以利用粗糙度Ra来表征活塞合金在高温下表面形貌及组织变化是非常有必要的。

粗糙度的研究对于研究活塞结构件间的精密配合与内燃机的使用寿命具有重要意义,之前Al-Si合金的热处理研究[10-14]主要针对合金内部组织变化与合金性能之间的关系,对合金表面在高温环境下的宏观变化与微观组织变化研究较少,且并未有较为准确的表征方式来反映合金表面变化。因此,本课题以经过热处理的Al-Si合金为研究对象,探究其在250~550 ℃下保温2 h后,表面粗糙度的变化趋势及表面微观组织形貌的演变,为优化材料的使用性能和部件设计提供有效帮助。

1 实验

1.1 材料制备

试验用Al-Si二元合金所用原料为工业纯铝(纯度≥99.7%)、结晶硅(纯度≥99.5%),在中频感应炉中熔炼。首先将工业纯铝、结晶硅加入到石墨坩埚中进行熔化;待熔体全部熔融后,升温至730~ 780 ℃,采用1.5%(质量分数)磷盐和0.35%稀土Nd(纯度≥99.5%)进行复合变质处理,静置保温10 min;待熔液温度至710~730 ℃时,采用1%(质量分数)C2Cl6进行精炼除气,静置保温15 min后加入1.5% (质量分数)Al-Ti-C进行细化处理,保温10 min后撇渣,然后将合金熔体浇入预热好的金属模具中,浇铸温度和模具预热温度分别设定为730 ℃和250 ℃。

1.2 测试表征

为了方便比较,所有用于试验的试样均取自铸锭的心部,利用线切割机将铸态试样切割为10 mm×10 mm×10 mm小块。将铸态试样一个面利用不同粒度的SiC砂纸打磨和机械抛光后测量原始表面粗糙度(Ra0),本试验采用T6热处理来优化合金微观结构,热处理工艺为(500 ℃、6 h固溶(60~80 ℃热水淬火))+(180 ℃、6 h时效(空冷)),将热处理后的试样抛光面进行表面粗糙度测量(Ra1)。T6热处理后,将上述合金试样分别在不同温度(250、350、450、550 ℃)下保温2 h,继续测量抛光面的表面粗糙度(Ra2),根据式(1)计算材料的粗糙度变化:

(1)

(1)

使用尺寸为141 mm×56 mm×48 mm的TR200手持式表面粗糙度仪,以触针法(接触式测量法)测量表面粗糙度,针尖材料为金刚石,半径5 μm,测量范围0.025~12.500 μm,分辨率0.01 μm,测量行程长度:2 mm,最大示值误差:±10%;对不同状态下合金试样抛光面粗糙度进行测量,每个试样的表面粗糙度测量均进行6次,取平均值,进而分析合金不同热暴露温度下的粗糙度变化;利用专业型同步热分析仪(TGA/DSC 1)对合金相变温度进行监测,温度范围为25~700 ℃,升温速率为10 ℃/min;利用光学显微镜(NIKON EPIHOT3000)观察合金截面的金相组织;使用扫描电子显微镜(Quanta-400F)观察合金表面微观组织形貌;借助扫描电子显微镜配备的能量色散光谱(EDS)分析各相成分。

2 结果与分析

2.1 铸态Al-Si合金的相变温度

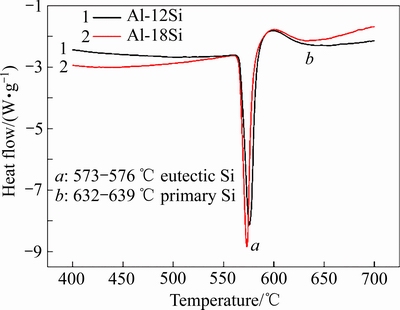

图1所示为两种Al-Si合金的DSC热分析结果。结合DSC曲线及合金凝固特性可知,Al-Si合金在逐步升温过程中会发生相变和Si相熔化,这些过程均需要吸热,吸热峰起始点即为相变开始的温度点。在本文中重点研究Si相与α(Al)相,由图1可知:a、b两点分别对应共晶硅与初生硅的熔化温度,共晶硅的熔化温度在573~576 ℃,初生硅熔化温度在632~639 ℃;对比两曲线可发现,对比Al-18%Si合金,Al-12%Si的共晶反应更早发生。

图1 铸态Al-Si合金DSC曲线

Fig. 1 DSC curve of as-cast Al-Si alloys

2.2 铸态Al-Si合金的显微组织

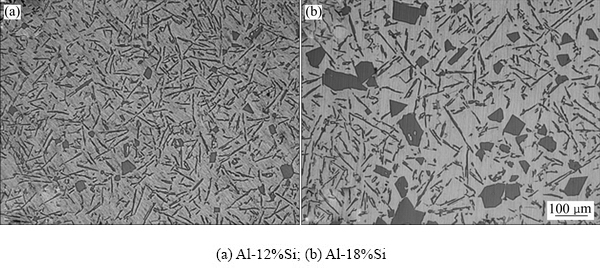

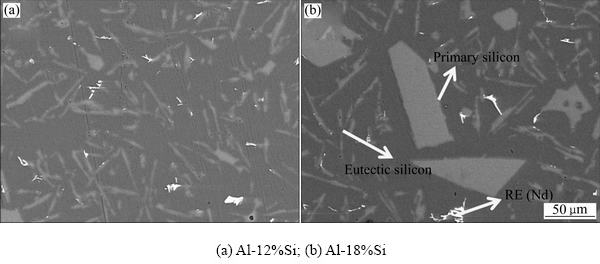

图2所示为Al-12%Si与Al-18%Si合金铸态的金相照片。从图2可以看出,材料主要由灰白色、深灰色两个相组成,其中灰白色部分为α(Al)相,深灰色为Si相。根据形态特征,Si相中深灰色长条状、短棒状部分为共晶Si,长径比多大于3;深灰色块状、球状部分为初生Si。铸态下的共晶硅为纤维长条状,对合金基体的割裂作用大;初生硅呈尖角块状,同样会割裂基体。图3所示为Al-12%Si与Al-18%Si合金铸态的表面扫描照片。其中,灰色纤维状、颗粒状的为共晶硅;块状的为初生硅;白色颗粒状、条状的为稀土相,富Nd稀土相较少,这是由于Nd固溶到Si相和α(Al)中,会造成Si相和α(Al)晶格常数增大[15]。

图2 铸态Al-Si合金的金相组织

Fig. 2 Metallurgical structures of as-cast Al-Si alloys

图3 铸态Al-Si合金的SEM像

Fig. 3 SEM images of as-cast Al-Si alloys

2.3 高温热暴露中Al-Si合金的微观组织演变

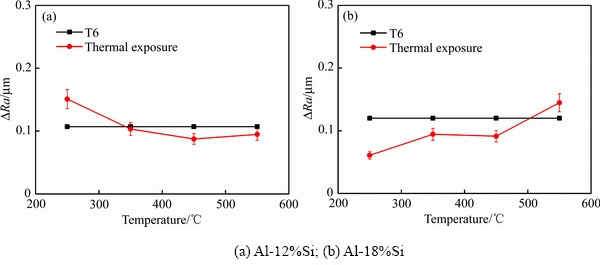

图4所示为合金经过不同温度(250、350、450、550 ℃)保温2 h后粗糙度变化规律演变,按照表面粗糙度仪最大示值误差10%设置误差棒。由图4可以看出:经过T6热处理后,两种Al-Si合金表面粗糙度明显高于铸态;在经过热暴露处理后,粗糙度较热处理状态大致呈现降低趋势。两种Al-Si合金的表面粗糙度均基本遵循Ra, T6>Ra, thermal exposure> Ra, as-cast。在Al-12%Si中热处理后粗糙度明显增大,在经过250 ℃热暴露后粗糙度继续升高,随着热暴露温度的升高,粗糙度开始下降,在450 ℃时降到最低,但在550 ℃时粗糙度又发生少许回升。Al-18%Si在热处理后粗糙度明显升高,但热暴露后的粗糙度较热处理后的发生小幅度降低,随着热暴露温度的升高粗糙度发生缓慢升高,比较450与550 ℃热暴露发现:Al-18Si合金在经过550 ℃热暴露后,粗糙度明显增大。

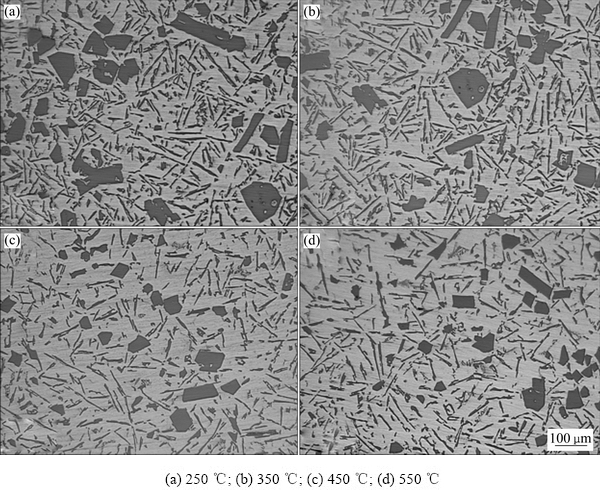

图5所示为Al-12%Si与Al-18%Si经过T6热处理后的金相组织。从图5可以得出,在热处理的作用下α(Al)发生少许熔断;初生硅相发生尖角钝化,从之前铸态的块状变为球状或短棒状;试样经过热处理后,共晶硅组织发生很大变化,共晶硅相在热处理过程中发生了熔断与球化。图6所示为Al-12%Si与Al-18%Si经过T6热处理后的SEM像。由图6可以看出,块状的初生硅相、短棒状的共晶硅以及白色细条状的稀土相。在试样经过T6热处理后,棒状的共晶硅发生熔断,初生硅发生了钝化。观察高倍扫描照片,发现Si相有浮凸迹象,且从图6(a)、(b)中的Al/Si相界开裂处析出许多白色点状相,经EDS能谱分析后发现其为稀土相(Nd),Si相的浮凸是造成T6热处理后粗糙度升高的主要原因。

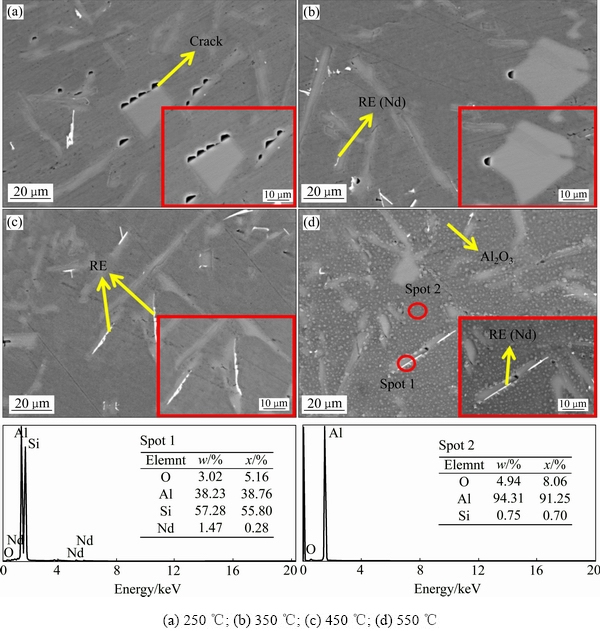

图7所示为Al-12%Si合金在不同温度下热暴露2 h后表面的SEM像和EDS分析结果。从图7可以看出,热处理后的Si相边缘有开裂的痕迹,与Al的界面高度不一致;250 ℃热暴露后,Al/Si相界出现很多由热应力导致的塑性变形,Al/Si相界发生明显开裂;在经过350 ℃热暴露后,开裂有所减少,在Al/Si相界处发现了很少量的白色细条状相;在450 ℃的热暴露扫描照片中发现,开裂现象进一步减少,且出现了更多的白色条状相附着在Al/Si相界之间,经过对其进行能谱分析,发现其为含Nd的稀土相,随着热暴露温度的升高,逐渐时效析出。在550 ℃热暴露中发现了非常多、均匀分散的小颗粒,经过能谱分析,发现其为高温下合金氧化产生的Al2O3颗粒。

图4 Al-Si合金表面粗糙度变化曲线

Fig. 4 Changing curves of surface roughness of Al-Si alloys

图5 T6态Al-Si合金的金相组织

Fig. 5 Metallographic structures of Al-Si alloys after T6 heat treatment

图6 T6态Al-Si合金的SEM像

Fig. 6 SEM images of Al-Si alloys after T6 heat treatment

图7 Al-12%Si合金在不同温度下热暴露2 h后表面的SEM像和EDS分析结果

Fig. 7 High magnification SEM images and EDS analysis of surface of Al-12%Si alloys after thermal exposure at various temperatures for 2 h

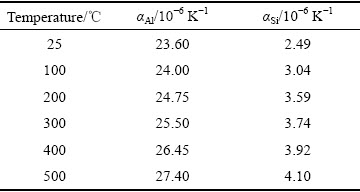

图8所示为Al-12%Si热暴露后的截面金相组织。从图8可以看出,在Al-12%Si合金进行T6热处理后,合金中的初生硅发生钝化,共晶硅有所熔断;随热暴露温度的升高,共晶硅持续熔断为细小的棒状或颗粒状,初生硅变得细小且分布均匀。由Al-12%Si的截面金相与表面扫描可以观察到粗糙度变化的原因:T6热处理较原始的粗糙度发生升高是因为Al/Si相界的界面有开裂趋势,此过程中Al相由于较大的热膨胀系数而先发生膨胀,Al相膨胀产生的热应力造成Si相有凸出的迹象,引发粗糙度升高;250 ℃热暴露后,Al/Si相界发生明显开裂,开裂现象在共晶硅与初生硅上均有发生,造成粗糙度的进一步升高;Al、Si的热膨胀系数与温度关系见表1。由表1可知,Al/Si相界开裂是由于Al的热膨胀系数(23.6×10-6 K-1)远大于Si的热膨胀系数(2.49×10-6 K-1),因而Al相先发生膨胀,Al相膨胀产生的热应力作用在Si相上。进而造成Al/Si相界之间发生开裂。在350 ℃与450 ℃中,发现开裂的现象有很大程度的减小,同时表面粗糙度也发生了降低,这是由于随着温度升高稀土相从α(Al)中析出,附着在Al/Si相界的开裂处,造成了开裂的弥合。在550 ℃时,粗糙度发生回升。原因是在550 ℃热暴露下,合金发生高温氧化,表面产生了许多Al2O3颗粒,造成了合金表面粗糙度的升高。

表1 Al、Si的热膨胀系数与温度的关系[16]

Table 1 Relationship between thermal expansion coefficients of Si and Al and temperature

图8 Al-12%Si热暴露后的截面金相组织

Fig. 8 Metallographic structures of section of Al-12%Si alloys after thermal exposure at various temperatures for 2 h

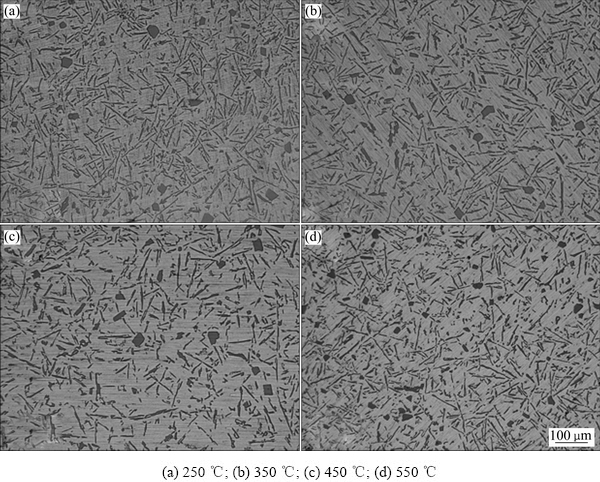

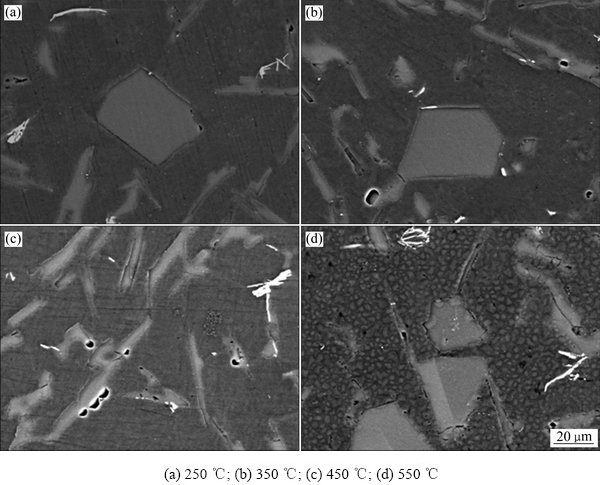

图9所示为Al-18%Si合金在不同热暴露温度下的表面扫描组织。由图9可以看出,合金在250 ℃热暴露后,Si相有浮凸迹象,Al相与Si相之间产生界面高度差,且在扫描照片中发现有少量Si相发生破碎;350 ℃热暴露后Al/Si相界边缘已经出现轻微的开裂,且有极少量的稀土相附着在Al/Si相界处;450 ℃时Al/Si相界的开裂加剧;在经历了550 ℃时的热暴露后,表面出现了许多弥散分布的Al2O3小颗粒。图10所示为Al-18%Si合金不同热暴露温度下的截面金相照片。从图10可以看出,在250 ℃热暴露下,合金内部α(Al)有所熔断,共晶硅有所熔断,初生硅边角发生钝化现象;350 ℃热暴露后,初生硅钝化加剧,共晶硅熔断为球状或块状的小颗粒;450 ℃时,初生硅发生明显的熔断,较之前的初生硅明显变小;550 ℃时,初生硅的分布十分均匀。结合Al-18%Si在不同温度热暴露后的表面扫描及截面金相可以发现:Al-18%Si的原始铸态内部无明显开裂与缺陷,在经过T6热处理后硅相与Al之间产生开裂的迹象,即Si相有浮凸迹象,但并未发生开裂,这种Si相与Al相由于浮凸导致的相界高度差,使得粗糙度升高;250 ℃热暴露后,表面仍有继续开裂的迹象,但由于初生硅的钝化。共晶硅的球化作用使得Al/Si相界之间由于热膨胀而产生的应力有所减弱,造成250 ℃时粗糙度的减小;在350 ℃与450 ℃的扫描照片中发现了Al/Si相界的明显开裂,造成粗糙度升高;550 ℃时Si相产生裂纹、Al/Si相界开裂明显,再加之高温氧化产生的Al2O3小颗粒,使得合金粗糙度继续升高。

2.4 硅含量对合金热暴露后表面特性与微观组织的影响

对Al-12%Si与Al-18%Si分别进行不同温度(250、350、450、550 ℃)下热暴露2 h,发现其表面粗糙度在T6热处理后都发生了增大,且都基本遵循Ra, T6>Ra, exposure>Ra, as-cast,Al-12%Si在热暴露阶段,粗糙度随热暴露温度的升高而降低,在550℃时又发生少许回升;Al-18%Si在热暴露阶段,粗糙度随热暴露温度的升高而升高。粗糙度发生变化的原因有4种可能性:1) Al/Si相界之间由于热膨胀系数的差异而产生开裂;2) Si相在高温下出现裂纹;3) 初生硅与共晶硅在高温作用下的形态变化;4) 合金表面在高温下发生氧化,产生Al2O3颗粒。Al-12%Si合金在250 ℃时就发生了铝硅相界的开裂,并且此时的开裂为峰值;而Al-18%Si合金在350℃时才发生了开裂,在450 ℃时开裂发生加剧。Al-12%Si合金随热暴露温度升高开裂不再加剧,且逐渐弥合,而Al-18%Si合金随热暴露温度升高开裂逐渐加剧,不同温度的热暴露又会影响合金中Si相组织,使初生硅与共晶硅形态发生变化,不同Si含量的不同开裂温度说明了Si相形态和体积分数对Al-Si合金的线膨胀系数有着重要影响。Al-12%Si中Si含量较少,且多是共晶硅颗粒,导致其线膨胀系数较大,易在长时间高温下发生膨胀,进而导致相界开裂。于是在250 ℃热暴露下,相界发生开裂,之后升高温度,一方面导致稀土相从α(Al)中的析出与扩散,造成开裂的愈合,另一方面使得共晶硅颗粒细化,由最初的长棒状变为颗粒状,造成开裂的减弱,两方面共同作用导致合金粗糙度减小。550 ℃热暴露中产生了许多的Al2O3颗粒,造成了粗糙度的少量增大。对于Al-18%Si合金,其Si含量较多,粗糙度呈现缓慢增高趋势。由图9发现:Al-18%Si合金在350 ℃时才出现明显开裂,450 ℃时开裂程度加剧,说明Si含量的增加可有效降低Al-Si合金的热膨胀系数,使得合金在较低温度下难以发生相界开裂,且Si元素体积分数的增加和初生硅的析出可有效降低Al-Si合金的线膨胀系数,造成Al-18%Si需在比Al-12%Si更高的温度下才能发生相界开裂,这与文献[17-19]研究的硅相对Al-Si合金线膨胀系数的影响相契合。对于Al-Si系的合金,Si含量越高,其线膨胀系数越小,随温度变化幅度减小;由Al-18%Si的粗糙度变化结合微观组织形貌可知:Al-18%Si在450 ℃或更高温度下才能到达开裂的峰值,粗糙度由于Al/Si相界的开裂而持续增大,随后本应由于由于稀土相的析出与扩散而发生愈合,造成粗糙度的降低,但由于在550 ℃条件下,Al-18%Si会发生氧化,产生许多弥散分布的Al2O3颗粒。造成了粗糙度的进一步增大。

图9 Al-18%Si合金在不同温度下热暴露2 h后表面的SEM像

Fig. 9 High magnification SEM images of surface of Al-18%Si alloys after thermal exposure at various temperatures for 2 h

图10 Al-18%Si合金在不同温度下热暴露2 h后截面的金相组织

Fig. 10 Metallographic structures of section of Al-18%Si alloys after thermal exposure at various temperatures for 2 h

3 结论

1) Al-12%Si和Al-18%Si合金在250~550 ℃(间隔100 ℃)下保温2 h后,表面粗糙度均基本遵循Ra, T6>Ra, exposure>Ra, as-cast。

2) Al-12%Si合金随热暴露温度升高,粗糙度基本呈现下降趋势,合金在T6及低温热暴露下由于Al相与Si相之间的热膨胀系数差异过大,而发生开裂,随着热暴露温度的升高,稀土相从α(Al)中析出,造成开裂的弥合,在550 ℃时由于高温氧化而产生少许回升。

3) Al-18%Si随热暴露温度升高,开裂逐步加剧,使得粗糙度基本呈现上升趋势。在550 ℃时由于高温氧化使得粗糙度增幅加剧。

4) Al-18%Si较Al-12%Si有更好的高温稳定性,即Si含量的增加使得铸造Al- Si合金在较低温度下难以发生相界开裂。

REFERENCES

[1] JIANG L T, WU G H, YANG W S, et al. Effect of heat treatment on microstructure and dimensional stability of ZL114A aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(11): 2124-2128.

[2] TIAN L S, GUO Y C, LI J P, et al. Elevated re-aging of a piston aluminium alloy and effect on the microstructure and mechanical properties[J]. Materials Science and Engineering A, 2018, 738(19): 375-379.

[3] 程 峰, 程和法, 黄笑梅, 等. 高温长时间保温对共晶铝硅合金组织及力学性能的影响[J]. 特种铸造及有色合金, 2019, 39(8): 918-921.

CHENG Feng, CHENG He-fa, HUANG Xiao-mei, et al. Effect of high temperature and long-term heat preservation on microstructure and mechanical properties of eutectic Al-Si alloy[J]. Special Casting & Nonferrous Alloys, 2019, 39(8): 918-921.

[4] WIJN A. Why surface roughness is similar at different scales[J]. Nature, 2020, 578(7795): 366-367.

[5] 潘亚文. 影响材料发射率因素的实验研究[D]. 新乡: 河南师范大学, 2013: 22-27.

PAN Ya-wen. Experimental study on the factors affecting the emissivity of materials[D]. Xinxiang: Henan Normal University, 2013: 22-27.

[6] 朱 波, 曹伟伟, 井 敏, 等. C/C复合材料的光谱发射率研究[J]. 光谱学与光谱分析, 2009, 29(11): 2909-2913.

ZHU Bo, CAO Wang-wang, JING Min, et al. Study on spectral emissivity of C/C composites[J]. Spectroscopy and Spectral Analysis, 2009, 29(11): 2909-2913.

[7] 陈煜达, 潘金芝, 刘鹏涛, 等. 表面粗糙度对动车组车轮钢弯曲疲劳性能的影响[J]. 表面技术, 2017, 46(2): 172-177.

CHEN Yu-da, PAN Jin-zhi, LIU Peng-tao, et al. Effect of surface roughness on bending fatigue performance of EMU wheel steel[J]. Surface Technology, 2017, 46(2): 172-177.

[8] 章 刚, 刘 军, 刘永寿, 等. 表面粗糙度对表面应力集中系数和疲劳寿命影响分析[J]. 机械强度, 2010, 32(1): 110-115.

ZHANG Gang, LIU Jun, LIU Yong-shou, et al. Analysis of the effect of surface roughness on surface stress concentration factor and fatigue life[J]. Mechanical Strength, 2010, 32(1): 110-115.

[9] BAGHEL V, SIKARWAR B S, SHARMA D K, et al. A correlation of metallic surface roughness with its hydrophobicity for dropwise condensation[J]. Materials Today (Proceedings), 2020, 21: 1446-1452.

[10] 张新明, 刘 波, 刘 瑛, 等. 温度与保温时间对2519A铝合金高温力学性能的影响[J]. 中国有色金属学报, 2007, 17(10): 1561-1566.

ZHANG Xin-ming, LIU Bo, LIU Ying, et al. Effect of temperature and holding time on mechanical properties of 2519A aluminum alloy at high temperature[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(10): 1561-1566.

[11] ZEREN M. The effect of heat-treatment on aluminum-based piston alloys[J]. Materials and Design, 2007, 28(9): 2511-2517.

[12] 谢忠华, 范 亮. 汽车用铸造Al-Si合金的热处理与力学性能[J]. 金属热处理, 2019, 44(3): 32-36.

XIE Zhong-hua, FAN Liang. Heat treatment and mechanical properties of cast Al-Si alloys for automotive applications[J]. Heat Treatment of Metals, 2019, 44(3): 32-36.

[13] WANG M, PANG J C, ZHANG M X, et al. Thermo-mechanical fatigue behavior and life prediction of the Al-Si piston alloy[J]. Materials Science and Engineering A, 2018, 715: 62-72.

[14] LIN B, LI H Y, XU R, et al. Thermal exposure of Al-Si-Cu-Mn-Fe alloys and its contribution to high temperature mechanical properties[J]. Journal of Materials Research and Technology, 2020, 9(2): 1856-1865.

[15] 石为喜, 高 波, 涂赣峰, 等. Nd变质过共晶Al-17.5%Si合金的微观组织和断口形貌[J]. 中国有色金属学报, 2011, 21(4): 719-726.

SHI Wei-xi, GAO Bo, TU Gan-feng, et al. Microstructure and fracture morphology of Nd modified hypereutectic Al-17.5% Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(4): 719-726.

[16] 马广辉, 李润霞, 白彦华, 等. Si相对铸造Al-Si合金低温拉伸断裂行为的影响[J]. 中国有色金属学报, 2016, 26(8): 1615-1623.

MA Guang-hui, LI Run-xia, BAI Yan-hua, et al. Effect of Si on tensile fracture behavior of cast Al-Si alloy at low temperature[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(8): 1615-1623.

[17] 刘 超, 浦玉萍, 沈 伟, 等. Si-Al复合材料热膨胀系数的有限元计算方法研究[J]. 粉末冶金技术, 2012, 30(6): 428-431.

LIU Chao, PU Yu-ping, SHEN Wei, et al. Research on finite element calculation method of thermal expansion coefficient of Si-Al composite[J]. Powder Metallurgy Technology, 2012, 30(6): 428-431.

[18] 蒋 伟, 胡恺琪, 朱向镇, 等. Al-Si合金力学行为对Si相形貌敏感性的差异[J]. 中国有色金属学报, 2017, 27(1): 15-23.

JIANG Wei, HU Kai-qi, ZHU Xiang-zhen, et al. The difference of sensitivity of mechanical behavior of al-si alloy to morphology of Si phase[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(1): 15-23.

[19] 武玉英, 刘相法, 戴 勇, 等. 硅相形态及含量对Al-Si合金线膨胀系数的影响[J]. 中国有色金属学报, 2007, 17(5): 688-692.

WU Yu-ying, LIU Xiang-fa, DAI Yong, et al. Effect of silicon phase morphology and content on linear expansion coefficient of Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(5): 688-692.

Evolution mechanism of cast Al-Si alloy surface roughness at high temperature

LI Yang, LI Jian-ping, LIU Lei, GUO Yong-chun, BAO Tong, GAO Yu, GONG Wen-jian, WANG Yuan

(School of Materials and Chemical Engineering, Xi’an Technological University, Xi’an 710021, China)

Abstract: Thermal exposure tests were performed on two cast Al-Si alloys by T6 heat treatment at different temperatures (250, 350, 450 and 550 ℃) for 2 h. The surface roughness tester, metallographic microscope, scanning electron microscope, simultaneous thermal analyzer and other testing methods were used to study the change of the surface state of two Al-Si alloys under high temperature thermal exposure conditions. The results show that the roughness change of Al-x%Si binary alloy basically follows the law of Ra, T6>Ra, thermal exposure> Ra, as-cast; with the increase of thermal exposure temperature, the roughness of Al-12%Si tends to decrease first and then increases, while that of Al-18%Si tends to increase continuously. The change of alloy surface roughness is related to Al/Si phase boundary cracking and precipitation of rare earth phase during thermal exposure test. By comparing the roughness and phase changes, it is found that Al-18%Si has better high temperature stability than Al-12%Si. That is to say, at lower temperature, with the increase of Si content, the tendency of Al-x%Si cracking gradually decreases.

Key words: Al-Si alloys; roughness; microstructure; thermal exposure

Foundation item: Project(2020JQ-808) supported by the Fund from the Science and Technology Fund of Shaanxi Province, China; Projects(19JK0400, 19JK0402) supported by the Education Fund of Shaanxi Province, China; Project(DLBF2018-KY-JS-066-J) supported by the China North Engine Research Institute, China; Project(XAGDXJJ17008) supported by the Principal Fund of Xi’an Technological University, China

Received date: 2020-05-28; Accepted date: 2021-04-10

Corresponding authors: LI Jian-ping; Tel: +86-13991927289; E-mail: jpli_0416@163.com

LIU Lei; Tel: +86-13629209053; E-mail: liuleiNIN@126.com

(编辑 龙怀中)

基金项目:陕西省科学技术基金资助项目(2020JQ-808);陕西省教育基金资助项目(19JK0400,19JK0402);中国北方发动机研究所资助项目(DLBF2018-KY-JS-066-J);西安工业大学校长基金资助项目(XAGDXJJ17008)

收稿日期:2020-05-28;修订日期:2021-04-10

通信作者:李建平,教授;电话:13991927289;E-mail:jpli_0416@163.com

刘 磊,讲师;电话:13629209053;E-mail:liuleiNIN@126.com