Article ID: 1003-6326(2005)05-1067-05

Joining of SiCp/Al composites by insert powder layers

HUANG Ji-hua(黄继华), DONG Yue-ling(董月铃), WAN Yun(万 云),

ZHANG Jian-gang(张建纲), ZHOU Guo-an(周国安)

(School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Mixed Al-Si, Al-Si-SiC and Al-Si-W powders were employed as insert layers to reactive diffusion bond SiCp/6063 MMC. The results show that SiCp/6063 MMC joints bonded by the insert layer of the mixed Al-Si powder have a dense joining layer with a typical hypoeutectic

microstructure. Using mixed Al-Si-SiC powder as insert layer, SiCp/6063 MMC can be reactive diffusion bonded by a composite joint. Because of the SiC segregations, however, there are a number of porous zones in the joining layer, which results in the low shear strength of the joints, even lower than that of joints reactive diffusion bonded by the insert layer of mixed Al-Si powder. The W added into the insert layer of Al-Si-W nearly all reacts with Al to form intermetallic WAl12 during bonding. The reaction between the W and Al facilitates to form a dense joint of high quality, and the formed intermetallic WAl12 has a reinforcing effect on the joints, which lead to the high shear strength of the joints. In general, under the condition of fixed bonding time (temperature), the shear strengths of the joints increase as the bonding temperature (time) increases, but tend to a maximum at bonding temperature of 600℃(time 90min).

Key words: reactive diffusion bonding; insert powder layer; SiCp/Al MMCs CLC number: TG456.9

Document code: A

1 INTRODUCTION

SiCp reinforced aluminium metal matrix composites (SiCp/Al MMCs) have a unique combination of mechanical and physical properties, such as high specific strength and specific modulus of elasticity, low thermal expansion coefficient and good wear resistance, being widely used in aerospace engineering, automotive industry, electronic packaging, medical appliances, etc. As is well known, joining is an indispensable processing for industrial applications of any material. Up to now, the majority of joining processes including fusion welding[1-8], diffusion bonding[9-11] and brazing[12, 13] have been investigated to join SiCp/AlMMCs. Because of the specific characteristics in composition and microstructure, however, SiCp/Al MMCs display a bad join-ability. In fusion welding (TIG, MIG, EBW, LBW, etc), some weld defects, such as incomplete backfill, slag inclusions, blow holes and SiC segregation are liable to form in welded joints. Moreover, serious reaction between Al matrix and SiC particles will occur in the molten pool[1-6, 14]. Diffusion bonding need not melt the materials to be bonded during bonding, which should be an effective joining process for the heterogeneous composite materials, especially the ceramic particle reinforced metal matrix composites like the SiCp/Al MMCs. Unfortunately, the stable aluminium oxide film and the exposed SiC particles on the surface of the composites hinder atom diffusion and interfacial bonding during diffusion bonding. The direct solid diffusion bonding of the SiCp/Al MMCs is verified to be difficult. As for the brazing of SiCp/Al MMCs, a fatal weakness is the low strength of the brazed joints.

An effective method for joining of SiCp/Al MMCs is the process called as reactive diffusion bonding(RDB) or reactive brazing(RB), which is also classified as transient liquid phase diffusion bonding(TLP) by some investigations[15, 16]. Until the present, however, only the metal insert layers in the shape of foil, such as Cu foil, Ag foil, have been investigated to reactive diffusion bond the SiCp/Al MMCs[15]. Generally, there is a zone without composite in the joints of RDB by metal insert layers in the shape of foil, which obviously differs from the bonded composites in microstructure and mechanical properties. In addition, the foil metal insert layers have limitations on the structures to be bonded, being only suitable to bonding some simple structures. In order to explore a possible RDB process to surmount the limitations of the existent RDB process by foil metal insert layers on the structures to be bonded, and bond SiCp/Al MMCs by a joint with the mechanical properties, even with the composite microstructure similar to the bonded materials, in this investigation, mixed Al-Si, Al-Si-SiC and Al-Si-W powders are employed to replace foil metals as insert layers for reactive diffusion bonding of SiCp/Al MMCs, in which SiC and W powders are added in the insert layers as ceramic reinforcing phase and metal reinforcing phase respectively to obtain composite joints. Considering the bad wettability of SiC, W is investigated as reinforcing phase to add into the insert layer.

2 EXPERIMENTAL

The composite material to be bonded in this investigation was 15%SiCp(volume fraction, %) reinforced 6063 aluminium alloy matrix composite(SiCp/6063 MMC), which was cut into samples of 15mm×10mm×5mm. The particle sizes of the Al and Si powders as the reactive constituents, and the SiC and W powders as reinforcing phases of the joining layer were 〈74μm, 〈45μm, 5μm and 3-5μm, respectively. The Al, Si, SiC and W powders were mixed with ethanol to prepare slurries of 87.4%Al+12.6%Si(mass fraction), (87.4%Al+12.6%Si)+10%SiC(volume fraction) and (87.4%Al+12.6%Si)+10%W(volume fraction), respectively. The insert layers for bonding were prepared by coating the slurry on surfaces of the SiCp/6063 MMC samples to be bonded. The reactive diffusion bonding was performed at 580-605℃ for 15-120min under conditions of a pressure of 3×10-3MPa, a vacuum of 3.8×10-3Pa and heating rate of 10℃/min. The X-ray diffraction(XRD) investigation was carried out using a Rigaku Rotaflex D/max-rb diffractometer. Microstructural observation for the joining layers was performed with a LEO-1450 scanning electron microscope.

3 RESULTS AND DISCUSSION

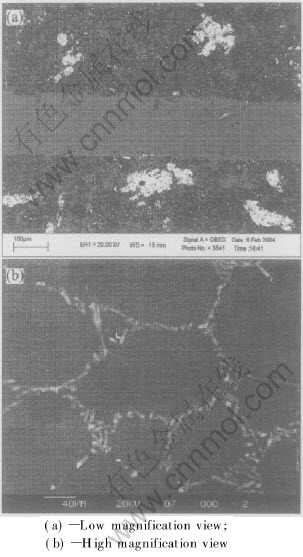

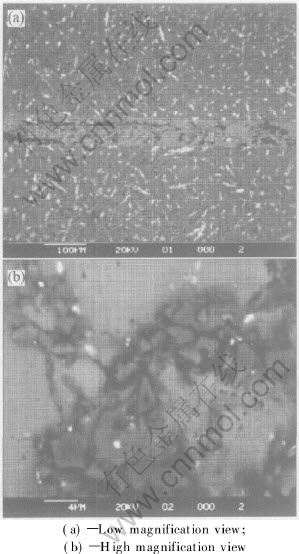

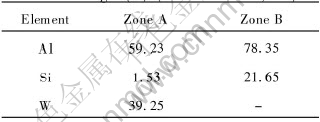

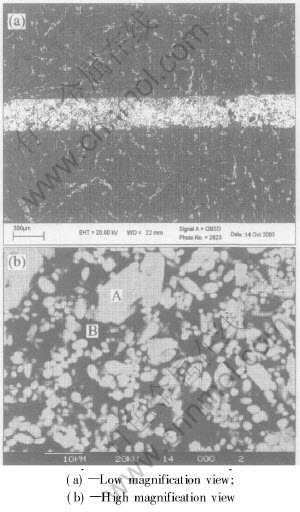

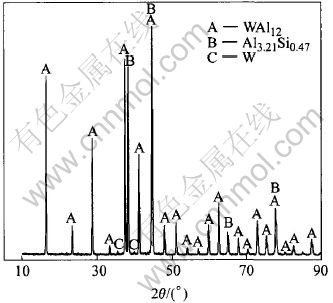

Fig.1 shows the SEM micrographs (back-scattered electron images) of a typical SiCp/6063 MMC joint reactive diffusion bonded by insert layer of the mixed Al-Si powder. It is clear that a dense joint is formed by the eutectic reaction of Al and Si during bonding, and the interfaces between the bonded materials and the joining layer have a good bond. The joining layer is possessed of a typical hypoeutectic microstructure, which indicates that besides the Al added as the reactive constituents of the insert layer, some Al from the bonded composite dissolve into the joining layer. Fig.2 shows the back-scattered SEM micrographs of a typical reactive diffusion bonded SiCp/6063 MMC joint by insert layer of the mixed Al-Si-SiC powder. The low magnification view (Fig.2(a)) shows that the mixed Al-Si-SiC powder has reacted to form a composite joint. Within the joining layer, however, there are a number of porous zones, which are demonstrated to result from the SiC segregations, as shown in the high magnification view of Fig.2(b). The bad wettability of SiC for liquid aluminium base alloys is considered to be responsible for the SiC segregations. In fact, the bad wettability of SiC has been one of the problems for preparation of the SiCp reinforced aluminium metal matrix composites. The back-scattered SEM images of a typical SiCp/6063MMC joint reactive diffusion bonded by the mixed Al-Si-W powder as insert layer are shown in Figs.3(a) and (b). It is interesting that the addition of W as reinforcing phase in the insert layer only facilitates to form a dense joint of high quality. Fig.4 shows the X-ray diffraction pattern of the joining layer using mixed Al-Si-W powder as insert layer, by which only little pure W phase is found in the joining layer. The X-ray diffraction pattern and electron-probe microanalyses as shown in Table 1 indicate that although W is attempted to add as metal reinforcing particles of joining layer into the insert layer, nearly all the W in the insert layer reacts with Al to form intermetallic WAl12 (labeled A in Fig.3(b))during bonding. The reaction between W and Al seems to be favorable for forming a dense joint.

Fig.1 SEM micrographs of typical SiCp/6063MMC joint reactive diffusion bonded by

insert layer of mixed Al-Si powder

Fig.2 SEM micrographs of typical SiCp/6063MMC joint reactive diffusion bonded

by insert layer of mixed Al-Si-SiC powder

Table 1 EPMA composition of characteristic zones in Fig.3(b) (mass fraction, %)

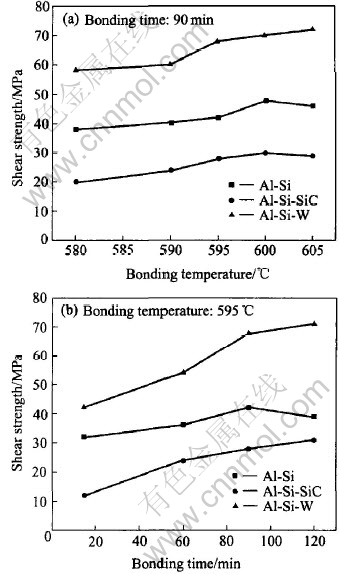

The effects of bonding parameters (bonding temperature and time) on the shear strengths of the SiCp/6063MMC joints reactive diffusion bonded by insert layers of the mixed Al-Si, Al-Si-SiC and Al-Si-W powders are shown in Fig.5. It is obvious that the joints bonded by the mixed Al-Si-W powder as insert layer present the highest shear strength reaching 72.0MPa. Evidently, the formation of the intermetallic WAl12 has not any detrimental effect on the joint shear strength, but rather reinforces the joints. The W added into the insert layer still plays the role of reinforcing agent as designed. In the same figure, the joints reactive diffusion bonded by insert layer of the mixed Al-Si-SiC powder are shown to have a bad shear strength, even lower than that of joints reactive diffusion bonded by the insert layer of the mixed Al-Si powder, which should be caused by the segregation of SiC particles and formation of the porous zones in joining layer. In the main, under the condition of fixed bonding time, the shear strengths of the joints by insert layers of the mixed Al-Si, Al-Si-SiC and Al-Si-W powders increase as the bonding temperature rises, but tend to maxima at bonding temperature of 600℃. Conversely, under the condition of fixed bonding temperature, all the shear strengths of the joints increase as the bonding time increases, and tend to a maximum at bonding time 90min.

Fig.3 SEM micrographs of typical SiCp/6063MMC joint reactive diffusion bonded by

insert layer of mixed Al-Si-W powder

Fig.4 XRD pattern of joining layer by mixed Al-Si-W powder as insert layer

Fig.5 Shear strengths of joints reactive diffusion bonded by insert layers of mixed Al-Si,

Al-Si-SiC and Al-Si-W powders vs bonding parameters

4 CONCLUSIONS

1) Mixed Al-Si powder can be used as insert layer to reactive diffusion bond SiCp/Al MMCs. The SiCp/6063 MMC joints bonded by insert layer of the mixed Al-Si powder have a dense joining layer of high quality and a hypoeutectic microstructure.

2) Using mixed Al-Si-SiC powder as insert layer, SiCp/6063 MMC can be reactive diffusion bonded by a composite joint. However, the SiC segregation results in the low shear strength of the joints, even lower than that of joints reactive diffusion bonded by insert layer of the mixed Al-Si powder.

3) W added into insert layer of the mixed Al-Si-W powder nearly all reacts with Al to form intermetallic WAl12 during bonding. The reaction between the W and Al facilitates the formation of a dense joint of high quality. In addition, the formed intermetallic WAl12 has a reinforcing effect on the joints, which leads to the high shear strength of the joints bonded by insert layer of the mixed Al-Si-W powder.

4) Under the condition of fixed bonding time (temperature), the shear strengths of the joints by insert layers of both the mixed Al-Si, Al-Si-SiC and Al-Si-W powders increase as the bonding temperature (time) increases, but tend to a maximum at bonding temperature 600℃(time 90min).

REFERENCES

[1]Urena A, Escalera M D, Gil L. Influence of interface reactions on fracture mechanisms in TIG arc-welded aluminum matrix composites [J]. Composite Science and Technology, 2000, 60(4): 613-622.

[2]CHEN Mao-ai, WU Chuan-song, WANG Jian-guo. Effect of composition of welding wire on microstructure and mechanical properties of weld metal in SiC particle reinforced 6061 Al matrix composite [J]. Transactions of the China Welding Institution, 2003, 24(5): 69-72.(in Chinese)

[3]Lean P P, Gil L, Urena A. Dissimilar welds between unreinforced AA6082 and AA6092/SiC/25p composite by pulsed-MIG arc welding using unreinforced filler alloys(Al-5Mg and Al-5Si) [J]. Journal of Materials Processing Technology, 2003, 143-144(1): 846-850.

[4]Huang R Y, Chen S C, Huang J C. Electron and laser beam welding of high strain rate superplastic Al-6061/SiC composite [J]. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 2001, 32(10): 2575-2584.

[5]Gurler R. Fusion welding of SiC particulate-reinforced aluminum 392 metal matrix composite [J]. Journal of Materials Science Letters, 1998, 17(8): 1543-1544.

[6]Lienert T J, Wiezorek J M K, Fraser H L, et al. TEM characterization of microstructures in laser beam welds on A356/SiC/15p [A]. Proceedings of Materials Solutions Conference98 on Journal of Advanced and Specialty Materials [C]. Rosemont, IL, USA: ASM International, 1998. 117-126.

[7]CHEN M A, WU C S, GAO J Q. Welding of SiC particle reinforced 6061 Al matrix composite with pulsed TIG [J]. Trans Nonferrous Met Soc China, 2002, 12(5): 805-810.

[8]LIU L M, ZHU M L, XU D S, et al. Interface reaction in aluminium matrix composite at laser welding [J]. Trans Nonferrous Met Soc China, 2001, 11(5): 671-674.

[9]YAN J C, XU H B, XU Z W, et al. Modelling behavior of oxide film during vibration diffusion bonding of SiCp/A356 composite in air [J]. Materials Science and Technology, 2004, 20(11): 1489-1492.

[10]ZHANG X P, YE L, MAI Y W, et al. Investigation on diffusion bonding characteristics of SiC particulate reinforced aluminum metal matrix composites (Al/SiCp-MMC) [J]. Composites-Part A: Applied Science and Manufacturing, 1999, 30(12): 1415-1421.

[11]ZHAO Ming-jiu, CHEN Li-qing, BI Jing, et al. Diffusion bonding of silicon carbide particulate reinforced 2024Al composites [J]. Journal of Materials Science and Technology, 2000, 16(5): 471-474.

[12]ZHANG X P, QUAN G F, WEI W. Preliminary investigation on joining performance of SiC-reinforced aluminum metal matrix composite (Al/SiC-MMC) by vacuum brazing [J]. Composites-Part A: Applied Science and Manufacturing, 1999, 30(6): 823-827.

[13]Urena A, Escalera M D, Femandez M I. Study of brazeability of aluminum matrix composites [J]. Welding Journal, 1997, 76(2): 92-102.

[14]NIU J, ZHANG D, JI G. Mechanism of laser beam welding for SiCp/6063Al composite [J]. Rare Metals, 2002, 21(2): 123-126.

[15]Klehn R, Eaqer T W. Joining of 6061 aluminum matrix-ceramic particle reinforced composites [J]. Welding Research Council Bulletin, 1993, 385(9): 1-26.

[16]Shirzadi A A, Wallach E R. Analytical modeling of solidification during temperature gradient TLP diffusion bonding [J]. Materials Science Forum, 2000, 329-330: 351-360.

Foundation item: Project(50175004) supported by the National Natural Science Foundation of China

Received date: 2004-11-08; Accepted date: 2005-04-11

Correspondence: HUANG Ji-hua, Professor, PhD; Tel: +86-10-62334859; Fax: +86-10-62332360; E-mail: jihuahuang47@sina.com

(Edited by YUAN Sai-qian)