文章编号:1004-0609(2008)03-0414-07

铜/铝复合材料的固-液复合法制备及其界面结合机理

张红安,陈 刚

(江苏大学 材料科学与工程学院,镇江 212013)

摘 要:采用固-液复合法制备了铜/铝双金属复合材料,并对铜/铝复合界面的组织结构和结合性能进行了研究。在分析工艺参数对铜/铝复合界面影响规律的基础上,对复合工艺进行了优化。结果表明,在使用混合熔剂对铜板进行预处理的情况下,当铜板预热温度为400 ℃、铝液浇注温度为700 ℃时,可以获得铜/铝界面过渡层厚度为45 μm、界面剪切强度达57 MPa的良好复合界面。进一步研究表明,铜/铝复合界面的结合是通过铜/铝接触面上铜的熔化和向铝中的扩散实现的。

关键词:铜/铝复合材料;界面;结合机理

中图分类号:TB 331 文献标识码:A

Fabrication of Cu/Al compound materials by

solid-liquid bonding method and interface bonding mechanism

ZHANG Hong-an, CHEN Gang

(School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China)

Abstract Cu/Al compound materials were fabricated by solid-liquid bonding method, and then the microstructures and bonding properties of Cu/Al interfaces were studied. According to the analysis of the effects of the processing parameters on Cu/Al interfaces, the bonding process was optimized. The results show that the well-bonded interface with a transition layer of about 45 μm in thickness and a shear strength of 57 MPa can be obtained as the Cu plate pre-treated in a mix solution is preheated at 400 ℃ and the pouring temperature is 700 ℃. From further study, it is indicated that the bonding of the Cu/Al interface is carried out by the melting of copper and its diffusion in aluminum.

Key words: Cu/Al compound materials; interface; bonding mechanism

电工产品以铝代铜以后,突出的问题是铜/铝接头的连接。实践证明,在负荷较大的情况下,用传统方法对铜与铝连接所生产的电工产品是极不可靠的[1]。采用表面堆焊、爆炸复合、轧制复合等多种方法均可成功制备铜/铝连接件,然而就性能和价格比而言,采用铸造法制备复合接头具有明显的优势,通过该方法形成的铜/铝连接件可以降低成本、减轻构件质量以及发挥铜、铝各自的优点,并能变异种金属的焊接为同种金属的焊接[2-4]。铜、铝复合时,在复合界面上会生成一层金属间化合物(如CuAl2等),这类金属间化合物硬而脆,会导致复合板的结合强度和弯曲性能等降低,且导电性变差[5-6],因此,这种过渡层不能太厚,否则将对材料的使用特性产生影响。另外,由于铝的线收缩系数大于铜的线收缩系数,在冷却过程中铜/铝复合界面附近产生很大的应力,当界面结合强度不足时,将致使原先良好的铸造结合面开裂。因此,选择合理的复合工艺至关重要。本文作者采用改进的铸造方法—固-液复合法对铜/铝异种金属进行了复合,获得了质量良好的复合界面,并对双金属复合材料的界面结构、性能和结合机理进行了分析。

1 实验

实验采用纯度为99.99%的纯铝和99.99%的无 氧铜为原材料,其中实验用铜板的尺寸为60 mm× 60 mm×10 mm。铜/铝复合材料采用固-液复合法制备,其过程为:首先将铜板在脱脂剂中进行脱脂处理,用清水冲洗后在钢丝轮上进行除锈和打毛处理,打毛的目的是为增加界面的接触面积,然后将经上述处理的铜板浸入100 ℃的自制熔剂水溶液中进行预处理,3 min后取出并烘干,在铜板表面形成一层致密的熔剂覆盖层。控制熔剂覆盖层在合适的厚度非常必要,一方面致密的覆盖层可以保证铜板在浇注前的预热过程中不被氧化,另一方面不太厚的覆盖层在铝液浇注后能及时分解而避免形成夹杂。将铜板放置在耐火材料铸型中,保持铜板两侧各有5 mm厚的空腔供铝液填充,浇注前将铸型连同铜板一起预热。浇注完成后试样在铸型内冷至室温。

通过改变工艺参数制备了一系列试样,各试样的工艺参数如表1所示。复合后对复合板的中间部分进行切割,从宏观上观察界面结合质量和缺陷,再用线切割切成小样品,制备成金相试样。金相试样经抛光和腐蚀后,分别进行光学显微镜和扫描电子显微镜观察,并进行点、线能谱分析,以确定界面层厚度、界面反应产物的相组成等。为了检测试样的抗弯能力,采用以前研究工作中设计的抗弯检测装置[7],对尺寸为18 mm×10 mm×5 mm 的试样进行了抗弯实验。实验中,铜的一侧用夹头固定,固定端距铜/铝界面 8 mm,在距铜/铝界面4 mm的铝侧施加剪切力,直到试样断裂为止。

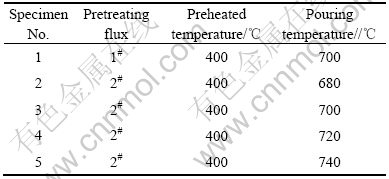

表 1 铜/铝复合实验的主要参数

Table 1 Main fabrication parameters of Cu/Al compound materials

2 结果与讨论

2.1 固-液复合工艺参数的确定

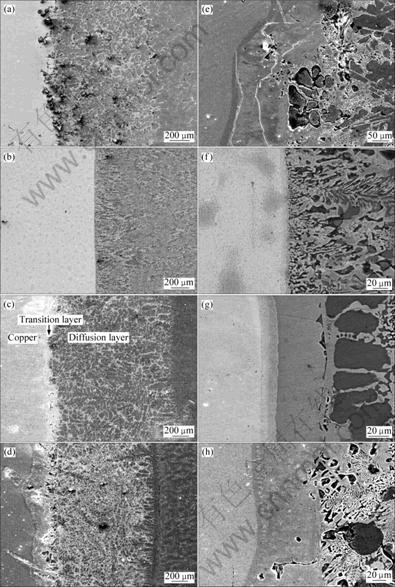

在固-液复合过程中,许多工艺参数,如表面处理方式、铜板预热温度、铝液浇注温度等,都将影响铜/铝界面的结合质量[2]。铜/铝固-液复合过程的一个关键问题就是对接触界面氧化的控制,它直接关系到复合质量[8]。本研究分别采用熔剂1#或熔剂2#对铜板进行预处理,并预热至400 ℃,然后将精炼后的工业纯铝(99.99%)加热到表1中指定的温度,分别与前述预热后铜板进行复合实验。图1(a)和(e)所示为试样1的铜/铝界面扫描电镜照片。由图可知,复合界面处存在形状较大、数量较多的黑色颗粒状组织。这些黑色部分为气渣孔,界面附近还出现了裂纹。由此可见,用熔剂1#预处理时,试样复合界面上易产生气孔与裂纹。出现这种情况是因为该熔剂与700 ℃的铝液接触后,熔剂中的盐与铝发生化学反应的速度慢,生成的气体来不及排出,在界面上被温度降低并开始凝固的铝固化而形成气孔。这一结果使界面的有效结合面积大大缩小,同时界面上由于凝固过程和冷却形成了应力,因而容易出现裂纹,使结合强度下降。混合盐可以降低液态铝表面张力和促进铝液对铜的润 湿[8],为此,本实验又选用了熔剂2#。图1(b)和(f)所示为试样2的扫描电镜照片。从图中可以看出,铜侧和铝侧分界非常明显,几乎没有过渡层出现,这是由于浇注铝液温度低。图1(c)和(g)所示为试样3的扫描电镜照片。由图可见,铜/铝界面结合平直、完整、无夹渣,为连续复合,界面上有一层中间过渡层,界面过渡层与基体有良好的结合,铜侧界面比较平整,铝侧由于铜原子的扩散形成了扩散层。图1(d)和(h)所示为试样5的扫描电镜照片。由图可见,界面结合仍然完好,但是由于铝液浇注温度过高,导致界面过渡层明显增厚。实验表明,采用熔剂2#可避免或减少气孔的产生。

图1 不同试样的扫描电镜照片

Fig.1 SEM images for different specimens: (a), (e) Specimen 1; (b), (f) Specimen 2; (c), (g) Specimen 3; (d), (h) Specimen 5

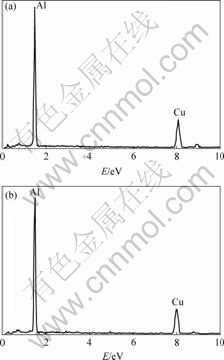

图2(a)所示为试样3界面处的扫描电镜电子探针成分分析结果,其中铝元素的含量为55.2%,铜元素的含量为44.8%,并且从图中可以看出成分只有铝和铜,未发现有任何夹杂物。这说明该熔剂在复合过程中可以完全分解排除,而且起到了润湿铜板表面的作用,使铜和铝达到了充分接触。图2(b)所示为试样5界面处的成分分析结果,其中铝元素的含量为68.16%,铜元素的含量为31.84%,铝的含量较试样3明显增多,这一结果与试样5的浇注温度过高有关。

图2 试样3和5的界面处的能谱成分分析

Fig.2 EDAX patterns at Cu/Al interfaces of (a) specimen 3 and (b) specimen 5

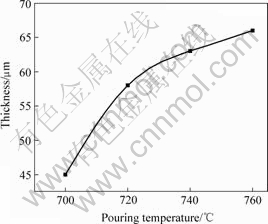

中间过渡层厚度随铝液浇注温度的变化曲线如图3所示。从图中可以看出,在铝液浇注温度超过700 ℃时,铜/铝的过渡层厚度随着温度的升高呈上升趋势。结合图1(f)、(g)和(h)所示的显微组织可以看出,在铝液浇注温度为700 ℃的情况下,复合界面过渡层比较薄,且界面呈紧密结合状态。铜/铝复合的界面性能主要是由过渡层的厚度及界面组成相的性质决定,在铝液浇注温度较高的情况下,过渡层变厚而导致界面结合强度下降。

`

图3 试样过渡层厚度随铝液温度的变化

Fig.3 Variation of transition layer thickness with pouring temperature

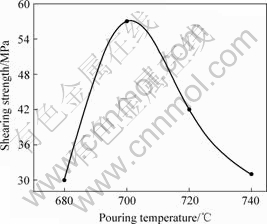

本研究采用抗弯检测装置对试样的剪切强度进行了检测。试样采用线切割加工,规格为18 mm×10 mm×5mm,将拉力施加在距Cu/Al界面4 mm的铝侧,拉力与试样长度方向的中心线保持垂直,直到试样断裂为止。在不同条件下获得的材料均测试3个试样,获得试样发生断裂时的拉力,并对其取算术平均值,然后算出界面的剪切强度。图4所示为试样的的抗剪切强度随铝液浇注温度的变化。从图中可以看出,在铝液浇注温度为680 ℃的情况下,由于铜/铝界面不是冶金结合,而是机械咬合,因此,界面抗剪切强度较低。随着铝液浇注温度的升高,试样的剪切强度呈下降趋势,这与图1中铜/铝复合界面过渡层厚度随着铝液温度的升高而加厚呈对应关系。许多强度实验数据的分析结果以及强度与过渡区金相组织的关系都说 明[9],铜与铝接头的金属间化合物层厚度越小,界面结合强度越高。本研究得出的结果与已有的研究结论相当一致。

图4 试样剪切强度随铝液温度的变化

Fig.4 Variation of shear strength with pouring temperature

由此可见,铜/铝复合工艺参数对结合界面的影响主要表现在界面过渡层厚度和界面剪切强度的变化。通过对以上试验结果的分析,可以确定比较合理的铜/铝固-液复合工艺规范为:用熔剂2#对铜板进行浸镀,铜板预热温度为400 ℃,铝液浇注温度为700 ℃。

2.2 界面结构及组织分析

在铸造条件下,铜与铝的结合是通过结合面附近物质的相互作用及随后扩散形成的界面来实现的,结合强度取决于这个界面的质量、厚度和组成。其中,界面质量是指其连续性和完整性。在本实验中,由于在浇注前,铜板在自制混合熔剂的保护下,避免了表面的氧化和污染,从而使铜板和铝具有形成完整界面的结合条件,铜板表面结合的有效面积没有减少,从而可以保证界面的结合强度。

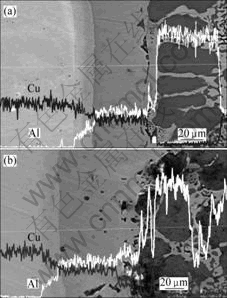

对试样3和试样5,在铜/铝复合界面上铝、铜出现了不同程度的扩散,如图5所示。在浇注温度为 700 ℃时,界面层热作用时间短,铜元素在界面处的质量分数较低,铜/铝扩散区较窄(图5(a)),而在740 ℃时,则形成了比较宽的界面扩散层,铝、铜的扩散更加充分(图5(b))。总之,随着铝液浇注温度的升高,铜、铝扩散程度明显呈增大,扩散层厚度变宽。

图5 试样的电镜扫描成分分析

Fig.5 Composition analysis results of specimen (a) 3 and (b) specimen 5 under SEM

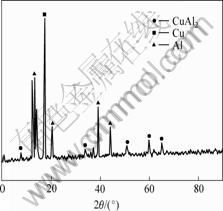

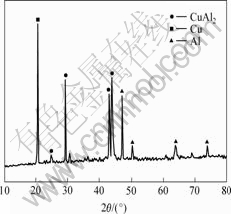

为进一步确认扩散界面的生成相,取试样3和试样5的断口表面(铜侧)进行X射线衍射分析,结果如图6所示。从图中可以看出,新相为金属间化合物CuAl2。在铜、铝均存在的情况下,CuAl2的峰值并不高,可以推测CuAl2的含量比较低,也说明在本研究的实验条件下生成的金属间化合物较少。出现这种情况是由于铜板两侧的铝层厚度有限,使铜/铝复合界面能够快速冷却下来。在这种条件下,液固相线的推移速度大于合金元素的扩散速度,在合金元素向液相中迁移还不充分的情况下就已经被固液界面所捕获,因而扩散过渡层较窄(图1(c))。而对于试样5,与试样3相比较,CuAl2的峰值明显增高,如图7所示,说明在此条件下生成的金属间化合物较多,导致复合界面较宽。

图6 试样3的X射线衍射(铜侧)

Fig.6 XRD pattern of specimen 3 (Cu side)

图7 试样5的X射线衍射(铜侧)

Fig.7 XRD pattern of specimen 5 (Cu side)

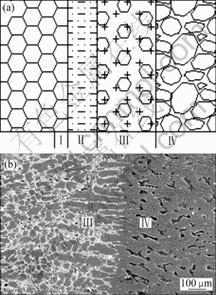

铜/铝复合界面结构示意如图8(a)所示,主要包括:1)富铜区(区域Ⅰ);2)界面过渡区(区域Ⅱ);3)富铝凝固区(区域Ⅲ和Ⅳ)。在铜/铝固-液复合时,高温的铝液使铜表面发生熔化,铝向铜中发生了明显扩散,形成富铜区。在此过程中,铝与铜发生反应,生成金属间化合物,形成过渡层。靠近过渡层,由铝和金属间化合物形成富铝凝固区。区域Ⅲ和Ⅳ的区别在于金属间化合物的形态,区域Ⅲ中主要呈颗粒状,而区域Ⅳ中则呈条状,出现这种现象主要是铜在区域Ⅲ和Ⅳ中的浓度不同。区域Ⅲ和Ⅳ之间存在着明显的过渡,如图8(b)所示。

图8 试样3的界面结构示意图及其界面区域Ⅲ和Ⅳ

Fig.8 Schematics of interface structure (a) and SEM image shown zones Ⅲ and Ⅳ (b) in specimen 3

研究表明,扩散层是按抛物线规律增长,而抛物线参数K则取决于铝液浇注温度[10]。因此,正确设定和准确控制铝液的浇注温度,可有效地控制过渡层的厚度。在合适的浇注温度下,可获得界面过渡层厚度为45 μm的界面(见图1(g))。即使扩散层厚度仅在100 nm数量级范围内,但是异种金属间的复合必然存在着化学反应,铜与铝相互作用时,金属间化合物生长速度很快[11]。根据Al-Cu合金相图,扩散层由γ2(CuAl2)、富铝的α-固溶体以及δ相组成。扩散区无论产生哪种晶格类型的铜/铝金属间化合物,都在铜侧出现硬度高峰区,使脆性增大。所以,应通过调整预热温度、浇注温度等工艺参数,控制铝向结合界面的扩散量[12]。

2.3 界面结合机理

铜/铝复合层的形成主要是铜与铝的界面反应和相互扩散的结果,复合界面的冶金结合是通过接触面上金属的熔化和扩散过程实现的。当液态铝与固态铜接触时,固态铜表面发生界面反应以及铜和铝原子的相互扩散,并在两种金属中形成扩散层,在界面上还形成金属间化合物。复合界面的冶金结合是通过界面层上固体的局部熔化和原子扩散的物理冶金过程实现的。在液固复合条件下,铜/铝异种金属复合材料的界面结合机理可以分为以下两类[4]。

2.3.1 熔合结合

界面形成过程为:1) 铝液与铜材相接触;2) 接触界面处的铝液瞬时凝固;3) 接触凝固层在后续铝液作用下再次熔化;4) 再熔化铝液与未凝固铝液混合;5) 铜材表层开始熔化,并与铝液共混形成合金;6) 外层铝液自外向内凝固。

2.3.2 扩散结合

界面形成过程为:1) 铝液与铜板相接触;2) 接触的铝液凝固;3) 接触凝固层中的铝元素向铜一侧扩散,同时铜向铝液中扩散;4) 接触凝固层部分或全部熔化;5) 外层铝液自外向内凝固。

复合材料界面结构通常是这2种机理综合作用的结果。在高温浇注作用下,微观接触区域的应力水平远远超过铜板的屈服强度极限,引起材料局部塑性变形,扩散接触面积迅速增大,应力随之减小。当应力下降到材料屈服极限时,塑性变形停止,铜板在高温下发生蠕变,接触面积继续增大,原子相互扩散并在复合界面形成金属键。同时,在已经凝固部分发生再结晶,使过渡区域附近的晶粒比较细小。而扩散结合是双金属复合材料制备中所特有的现象,铝、铜元素在界面上相互扩散,使铝与铜在连接表面处实现冶金结合。

在铜/铝固-液复合过程中,从Al/Cu接触反应行为特征来看,铝液相明显有沿表面方向优先扩展和深度方向优先晶界渗透的特点[13],这是由铝基体的金属学结构以及铝、铜之间特定的冶金作用所决定的。从晶体结构上讲,金属表面及晶界等处都包含有大量的金属学缺陷,晶格畸变比较严重,这样会大大增加这些区域内原子的能量,使其具有较高的跳动频率,同时也有利于物质的扩散[14]。有人通过计算得出,在0.5~0.75倍基体熔点的温度区间内,沿晶界扩散系数是沿晶内扩散的105倍,虽然升高温度会增大晶内扩散的速度,晶内扩散与晶间扩散仍有103的差距[15],沿表面的扩散又比晶界扩散快得多。

因此,铜/铝双金属的界面结合可概括为:铝液与铜板相互接触后,在铝液的高温作用下,铜表面原子被激活,形成激活中心而使新鲜质点间产生原子键结合,通过铜/铝接触面上铜的熔化和铜与铝之间的扩散实现冶金结合。

3 结论

1) 在固-液复合的条件下,使用熔剂2#对铜板进行预浸镀,在铝液浇注温度为700 ℃,铜板预热温度为400 ℃时,获得了界面过渡层厚度为45 μm、剪切强度为57 MPa的良好复合界面。

2) 熔剂处理、铝液浇注温度对复合界面的结构和性能具有明显的影响。采用熔剂1#获得的复合界面产生大量的气孔,界面甚至出现裂纹;而采用熔剂2#对铜板预浸镀、当铝液温度超过700 ℃时,所获得的界面过渡层明显增厚,界面抗剪切强度呈下降趋势。

3) 固-液复合界面上存在熔化区和非熔化区,铜/铝复合界面的结合是通过铜/铝接触面上铜的熔化和铜与铝之间的扩散实现的。

REFERENCES

[1] 李亚江, 王 娟, 刘 强. 有色金属的焊接及应用[M]. 北京: 化学工业出版社, 2006: 285-290.

LI Ya-jiang, WANG Juan, LIU Qiang. Welding and application of nonferrous metal[M]. Beijing: Chemical Industry Press, 2006: 285-290.

[2] 刘海峰, 刘耀辉. 高速钢复合轧辊现状及研究进展[J]. 钢铁研究学报, 1999, 11(5): 67-71.

LIU Hai-feng, LIU Yao-hui. Present status and development of high speed steel compound roll[J]. Journal of Iron and Steel Research, 1999, 11(5): 67-71.

[3] 于九明, 王群骄, 孝云祯, 陈金英. 铜/钢反向凝固复合实验研究[J]. 中国有色金属学报, 1999, 9(3): 474-475.

YU Jiu-ming, WANG Qun-jiao, XIAO Yun-zhen, CHEN Jin-ying. Experimental study of inversion casting of copper clad steel[J]. The Chinese Journal of Nonferrous Metal, 1999, 9(3): 474-475.

[4] 刘耀辉, 刘海峰, 于思荣. 液固结合双金属复合材料界面研究[J]. 机械工程学报, 2000, 36(7): 81-85.

LIU Yao-hui, LIU Hai-feng, YU Si-rong. Study on bimetal composite material interface by liquid-solid bonding[J]. Journal of Mechanical Engineering, 2000, 36(7): 81-85.

[5] 张胜华, 郭祖军. 铜-铝复合材料的研究[J]. 中国有色金属学报, 1995, 5(4): 128-130.

ZHANG Sheng-hua, GUO ZU-Jun. Study on Cu/Al compound materials[J]. The Chinese Journal of Nonferrous Metal, 1995, 5(4): 128-130.

[6] 谢 军, 吴卫东, 杜 凯, 郑凤成, 叶成钢, 黄丽珍, 袁光辉. Al/Cu微米级厚度薄膜扩散连接工艺及显微组织分析[J]. 原子能科学技术, 2004, 38(7): 120-124.

XIE Jun, WU Wei-dong, DU Kai, ZHENG Feng-cheng, YE Cheng-gang,, HUANG Li-zhen, YUAN Guang-hui. Process and microstructure analysis in vacuum diffusion bonding of aluminum and copper films[J]. Automic Energy Science and Technology, 2004, 38(7): 120-124.

[7] 张红安, 孙跃志, 陈存宏, 陈 刚. 工作条件对钢铝导电杆组织及性能的影响[J]. 特种铸造及有色合金, 2007, 27(3): 232-233.

ZHANG Hong-an, SUN Yue-zhi, CHEN Cun-hong, CHEN Gang, Effects of working condition on the microstructure and properties of steel-aluminum electricity conducting rods[J]. Special Casting & Nonferrous Alloys, 2007, 27(3): 232-233.

[8] 张 鹏, 崔建忠, 杜云慧. 钢-铝固液相复合中浸镀助焊剂的应用研究[J]. 金属学报, 1997, 33(8): 869-872.

ZHANG Peng, CUI Jian-zhong, DU Yun-hui. Study on the flux in steel-aluminum solid to liquid bonding[J]. Journal of Metal, 1997, 33(8): 869-872.

[9] 里亚博夫 B P. 铝及铝合金与其它金属的焊接[M]. 王义衡, 赵瑞湘, 译. 北京: 宇航出版社, 1990.

REABOV B P. Welding of aluminum and aluminum alloy with other materials[M]. WANG Yi-heng, ZHAO Rui-xiang, transl. Beijing: Aerospace Industry Press, 1990.

[10] TANAKA Y, KAJIHARA M, WATANABE Y. Growth behaviour of compound layers during reactive diffusion between solid Cu and liquid Al[J]. Mater Sci Eng, A, 2007, A445: 355-363.

[11] 李宝绵, 许光明, 李兴刚, 崔建忠. 铜-钢反向凝固复合带的实验研究[J]. 东北大学学报: 自然科学版, 2002, 23(9): 880-882.

LI Bao-mian, XU Guang-ming, LI Xing-gang, CUI Jian-zhong. Copper clad steel coil produced by inversion casting[J]. Journal of Northeastern University: Natural Science, 2002, 23(9): 880-882.

[12] 李亚江, 吴会强, 陈茂爱, 杨 敏, 冯 涛. Cu/Al真空扩散焊接头显微组织分析[J]. 中国有色金属学报, 2001, 11(3): 424-427.

LI Ya-jiang, WU Hui-qiang, CHEN Mao-ai, YANG Min, FENG-Tao. Microstructure analyses in vacuum diffusion welded joint of copper and aluminum[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3) : 424-427.

[13] 董占贵, 钱乙余, 石素琴, 吴培莲. Al/Cu/Al接触反应液相行为及其连接[J]. 焊接学报, 2001, 22(6): 45-47.

DONG Zhan-gui, QIAN Yi-yu, SHI Su-qin, WU Pei-lian. Behavior of Al/Cu/Al contact reaction liquid and its brazing[J]. Transactions of the China Welding Institution, 2001, 22(6): 45-47.

[14] JACOBSON M H, UMPSTON G. Diffusion solder[J]. Solder & Surface Mount Technology, 1992, 17(10): 27-32.

[15] ZHOU Y, NORTH T H. Numerical model for the effect of grain boundaries on the total amount diffusion[J]. Acta Metall, 1994, 42(3): 1025-1029.

收稿日期:2007-05-09;修订日期:2007-12-24

通讯作者:陈 刚,教授,博士;电话:0511-8792033;E-mail: gchen@ujs.edu.cn

(编辑 何学锋)