DOI: 10.11817/j.issn.1672-7207.2020.11.001

母合金法MIM418涡轮的近终成形与致密化机理

陈晓玮1,刘烨2,章林1,曲选辉1

(1. 北京科技大学 新材料技术研究院,北京,100083;

2. 湘潭大学 材料科学与工程学院,湖南 湘潭,411100)

摘要:以母合金粉末和羰基镍粉为原料,采用母合金法制备MIM418高温合金,并通过注射成形实现增压涡轮的近终成形。研究结果表明:通过真空烧结与热等静压,MIM418涡轮相对密度达到99%以上。对烧结态的合金显微组织进行表征,发现γ'相形貌和大小均匀,为0.5 μm左右。在烧结过程中产生了瞬时液相,液相中主要合金元素为Cr,在等温凝固后演变为晶界碳化物。瞬时液相的出现大大促进了致密化与扩散均匀化过程。母合金法MIM418合金的抗拉强度、屈服强度分别为931 MPa和788 MPa,比铸造K418合金的抗拉强度和屈服强度分别提高了48%和126%。

关键词:MIM418高温合金;母合金法;金属注射成形;力学性能

中图分类号:TF12 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-2999-08

Net-shape forming and densification mechanism of MIM418 turbine wheel using master alloy method

CHEN Xiaowei1, LIU Ye2, ZHANG Lin1, QU Xuanhui1

(1. Institute for Advanced Materials and Technology, University of Science and Technology Beijing,Beijing 100083, China;

2. School of Materials Science and Engineering, Xiangtan University, Xiangtan 411100, China)

Abstract: Using master alloy powder and carbonyl Ni powder as raw materials, MIM418 superalloy was prepared through master alloy approach, and near-net shape forming of MIM418 turbine wheel was realized by metal injection molding. The results show that through vacuum sintering and hot isostatic pressing, the relative density of MIM418 turbine wheel is up to 98%. The morphology and size of γ' phase are uniform and the size of γ' phase is about 0.5 μm. The transient liquid phase is generated in the sintering process. The main alloying element in the liquid phase is Cr, which transforms to the carbides along grain boundaries after isothermal solidification. The appearance of transient liquid phase greatly promotes the densification and diffusion process. The tensile strength and yield strength of MIM418 turbine using the parent alloy method are 931 MPa and 788 MPa, respectively, which are 48% and 126% higher than those of casted K418 alloy.

Key words: MIM418 superalloy; master alloy method; metal injection molding; mechanical properties

涡轮增压器由高温的发动机废气驱动,可以有效提高发动机的燃料利用率以及输出功率[1]。MARTISCHIUS等[2]综述了涡轮增压技术的发展趋势,并指出高性能涡轮在推广该项技术在汽油发动机中应用的重要性。K418合金是我国1970年代自主发展的一个高温合金牌号[3],主要用于在900 ℃以下服役的高温零部件,是我国目前柴油机增压涡轮使用量最大、最广泛的合金。K418是镍基的沉淀析出强化高温合金,具有良好的高温力学性能与抗热腐蚀性能。该合金的显微组织主要由γ基体、沉淀析出的γ'相、少量碳化物与硼化物组成,铸态下存在部分(γ+γ')共晶[4]。传统制备K418合金的方法为真空感应熔炼铸造法[5],然而,对于合金含量高的镍基高温合金来说,铸造法存在合金元素偏析、缩孔、晶粒粗大以及析出相不均匀等缺点,无法充分发挥合金应有的性能[6]。随着涡轮服役温度的提高,对高性能涡轮的需求急剧上升。粉末冶金法能够有效解决高合金化的镍基高温合金中偏析、缩孔、晶粒粗大、显微组织不均匀等问题,而结合了粉末冶金法与近终成形方法的粉末注射成形技术为制备具有复杂形状的高性能增压涡轮提供了可能。金属注射成形工艺对粉末的要求较高,一般要求粉末具有良好的球形度、良好的流动性、低氧含量,粉末粒径一般要求在50 μm以下。粉末的制备工艺通常为气雾化法、水雾化法[7]以及旋转电极雾化法[8],粉末制备的工艺成本较高。而传统的粉末高温合金的制备采用预合金粉末,由于高温合金的熔点较高,烧结所需的温度也较高,烧结活性有限,因此,提出采用母合金法制备注射成形高温合金。母合金法是一种强化烧结的粉末冶金方法,母合金粉中含有大部分的合金元素[9],同时具有低的熔点,在与基体的羰基铁粉或羰基镍粉混合后,在烧结过程中能够产生瞬时液相[10],从而促进粉体的致密化过程。由于制备过程中添加了一部分低成本的羰基粉末,因此,能够有效降低粉末的成本。通过母合金粉与羰基粉末之间的粉末级配,母合金法制备得到的注射生坯的强度也比预合金法的注射生坯的高[11]。

本文作者采用母合金法制备了注射成形MIM418高温合金涡轮,涡轮具有中空结构,能够有效减轻涡轮的质量,减少脱脂与烧结过程中产生的缺陷,同时对脱脂过程、烧结态与热处理态的显微组织与力学性能进行了表征。

1 实验

1.1 实验原料与样品制备

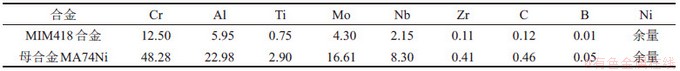

通过铸锭-破碎法制备母合金粉末,母合金MA74Ni与目标合金MIM418成分如表1所示。

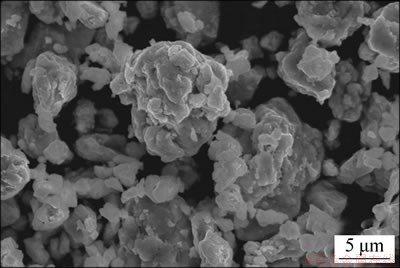

母合金铸锭由真空感应熔炼制备,去除表面氧化物后,通过机械破碎成为粉末,破碎后的母合金粉末经过振动筛,筛选出粒径在38 μm以下的细粉,粉末形貌如图1所示。破碎后的粉末粒径较小,颗粒累积分布为10%,50%和90%的粒径D10,D50和D90分别为3.1 μm,7.7 μm和17.6 μm,粉末呈现近球形,粉末边缘棱角不明显。经过化学元素分析,母合金粉末的氧质量分数为0.2%。

表1 MIM418与母合金粉末的化学成分(质量分数)

Table 1 Chemical compositions of MIM418 superalloy and master alloy powder %

图1 MA74Ni母合金粉末形貌

Fig. 1 Morphology of MA74Ni master alloy powder

母合金粉末与羰基镍粉(粒径约5 μm)按照质量比26:74的比例在氩气保护下进行混合,混合均匀后与石蜡基黏结剂在150 ℃下进行混炼,粉末装载量为60%。混炼后的喂料在CJ-80E型注射机上进行注射成涡轮生坯与拉伸试样生坯。注射生坯经过溶剂脱脂与热脱脂,脱除黏结剂,然后将脱脂坯在真空环境1 240 ℃烧结2 h,获得烧结坯体。烧结坯体后续通过无包套热等静压工艺进一步提高致密度,热等静压工艺压力为180 MPa,温度为1 210 ℃,保温时间为2 h。

1.2 热力学计算

热力学模拟使用Thermo-Calc软件,获得相关相组成与元素含量。计算过程中使用的数据库为TCNI8。

1.3 样品表征

根据阿基米德排水法测量样品的密度。采用XPS分析仪(Thermo Scientific Escalab 250Xi)测量粉末的XPS曲线。经过电解抛光与电解侵蚀后,γ'相与碳化物的形貌采用场发射电镜(ZEISS ULTRA 55)观察,并使用Image J软件对析出相尺寸进行测量与统计。力学性能测试由WDW-200力学测试系统完成。

2 结果与讨论

2.1 母合金粉末的显微组织与表面状态

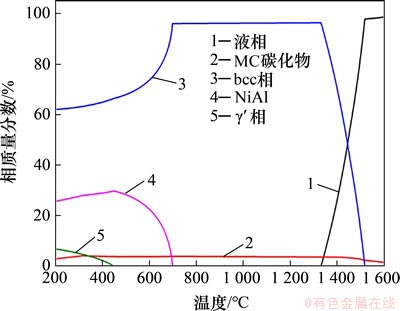

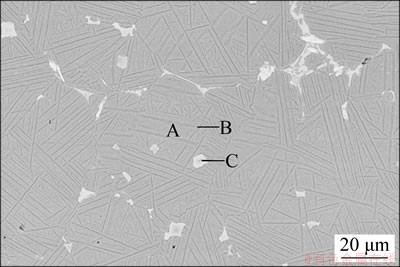

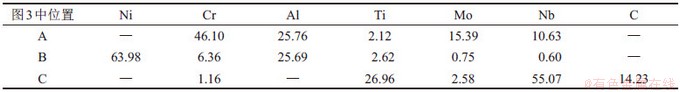

在烧结过程中,母合金粉末与羰基Ni粉之间会发生复杂的扩散与相变,因此,母合金的初始组成将影响烧结过程中合金的扩散均匀化过程,而母合金的表面状态也将直接影响烧结活性,并最终影响合金的致密度与力学性能。首先通过热力学计算获得了MA74Ni母合金的平衡相组成,如图2所示。从图2可以看出,MA74Ni的平衡相主要由富Cr的bcc相、NiAl相组成,同时有少量的γ'相,碳化物类型为富Nb和Ti的MC碳化物。MA74Ni母合金铸锭的显微组织如图3所示,结合热力学计算与EDS能谱分析结果(如表2所示)可以发现,母合金铸锭的主要基体为α-Cr(图3中A点),即富Cr的bcc相。在晶粒内部,NiAl呈长针状分布(图3中B点)。而MC碳化物(图3中C点)主要分布在晶界处,晶界碳化物呈长条形,少量的晶内碳化物呈颗粒状分布。

图2 MA74Ni母合金平衡相组成

Fig. 2 Equilibrium phase composition of MA74Ni master alloy

图3 MA74Ni母合金铸锭的显微组织

Fig. 3 Microstructure of MA74Ni master alloy ingot

表2 图3中不同区域EDS能谱结果(质量分数)

Table 2 EDS results of varied areas in Fig.3 %

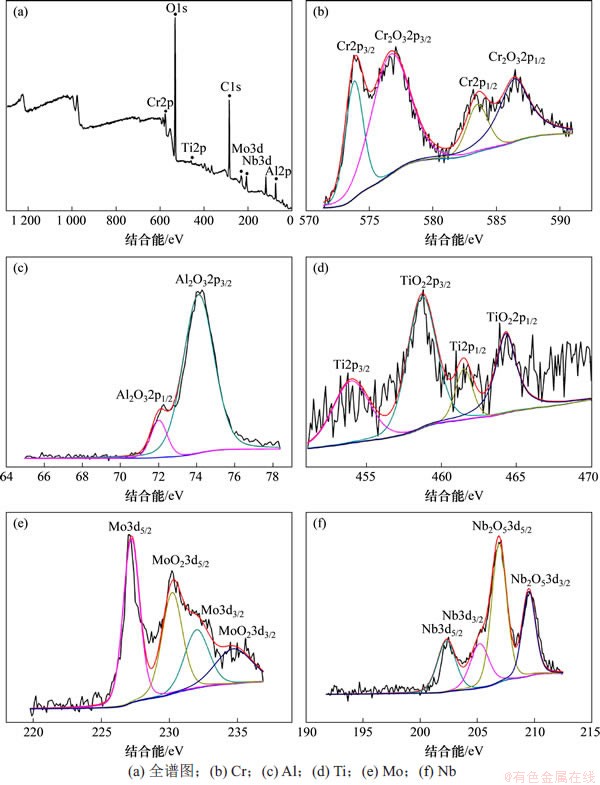

为了表征母合金粉末表面的氧化状态以及表面氧化物类型,对粉末表面进行了XPS分析,结果如图4所示。从图4可见:母合金粉末表面的氧化物主要为Cr2O3,Al2O3,MoO2,Nb2O3和TiO2。除了Al元素,其余元素都存在未氧化的价态。根据拟合峰面积计算得到,氧化物与未氧化态物质质量比为1:1。而Al元素未存在未氧化的价态,这表明母合金表面Al元素氧化严重,均氧化为Al2O3,这将对母合金粉末烧结后的显微组织与性能造成不利影响。

图4 MA74Ni母合金粉末表面的XPS能谱分析结果

Fig. 4 XPS spectrum of the surface of MA74Ni master alloy powder

2.2 脱脂工艺的优化

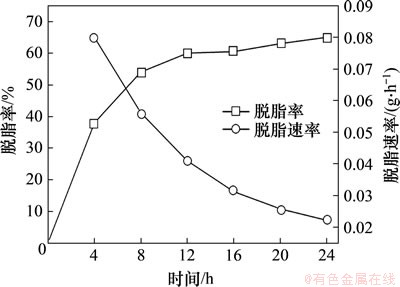

由于涡轮形状复杂,涡轮的芯部与叶片的壁厚相差很大,因此,脱脂过程在注射成形涡轮的制备过程中十分重要,合理的脱脂工艺能够大幅度提高成品率,反之,黏结剂脱除过快或热脱脂工艺不合理,都会导致零件产生不可逆的缺陷,例如鼓泡、开裂等,影响成品率。本文采用溶剂脱脂+热脱脂的两步脱脂工艺。溶剂脱脂在三氯乙烯溶剂中进行,该步骤主要脱除黏结剂中的石蜡。溶剂脱脂温度必须控制在黏结剂的软化点之下,对于石蜡基黏结剂来说,一般低于60 ℃。同时,为了降低溶脱过程中外界环境温度对该过程的影响,三氯乙烯溶剂经过恒温加热保持在30 ℃。图5所示为溶脱过程中脱脂率与脱脂速率的变化曲线。从图5可以看出:在溶剂脱脂过程中,在8 h之前,黏结剂脱除速率较快,脱脂率达到54%,之后脱除速率变小,溶脱24 h时脱脂率达到64.6%。这是由于随着脱脂时间的增加,溶解在三氯乙烯中的石蜡等可溶性黏结剂组分浓度逐渐增加,坯体内的黏结剂中可溶性组分的浓度逐渐减少,两者之间的浓度梯度将减少,溶解减慢,由于坯体厚度很小,小于临界厚度Hc,溶解成为溶脱过程中的主要控制因素,溶解减慢使得溶脱速率下降。同时,坯体内黏结剂中可溶性组分浓度梯度减小,根据菲克定律,扩散将逐渐减慢,溶脱24 h后,可溶性组分基本完全脱除,将溶脱后坯置于干燥箱中于70 ℃烘干4 h以除去坯体孔隙中的溶剂。

图5 溶脱过程中脱脂率与脱脂速率的变化曲线

Fig. 5 Curves of debinding ratio and debinding rate during debinding process

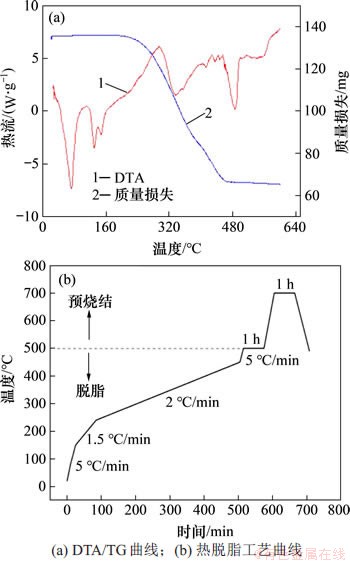

溶脱后,注射坯体中的石蜡基本被脱除,而黏结剂中的骨架成分依然存在于坯体中,维持坯体的形状。这些有机物骨架中含有大量的C和O,因此,在烧结之前需要完全脱除,否则会增加合金的C和O含量,降低合金的性能。图6所示为黏结剂的DTATG曲线与热脱脂工艺曲线。从图6可以看出:黏结剂在80 ℃和150 ℃存在2个吸热峰,在此过程中石蜡和硬脂酸等低熔点物质开始融化,在320,450和500 ℃有明显的吸热峰。从对应的失重曲线可以看出:在这一阶段黏结剂不但软化挥发,而且发生了分解;在200~450 ℃,黏结剂的质量下降明显,因此,选择在该温度区间内保温能够有效脱除粘结剂中的有机物骨架。在该温度区间内缓慢升温,保证黏结剂的脱除速率缓慢,减少坯体的变形率。之后在500 ℃保温1 h,确保黏结剂的完全脱除。然而,一旦黏结剂中的有机物骨架脱除之后,坯体的强度大幅度降低,难以维持其复杂形状。因此,热脱脂过程中增加了预烧结步骤,在有机物骨架完全脱除后,在700 ℃下预烧结1 h,保证脱脂坯体在该步骤后依然具有一定的强度,防止在搬运、存储过程中发生变形或损坏。

图6 黏结剂的DTA/TG曲线与热脱脂工艺

Fig. 6 DTA/TG curve of binder and thermal debinding process

2.3 母合金粉末烧结过程中的致密化机理

由于母合金中合金元素含量高,涉及的相变过程十分复杂,因此,通过热力学计算获得了烧结温度下的相含量变化曲线,如图7所示。从图7可以看出:母合金粉末烧结过程中出现了瞬时液相;随着Ni与母合金之间扩散的进行,界面前沿合金元素浓度下降,液相逐渐消失,最终在扩散均匀化后,合金形成稳定的γ相与MC碳化物。在整个烧结过程中,液相区出现2次,按照先后顺序命名为LP1和LP2,结合液相中合金元素的变化曲线可以发现,LP1液相富Al,而LP2液相主要合金元素为Ni和Cr。然而,在实际的烧结升温过程中,在瞬时液相出现之前合金元素通过固相已经开始向Ni基体中扩散,尤其以Al的扩散最为明显。这在我们之前的研究中已经发现[12],在达到烧结温度前,Al通过固相扩散进入Ni基体中,同时在界面附近形核析出了γ'相。因此,可以推断,在实际烧结是LP1液相少量存在甚至并不出现,主要的瞬时液相为LP2液相,即富Cr的液相。

图7 1 240 ℃下MA74Ni母合金粉末烧结过程中的扩散相变以及液相成分

Fig.7 Phase evolution of MA74Ni master alloy powder during diffusion process at 1 240 ℃ and composition of liquid phase

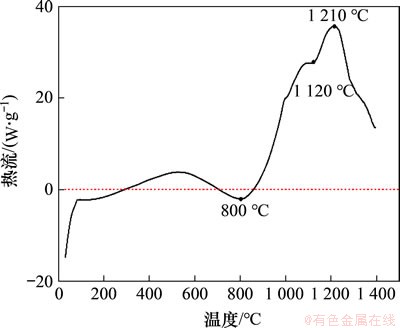

为了进一步研究实际烧结过程中粉体的相变规律,对脱脂后的坯体进行了DSC分析,如图8所示。从图8可以发现:在800 ℃和1 120 ℃有明显的吸热峰,而在1 210 ℃有明显的放热现象。通过热力学计算和瞬时液相烧结规律可知:1 120 ℃为瞬时液相产生的温度,瞬时液相产生后,Ni颗粒部分溶解于液相中,同时,合金元素快速扩散,造成固液界面前沿处合金元素浓度急剧下降;在1 210 ℃时,瞬时液相消失,液相的凝固产生放热现在,在曲线中出现了1个放热峰。

图8 MIM418脱脂坯体的DSC曲线

Fig. 8 DSC curve of MIM418 debinding part

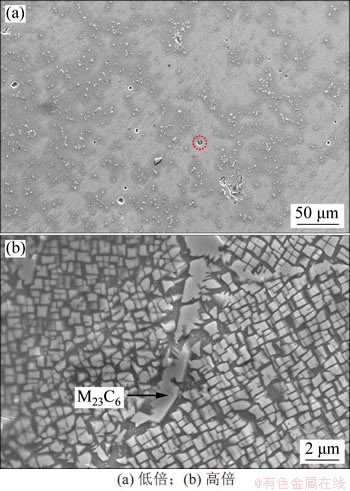

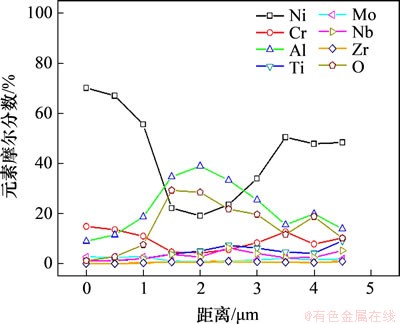

瞬时液相的生成促进了合金的致密化与均匀化过程,在液相存在时,通过颗粒重排促进致密化,同时,固液相互作用提高了扩散速率,促进母合金粉末中的合金元素扩散进入基体中。然而,由于瞬时液相也造成了粉体局部膨胀,在液相凝固后,原本的液相区域留下孔洞,因此,选择烧结温度为略高于瞬时液相消失的温度(1 240 ℃),在该温度下保温消除液相区域的孔洞。在真空气氛下1 240 ℃烧结2 h后,MIM418合金的相对密度达到了96%,其显微组织如图9所示。从图9(a)可以看出,烧结态的显微组织中没有明显元素偏析,但有少量因液相膨胀而留下的孔洞。晶界处存在链状的碳化物相,经EDS能谱分析可知是富Cr的M23C6碳化物。这是由于瞬时液相中主要合金元素为Cr,在等温凝固发生之后与界面处的C结合转变为了富Cr和Mo的M23C6,而在烧结过程中,晶粒倾向于在粉末颗粒界面处形核,使得原先粉末颗粒界面处的富Cr碳化物随着颗粒界面的迁移而停留在晶界处,最终形成了晶界M23C6碳化物。这一现象有利于细化晶粒,钉扎晶界。晶内的γ'相均呈方形,大小均匀,粒径约为0.5 μm。对烧结后存在的孔洞出的合金元素进行了定量分析,孔洞中心Al和O含量达到峰值,而其他合金元素均呈现峰谷。在烧结过程中,由于瞬时液相的出现加速合金元素的扩散均匀化,大部分合金元素向基体内部均匀扩散,但已经形成稳定氧化物的合金元素,在局部熔池形成的过程中变成液相无法溶解的残渣,且流动性较差,无法随着液相在脱脂坯体内部的通孔中迁移,因此,在烧结结束后,随着液相的消失,母合金粉末与基体粉末原有的界面处,母合金粉末表面高熔点氧化物残留形成海绵状残渣,构成局部氧化物集中。而通过XPS分析可知,母合金粉末表面主要的氧化物为Al2O3,结合定量分析也证明了液相孔洞处残留海绵状物质为Al2O3。

图9 MIM418合金烧结态显微组织

Fig. 9 Microstructure of MIM418 superalloy after sintering

图10 图9(a)中标识的孔洞处合金元素的线分布

Fig. 10 Line distribution of alloying elements in pore marked in Fig. 9(a)

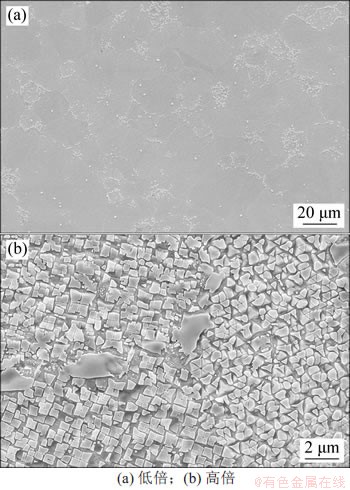

为了进一步提高合金的致密度,消除液相残留孔洞,对烧结后的合金进行了无包套热等静压,经热等静压后,合金的相对密度达到99%以上。热等静压后的显微组织如图11所示。从图11可以看出,热等静压后合金中的孔隙基本闭合。由于热等静压的温度高于合金的固溶温度,因此,在一定程度上也对合金进行了均匀化处理。晶界碳化物相比烧结态尺寸有所减小,分布更加离散,热等静压后γ'相没有明显变化。

图11 MIM418合金热等静压处理后的显微组织

Fig. 11 Microstructure of MIM418 superalloy after HIP

2.4 力学性能

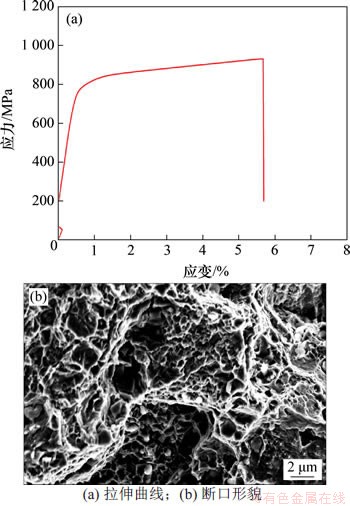

经过热等静压后,MIM418合金拉伸曲线与断口形貌如图12所示。可见:MIM418合金抗拉强度、屈服强度和伸长率分别为913 MPa,788 MPa和5.03%,相比铸造合金(抗拉强度和屈服强度分别为629 MPa和349 MPa)[13],其抗拉强度和屈服强度分别提升了48%和126%。从断口形貌可以看出,断口主要为等轴韧窝断口,韧窝尺寸在1.5 μm左右,断裂方式主要为塑性断裂。

图12 MIM418合金的拉伸曲线与拉伸断口形貌

Fig. 12 Stress-strain curve and fracture morphology of MIM418 superalloy

3 结论

1) 采用注射成形方法,使用低成本母合金粉末制备得到MIM418合金涡轮,相对密度达到96%。

2) 在烧结过程中,通过母合金的瞬时液相促进了粉末坯体的致密化过程以及合金元素的扩散均匀化。液相中主要合金元素为Cr,在等温凝固后演变为晶界碳化物。烧结态样品显微组织均匀,无明显元素偏析。通过后续热等静压处理,母合金法MIM418合金的相对密度提高至99%以上,抗拉强度、屈服强度和伸长率分别为913 MPa,788 MPa和5.03%,远高于铸造法制备的K418合金的力学性能指标。

参考文献:

[1] KANG D S, WOO K D, KIM D G, et al. Heat resistant turbine wheel development of automobile[J]. Advanced Materials Research, 2013, 658: 372-375.

[2] MARTISCHIUS D, WOHLFROMM H, KERN A, et al. Turbocharger technology presents new opportunities for metal injection moulding(MIM)[J]. Powder Injection Moulding Int, 2009(3): 37-42.

[3] SHI Zhaoxia, DONG Jianxin, ZHANG Maicang, et al. Solidification characteristics and segregation behavior of Ni-based superalloy K418 for auto turbocharger turbine[J]. Journal of Alloys and Compounds, 2013, 571: 168-177.

[4] 曲红霞. 镍基高温合金组织性能与净化工艺的研究[D]. 兰州: 兰州理工大学材料科学与工程学院, 2016: 5-10.

QU Hongxia. Investigation of microstructure and mechanical properties and purification technology of nickel-based superalloy[D]. Lanzhou: Lanzhou University of Technology. School of Material Science and Engineering, 2016: 5-10.

[5] 李飞, 侯正乾, 赵彦杰, 等. 熔模铸造工艺对K418B涡轮导向器充型性能与晶粒组织的影响[J]. 铸造技术, 2019, 40(3): 260-262, 275.

LI Fei, HOU Zhengqian, ZHAO Yanjie, et al. Effect of investment casting process on filling performance and grain structure of K418B turbine guide[J]. Foundry Technology, 2019, 40(3): 260-262, 275.

[6] ZHENG X G, SHI Y N, LOU L H. Healing process of casting pores in a Ni-based superalloy by hot isostatic pressing[J]. Journal of Materials Science & Technology, 2015, 31(11): 1151-1157.

[7] ZHANG Lin, CHEN Xiaowei, LI Dan, et al. A comparative investigation on MIM418 superalloy fabricated using gas- and water-atomized powders[J]. Powder Technology, 2015, 286: 798-806.

[8] ZHAO Xiaoming, CHEN Jing, LIN Xin, et al. Study on microstructure and mechanical properties of laser rapid forming Inconel 718[J]. Materials Science and Engineering: A, 2008, 478(1/2): 119-124.

[9] DAVIES P, DUNSTAN G, HOWELLS R, et al. Aerospace adds lustre to appeal of master alloy MIM feedstocks[J]. Metal Powder Report, 2004, 59(10): 14-19.

[10] ORO R, CAMPOS M, TORRALBA J M. Study of high temperature wetting and infiltration for optimising liquid phase sintering in low alloy steels[J]. Powder Metallurgy, 2012, 55(3): 180-190.

[11] DAVIES P A, DUNSTAN R, HOWELLS R. Development of master alloy powders, including nickel-based superalloys for Metal Injection Molding (MIM)[J]. Advanced Powder Metallurgy Part Material, 2003(8): 8-20.

[12] CHEN Xiaowei, LIU Ye, ZHANG Lin, et al. Phase formation and evolution during transient liquid phase sintering of MIM418 superalloy with master alloy addition[J]. Journal of Alloys and Compounds, 2020, 829: 154583.

[13] CHEN Xiaowei, ZHANG Lin, LIU Ye, et al. Phase evolution and densification behavior of MIM418 superalloy utilizing master alloy approach[J]. Journal of Alloys and Compounds, 2019, 771: 33-41.

(编辑 赵俊)

收稿日期: 2020 -08 -30; 修回日期: 2020 -10 -05

基金项目(Foundation item):国家自然科学基金资助项目(51604240; 51974029);湖南省自然科学基金资助项目(2019JJ50585) (Projects(51604240; 51974029) supported by the National Natural Science Foundation of China; Project(2019JJ50585) supported by the Natural Science Foundation of Hunan Province)

通信作者:章林,博士,教授,博士生导师,从事先进粉末冶金材料及成形技术研究;E-mail:zlin@ustb.edu.cn