DOI: 10.11817/j.issn.1672-7207.2015.02.010

锻造方式对ZK21镁合金显微组织和力学性能的影响

吴远志1, 2,严红革3,朱素琴3,刘先兰1, 2,刘安民1, 2,张蓉1, 2

(1. 湖南工学院 机械工程学院,湖南 衡阳,421002;

2. 汽车零部件制造与绩效提升技术湖南省应用基础研究基地,湖南 衡阳,421002;

3. 湖南大学 材料科学与工程学院,湖南 长沙,410082)

摘要:采用空气锤对ZK21合金进行高应变速率锻造成形,对比研究单向、双向和三向锻造合金的显微组织和力学性能。研究结果表明:锻造成形时通过改变载荷方向可以提高合金所能承受的累积应变,从而获得良好的晶粒细化效果和优异的综合力学性能。双向锻造时,再结晶机制主要为孪生诱发动态再结晶,合金最终锻造组织为平均晶粒粒径约为0.3 μm的超细晶粒组织;而三向锻造时,再结晶机制主要为旋转动态再结晶和孪生诱发动态再结晶,合金最终锻造组织为平均晶粒粒径为15 μm的蜂窝状粗大再结晶组织和平均晶粒粒径约为0.3 μm的岛状细小再结晶组织。累积应变为2.64时,双向锻造合金的抗拉强度、屈服强度和伸长率分别为355.7 MPa,295 MPa和16.6%,三向铸造合金的抗拉强度、屈服强度和伸长率分别为341.6 MPa,270.7 MPa和25.1%。

关键词:ZK21镁合金;高应变速率锻造;锻造方式;显微组织;力学性能

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2015)02-0444-08

Effects of forging technique on microstructure and mechanical properties of ZK21 magnesium alloy

WU Yuanzhi1, 2, YAN Hongge3, ZHU Suqin3, LIU Xianlan1, 2, LIU Anmin1, 2, ZHANG Rong1, 2

(1. Department of Mechanical Engineering, Hunan Institute of Technology, Hengyang 421002, China;

2. Institution of Applied Fundamental Research of Hunan Province for Automobile Parts Manufacturing and

Efficiency Promotion Technology, Hengyang 421002, China;

3. School of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: The high strain rate forging of ZK21 magnesium alloy was conducted on the pneumatic power hammer, and the microstructure and mechanical properties of the forged alloys processed by different forging techniques including uniaxial forging (UF), biaxial forging (BF) and triaxial forging (TF) were investigated. The results show that higher strain should be accumulated on ZK21 alloy by alternating the loading direction, which consequently results in extensive grain refinement and excellence mechanical properties. Twinning induced dynamic recrystallization (TDRX) is the main DRX mechanism of BF, which consequently results in ultrafine grains with average grain size of 0.3 μm. However, both rotation DRX (RDRX) and TDRX are responsible for the DRX during TF, which consequently results in a novel mixed structure of honeycombe-like coarse DRX grains with average grain size of 15 μm and island-like ultrafine grains with average grain size of 0.3 μm. An excellent combination of mechanical property is achieved in biaxial forged and triaxial forged alloys at accumulated strain of 2.64. The ultimate tensile strength (UTS), yield strength (YS) and elongation of biaxial forged alloy are 355.7 MPa, 295 MPa and 16.6%, respectively. The VTS, YS and elongation of triaxial forged alloy are 341.6 MPa, 270.7 MPa and 25.1%, respectively.

Key words: ZK21 magnesium; high strain rate forging; forging technique; microstructure; mechanical properties

镁合金是最轻的金属结构材料,具有高比强度、高比刚度、良好的减振能力、优良的导热性和导电性、良好的尺寸稳定性、电磁屏蔽性和易于回收等特点[1]。随着能源和环境问题的日益突出,镁合金作为新型工程材料迅速崛起,在航空航天、交通运输和电子通讯等领域具有广阔的应用前景[2]。但由于镁合金一般为密排六方结构,在室温变形条件下独立滑移系较少,塑性加工困难,到目前为止镁合金产品主要以压铸件为主。而铸造镁合金的晶粒组织和第二相比较粗大,且存在气孔、缩孔等缺陷,采用铸造方法生产的镁合金力学性能不够理想,难以满足高性能结构材料的需求,严重制约了镁合金的广泛应用[3]。大量研究结果表明,热变形工艺可以细化镁合金晶粒组织并消除铸造缺陷,提高合金综合力学性能,从而扩大其使用范围[4]。其中,锻造加工生产效率高,锻件形状和尺寸稳定性好,并且可以制备综合性能优异的大尺寸结构件。然而,由于镁合金塑性成形能力差、锻造温度区间窄、锻造过程降温快以及对应变速率敏感等特点,使得镁合金锻造成形难度大且防护困难[5],目前关于镁合金锻造的研究报道较少[6-8]。Wu等[9-10]研究了ZK系列镁合金高应变速率变形行为,结果表明,在高应变速率(≥10 s-1)变形条件下,大量的孪晶以及孪晶诱发的动态再结晶可以消耗变形储能抑制裂纹的产生,从而从根本上提高合金的塑性成形能力;此外,高应变速率变形产生的变形温升还可以弥补散热造成的温度下降。在此基础上,Wu等[11-13]采用高应变速率锻造工艺制备了高性能ZK21,ZK60和AZ31镁合金锻坯,证明了镁合金高应变速率变形的可行性。在此,本文作者研究高应变速率锻造方式对ZK21合金显微组织和力学性能的影响,可为镁合金高应变速率锻造工艺的制定提供一定的参考。

1 实验方法

实验用材料为铸态ZK21镁合金,名义成分为Mg-2.3Zn-0.45Zr,其平均晶粒尺寸约为150 μm。将铸锭加工成长×宽×高分别为40 mm×35 mm×35 mm的锻坯,并除去尖锐的棱角,避免由于应力集中引起的开裂。高应变速率锻造实验在空气锤上进行,空气锤的锻打频率为200次/min,锻打速度约为5 m/s。锻造方式包括单向、双向和三向锻造。单向锻造时,锻造方向始终沿样品的长度方向;双向锻造时,锻造方向按样品长和宽的方向依次循环变化;三向锻造时,锻造方向则按样品长、宽、高的方向依次循环变化。锻造前将样品置于300 ℃的电阻炉中保温10 min,所有试样均采用一次加热成形,即道次间不进行加热,道次变形量为20%,即道次应变Δε=0.22。锻造完成后对试样进行水淬以保留高温变形组织,锻坯表面良好没有明显裂纹。

取锻坯芯部垂直于最终锻造方向的平面进行组织观察。采用Leitz MM6卧式金相显微镜进行金相组织观察,观察前经打磨、抛光、腐蚀,腐蚀剂成分为1 g草酸+1 mL硝酸+98 mL蒸馏水。采用JEOL 1400和TECNAI G220型透射电镜进行透射电镜(TEM)观察,所采用加速电压分别为120 kV和200 kV,透射样品采用双喷法经电解抛光减薄制得,电解液成分为5.3 g氯化锂+11.16 g高氯酸镁+500 mL甲醇+100 mL 2-丁基乙醚。使用TCI平均晶粒度分析评级软件测定平均晶粒尺寸,测定方法为直线截点法。在锻坯芯部加工片状拉伸试样进行室温拉伸实验,片状试样标距长×宽×厚为10 mm×3 mm×2.5 mm,拉伸方向垂直于最终锻造方向。拉伸实验在WDW E200型电子万能试验机上进行,拉伸速度为0.5 mm/min。

2 实验结果与分析

2.1 显微组织

图1所示为ZK21合金高应变速率单向锻造组织演变。累积应变为0.22时,大量的孪晶分割初始晶粒,基本没有观察到再结晶晶粒,如图1(a)所示。随着累积应变的增大,孪晶密度升高。累积应变为0.44时,孪晶密度明显升高,在光学显微镜下依然观察不到再结晶晶粒,如图1(b)所示。累积应变为0.88时,孪晶密度继续升高,孪晶基本覆盖了整个样品,同时初始晶界附近出现少量再结晶晶粒,如图1(c)所示。累积应变增大到1.32时,孪晶密度进一步升高,再结晶的程度也有所增加,但其组织极不均匀,仍有少量没有孪晶也没有再结晶的区域,如图1(d)所示。继续增大累积应变,锻坯发生开裂,即经6道次单向锻造变形之后合金无法继续变形。

图2和图3所示为ZK21合金高应变速率双向锻造组织演变。累积应变为0.44时,大量相互交错的孪晶分割初始晶粒,基本没有观察到再结晶晶粒,如图2(a)所示。随着累积应变的增大,初始晶粒内的孪晶密度提高,在光学显微镜下依然观察不到再结晶晶粒,如图2(b)和(c)所示。对累积应变为1.32的样品进行TEM观察可以发现:相互交错的孪晶互成一定角度,孪晶上位错密度较高,但并没有观察到再结晶晶粒,如图3(a)所示。继续增大累积应变,初始晶粒内的孪晶密度进一步提高,同时再结晶开始在孪晶上启动,如图2(d)和(e)所示,对累积应变为2.64的样品进行TEM观察可以发现:变形初期相互交错的孪晶已经被细小的再结晶晶粒所替代,其再结晶晶粒尺寸约为0.3 μm,如图3(b)所示。结合图2(e),2(f)和3(b)可知:累积应变为2.64时,双向锻造ZK21合金显微组织主要由平均晶粒尺寸约为0.3 μm的超细晶粒构成。

图1 ZK21合金高应变速率单向锻造不同累积应变时的显微组织

Fig. 1 Microstructure of uniaxial forged ZK21 alloys at different accumulated strains

图4和5所示为ZK21合金高应变速率三向锻造组织演变。累积应变为0.66时,初始晶粒内形成大量的孪晶,如图4(a)所示。随着累积应变的增大,孪晶密度大幅提高,如图4(b)和(c)所示。对累积应变为1.1的锻坯进行TEM分析可以发现,孪晶片层已经细化至微米级,但孪晶上没有发现再结晶晶粒,如图5(a)所示。继续增大累积应变,再结晶开始启动,累积应变为1.76时,在初始晶界附近出现了大量的再结晶晶粒,其平均晶粒粒径约为15 μm,如图4(d)所示。当累积应变增大到2.64时,合金组织由蜂窝状粗大再结晶组织和岛状组织构成,如图4(e)和(f)所示。对岛状区域进行TEM观察可以发现,初始晶粒内的孪晶片层被平均晶粒粒径为0.3 μm的再结晶晶粒替代,如图5(b)所示。结合图3(e),3(f)和4(b)可知:累积应变为2.64时,ZK21合金显微组织由平均晶粒粒径为15 μm的蜂窝状粗大再结晶组织和平均晶粒粒径约为0.3 μm的岛状细小再结晶晶粒组成。

对比ZK21合金3种锻造工艺下的显微组织可以发现,单向锻造变形时,合金所能承受的累积应变较小,仅为1.32,未能获得均匀的再结晶组织;而双向锻造和三向锻造变形时,合金所能承受的累积应变远大于单向锻造变形,达到2.64甚至以上,合金晶粒细化效果明显。研究表明,镁合金单向锻造变形过程中,当变形量超过一定程度时,基面织构强度大幅增强,合金塑形成形能力下降[6];而双向和三向锻造成形则可以有效地控制基面织构强度,使合金具有良好的塑性成形能力[14-15]。由此可见,通过改变变形载荷方向可以削弱合金基面织构强度,提高合金持续变形能力,增加其所能承受的累积应变,从而获得较好的晶粒细化效果。

分析合金3种锻造方式下的组织演变还可以发现,孪生在高应变速率锻造过程中发挥着重要的作用。孪生、滑移和晶界滑移是镁合金塑性变形的主要机制;由于本文所用材料初始组织粗大,晶界滑移难以在变形中发挥作用;此外,由于高应变速率锻造成形时变形在很短的时间内完成,位错滑移的有效时间缩短,位错滑移的作用减弱;因此,大量的孪生启动以协调变形,从而使孪生成为高应变速率锻造的主要变形机制。孪晶界与晶界一样可以阻碍位错运动,为再结晶提供储能,从而在孪晶上形成再结晶晶粒,这种再结晶机制被称为孪生诱发动态再结晶(twin induced DRX, TDRX)[16]。从图2和图4可以看出,孪生诱发动态再结晶是ZK21合金双向和三向锻造过程中主要的晶粒细化机制。

图2 ZK21合金高应变速率双向锻造不同累积应变时的显微组织

Fig. 2 Microstructure of biaxial forged alloys at different accumulated strains

图3 不同累积应变双向锻造合金TEM像

Fig. 3 TEM images biaxial forged alloys at different accumulated strains

图4 ZK21合金高应变速率三向锻造不同累积应变时的显微组织[11]

Fig. 4 Microstructure of triaxial forged alloys at different accumulated strains

图5 不同累积应变三向锻造合金TEM像

Fig. 5 TEM images triaxial forged alloys at different accumulated strains

值得注意的是,累积应变为2.64时,三向锻造合金组织由平均晶粒粒径为15 μm的蜂窝状粗大再结晶组织和平均晶粒粒径约为0.3 μm的岛状细小再结晶晶粒组成,而双向锻造合金组织则由平均晶粒粒径约为0.3 μm的超细晶粒构成。高应变速率三向锻造过程中,外加载荷方向循环变化,其基面也有循环改变的趋势,在这样的情况下,大量的晶粒旋转必须启动才能协调基面变化的趋势。晶粒的旋转会使晶粒之间产生剪切应力,并在初始晶界附近形成畸变区,从而成为动态再结晶优先形核的区域,这种再结晶机制被称为旋转动态再结晶(rotation DRX, RDRX)[10]。由于初始晶界附近和初始晶粒内部的再结晶机制不同,三向锻造合金初始晶界附近的再结晶晶粒粒径与初始晶粒内部的晶粒粒径差别很大。而双向锻造时,由于正交循环的双向载荷可以降低合金初始晶界附的应力集中,使初始结晶附近的位错密度下降[17],从而使再结晶难以在初始晶界附近直接形核,转而通过在孪晶上形核以实现其晶粒细化。由于初始结晶附近和初始晶粒内部的再结晶机制均为孪生诱发动态再结晶,双向锻造合金再结晶组织更为均匀。

2.2 力学性能

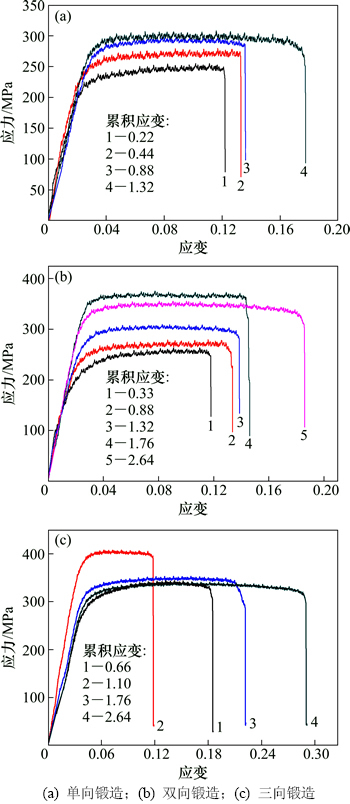

图6所示为不同锻造方式的ZK21合金室温拉伸曲线,表1给出了其室温力学性能,包括屈服强度σs、抗拉强度σb和伸长率δ。从图6(a)和表1可以看出:单向锻造ZK21合金的强度和延伸率均随累积应变的增大而升高。累积应变为1.32时,合金抗拉强度为308 MPa,伸长率则为15.2%。而双向锻造合金强度随累积应变的增大先升高后降低,伸长率则随累积应变的增大而上升,如图6(b)和表1所示。累积应变为1.76时,合金抗拉强度达到最高为373.4 MPa;而当累积应变为2.64时,合金抗拉强度下降至355.7 MPa,伸长率则提高到16.6%。三向锻造合金强度随累积应变的变化关系与双向锻造合金类似,但其伸长率则随累积应变的增大先降低后升高,如图6(c)和表1所示。累积应变为1.1时,合金的抗拉强度达到最高为401 MPa,伸长率最低仅为9.6%;累积应变增大到2.64时,合金抗拉强度降低至341.6 MPa,伸长率则增大到25.1%。

图6 不同锻造方式ZK21合金室温拉伸曲线

Fig. 6 Room temperature tensile curves of ZK21 alloys forged by different techniques

对不同锻造方式ZK21合金组织和力学性能分析可以发现,单向锻造变形时,由于合金所能承受的极限变形量有限,难以获得均匀细小的再结晶组织,其综合力学性能不够理想;而双向和三向锻造变形时,合金所能承受的累积应变大幅增加,晶粒细化效果明显,其综合力学性能得到大幅提高。累积应变为2.64时,双向和三向锻造合金具有良好的综合力学性能,双向锻造合金的抗拉强度、屈服强度和伸长率分别为355.7 MPa,295 MPa和16.6%,三向锻造合金的抗拉强度、屈服强度和伸长率分别为341.6 MPa,270.7 MPa和25.1%。

对比双向和三向锻造合金力学性能变化规律还可以发现,合金的强度均随累积应变的升高先增大后减小。结合ZK21合金双向和三向锻造组织演变可知:变形前期,孪生主导变形,随着累积应变的升高,孪晶密度急剧上升,孪晶界的数量增大,而孪晶界可以有效地阻碍位错的运动,从而大幅提高材料的强度[18],因此合金的强度随累积应变的升高而增大;而变形后期,再结晶主导变形,合金再结晶程度随累积应变的升高而增大,众所周知再结晶可以释放变形储能、降低位错密度从而引起合金软化[19],因此合金强度随累积应变的升高而降低。

表1 不同锻造方式ZK21合金室温力学性能

Table 1 Room temperature mechanical properties of ZK21 alloys forged by different techniques

3 结论

1) 单向锻造成形时,由于合金所能承受的变形量有限,难以获得均匀的组织;而通过改变锻造成形的载荷方向可以提高合金持续变形能力,增加其所能承受的累积应变,从而获得良好的晶粒细化效果。

2) 双向锻造时,再结晶机制主要为孪生诱发动态再结晶,合金最终锻造组织为平均晶粒粒径约为0.3 μm的超细晶粒组织;而三向锻造时,再结晶机制主要为旋转动态再结晶和孪生诱发动态再结晶,合金最终锻造组织为平均晶粒粒径为15 μm的蜂窝状粗大再结晶组织和平均晶粒粒径约为0.3 μm的岛状细小再结晶晶粒。

3) 双向和三向锻造工艺可以大幅提高ZK21合金的综合力学性能,累积应变为2.64时,双向和三向锻造合金具有良好的综合力学性能,双向锻造合金的抗拉强度、屈服强度和延伸率分别为355.7 MPa,295 MPa和16.6%,三向锻造合金的抗拉强度、屈服强度和伸长率分别为341.6 MPa,270.7 MPa和25.1%。

参考文献:

[1] Mordike B L, Ebert T. Magnesium properties- applications-potential[J]. Materials Science and Engineering A, 2001, 302(1): 37-45.

[2] Aghion E, Bronfin B, Eliezer D. The role of the magnesium industry in protecting the environment[J]. Journal of Materials Processing Technology, 2001, 117(3): 381-185.

[3] Avedesian M M, BAKER H. ASM specialty handbook: Magnesium and magnesium alloys[M]. Materials Park: ASM International, 1999: 7-8.

[4] 陈振华. 变形镁合金[M]. 北京: 化学工业出版社, 2005: 2-10.

CHEN Zhenhua. Wrought magnesium alloy[M]. Beijing: Chemical Industry Press, 2005: 2-10.

[5] Kainer K U. Magnesium alloys and technology[M]. Weinheim: GKSS Research Center Geesthacht GmbH, 2003: 99-104.

[6] 曲家惠, 李四军, 王福, 等. AZ31镁合金挤出棒材锻造变形时的组织与织构的变化[J]. 材料与冶金学报, 2006, 5(7): 221-225.

QU Jiahui, LI Sijun, WANG Fu, et al. Texture evolution during forging of magnesium AZ31 alloy[J]. Journal of Materials and Metallurgy, 2006, 5(7): 221-225.

[7] Matsumoto R, Osakada K. Ductility of magnesium alloy in warm forging with controlled forming speed using CNC servo press[J]. Journal of Materials Processing Technology, 2010, 210(14): 2029-2035.

[8] ZHENG Xingwei, DONG Jie, YIN Dongdi, et al. Forgeability and die-forging forming of direct chill casting Mg-Nd-Zn-Zr magnesium alloy[J]. Materials Science and Engineering A, 2010, 527(16/17): 3690-3694.

[9] WU Yuanzhi, YAN Hongge, CHEN Jihua, et al. Hot deformation behavior and microstructure evolution of ZK21 magnesium alloy[J]. Materials Science and Engineering A, 2010, 527(16/17): 3670-3675.

[10] YAN Hongge, WU Yuanzhi, CHEN Jihua, et al. Microstructure evolution of ZK40 magnesium alloy during high strain rate compression deformation at elevated temperature[J]. Materials Science and Technology, 2011, 27(9): 1416-1421.

[11] WU Yuanzhi, YAN Hongge, CHEN Jihua, et al. Microstructure and mechanical properties of ZK21 magnesium alloy processed by multiple forging at different strain rate[J]. Materials Science and Engineering A, 2012, 556: 164-169.

[12] WU Yuanzhi, YAN Hongge, CHEN Jihua, et al. Microstructure and mechanical properties of ZK60 alloy fabricated by multiple forging[J]. Material Science and Technology, 2013, 29(1): 54-59.

[13] 吴远志, 严红革, 陈吉华, 等. AZ31镁合金高应变速率多向锻造组织演变及力学性能[J]. 中国有色金属学报, 2012, 22(11): 3000-3005.

WU Yuanzhi, YAN Hongge, CHEN Jihua, et al. Microstructure evolution and mechanical properties of AZ31 magnesium alloy fabricated by high strain rate triaxial-forging[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3000-3005.

[14] Xin Y C, Liang J, Chapuis A, et al. Plastic deformation behavior of AZ31 magneisum alloy under multiple pass cross compression[J]. Materials Science and Engineering A, 2012, 532: 50-57.

[15] YANG Xuyue, SUN Zhengyan, XING Jie, et al. Grain size and texture changes of magnesium alloy AZ31 during multi-directional forging[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(1): 200-204.

[16] Ma Q, Li B, Marin E B, et al Twinning-induced dynamic recrystallization in a magnesium extruded at 450 ℃[J]. Scripta Materialia, 2011, 65(9): 823-826.

[17] Pinheiro P, Monteiro W A, Bardosa R, et al. The effect of strain path on the mechanical behavior and dislocation arrangements in the hot working of copper[J]. Materials Science and Engineering A, 2004, 368(1/2): 280-285.

[18] SHEN Yongfeng, LU Lei, LU Qiuhong, et al. Tensile properties of copper with nano-scale twins[J]. Scripta Materialia, 2005, 52(10): 989-994.

[19] ZHU Shuqin, YAN Hongge, CHEN Jihua, et al. Effect of twinning and dynamic recrystallization on the high strain rate rolling process[J]. Scripta Materialia, 2010, 63(10): 985-988.

(编辑 赵俊)

收稿日期:2014-03-17;修回日期:2014-06-23

基金项目(Foundation item):湖南省自然科学基金资助项目(14JJ6047);湖南省教育厅科学研究青年项目(14B045)(Project (14JJ6047) supported by the Natural Science Foundation of Hunan Province of China; Project (14B045) supported by the Sciencetific Research Funds of Hunnan Provincial Education Department)

通信作者:吴远志,博士,从事高性能变形镁合金制备技术研究;E-mail:ranco007@163.com