Hot deformation behavior of Al-Cu-Li-Mg-Zr alloy containing Zn and Mn

CHEN Yong-lai(陈永来)1, LI Jin-feng(李劲风)2, L? Hong-jun(吕宏军)1, LI Shi-chen(李世晨)2,

ZHENG Zi-qiao(郑子樵)2, ZHANG Yu-wei(张宇伟)1, ZHANG Xu-hu(张绪虎)1

1. Aerospace Research Institute of Materials and Processing Technology, Beijing 100076, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China

Received 15 July 2007; accepted 10 September 2007

Abstract: The hot deformation behavior of a new Al-Cu-Li-Mg-Zr alloy was studied, and its microstructure and true stress were characterized as function of the deformation temperature and the strain rate using Gleeble-1500 thermal mechanical simulator. The results show that, with the increase of the strain rate from 0.001 s-1 to 10 s-1, the peak value of true stress is elevated at the same deformation temperature, and at the same strain rate the peak value of the true stress decreases with the increase of the deformation temperature from 360 ℃ to 520 ℃. Dynamic recrystallization easily occurs in the new Al-Cu-Li-Mg-Zr alloy under the lower strain rate and the higher deformation temperature, and dynamic recovery can usually be seen in this alloy under the higher strain rate of 10 s-1 and the lower deformation temperature.

Key words: Al-Li alloy; hot compression deformation; flow stress

1 Introduction

The addition of 1% Li to Al alloy can lower its density by 3% and increase its elastic modulus by 6%[1]. Compared with traditional Al alloys, Al-Li alloys also possess higher special strength. Al-Li alloys have been used in space shuttles and airplanes[2-3], and their application would be extended. Different applications require various properties of Al-Li alloys. To accommodate various applications, new Al-Li alloys are developed by addition and adjustment of alloying elements. A new Al-Cu-Li-Mg-Zr alloy with small additions of Zn and Mn was designed, and the effects of solution and aging temperatures on its mechanical properties and microstructures were investigated, but its hot deformation behavior was not studied.

The flow stress features of 2519 aluminum alloy were studied by isothermal compression at 300-450 ℃ and strain rate of 0.01-10 s-1 with Gleeble-1500 thermal mechanical simulator [4]. And the flow stress behavior of 2195 aluminium-lithium alloy during hot compression deformation was studied with the strain rate ranging from 0.001 s-1 to 10 s-1 and the temperature ranging from 360 ℃ to 520 ℃ by isothermal compression test at Gleeble-1500 thermal mechanical simulator[5].

In this work, the hot deformation behavior of a new Al-Cu-Li-Mg-Zr alloy was studied, and its microstructure and true strength were characterized as function of the deformation temperature at 360-520 ℃ and the strain rate from 0.001 s-1 to 10 s-1 using Gleeble-1500 thermal mechanical simulator.

2 Experimental

The alloy with chemical composition of Al-3.85Cu-1.55Li-0.38Mg-0.57Zn-0.28Mn-0.16Zr was designed. The cast ingot was homogenized at 500 ℃ for 24 h. Then cylindrical specimens with a diameter of 10 mm and a height of 15 mm were machined from the homogenization-treated ingot. The flat ends of the specimen were recessed to a depth of 0.2 mm to entrap the lubricant of graphite mixed with machine oil during deformation so that friction at the specimen/die interface could be minimized.

The thermal-compression test with a compression ratio was conducted on a Gleeble-1500 thermal mechanical simulator. The deformation temperatures of 360-520 ℃ and strain rates of 0.001, 0.01, 0.1 and 1 s-1 were chosen. Before compression, the sample was resistance-heated to deformation temperature at a heating rate of 5 ℃/s and maintained for 180 s. During the compression test, true stain and true stress were recorded. As the thermal deformation test was finished, the deformed specimens were quenched with cold water.The microstructure of the deformed samples was observed with a Transmission Electron Microscope (TEM). The TEM samples were prepared by conventional electrolytic etching method using an electrolyte of 25% HNO3 and 75% CH3OH, and the TEM observation was carried out with a Tecnai G2 20 Transmission Electron Microscope.

3 Results and discussion

3.1 Flow stress dependence on temperature and strain rate

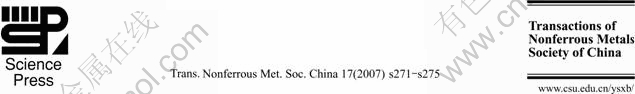

The stress—strain (σ-ε) curves are presented in Fig.1. It is found that the stress level decreases with the increase of deformation temperature. This should be associated with the decrease of critical shear stress of dislocation as temperature is elevated. Meanwhile, because deformation temperature is increased, recrystallization and recovery also occur at a lower strain level, which can be deduced from that the stress decreases at lower strain. While the stress level increases with strain rate. It can be explained by that the shear stress for dislocation motion is increased at a higher velocity of dislocation motion.

It also can be seen that all the curves exhibit a peak stress followed by dynamic softening. Flow softening is a common characteristic of true stress—true strain curves for many alloys deformed at elevated temperatures. It can be caused by deformation heating and also by microstructural instabilities inside the material, such as dynamic recrystallization, texture formation, dynamic precipitation and dissolution. In the present case, the flow softening seems more pronounced at low strain rates, indicating that microstructure instability plays an important role in the flow softening, especially dynamic recrystallization. It can be deduced from the stress-strain characterization that dynamic recrystallization occurs in the alloy during hot compression under various conditions.

During thermal deformation of metallic alloys, flow stress σ is dependent on strain rate  At a lower stress level, this relationship can be expressed as Eqn.(1). At a higher stress level, it can be expressed as Eqn.(2)[6-8].

At a lower stress level, this relationship can be expressed as Eqn.(1). At a higher stress level, it can be expressed as Eqn.(2)[6-8].

(1)

(1)

(2)

(2)

where A1, A2, m and β are constants that are independent of temperature.

Fig.1 True stress vs true strain curves of new Al-Li alloy during thermal deformation at various compression strain rates: (a) 0.001 s-1; (b) 0.01 s-1; (c) 0.1 s-1; (d) 1 s-1

At all flow stress level, a hyperbolic sine law, Eqn.(3) including deformation activation energy Q and deformation temperature T is given:

(3)

(3)

(4)

(4)

where A, α and n are constants that are independent of temperature, R is gas constant, n is stress exponent and Z is the Zener-Hollomon parameter. Meanwhile, a is dependent on β and m:

a=b/m (5)

Eqns.(6) and (7) can be obtained from Eqns.(1) and (2):

(6)

(6)

(7)

(7)

where σ is the peak flow stress. The relationship between strain rate  and peak stress σ of the new Al-Li alloy can be represented in Figs.2(a) and (b). The average slope of five line, i.e. the value of m can be fitted from Fig.2(a), which is 10.46. Meanwhile, the constant of β, 0.149, is fitted from Fig.2(b). As a result, the constant of α, α=β/m=0.014 2 can be obtained.

and peak stress σ of the new Al-Li alloy can be represented in Figs.2(a) and (b). The average slope of five line, i.e. the value of m can be fitted from Fig.2(a), which is 10.46. Meanwhile, the constant of β, 0.149, is fitted from Fig.2(b). As a result, the constant of α, α=β/m=0.014 2 can be obtained.

Fig.2 Relationship between flow stress (σ) and strain rate ( ) at various temperatures: 1—520 ℃; 2—480 ℃; 3—440 ℃; 4—400 ℃; 5—360 ℃

) at various temperatures: 1—520 ℃; 2—480 ℃; 3—440 ℃; 4—400 ℃; 5—360 ℃

As shown in Fig.3, the peak stress obtained from the compression test at various strain rates and temperatures can be approximated by a group of parallel and straight lines, indicating that the peak stress for the studied Al-Li alloy can be represented by a Zener-Hollomon parameter in an exponent-type equation. The stress exponent n, i.e. the average slope of the four straight lines in Fig.3(b) is 4.759 575. The average slope of the five straight lines in Fig.3(a) is 7.112 58. The activation energy for this studied alloy derived from the Arrennius law is about 279.41 kJ/mol.

Fig.3 Relationship among peak flow stress, strain rate and deformation temperature: 1—0.001 s-1; 2—0.01 s-1; 3—0.1 s-1

According to Eqn.(4), there is

(8)

(8)

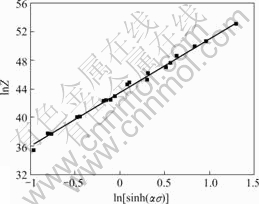

Z can be calculated by substituting Q and the deformation condition into Eqn.(3). The relationship between ln[sinh(ασ)] and lnZ is shown in Fig.4 and the data are linearly regressed. From Eqn.(8), the slopes in Fig.4 is really the stress index, n, and the intercept is really lnA. From this figure, it can be known that n=7.57, α=0.014 2 mm2/N and A=8.59×1018 s-1.

Substituting the values of different materials parameters into Eqn.(3), the flow stress equation of this alloy during hot-compression can be obtained as follow:

=8.59×1018[sinh(0.014 2σ)]1/7.57exp(-279.41/(RT))

=8.59×1018[sinh(0.014 2σ)]1/7.57exp(-279.41/(RT))

Fig.4 Relationship between flow stress and Zener-Hollomon parameter

Z can be described as

Z= exp(279.407/(RT))

exp(279.407/(RT))

The equation of flow stress can also be described with parameter Z as follow[9]:

3.2 Microstructure evolution

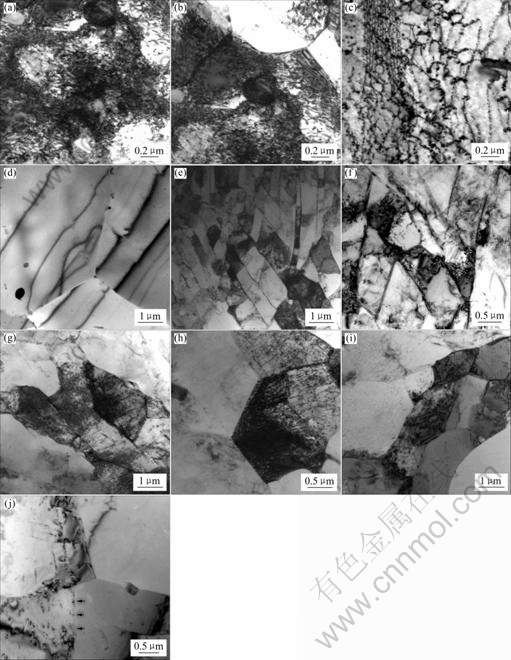

Fig.5 shows the microstructures of the alloy compressed at different conditions. As the alloy is compressed at the lowest temperature (360 ℃) with the lowest strain rate (0.001 s-1), dislocation cells are found in the quenched deformed alloy (shown in Fig.5(a)), indicating that recovery occurs[10-11]. Meanwhile, recrystallized grains are also found in Fig.5(b). This shows that incomplete dynamic recrystallization occurs in the alloy during its deformation process. As deformation temperature is elevated up to 520 ℃, although dislocations are found in the alloy, no dislocation cell is formed (shown in Fig.5(c)). Meanwhile, a lot of recrystallized grains surrounded by straight grain boundaries with a included angle of nearly 120? indicate that nearly complete dynamic crystallization occurs in the alloy deformed at 520 ℃ with a strain rate of 0.001 s-1

Fig.5 TEM images of alloy deformed under various conditions: (a), (b) 360℃,  =0.001s-1; (c), (d) 520 ℃,

=0.001s-1; (c), (d) 520 ℃,  =0.001 s-1; (e), (f) 360 ℃,

=0.001 s-1; (e), (f) 360 ℃,  =1.0 s-1; (g), (h) 440 ℃,

=1.0 s-1; (g), (h) 440 ℃,  =1.0 s-1; (i), (j) 520 ℃,

=1.0 s-1; (i), (j) 520 ℃,  =1.0 s-1

=1.0 s-1

As strain rate increases to 1.0 s-1, at the deformation temperature of 360 ℃, it can be seen from Fig.5(e) that few dislocation is formed and the structure similar to the shear zone is found in the alloy. Meanwhile, the dislocation polygonization structure emerges in the alloy, which indicates this alloy occurs dynamic recovery on this deformation condition[10-11]. As the deformation temperature is elevated to 440 ℃, the dislocation and a lot of subgrain can be observed in the alloy, and dynamic recrystallization also occur at the same stress rate(1.0 s-1). As the deformation temperature is elevated to 520 ℃, subgrain merge is observed in the alloy (shown in Fig.5(i)). Meanwhile, grain boundary migration during the hot compression is found. This indicates that there exists two kinds of dynamic recrystallization mechanisms, i.e., subgrain merge and grain boundary migration.

4 Conclusions

1) At the same deformation temperature, the peak value of true stress increases with the increase of the strain rate form 0.001 s-1 to 10 s-1, and at the same strain rate the peak value of the true stress decreases with the increase of the deformation temperature from 360 ℃ to 520 ℃.

2) The flow stress of a new Al-Cu-Li-Mg-Zr alloy during high temperature deformation can be represented by Zener-Hollomon parameter including the Arrhemius term. The parameters of A, α and n can be calculated as 8.59×1 018 s-1, 0.014 2 mm2/N and 7.57. The active energy of the deformation, Q, can be calculated as 279.41 kJ/mol.

3) Dynamic recrystallization is easily occurred in the new Al-Cu-Li-Mg-Zr alloy under the lower strain rate and the higher deformation temperature. Dynamic recovery is usually seen in its alloy under the higher strain rate of 10 s-1 and lower deformation temperature.

References

[1] WILLIAMS J C, STARKE J E A. Progress in structural materials for aerospace system [J]. Acta Materialia, 2003, 51: 5775-5799.

[2] XIANG Shu-guang, JIANG Na, WANG Bin. The heat-treatment and properties for 2195 Al-Li alloy [J]. Aluminium Processing, 2002, 25(2): 51-53.

[3] XIONG Huan. Cryogenic tank and application of Al-Li alloy [J]. Missiles and Space Vehicles, 2001(6): 33-41.

[4] LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, ZHOU Zhuo-ping. Hot deformation behavior of 2519 aluminum alloy [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 621-625. (in Chinese)

[5] HAN Dong-feng, ZHENG Zi-qiao, JIANG Na, LI Jing-feng. Flow stress of high-strength weldable 2195 aluminium-lithium alloy during hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 2090-2095. (in Chinese)

[6] Poirier J P. GUAN De-lin Trans. High temperature plastic deformation of crystals[M]. Dalian: Dalian University of Science and Technology Press, 1989.

[7] SHEN Jian. Behavior of flow stress of 2091 Al2Li alloy during hot compression [J]. Chinese Journal of Rare Metals, 1998, 22(1): 47-50. (in Chinese)

[8] SHEPPARD T, PARSON N C, ZAIDI M A. Dynamic recrystallization in Al-Mg [J]. Met Sci, 1983, 17(10): 481-487.

[9] RAYBOULD D, SHEPPARD T. Axisymmetric extrusion:The effect of temperature rise and strain rate on the activation enthalpy and material constants of some aluminium alloys and their relation to recrystallization, substructure, and subsequent mechanical properties[J]. Inst Metals, 1973, 101: 65-72.

[10] LIN Gao-yong, ZHANG Hui, GUO Wu-chao. Flow stress of 7075 aluminium alloy during hot compression deformation [J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 412-415. (in Chinese)

[11] ZHANG Yu-zu, ZHANG Hui, PENG Da-shu. Experimental simulation on continuous hot rolling of 6201 aluminium alloy [J]. The Chinese Journal of Nonferrous Metals, 2000, 10(4): 525-528. (in Chinese)

Corresponding author: CHEN Yong-lai; Tel: +86-10-68383256; E-mail: chenyonglai@263.net

(Edited by CHEN Can-hua)