文章编号:1004-0609(2016)-01-0118-08

研磨-煅烧法制备WO3/ZnS异质结光催化剂及其光催化性能

樊启哲1,余长林1,李家德1,李 鑫1,周晚琴2

(1. 江西理工大学 冶金与化学工程学院,赣州 341000;

2. 江西理工大学 信息工程学院,赣州 341000)

摘 要:采用研磨-煅烧法在ZnS中复合不同含量的WO3(0.5%~8%,质量分数),形成WO3/ZnS异质结光催化剂,利用N2物理吸附、X射线衍射(XRD)、扫描电镜(SEM)、透射电镜(TEM)、紫外可见漫反射光谱(UV-vis DRS)、红外光谱(FT-IR)、光电子能谱(XPS)和光致发光谱(PL)等对合成的样品进行了表征;考察不同WO3含量样品对ZnS的结晶度、比表面积、表面羟基、光吸收性能的影响,并以λ=254 nm的紫外光为光源,评价该催化剂光催化降解酸性橙Ⅱ的活性,考察WO3复合对WO3/ZnS样品光催化性能的影响。结果表明:WO3的复合可抑制ZnS晶粒在煅烧过程中的长大,同时提高催化剂的比表面积和催化剂表面的羟基数量,并能有效地抑制光生电子与空穴的复合。当复合1%WO3(质量分数),所制备的WO3/ZnS催化剂的活性最高,比纯ZnS的活性提高了1.8倍。其原因是复合样品具有较好的组织结构的性能,同时,形成的WO3/ZnS异质结有利于光生电子与空穴的分离,从而显著提高光催化剂的脱色活性和稳定性。

关键词:研磨-煅烧; ZnS;WO3 耦合;异质结;光催化;染料

中图分类号:O644.1 文献标志码:A

半导体光催化技术在环境污染物的降解和能源转化具有潜在的运用前景[1-6]。在已研究的半导体光催化剂中,二氧化钛研究和使用最多[7-9]。与钛基催化剂相比,锌基半导体(ZnO、ZnS等)光催化剂的主要缺点是催化活性不高,同时易发生光腐蚀,导致稳定性低。ZnO和ZnS光催化性质和他们的晶体结构、形貌和表面性能密切相关。如NASI等[10]等报道用乙二胺制备的ZnS纳米粒子对亚甲基蓝具有较强的光催化降解能力。另外采用金属沉积[11]、金属离子掺杂[12],石墨烯或碳纳米管复合[13-14]可较大幅度提高ZnS的光催化活性。如CHEN等[11]则报道了用半胱氨酸辅助合成的ZnS-Au复合纳米晶能高效降解硫堇;ZHANG等[13]发现ZnS-石墨烯纳米复合物具有很强的可见光催化能力。本文作者的近期研究表明[15-17],在ZnO表面形成WO3/ZnO、MoO3/ZnO和Bi2WO6/ZnO异质结可以大幅度提高ZnO的光催化活性和抗光腐蚀性能。当不同的半导体紧密接触时,会形成异质结,在异质结的两侧由于其能带等性质的不同会形成空间电势差。这种空间电势差的存在可使光生载流子从一种半导体的能级注入到另一种半导体的能级,从而有利于电子-空穴的分离,提高光催化的效率[18]。

本文作者采用研磨-煅烧法在ZnS中复合不同含量的WO3(0.5%~8%,质量分数),形成WO3/ZnS异质光催化剂,考察WO3复合对ZnS结构、表面性质、光生电子和空穴对的分离效率及光催化降解酸性橙Ⅱ的性能影响,发现少量WO3的复合可以显著提高ZnS的光催化活性和稳定性。

1 实验

1.1 WO3/ZnS制备

所用试剂均为分析纯,来自上海国药集团。首先制备黄钨酸。准确称取3.00 g钨酸钠(Na2WO4·2H2O)和0.05 g十六烷基三甲基溴化铵(CTAB)溶于10 mL去离子水中,磁力搅拌使其完全溶解,然后缓慢滴入

10 mL 1.5 mol/L硝酸溶液,继续搅拌2 h。过滤,用去离子水、无水乙醇洗涤3次,80 ℃恒温干燥,得到黄钨酸备用。然后制备WO3/ZnS复合催化剂。按摩尔比为1:1称取硫化钠(Na2S·9H2O)和二水合醋酸锌(Zn(CH3COO)2·2H2O,AR),分别溶于适量蒸馏水中,缓慢混合,不断搅拌至完全沉淀。对沉淀进行过滤,用去离子水、无水乙醇洗涤3次,80 ℃恒温干燥。按不同的质量分数加入上述所得黄钨酸,充分研磨30 min后于马弗炉中以3 ℃/min升温速率升温到350 ℃煅烧2 h,得到不同含量的WO3/ZnS复合催化剂。W和其他元素的最终含量用PW2424 型X荧光分析仪(荷兰Panalytical)分析测定。同时,采用煅烧法制备纯WO3和ZnS催化剂。

1.2 试样的性能表征

在北京金埃谱科技有限公司生产的V-Sorb2800比表面积及孔径分析仪上进行N2物理吸附-脱附测定样品的比表面积。试测试前,样品首先在150 ℃的真空下脱气处理2 h,然后以N2为吸附质在77 K下恒温吸附。比表面积通过BET方程求得。样品的X射线粉末衍射(XRD)表征在德国Bruker D8型X射线衍射仪(Cu Kα λ=0.154178 nm)上进行。电压40 kV,电流40 mA,扫描速率5 (°)/min,扫描范围10°~80°。采用Nova Nano SEM 230扫描电子显微镜(SEM)(美国FEI)观察样品整理形貌。紫外可见漫反射光谱(UV–vis DRS)在UV-2550(日本岛津)型紫外可见分光光度计上获得,以BaSO4做参照。样品的傅里叶红外光谱分析采用Bruker Tensor 27(德国布鲁克)型红外光谱仪测得,使用KBr压片制样。室温下,利用日立F-4600(日本Hitachi)型荧光光谱仪测试样品的光至发射光谱(PL),以400 nm激光做激发光源。样品各元素的化学价态利用Quantum2000型X射线光电子能谱(XPS)(荷兰飞利浦)分析获得。

1.3 光催化降解染料酸性橙Ⅱ

光催化反应在自制的光催化反应器中进行。光反应器中心光源为7 W 紫外灯(254 nm, Cole-Parmer 仪器公司)。 在光催化反应中,染料酸性橙Ⅱ溶液的初始浓度为20 mg/L,溶液体积为80 mL,催化剂用量为50 mg。反应前,含催化剂的染料悬浮液在暗处搅拌吸附40 min 以达平衡,然后打开光源. 在光照的不同时间段取样1~2 mL,高速离心分离后,除去里面的催化剂颗粒,用721型分光光度计在 484 nm 处测定上层清液的吸光度。根据下式计算得酸性橙Ⅱ的降解率D,即D=(A0-A)/A0×100%(其中,A0和A分别为染料的初始吸光度和降解后的吸光度)。

2 结果与讨论

2.1 XRD和比表面积分析

采用X射线粉末衍射分析复合WO3对ZnS的结晶性能和晶相的影响。图1所示为含不同WO3的复合量样品的XRD谱。从图1中可以看出,各样品在(111)、(220)和(311)晶面出现了较强的特征衍射峰,与PDF卡中的ZnS(65-5476)相吻合,表明产物均为立方闪锌矿结构的ZnS,这些峰的峰形尖锐,说明合成的样品具有较高的结晶度。图中并未发现WO3的特征衍射峰,其主要原因是由于WO3处于高度分散状态或其浓度较低。为了考察复合WO3对样品晶粒大小的影响,根据Scherrer公式D=0.89λ/(βcosθ)计算ZnS的平均晶粒尺寸D(式中β为(111)晶面对应的最强衍射峰的半峰宽,λ为入射光波长(0.154 nm),θ为该晶面对应的衍射角)。计算得到的各样品的平均晶粒尺寸见表1。由表1中的数据可以看出,复合WO3对ZnS的平均晶粒尺寸略有影响,且随WO3含量的增加,WO3/ZnS样品的粒径逐渐减小,表明WO3的存在可以在一定程度上抑制ZnS粒子在煅烧过程中发生长大。这可能是由于W6+离子的半径为68  ,而Zn2+离子的半径为74

,而Zn2+离子的半径为74  ,两者相差不大,在煅烧过程中可能有部分W6+离子可以进入到ZnS的晶格中,抑制ZnS晶粒的长大。

,两者相差不大,在煅烧过程中可能有部分W6+离子可以进入到ZnS的晶格中,抑制ZnS晶粒的长大。

图1 样品的XRD谱

Fig. 1 XRD patterns of samples

表1 样品的平均晶粒粒径

Table 1 Average grain size of prepared samples

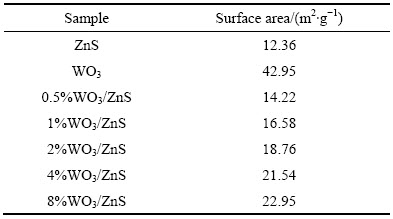

表2所列为所制备光催化剂的比表面积。从表2可以看出,所制备的纯ZnS和WO3的比表面积分别为12.36和42.95 m2/g。随着WO3复合含量的增加,WO3/ZnS复合光催化剂的比表面积逐渐增大,这可能是由于WO3自身的比表面积较大。另外,WO3复合可能在一定程度上抑制了ZnS颗粒在煅烧过程发生烧结长大,从而有利于比表面积的增大,较大的比表面积往往有利于反应底物和光的吸附,进而提高样品的光催化活性。

表2 样品的比表面积

Table 2 Surface area of samples

2.2 SEM和TEM分析

采用扫描电镜和透射电镜对1% WO3/ZnS典型样品进行整体形貌和颗粒大小进行分析。图2所示为 WO3/ZnS的SEM和TEM像。由图2(a)可以看出,样品由尺寸比较均匀的不规则颗粒组成,颗粒的粒径大约在1 μm左右。图2 (b)表明,所制备的1% WO3/ZnS的一次粒子的大小比较均匀,约为1.5~3 nm,这和前面的XRD的计算结果基本一致。

2.3 紫外-可见漫反射光谱(UV-vis DRS)分析

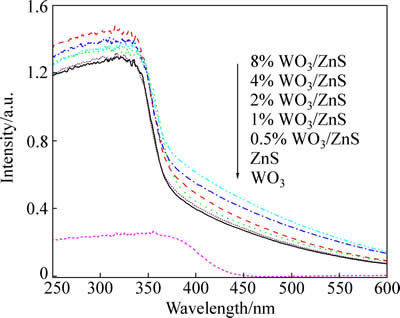

紫外可见漫反射吸收光谱可以反映固体样品对不同波长的光吸收情况及样品的带隙能变化。图3所示为纯ZnS、WO3/ZnS以及纯WO3样品的紫外可见漫反射吸收光谱。由图3可以看出,纯ZnS在300~380 nm的紫外光波段具有较强吸收峰,而在可见光波段(>420 nm)具有一定的吸收能力。同时,发现WO3在紫外和可见光的吸收也很弱。复合WO3之后,复合样品的吸收边略向长波方向移动,且随着WO3含量的提高,吸收能力显著增强,同时,吸收边红移也越明显。其可能原因是由于部分W6+离子进入ZnS晶格后,在ZnS中产生缺陷氧空位,因此,在ZnS的导带和价带之间形成了缺陷氧能级,从而导致吸收边发生红移。分别做它们的吸收曲线的切线与X轴相交得样品的光吸收边,即光吸收阈值λg,然后根据带隙能(eV)公式:Eg=1240/λg,估算出各催化剂的带隙能Eg,其结果见表3。表3表明,复合WO3后,复合催化剂的带隙能略有降低。

图2 1% WO3/ZnS样品的SEM像和TEM像

Fig. 2 SEM (a) and TEM (b) images of 1% WO3/ZnS sample

图3 样品的UV-vis DRS谱

Fig. 3 UV-vis DRS of samples

表3 样品的带隙能

Table 3 Band gap energy of samples

2.4 样品的光致发光(PL)光谱

光致发光谱通常可以用来表征光催化剂的光生电子空穴对的复合强度。实验中的光致发光谱是在激发波长为400 nm和室温条件下获得的。图4所示为纯ZnS和WO3/ZnS样品的光致发光光谱。由图4可知,各样品的发射峰都在480~500 nm附近,其归属可能是由于在ZnS晶体中形成的Zn2+缺陷导致的发光所引起。加入少量的WO3时,样品的发射峰强度大幅减弱,表明WO3的存在减少了ZnS表面光生电子与光生空穴的复合,其原因在于Zn2+缺陷可能得到抑制或W6+能够有效捕获光生电子(e),从而加速光生电子(e)和空穴(h+)对的分离,减少了半导体表面光生电子-空穴对的复合几率。光催化反应中,e和h+可以分别生成O2.-和·OH等自由基,这些自由基是降解染料的主要活性基团。由图4还可以发现,复合样品的发射峰强度还和WO3的含量密切相关。当WO3复合量为1%时,发射峰强度降到最低,说明此时样品的光生电子-空穴对的复合几率达到最低,这表示该样品可能具有更高的光催化活性。继续增加WO3的含量,发光强度反而上升。

图4 样品的光致发光(PL)光谱

Fig. 4 PL spectra of samples

2.5 红外光谱(FT-IR)分析

图5所示为各样品的FT-IR谱。由图5可见,各样品在3440 cm-1附近出现的较宽的吸收峰和1640 cm-1附近出现的尖锐的吸收峰,分别对应于ZnS表面羟基的特征弯曲振动峰。催化剂表面的羟基通常被认为在光催化氧化反应中可以捕获空穴生成氧化染料分子的羟基自由基(·OH)。因此,催化剂表面羟基的数量和催化剂的光催化活性密切。羟基越丰富,越有利于光催化性能的提高[19]。由文献[20]可知,氧化钨的红外光谱中在930、880、774 cm-1附近存在吸收峰。但是在WO3/ZnS中,并没有发现WO3的特征吸收峰,这可能是由于WO3与ZnS产生了较强的相互作用,导致WO3的特征吸收峰消失。此外,由于WO3和ZnS在614 cm-1与1423 cm-1附近均无吸收峰,在这两处出现的吸收峰可能是WO3与ZnS的相互作用形成了W—S—Zn键所而产生的峰。而480 cm-1附近的吸收峰为Zn—S键的特征伸缩振动峰。从图5中还可以看出,加入一定量的WO3使得3440 cm-1处的表面羟基峰变强,表明复合催化剂具有更丰富的表面羟基,这可能是由于WO3的存在,改善了催化剂的比表面积等表面性能。在染料分子的光催化降解反应中,羟基自由基是其被氧化的主要活性物种。因此,WO3/ZnS的光催化性能将可能提高。

图5 样品的FT-IR谱

Fig. 5 FT-IR infrared spectra of samples

2.6 光电子能谱(XPS)分析

典型样品1%WO3/ZnS中各元素的化学价态利用X射线光电子能谱(XPS)进行分析,获得各元素的高分辨光电子能谱图结果如图6所示。由图6(a)可看出,O1s的结合能为531 eV, 比文献[21]报道的530 eV略高,这可能由于WO3与ZnS产生了较强的相互作用;S2p的结合能为 161.7 eV, 表明样品中的S 为S2-;W4f7/2和 W 4f5/2结合能分别为35.53eV和37.67 eV,表明W的化学价态为W6+,这与文献[22]报道的W6+的化学价态一致; Zn 2p的结合能为1021.5 eV,表明Zn为W2+[23]。

图6 1%WO3/ZnS的XPS谱

Fig. 6 XPS spectra of 1%WO3/ZnS

2.7 光催化性能测试

以波长为254 nm的紫外灯为光源,对含有染料酸性橙Ⅱ的水溶液进行光催化活性测试。反应开始前,先于暗处搅拌吸附40 min达到物理吸附和脱附平衡后打开光源。染料浓度随光照时间的变化曲线如图7(a)所示。酸性橙Ⅱ没有光催化存在时,在光照下基本没光解发生,说明它是一个稳定的分子。由图7(a)可知,纯WO3的活性较低,经紫外灯光照6 h后,染料酸性橙Ⅱ的降解率还不到15%。但是复合少量的WO3(1%)后,WO3/ZnS复合光催化剂的活性有了很大的提高。但继续增加WO3的含量,其光催化活性又开始降低。为了定量了解不同WO3复合量的对ZnS催化剂降解染料反应动力学常数的影响,采用准一级动力学方程ln(c/c0)=kt求解近似光催化降解一级速率常数[24]。式中c0和c分别为0和t时刻染料溶液的浓度。图5(b)是以ln(c/c0)对时间t做线性回归分析,发现ln(c/c0)与t呈良好线性关系(R2>0.97),得到的各样品对染料酸性橙Ⅱ的催化反应速率常数,其数值同时列于图中。由图7(b)可以看出,染料的降解反应表现一级动力学过程。1%WO3/ZnS对酸性橙Ⅱ的降解速率常数达到最大,为0.39 h-1,是纯ZnS的1.8倍。为了比较1%WO3/ZnS和ZnS的稳定性,对这两个催化剂进行循环反应。经过5次循环后,1%WO3/ZnS对酸性橙Ⅱ的降解率由第1次的91% 降到65%,而在ZnS上的酸性橙Ⅱ的降解率由第1次的77% 降到40%。因此,复合1%WO3时,1%WO3/ZnS的活性和稳定性同时得到大幅度提高。

同时,对该系列催化剂进行可见光降解染料酸性橙Ⅱ的性能测试。测试时将紫外灯换为300瓦钨灯,其它条件相同。测试结果见图8。由图8可见,WO3和ZnS在可见光照射下,对染料具有一定的降解活性。

图7 紫外光下不同含量WO3复合催化剂对染料酸性橙Ⅱ光催化降解性能比较

Fig. 7 Comparison of photocatalytic performance of catalysts with different WO3 contents under UV light irradiation

图8 可见光下不同含量WO3复合催化剂对染料酸性橙Ⅱ光催化降解性能比较

Fig. 8 Comparison of photocatalytic performance of catalysts with different WO3 contents in degradation of acid orange II under visible light irradiation

当WO3和ZnS复合后,可见光催化活性也有一定程度的提高。

2.8 光催化机理分析

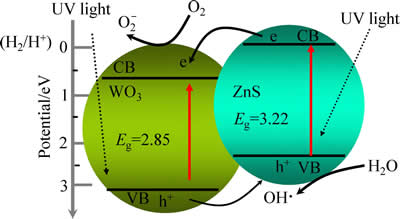

为了理解WO3/ZnS活性提高的机理,利用电负性原理结合紫外-可见漫反射光谱测试结果,对WO3和ZnS的电子能级结构进行分析。半导体的导带(CB)和价带(VB)的电势可以根据公式[25-26]:EVB=X-Ee+0.5Eg进行计算(式中X是半导体的几何平均电负性;Ee的取值为4.5 eV;EVB时价带顶的电势;Eg是半导体的禁带宽度),可以根据公式 Eg=1240/λg (eV)进行计算(式中λg是半导体的紫外-可见漫反射光谱吸收边)。这里WO3和ZnS的Eg分别为2.85 eV和3.22 eV。WO3和ZnS的平均电负性X 值分别为 6.57 eV 和5.26 eV。根据以上结果计算得到WO3的价带顶和导带底的位置分别为3.50 eV和0.65 eV;ZnS的价带顶和导带底的位置分别为2.37 eV和-0.85 eV。它们的能级关系见图9。ZnS的价带和导带位置比WO3更负,当WO3与ZnS复合后,由于它们的价带和导带能级位置的差异,可形成空间电势差。ZnS导带中被激发的电子容易被WO3接受,W6+易被还原成W5+[27]成为俘获电子的中心,同时,ZnS价带产生的空穴可以迁移到WO3的价带上去,这样就加速了光生电子和空穴的分离,降低了光生电子和空穴的复合几率,从而提高了其光催化活性。但是继续提高WO3的复合量时,浓度过高的WO3会破坏WO3在ZnS上的分散,且捕获载流子的捕获位间距离变小,WO3反而可能成为电子和空穴的复合中心,使得光生电子-空穴分离效率降低,从而降低了样品的光催化活性。

图9 WO3/ZnS复合光催化剂的光催化机理

Fig. 9 Photocatalytic mechanism of WO3/ZnS composite photocatalyst

3 结论

1) 采用研磨-煅烧法制备系列WO3/ZnS异质结复光催化剂,研究复合不同含量的WO3对ZnS结构、表面性质、光生电子和空穴对的分离效率及光催化降解酸性橙II的性能影响。

2) 少量WO3的复合可以抑制ZnS晶粒在煅烧过程中的长大,提高催化剂的比表面积和改善催化剂的表面羟基数量。

3) WO3/ZnS异质的形成可抑制光生电子与光生空穴的复合,从而显著提高其光催化脱色活性和稳定性。

REFERENCES

[1] YU C L, YANG K, XIE Y, FAN Q Z, YU J C, SHU Q, WANG C Y. Novel hollow Pt-ZnO nanocomposite microspheres with hierarchical structure and enhanced photocatalytic activity and stability[J]. Nanoscale, 2013, 5: 2142-2151.

[2] 刘国聪, 金 真, 张喜斌, 李险峰, 刘 鸿. La掺杂BiVO4微米球的水热合成和光催化性能[J]. 中国有色金属学报, 2013, 23(3): 793-801.

LIU Guo-cong, JING Zhen, ZHANG Xi-bing, LI Xian-feng, LIU Hong. Hydrothermal synthesis and photocatalytic properties of La-doped BiVO4 microspheres[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 793-801.

[3] WU D Z, FAN X M, TIAN K, DAI J, LIU H R. Fabrication and photocatalytic properties of Cu2S/T-ZnOw heterostructures via simple polyol process[J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1620-1628.

[4] ZHOU W Q, YU C L, FAN Q Z, WEI L F, CHEN J C, YU J C. Ultrasonic fabrication of N‐doped TiO2 nanocrystals with mesoporous structure and enhanced visible light photocatalytic activity[J]. Chinese Journal of Catalysis, 2013, 34(6): 1250-1255.

[5] 李爱昌, 赵 娣, 李 倩, 张 敬, 郑彦俊. (NiMo)TiO2纳米薄膜的制备及其光催化降解罗丹明 B 的性能[J]. 中国有色金属学报, 2012, 22(2): 526-532.

LI Ai-chang, ZHAO Di, LI Qian, ZHANG Jing, ZHENG Yan-jun. Preparation of (NiMo)TiO2 thin films and their photocatalytic activity of Rhodamine B[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 526-532.

[6] 余长林, 陈建钗, 操芳芳, 李 鑫, 樊启哲, YU Jimmy C, 魏龙福. Pt/BiOCl 纳米片的制备、表征及其光催化性能[J].催化学报, 2013, 34(2): 385-390.

YU Chang-lin, CHEN Jian-chai, CAO Fang-fang, LI Xin, FAN Qi-zhe, YU Jimmy C, WEI Long-fu. Preparation, characterization, and photocatalytic properties of Pt/BiOCl nanoplates[J]. Chinese Journal of Catalysis, 2013, 34(2): 385-390.

[7] YU C L, YU J C. A simple way to prepare C-N-codoped TiO2 photocatalyst with visible light activity[J]. Catal Lett, 2009, 129: 462-470.

[8] HENDERSONM A, LYUBINETSKY I. Molecular-level insights into photocatalysis from scanning probe microscopy studies on TiO2(110)[J]. Chem Rev, 2013, 113(6): 4428-4455.

[9] YU C L, YU J C, CHAN M. Sonochemical fabrication of fluorinated mesoporous titanium dioxide microspheres[J]. J Solid State Chem, 2009, 182: 1061-1069.

[10] NASI L, CALESTANI D, BESAGNI T, FERRO P, FABBRI F, LICCI F, MOSCA R. ZnS and ZnO nanosheets from ZnS(en)0.5 precursor: Nanoscale structure and photocatalytic properties[J]. J Phys Chem C, 2012, 116(12): 6960-6965.

[11] CHEN W T, HSU Y J. L-cysteine-assisted growth of core-satellite ZnS-Au nanoassemblies with high photocatalytic efficiency[J]. Langmuir, 2010, 26(8): 5918-5925.

[12] 王海鹰, 杨 洋, 卢晓峰, 王 策. 硫化锌掺锰/聚乙烯醇复合纳米纤维的制备与表征[J]. 高等学校化学学报, 2006, 27(9): 1785-1787.

WANG Hai-Ying, YANG Yang, LU Xiao-Feng, WANG Che. Preparation and characterization of ZnS: Mn/PVA composite nanofibers via electrospinning[J]. Chemical Journal of Chinese Universities, 2006, 27(9): 1785-1787.

[13] ZHANG Y H, ZHANG N, TANG Z R, XU Y J. Graphene transforms wide band gap ZnS to a visible light photocatalyst. The new role of graphene as a macromolecular photosensitizer[J]. ACS Nano, 2012, 6(11): 9777-9789.

[14] FENG Shou-ai, ZHAO Jiang-hong, ZHU Zhen-ping. The manufacture of carbon nanotubes decorated with ZnS to enhance the ZnS photocatalytic activity[J]. New Carbon Materials, 2008, 23(3): 228-234.

[15] 余长林, 杨 凯, 舒 庆, YU Jimmy C, 操芳芳, 李 鑫. WO3/ZnO 复合光催化剂的制备及其光催化性能[J]. 催化学报, 2011, 32(4): 555-565.

YU Chang-lin, YANG Kai, SHU Qing, YU Jimmy C, CAO Fang-fang, LI Xin. Preparation of WO3/ZnO composite photocatalyst and its photocatalytic performance[J]. Journal of Chinese Catalysis, 2011, 32(4): 555-565.

[16] YU C L, YANG K, SHU Q, YU J C, CAO F F, LI X, ZHOU X C. Preparation, characterization and photocatalytic performance of Mo-doped ZnO[J]. Science in China Chemistry, 2012, 55(9): 1807-1815.

[17] 余长林, 杨 凯, YU Jimmy C, 操芳芳, 李 鑫, 周晓春. 水热合成Bi2WO6/ZnO 异质结型光催化剂及其光催化性能[J]. 无机材料学报, 2011, 26(11): 1157-1163.

YU Chang-lin, YANG Kai, YU Jimmy C, CAO Fang-fang, LI Xing, ZHOU Xiao-chun. Hydrothermal synthesis and photocatalytic performance of Bi2WO6/ZnO heterojunction photocatalysts[J]. Journal of Inorganic Materials, 2011, 26(11): 1157-1163.

[18] YU C L, YANG K, YU J C, CAO F F, LI X, ZHOU X C. Fast fabrication of Co3O4 and CuO/BiVO4 composite photocatalysts with high crystallinity and enhanced photocatalytic activity via ultrasound irradiation[J]. J Alloys Compd, 2011, 509: 4547-4552.

[19] HAN X G, HE H Z, KUANG Q, ZHOU X, ZHANG X H, XU T, X Z X, ZHENG L S. Controlling morphologies and tuning the related properties of nano/microstructured ZnO crystallites[J]. J Phys Chem C, 2009, 113: 584-589.

[20] GERALD G J, ARTHUR D, GUO J D, ZAVALIJ P, Whittingham M S. Novel tungsten, molybdenum, and vanadium oxides containing surfactant ions[J]. Chem Mater, 1996, 8(8): 2096-2101.

[21] YU C L, YU J C, ZHOU W Q, YANG K. WO3 coupled P-TiO2 photocatalysts with mesoporous structure[J]. Catal Lett, 2010, 140: 172-183.

[22] DUPIN J C, GONBEAU D, VINATIER P, LEVASSEUR A. Systematic XPS studies of metal oxides, hydroxides and peroxides[J]. Phys Chem Chem Phys, 2000, 2: 1319-132.

[23] YU C L, YU J C. Sonochemical fabrication, characterization and photocatalytic properties of Ag/ZnWO4 nanorod catalyst[J]. Mater Sci Eng B, 2009, 164: 16-22.

[24] YU C L, FAN C F, YU J C. Preparation of bismuth oxyiodides and oxides and their photooxidation characteristic under visible/UV-light irradiation[J]. Mater Res Bull, 2011, 46: 140-146.

[25] KIM Y, ATHERTON S J, BRIGHAM E S, MALLOUK T E. Sensitized layered metal oxide semiconductor particles for photochemical hydrogen evolution from nonsacrificial electron donors[J]. J Phys Chem, 1993, 97: 11802-11810.

[26] DAI G P, YU J G, LIU G. Synthesis and enhanced visible-light photoelectron catalytic activity of p–n junction BiOI/TiO2 nanotube arrays[J]. J Phys Chem C, 2011, 115: 7339-7346.

[27] TENNAKONE K, HEPERUMA O A, BANDARA J M S, KIRIDENA W C B. TiO2 and WO3 semiconductor particles in contact: photochemical reduction of WO3 to the non-stoichiometric blue form[J]. Semicond Sci Technol, 1992, 7(3): 423-424.

WO3/ZnS heterostructured photocatalysts prepared by grinding-calcination method and their photocatalytic performance

FAN Qi-zhe1, YU Chang-lin1, LI Jia-de1, LI Xin1, ZHOU Wan-qin2

(1. School of Metallurgy and Chemical Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China;

2. School of Information Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China)

Abstract: WO3 with different concentrations (0.5%, 1%, 2%, 4%, 8%) were coupled with ZnS by a grinding-calcination method and WO3/ZnS heterostructured photocatalyst was obtained. The prepared samples were characterized by N2- physical adsorption, X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), Fourier Transform Infrared spectroscopy (FT-IR), UV-visible spectroscopy, X-ray photoelectron spectroscopy (XPS) and photoluminescence (PL) spectroscopy. The photocatalytic activity of the samples was evaluated by photocatalytic degradation of acid orange II under UV light (λ=254 nm) irradiation. The results show that the coupling of WO3 can suppress the growth of ZnS crystals during the process of calcination, increase the surface area and enrich the surface OH groups of the sample. Moreover, the presence of WO3 restrains the recombination rate of photo generated e/h+ pairs. The photocatalytic activity of WO3/ZnS composite photocatalyst with 1% WO3 (mass fraction) increases about 1.8 times than that in pure ZnS. The increase of photocatalytic activity and stability is attributed to the improved texture property. Moreover, the formation of WO3/ZnS heterostructure greatly promotes the separation of e/h+ pairs.

Key words: grinding-calcination; ZnS; WO3 coupling; heterostructure; photocatalytic; dyes

Foundation item: Projects (21067004, 21567008, 21263005) supported by the National Natural Science Foundation of China; Project (GJJ12344) supported by Fund of Scinece and Technology in Jiangxi Province Department of Education, China; Project (20133BAB21003) supported by Jiangxi Province Natural Science Foundation of China Youth Science Fund, China; Project (KJLD14046) supported by the Landing Project of Science and Technology of Colleges and Universities in Jiangxi Province, China; Project (20122BCB23015) supported by Young Scientists Cultivating Object Program of Jiangxi Province, China

Received date: 2015-01-30; Accepted: 2015-04-03

Corresponding author: YU Chang-lin; Tel: 0797-8312334; E-mail: yuchanglinjx@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(21067004,21567008,21263005);江西省教育厅科技基金资助项目(GJJ12344);江西省自然科学基金青年科学基金计划(20133BAB21003);江西省教育厅高等学校科技落地计划项目(KJLD14046);江西省青年科学家培养项目(20122BCB23015)

收稿日期:2015-01-30;修订日期:2015-04-03

通信作者:余长林,教授,博士;电话:0797-8312334;E-mail:yuchanglinjx@163.com