DOI: 10.11817/j.ysxb.1004.0609.202037617

仿生结构Ti-Ta金属-金属复合材料的动态力学行为

李 谋1,刘 咏1,刘 彬1,汪冰峰2,李年丰3,徐圣航1, 4,陈曼可1

(1. 中南大学 粉末冶金国家重点实验室,长沙410083;

2. 中南大学 材料科学与工程学院,长沙410083;

3. 中南大学 湘雅医院 肝胆胰外科,长沙410008;

4. 浙江工业大学 材料科学与工程学院,杭州310014)

摘 要:仿贝壳结构或层状结构材料同时具有高的强度和韧性,是当前材料结构优化的重要设计模型之一。通过粉末冶金与热加工方法制备具有仿生结构特征的Ti-Ta金属-金属复合材料,并研究其动态力学行为。结果表明:仿生界面结构对Ti-Ta复合材料的变形行为具有重要影响,使材料的破坏行为表现为裂纹桥联和局部层裂,在力学变形上也表现出明显的应变速率强化、应变强化以及绝热软化特征。材料的屈服强度随着应变速率的提高而提高;在高应变速率下,随着变形量的增加,流变应力变化得较为平缓。采用改进的Johnson-Cook (J-C)本构模型能很好地描述Ti-Ta复合材料的动态行为,同时发现,Ti-Ta复合材料的应变速率强化指数C远低于纯Ta的,而略低于纯Ti的。

关键词:Ti-Ta金属-金属复合材料;应变速率强化;绝热软化;Johnson-Cook本构模型

文章编号:1004-0609(2020)-08-1818-10 中图分类号:TG146.2 文献标志码:A

Ti及Ti合金由于其强度高和耐腐蚀性好等诸多优点,被广泛应用在航空航天及国防工业等领域[1-3]。不同领域对Ti合金提出了不同的性能要求,当其应用在冲击载荷条件时,如装甲和防护材料,需要具备较高的动态力学性能。 材料在动态变形下通常受绝热软化、应变强化和应变速率强化的共同作用[4-6]。材料在高应变速率下变形时,产生的绝大部分塑性功转化为热量且来不及散失,相当于绝热过程,此时材料受到的软化作用被称为绝热软化[7-10]。绝热软化会降低材料的流变应力,随着应变量的增加,这种作用越来越明显[11]。应变强化是指材料的流变应力随着应变量的增加而提高,即加工硬化效应。应变速率强化是指材料的流变应力随着应变速率的增加而提高,这一现象普遍存在于Ti合金中[12-18]。 高应变速率下,材料所受应力在达到不同的临界剪切应力时,位错滑移、孪生和应力诱导马氏体便会分别发生。在一定程度上,高应变速率下由于局部应力较大,会有更多的位错,孪晶或马氏体产生[19]。LEE等[20]研究发现,位错密度随着应变速率的提高逐渐增加,高应变速率下位错的快速增殖和缠结将会对材料起强化效应。SALEM等[21]将孪晶引起应变速率强化的提高归因于两个方面:一是孪晶在晶粒内形成,产生的孪晶界将缩短位错滑移的有效距离,这相当于晶粒细化的Hall-Petch效应;二是孪晶本身的硬度也高于基体晶粒的硬度。此外,其他研究表明[19, 22-23],高应变速率下,应力诱发马氏体相变对合金有着显著的强化作用。 相比于传统均质材料,仿生结构材料如仿贝壳结构、层状结构等,拥有大量特殊的界面结构,材料的强度和韧性均得到明显改善[24-25]。这主要因为界面对位错运动和裂纹扩展均有着明显的阻碍作用,还可以通过应变分配协调材料整体的变形,同时提高材料的强度和韧性。常见的金属-金属复合材料有Ti-Al[26]、Cu-Al[27]和Ti-Ta[28]等。一些Ti基金属-金属复合材料具有仿生结构,其制备方法主要是多层板材或箔材的层叠加工变形[29-30]。但是这制备方法获得的界面结合力较弱,容易产生裂纹而提前失效,影响材料的力学性能。采用粉末冶金方法制备材料能够明显改善界面结构。

本文作者前期通过粉末冶金方法制备了Ti-Ta金属-金属复合材料。该材料具有低模量、高强度[28],在生物医用和其他领域具有很宽广的应用前景。目前,对Ti-Ta金属-金属复合材料的动态力学行为还未进行研究。此类研究将拓广Ti-Ta金属-金属复合材料未来在装甲和防护方向的应用。因此,本文作者采用放电等离子烧结和包套锻造的方法制备了Ti-Ta金属-金属复合材料,对其进行组织分析和0.004~2002 s-1速率下的压缩性能试验,并建立材料的动态本构模型,研究材料动态力学行为。

1 实验

1.1 材料制备

Ti-20Ta(摩尔分数,%)复合材料(以下简称“Ti-20Ta”)以Ti元素粉(纯度>99.9%,质量分数)和Ta元素粉(纯度>99.99%)为原料。粉末在V型混料机上混合6 h,混合前后的O含量如表1所列。随后,混合粉末通过放电等离子烧结(SPS)致密化,设备为日本生产的LABOX-6020Khv型号。烧结温度、压力和保温时间分别为1200 ℃、30 MPa和5 min。然后,将烧结后的试样在1000 ℃热处理60 min后进行包套锻造,在高度方向变形约为70%。

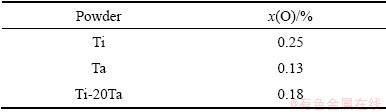

表1 粉末的氧含量

Table 1 O content of powders

1.2 组织和性能表征

材料的相结构分析采用Rigaku D/MAX-2250型X射线衍射仪(XRD)。材料的微观组织分析采用配备有能量散射X射线分析仪(EDX)的 FEI Quanta 250 FEG型扫描电子显微镜(SEM)。经过EDX分析之后,样品使用10%HF+5%HNO3+85%H2O(体积分数)的溶液进行腐蚀,再进行微观组织观察。 准静态压缩试验在Instron 8802机上进行,应变速率为4×10-3 s-1,采用d 6 mm×9 mm圆柱形试样。动态压缩试验在分离式霍普金森压杆(SHPB)上进行,应变速率为566~2002 s-1,采用d 6 mm×7.2 mm圆柱形试样。所有的样品均取自锻造变形区。为了对比,采用纯Ti和纯Ta的锻造棒材做参照。图1所示为SHPB装置示意图,其由撞击杆、入射杆和透射杆组成,入射杆和透射杆上均装有应变片来记录应力波。从SHPB试验中,可以得到入射脉冲应变 、反射脉冲应变

、反射脉冲应变 和透射脉冲应变

和透射脉冲应变 。然后,通过式(1)~(3)可得到工程应变

。然后,通过式(1)~(3)可得到工程应变 、工程应力

、工程应力 和应变速率

和应变速率 。

。

(1)

(1)

(2)

(2)

(3)

(3)

式中:A和E分别为压杆的横截面积和弹性模量;C0为压杆中的弹性纵波波速,可通过方程 计算得出,

计算得出, 为压杆的密度;Ls和As分别为试样的初始长度和初始横截面积;t为时间。

为压杆的密度;Ls和As分别为试样的初始长度和初始横截面积;t为时间。

真实应力 和真实应变

和真实应变 可通过式(4)和(5)求 出[31]。

可通过式(4)和(5)求 出[31]。

(4)

(4)

(5)

(5)

真实塑性应变 可由式(6)求出[8]。

可由式(6)求出[8]。

(6)

(6)

图1 SHPB装置示意图

Fig. 1 Schematic diagram of split Hopkinson bar system

2 结果分析

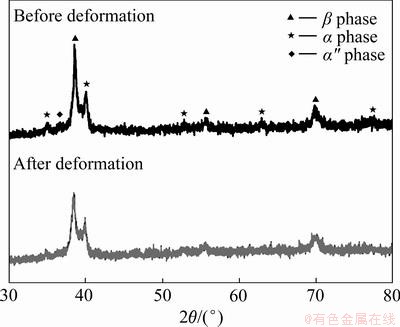

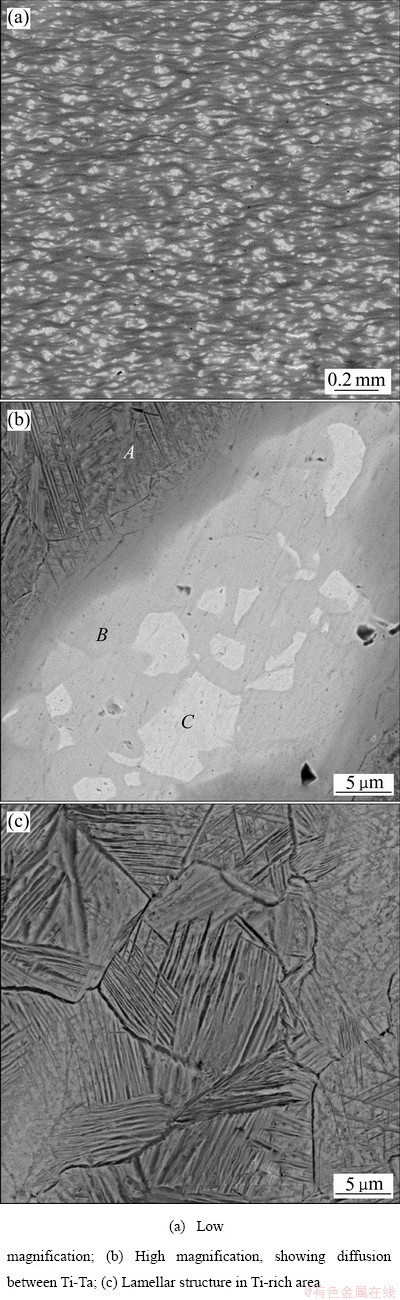

图2所示为Ti-20Ta复合材料动态变形前后的相成分分析。结果表明,Ti-20Ta复合材料主要由β和α两相组成。同时,材料中还有少量的马氏体α″相,这可能是在塑性变形过程中产生的。在动态变形之后,材料的主要相组成并未发生变化。图3所示为Ti-Ta复合材料的显微组织,表2所列为图3(c)中各点的化学成分。从图3(a)可以看到,由于Ta在Ti中扩散速度慢以及烧结时间较短,Ti和Ta的互扩散范围有限,微区成分未均匀化,表现出一个成分梯度的结构。从图3(b)可以看出,梯度结构存在3个区域(区域A、区域B和区域C)。区域A为双相结构,区域B和C均是单相结构,且区域之间具有明显的界面。通过表2的能谱分析可知,区域A为富Ti区域,区域C为富Ta区域,而区域B是Ti、Ta互扩散较多的区域。结合作者前期的工作[28],可知3个区域的主要相结构均是β相,而区域A中析出了细小的α相(见图3(c))。

图2 Ti-20Ta变形前后的XRD谱

Fig. 2 XRD patterns of Ti-20Ta composite before and after dynamic deformation

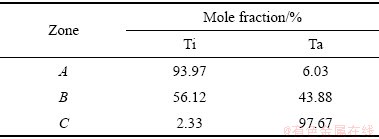

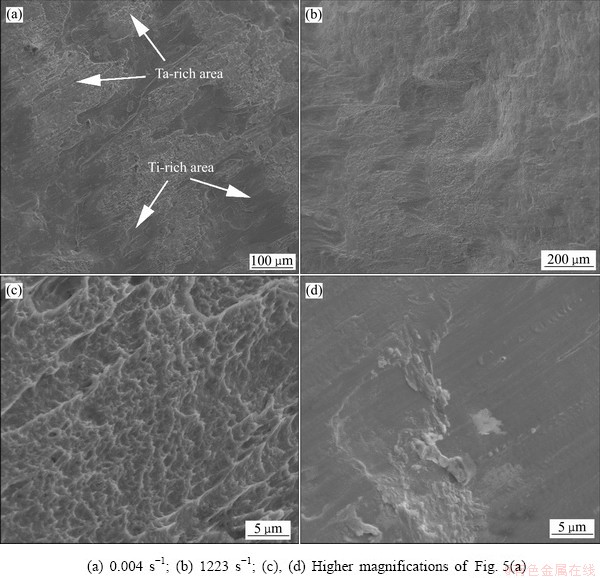

图4所示为Ti-20Ta复合材料在不同应变速率下的真实压缩应力-应变曲线以及压缩后的样品。随着应变速率从0.004 s-1增加至2002 s-1,Ti-20Ta复合材料的屈服强度从919 MPa增加到1312 MPa。应变速率为566 s-1时,样品由于入射杆提供的能量不足没有被破坏,其他应变速率下的样品均被压溃。Ti-20Ta复合材料的应力-应变曲线(应变速率为566 s-1的除外)可分为3个阶段。第一阶段,试样发生了弹性变形。对于高应变速率下的试样,这一过程的应力高,弹性变形量小。同时,在应变速率为1223 s-1和2002 s-1下,试样的变形是不均匀的,应力集中处会率先屈服而发生塑性变形,使流变应力达到极值后又突然下降。第二阶段,试样发生了塑性变形,流变应力缓慢增加。

图3 Ti-20Ta复合材料的微观结构

Fig. 3 Microstructures of Ti-20Ta composite

表2 不同区域的化学成分

Table 2 Chemical compositions of different zones

这个现象属于应变强化。在高应变速率下,试样还会受到绝热软化的作用。绝热软化作用与应变强化作用进行竞争,使流变应力变得平缓。第三阶段,试样的流变应力随着应变增加而迅速减小。这个现象可能主要由于样品内部局域破坏而发生了塑性失稳[19, 32-33]。

图4 Ti-20Ta复合材料不同应变速率下的真实压缩应力-应变曲线

Fig. 4 True compression stress-strain curves of Ti-20Ta composite at 0.004 s-1(a), 566 s-1, 1223 s-1 and 2002 s-1(b) with images of compressed specimens

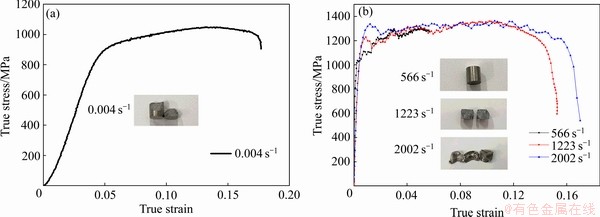

图5 Ti-20Ta复合材料的压缩断口形貌

Fig. 5 Compression fracture morphologies of Ti-20Ta composite

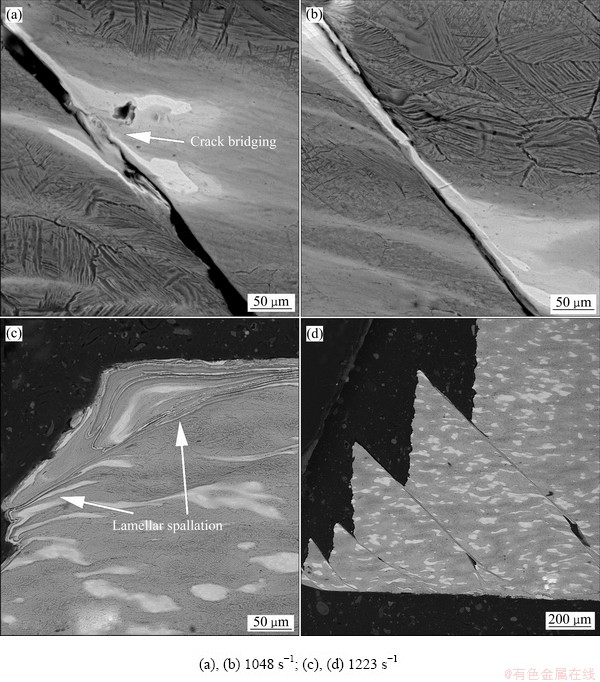

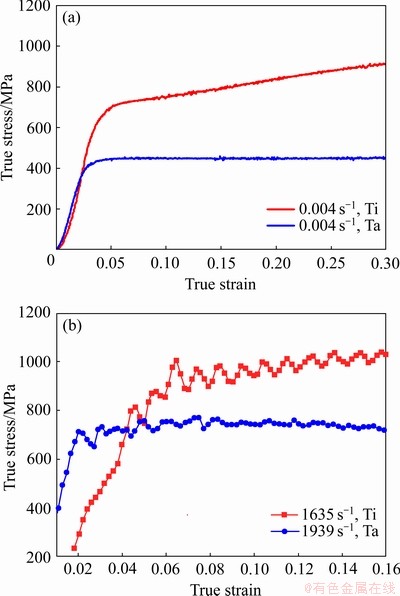

图5所示为Ti-20Ta复合材料在应变速率为0.004 s-1和1223 s-1下的断口形貌。结合EDS分析发现,在应变速率为0.004 s-1时,富Ta区的断口形貌由大量韧窝组成(见图5(c)),而富Ti区的断口形貌呈现出河流状花样(见图5(d))。应变速率为1223 s-1时,材料的断口形貌基本上都为韧窝,表明材料的断裂机制从剪切断裂和解理断裂的混合转变为纯剪切断裂。这同样与绝热软化作用有关。图6所示为Ti-Ta复合材料在应变速率为1048 s-1和1223 s-1的压缩试验后的截面组织,前者样品并未发生破坏,后者样品发生破碎。从图6(a)和6(b)可以看出,裂纹扩展的方向与加载方向有着45°的夹角,平行于最大剪切力方向。因此,Ti-Ta复合材料表现出剪切破坏特征。在裂纹周围,没有观测到明显绝热剪切带,说明材料在动态变形下的破坏机制不是绝热剪切。这可能是由于变形温度未达到绝热剪切所需要的条件。HAO等[16]研究发现,当加载温度高于473 K时,Ti-47Al-2Cr-2Nb合金的失效机制由脆性剪切断裂转变为绝热剪切断裂。通过MEYERS等[34]的工作可知,商业纯Ti也需要在一定的变形温度范围内才能发生绝热剪切。此外,还可以观察到,裂纹扩展至界面处时会发生桥接,即界面结构能够对裂纹扩展起到阻碍的作用。这对材料的韧性有着一定的促进作用[35]。从图6(c)和6(d)可以看出,试样局部出现层裂,并且试样有着破碎的趋势。动态断裂区别于准静态断裂的特点就是存在应力波。这些应力波的产生源于裂纹尖端,并可能从试样边界反射回来,反作用于裂纹尖端。这可导致试样的破裂,或者裂纹分叉。在应力波反射作用下,也可能局部产生拉应力。拉应力可使层状组织发生膨胀或破碎,即层裂[36]。这通常发生在试样的边缘,即与本文的试验结果相符。 为了对比研究,分别对纯Ti和纯Ta的准静态和动态压缩行为进行了研究,结果如图7所示。相比于纯Ti和纯Ta,Ti-20Ta复合材料在准静态和动态变形过程中均表现出更高的屈服强度,但纯Ti和纯Ta塑性较好,在试验条件下并未被破坏。

图6 Ti-20Ta复合材料变形后的截面图

Fig. 6 Cross section images of Ti-20Ta composite after deformation at different strain rates

图7 纯Ti和纯Ta的真实压缩应力-应变曲线

Fig. 7 True compression stress-strain curves of pure Ti and Ta under quasi-static deformation(a) and dynamic deformation(b)

3 讨论

作者研究发现,细晶强化、固溶强化和沉淀强化是Ti-20Ta复合材料表现出高屈服强度的主要原因,但是计算出来的屈服强度低于实验数值[28]。这说明材料的屈服强度还受到其他作用的影响。这个作用主要是界面结构。在塑性变形过程中,由于金属-金属之间的强度、模量和晶格类型等差异特别明显,较软金属先发生塑性变形,内部产生大量位错。在较软金属区堆积的位错在界面处产生塞积,从而引起局域强化效应。这种界面强化效应也被称为背应力强化或异质变形应力强化作用[25, 37-38]。因此,界面对位错的阻碍作用更加突出,从而使得Ti-20Ta复合材料的屈服强度得到提升。 在低的应变速率下,Ti-20Ta复合材料、纯Ti和纯Ta的真实压缩应力-应变曲线弹性段斜率相差不大,说明它们的模量相近。而高的应变速率下,按材料的动态模量由低到高排序,依次为:纯Ti,纯Ta,Ti-20Ta复合材料。随着应变速率的提高,纯Ti的模量没有发生明显的变化,纯Ta的模量有了一定的提升,而Ti-20Ta复合材料的模量提升最大。因此,Ti-20Ta复合材料由于它独特的界面结构使其刚性也得到了提高。 Ti-20Ta复合材料在动态变形下受到了应变强化、绝热软化和应变速率强化的共同作用。这些作用机制在材料动态变形过程中相互竞争。应变速率强化作用使得材料的流变应力随着应变速率的增加而增加,但是,应变速率强化作用具有一定的限度,随着速率的提高,应变速率强化增幅下降,可简单地表述为:

(7)

(7)

式中: 为流变应力;

为流变应力; 为应变速率。因此,当应变速率从0.004 s-1增加到566 s-1时,材料的流变应力急剧增加,而应变速率为566 s-1、1223 s-1和2002 s-1的流变应力相差并不是很大。

为应变速率。因此,当应变速率从0.004 s-1增加到566 s-1时,材料的流变应力急剧增加,而应变速率为566 s-1、1223 s-1和2002 s-1的流变应力相差并不是很大。

J-C本构模型常常用来对材料的动态变形应力-应变曲线进行描述和预测,其基本形式是:

(8)

(8)

式中:等号右边三项,依次表示的是应变强化、应变速率强化和温度对材料流变性能的影响。A、B、n、C和m均为模型常数;T、Tm和Tr分别是试验温度,材料的熔点和室温;本次试验在室温下进行,材料的熔点约为2173K(均质Ti-20Ta材料的熔点)。 为等效塑性应变;

为等效塑性应变; 为参比应变速率,取0.004 s-1为参比应变速率。

为参比应变速率,取0.004 s-1为参比应变速率。

此外,在高应变速率下材料的断裂机制由于绝热软化作用发生了改变,如图5所示。绝热产生温升不可忽略,塑性功转变为热量是温度上升的原因,温升ΔT可由下式表达:

(9)

(9)

式中: 为功热转变分数,通常取0.9;

为功热转变分数,通常取0.9; 为材料的密度,可通过阿基米德排水法测得,Ti-20Ta的密度为6680.58 kg/m3;

为材料的密度,可通过阿基米德排水法测得,Ti-20Ta的密度为6680.58 kg/m3; 为材料的比热容,可根据混合定律:

为材料的比热容,可根据混合定律: (cpi和mi分别为组元比热容和质量分数)求得,Ti-20Ta的比热容为324.58 J/(kg·K)。将式(9)代入式(8)对模型进行修正,可得[39]:

(cpi和mi分别为组元比热容和质量分数)求得,Ti-20Ta的比热容为324.58 J/(kg·K)。将式(9)代入式(8)对模型进行修正,可得[39]:

(10)

(10)

通过对应变速率为0.004 s-1和1223 s-1的应力-应变曲线拟合得:

(11)

(11)

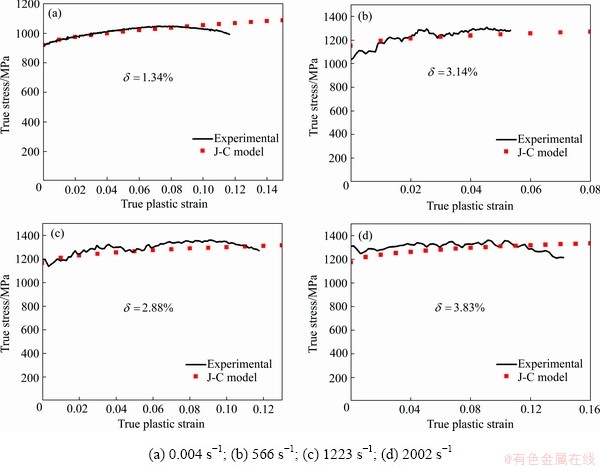

将得到的修正J-C模型与实验数据进行比较,如图8所示。再通过式(12)来计算平均相对误差 ,四组中最大误差为3.83%,这说明修正J-C模型能够较好地用来描述和预测Ti-20Ta复合材料的动态力学行为。

,四组中最大误差为3.83%,这说明修正J-C模型能够较好地用来描述和预测Ti-20Ta复合材料的动态力学行为。

(12)

(12)

式中: 为拟合使用的第i组实验数据中的强度;

为拟合使用的第i组实验数据中的强度; 为使用模型计算的对应塑性应变下的强度;N为拟合使用的实验数据总组数。

为使用模型计算的对应塑性应变下的强度;N为拟合使用的实验数据总组数。

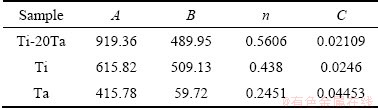

采用相同的方法对纯Ti和纯Ta进行计算,将所得到的A、B、n、C值与Ti-20Ta复合材料进行比较,如表3所列。A值反映材料的屈服强度,B和n值反映材料的应变强化,Ti-20Ta复合材料表现出高的屈服强度以及应变强化效应;C值反映材料的应变速率强化,Ti-20Ta复合材料的应变速率强化效应远低于纯Ta的,而略低于纯Ti的。 以上分析表明,由于Ti-20Ta复合材料的特殊界面和组织结构,使其表现出与纯Ti和纯Ta不一样的动态变形行为。复合材料高的屈服强度和应变强化效应,一方面是由于材料的组织更为细小,富Ti和富Ta区的固溶度更高;另一方面是Ti-Ta过渡界面对位错运动和裂纹扩展具有阻碍作用。在应变速率强化方面,由于富Ti区和富Ta区界面的存在,在高应变速率下,可能会抑制位错的拖曳效应而使得合金材料的应变速率硬化率略低于纯Ti的。

图8 Ti-20Ta复合材料实验数值与修正J-C塑性模型的比较

Fig. 8 Comparison between experimental flow stresses and their corresponding flow behaviors by using modified J-C plastic model for Ti-20Ta composite at different strain rates

表3 Ti-20Ta复合材料,纯Ti和纯Ta的J-C模型参数

Table 3 Parameters for J-C model of Ti-20Ta composite, purity Ti and purity Ta

4 结论

1) 随着应变速率从0.004 s-1增加至2002 s-1,Ti-Ta复合材料的屈服强度明显增加,表明具有明显的应变率强化作用。在应变速率为1223 s-1和2002 s-1时,随着应变的增加,Ti-Ta复合材料的流变应力增加得较为平缓,这是绝热软化和应变强化相互竞争的结果。 2) 相比于纯Ti纯Ta材料,Ti-Ta复合材料在不同应变速率下的屈服强度明显提高,这主要是由于细小的显微组织和界面对变形的强化作用。 3) Ti-Ta复合材料的断裂形式主要表现为裂纹的分叉和桥接,在试样边角由于应力波的反射作用,出现沿界面结构的层裂。 4) Ti-Ta复合材料的流变应力可用改进的J-C本构模型进行描述,其本构方程为

。

。

REFERENCES

[1] BOYER R R, BRIGGS R D. The use of β titanium alloys in the aerospace industry[J]. Journal of Materials Engineering and Performance, 2005, 14(6): 681-685.

[2] HUANG J, XING H, SUN J. Structural stability and generalized stacking fault energies in β Ti-Nb alloys: Relation to dislocation properties[J]. Scripta Materialia, 2012, 66(9): 682-685.

[3] MIN X H, TSUZAKI K, EMURA S, TSUCHIYA K. Enhancement of uniform elongation in high strength Ti-Mo based alloys by combination of deformation modes[J]. Materials Science and Engineering A, 2011, 528(13): 4569-4578.

[4] BOBBILI R, MADHU V. Physically-based constitutive model for flow behavior of a Ti-22Al-25Nb alloy at high strain rates[J]. Journal of Alloys and Compounds, 2018, 762: 842-848.

[5] WEI J, WANG G, JI X, DENG K, SHA F. Dynamic mechanical properties and constitutive relationship of particle-reinforced AZ91D composites[J]. Journal of Alloys and Compounds, 2018, 767: 210-214.

[6] BOBBILI R, MADHU V. Dynamic behavior and constitutive modeling of Ti-10-2-3 alloy[J]. Journal of Alloys and Compounds, 2019, 786: 588-593.

[7] 杨 扬, 程信林. 绝热剪切的研究现状及发展趋势[J]. 中国有色金属学报, 2002, 12(3): 401-408.

YANG Yang, CHENG Xin-lin. Current status and trends in researches on adiabatic shearing[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 401-408.

[8] CHEN G, REN C, QIN X, LI J. Temperature dependent work hardening in Ti-6Al-4V alloy over large temperature and strain rate ranges: Experiments and constitutive modeling[J]. Materials & Design, 2015, 83: 598-610.

[9] WANG B, SUN J, WANG X, FU A. Adiabatic shear localization in a near beta Ti-5Al-5Mo-5V-1Cr-1Fe alloy[J]. Materials Science and Engineering A, 2015, 639: 526-533.

[10] LI Z, ZHAO S, ALOTAIBI S M, LIU Y, WANG B, MEYERS M A. Adiabatic shear localization in the CrMnFeCoNi high-entropy alloy[J]. Acta Materialia, 2018, 151: 424-431.

[11] LI Z, WANG B, ZHAO S, VALIEV R Z, VECCHIO K S, MEYERS M A. Dynamic deformation and failure of ultrafine-grained titanium[J]. Acta Materialia, 2017, 125: 210-218.

[12] 张长清, 谢兰生, 陈明和. 高应变速率下两种损伤容限型钛合金的动态压缩变形行为[J]. 机械工程材料, 2016, 40(2): 94-97, 101.

ZHANG Chang-qing, XIE Lan-sheng, CHEN Ming-he. Dynamic compressive deformation behavior of two damage tolerance titanium alloys at high strain rates[J]. Materials for Mechanical Engineering, 2016, 40(2): 94-97, 101.

[13] 刘清华, 惠松骁, 叶文君, 王 国, 胡光山. 合金元素对TC4钛合金动态力学性能的影响[J]. 稀有金属材料与工程, 2013, 42(7): 1464-1468.

LIU Qing-hua, HUI Song-xiao, YE Wen-jun, WANG Guo, HU Guang-shan. Effect of the content of alloying elements on dynamic mechanical properties of TC4 a1lloy[J]. Rare Metal Materials and Engineering, 2013, 42(7): 1464-1468.

[14] ZHAN H, WANG G, KENT D, DARGUSCH M. Constitutive modelling of the flow behaviour of a β titanium alloy at high strain rates and elevated temperatures using the Johnson–Cook and modified Zerilli–Armstrong models[J]. Materials Science and Engineering A, 2014, 612: 71-79.

[15] WANG Y, ZENG W, SUN X, XU J. The microstructure characterization of adiabatic shearing band in Ti-17 alloy at high strain rates and elevated temperatures[J]. Materials Science and Engineering A, 2016, 677: 325-331.

[16] HAO Y, LIU J, LI J, LI S, WANG G. Investigation on dynamic properties and failure mechanisms of Ti-47Al-2Cr-2Nb alloy under uniaxial dynamic compression at a temperature range of 288K-773K[J]. Journal of Alloys and Compounds, 2015, 649: 122-127.

[17] ZHANG Q, ZHANG J, WANG Y. Effect of strain rate on the tension-compression asymmetric responses of Ti-6.6Al-3.3Mo-1.8Zr-0.29Si[J]. Materials & Design, 2014, 61: 281-285.

[18] CHU M Y, JIAO Z M, WANG Z H, WANG Y S, ZHANG J H, YANG H J, QIAO J W. Different deformation behaviors of two in-situ Ti-based metallic glass matrix composites upon quasi-static and dynamic compressions[J]. Materials Science and Engineering A, 2015, 639: 717-723.

[19] YANG H, WANG D, ZHU X, FAN Q. Dynamic compression-induced twins and martensite and their combined effects on the adiabatic shear behavior in a Ti-8.5Cr-1.5Sn alloy[J]. Materials Science and Engineering A, 2019, 759: 203-209.

[20] LEE W S, CHEN C W. High temperature impact properties and dislocation substructure of Ti-6Al-7Nb biomedical alloy[J]. Materials Science and Engineering A, 2013, 576: 91-100.

[21] SALEM A A, KALIDINDI S R, SEMIATIN S L. Strain hardening due to deformation twinning in α-titanium: Constitutive relations and crystal-plasticity modeling[J]. Acta Materialia, 2005, 53(12): 3495-3502.

[22] YUAN X H, YANG M S, ZHAO K Y. Effects of microstructure transformation on strengthening and toughening for heat-treated low carbon martensite stainless bearing steel[C]// HAN Y F, LIU X F, WU Y. Materials Science Forum. Switzerland: Trans Tech Publications, 2015: 667-674.

[23] KHAN A Q, VAN DER PERRE G, DELAEY L. Stress-induced phase transformations and enhanced plasticity in copper-aluminium and copper-aluminium-zinc martensites[J]. Journal of Materials Science, 1972, 7(12): 1401-1408.

[24] 徐圣航, 周承商, 刘 咏. 金属-金属层状结构复合材料研究进展[J]. 中国有色金属学报, 2019, 29(6): 1125-1142.

XU Sheng-hang, ZHOU Cheng-shang, LIU Yong. Research progress in metal-metal laminated structural composites[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(6): 1125-1142.

[25] WU H, FAN G, HUANG M, GENG L, CUI X, XIE H. Deformation behavior of brittle/ductile multilayered composites under interface constraint effect[J]. International Journal of Plasticity, 2017, 89: 96-109.

[26] YANG D, CIZEK P, HODGSON P, WEN C. Ultrafine equiaxed-grain Ti/Al composite produced by accumulative roll bonding[J]. Scripta Materialia, 2010, 62(5): 321-324.

[27] LEE W B, BANG K S, JUNG S B. Effects of intermetallic compound on the electrical and mechanical properties of friction welded Cu/Al bimetallic joints during annealing[J]. Journal of Alloys and Compounds, 2005, 390(1): 212-219.

[28] XU S, LIU Y, YANG C, ZHAO H, LIU B, LI J, SONG M. Compositionally gradient Ti-Ta metal-metal composite with ultra-high strength[J]. Materials Science and Engineering A, 2018, 712: 386-393.

[29] SEYED EBRAHIMI S H, DEHGHANI K, AGHAZADEH J, GHASEMIAN M B, ZANGENEH S. Investigation on microstructure and mechanical properties of Al/Al-Zn-Mg–Cu laminated composite fabricated by accumulative roll bonding (ARB) process[J]. Materials Science and Engineering A, 2018, 718: 311-320.

[30] MASHHADI A, ATRIAN A, GHALANDARI L. Mechanical and microstructural investigation of Zn/Sn multilayered composites fabricated by accumulative roll bonding (ARB) process[J]. Journal of Alloys and Compounds, 2017, 727: 1314-1323.

[31] LEE W S, KAO C H. Hot deformation behaviour and microstructural evolution of biomedical Ti-13Nb-13Zr alloy in high strain rate range[J]. Materials Science and Engineering A, 2016, 677: 230-239.

[32] LIU X, TAN C, ZHANG J, HU Y, MA H, WANG F, CAI H. Influence of microstructure and strain rate on adiabatic shearing behavior in Ti-6Al-4V alloys[J]. Materials Science and Engineering A, 2009, 501(1): 30-36.

[33] ZONG X, LI Z, LI J, CHENG X, CHEN R, TAN C, WANG H. High strain rate response of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy fabricated by laser additive manufacturing[J]. Journal of Alloys and Compounds, 2019, 781: 47-55.

[34] MEYERS M A, PAK H R. Observation of an adiabatic shear band in titanium by high-voltage transmission electron microscopy[J]. Acta Metallurgica, 1986, 34(12): 2493-2499.

[35] CHAN K S. Intermetallic composites toughened with ductile reinforcements[M]. MITRA R ed. UK: Intermetallic Matrix Composites, 2018: 359-407.

[36] MEYERS M A. Dynamic behavior of materials[M]. Canada: John Wiley & Sons, 1994: 488-566.

[37] MA X, HUANG C, MOERING J, RUPPERT M, HoPPEL H W, GOKEN M, NARAYAN J, ZHU Y. Mechanical properties of copper/bronze laminates: Role of interfaces[J]. Acta Materialia, 2016, 116: 43-52.

[38] YANG M, PAN Y, YUAN F, ZHU Y, WU X. Back stress strengthening and strain hardening in gradient structure[J]. Materials Research Letters, 2016, 4(3): 145-151.

[39] TANG Y L, ZHANG T W, SHI X H, QIAO J W, WANG Z H, ZHOU H F, WU Y C. Design novel Ti-based metallic glass matrix composites with excellent dynamic plasticity[J]. Journal of Alloys and Compounds, 2019, 773: 844-852.

Dynamic behavior of biomimic structure Ti-Ta metal-metal composite

LI Mou1, LIU Yong1, LIU Bin1, WANG Bing-feng2, LI Nian-feng3, XU Sheng-hang1, 4, CHEN Man-ke1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

3. Department of Hepatobiliary and Pancreatic Surgery, Xiangya Hospital, Central South University, Changsha 410008, China;

4. College of Materials Science and Engineering, Zhejiang University of Technology, Hangzhou 310014, China)

Abstract: Materials with shell-like or layered structure exhibit both high strength and toughness, which makes them become one of the important design models for material structure optimization. A Ti-Ta metal-metal composite with biomimic structure was prepared by powder metallurgy and thermal processing, and its dynamic behavior was studied. The results show that biomimic interface structure has an important influence on the deformation of the Ti-Ta composite, and the fracture behavior includes crack bridging and lamellar spallation. The metal-metal composite is subjected to the combined effects of strain rate strengthening, strain strengthening and adiabatic softening. Specifically, the yield strength of the composite increases with the increase of strain rate, and the flow stress changes more gently with the increase of deformation at high strain rate. The modified Johnson-Cook (J-C) constitutive model can well describe the dynamic behavior of Ti-Ta composite, and it is found that the strain rate strengthening index C of Ti-Ta composite is much lower than that of pure Ta and slightly lower than that of pure Ti.

Key words: Ti-Ta metal-metal composite; strain rate strengthening; adiabatic softening; Johnson-cook constitutive model

Foundation item: Project(51625404) supported by the National Natural Science Foundation of China Distinguished Young Fund; Projects(CX20190190, 2019zzts134) supported by the Fundamental Research Funds for the Central Universities of Central South University, China; Project(2016YFB11d403) supported by the National Key R&D Program of China

Received date: 2019-08-16; Accepted date: 2019-11-26

Corresponding author: LIU Yong; Tel: +86-731-88836939; E-mail: yonliu@csu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金杰出青年基金资助项目(51625404);中南大学中央高校基本科研业务费专项资金资助项目(CX20190190,2019zzts134);国家重点研发计划资助项目项目(2016YFB11d403)

收稿日期:2019-08-16;修订日期:2019-11-26

通信作者:刘 咏,教授,博士;电话:0731-88836939;E-mail:yonliu@csu.edu.cn