文章编号:1004-0609(2010)12-2320-07

置氢Ti-6Al-4V合金的切屑形成过程与机制

李 红1,孙中刚2, 侯红亮1,傅玉灿3

(1. 北京航空制造工程研究所,北京 100024;

2. 大连理工大学 材料科学与工程学院,大连 116085;

3.南京航空航天大学 机电学院,南京 210016)

摘 要:利用金相显微镜、X射线衍射仪和扫描电镜对置氢Ti-6Al-4V合金的微观组织和相组成及切屑形貌进行了观察分析,采用分离式Hopkinson压杆试验测试置氢Ti-6Al-4V合金的动态力学性能,研究氢对Ti-6Al-4V切屑形成过程及切屑形态的影响,探讨置氢Ti-6Al-4V合金的切屑形成机制。结果表明:置氢后Ti-6Al-4V合金切屑的收缩系数增加,表面层片结构尺寸减小,切屑锯齿化程度减轻;氢含量低于0.4%(质量分数)时,局部材料热塑失稳是形成锯齿切屑的主要原因,随氢含量增加,钛合金切屑的绝热剪切现象减轻,随着氢含量的进一步增加,锯齿切屑的形成是由微裂纹而致。

关键词:Ti-6Al-4V合金;置氢;切屑形成;绝热剪切

中图分类号:TG 146.2 文献标志码:A

Process and mechanism of chip formation in

cutting hydrogenated Ti-6Al-4V alloys

LI Hong1, SUN Zhong-gang2, HOU Hong-liang1, FU Yu-can3

(1. Beijing Aeronautical Manufacturing Technology Research Institute, Beijing 100024, China;

2. School of Material Sciences and Engineering, Dalian University of Technology, Dalian 116085, China;

3. School of Mecharonics, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China)

Abstract: The microstructure and phase composition of hydrogenated Ti-6Al-4V alloys and the morphology of chip were observed optical microscopy, X-ray diffractometry and scanning electron microscopy. The split Hopkinson bar was employed to test the dynamic mechanical property. The morphology and mechanism of chip formation in cutting Ti-6Al-4V alloys were investigated. The results show: compared with unhydrogenated chip, the chip compression ratio of hydrogenated Ti-6Al-4V alloys is greater, the dimension of lamellae and saw-tooth are less significantly. The thermo-plastic instability is the mechanism of saw-tooth chips formation due to the large plastic deformation when the addition o hydrogen is less than 0.4% (mass fraction). In contrast, the crack initiation mechanism is responsible for the saw-tooth chip with more hydrogen content.

Key words: Ti-6Al-4V alloy; hydrogen treatment; chip formation; adiabatic shearing

由于钛合金屈强比高、导热性差和弹性模量小,且与刀具的亲和性强,导致切削效率低,仅为铝合金加工效率的15%,因而切削过程具有尺寸控制难、刀具寿命短等问题。目前,国内外主要通过合理选择刀具、优化切削参数、改善切削条件等手段改善其切削加工性,并在一定程度上提高了生产效率。近年来,利用钛合金中氢的可逆合金化作用,通过对钛合金的热氢处理重构其微观组织,改变合金的热物性能、摩擦性能和力学性能等,从而从合金内部的本征角度改善其切削加工性能[1-2],并在切削加工后利用真空除氢去除残余氢以保证其服役性能,是一种有效的改善切削加工性能的新方法。KOLACHEV等[2-3]的研究表明,钛合金中加入适量的氢可以显著改善其切削加工性能,可以降低切削区温度和切削力,切削区温度可降低50~150 ℃,切削力降低1.3~1.5倍,改善切屑的形成,使带状切屑转变为断屑,提高刀具寿命和加工效率,刀具寿命可提高2~10倍。

切屑的形成与切削力、切削热的大小、刀具磨损的快慢以及加工表面质量均有直接的关系,并影响积屑瘤、断屑与切削过程振动等[4-5]。本文作者在分析置氢Ti-6Al-4V组织和力学性能变化规律的基础上,从宏观和微观角度阐明了组织与性能变化对切屑形成过程与机制的影响, 对深入研究置氢钛合金的切削行为及其控制具有重要的参考价值。

1 实验

实验材料为轧制退火态Ti-6Al-4V(TC4)棒材,切削试样尺寸为d16 mm×110 mm。采用管式氢处理炉进行置氢实验,抽真空至5×10-3 Pa以上,加热至800 ℃,充入高纯氢气,保温6 h,随炉冷却至室温。通过高精度物理天平采用称重法测定试样的实际氢含量,天平感量为10-5 g。

采用CA6140车床进行切削实验,选用肯纳K313刀具(成分为Go 15%,W 85%),切削深度1 mm,进给量0.1 mm/r,切削速度130 m/min,无冷却液。

采用OLYMPUS BX41M金相显微镜和STEREOSCAN 360扫描电镜观察置氢钛合金的微观组织;利用X射线衍射分析氢对合金相成分的影响。

采用分离式Hopkinson压杆实验进行动态力学性能测试,试样为d 2 mm×2 mm的圆柱试样,应变速率为5 000 s-1。

2 结果与分析

2.1 置氢钛合金的微观组织

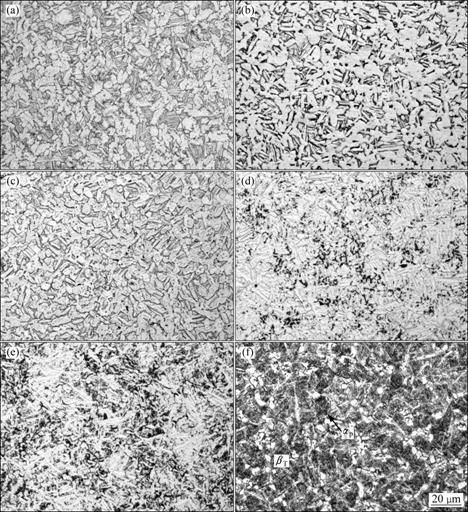

800 ℃置氢TC4炉冷后的金相组织如图1 所示。与原始双态组织相比,置氢后α和β两相的形貌和比例发生了变化:氢含量较低时,合金中初生α相(αp)基本没有变化,保持等轴组织,两相区内片层较原始组织稍显粗大,随着氢含量的增加,组织明显细化,两相由原来的板条状、层片状趋于球化,初生α相减少。氢含量达0.51%时,形成大量β转变组织,周围有少量球化的原始αp相。分析认为,一方面,随着氢含量的增加,合金的α/β相变点逐渐降低,片层中有更多的β相形成;另一方面,800 ℃置氢后,高温下的β相发生共析反应生成了α+β片层组织。

图2所示为TC4合金800℃置氢炉冷后的XRD谱。结果表明:随着氢含量的增加,初生α相衍射峰强度降低,表明初生α相数量减少,β相数量增加,与金相组织观察结果一致;同时发现,衍射峰逐渐变宽,主要是由于氢的加入,造成了晶格畸变,使晶格常数增大而致;氢含量达到0.3%时,有少量的氢化物峰值出现,可以观察到TiH、TiH1.971、TiH2等不同的氢化物衍射峰,氢化物由过饱和的α相在缓慢冷却过程中发生共析分解反应产生。此外,氢含量超过一定值时,β相衍射峰增加并不明显,经分析与氢化物的出现有关,其加宽的β相衍射峰掩盖在临近或重叠的氢化物衍射峰中而不容易识别。

2.2 置氢钛合金的力学行为

切削加工属于高速载荷作用下的材料塑性流变与断裂,通常伴随着绝热过程的热力学效应[6],一般采用分离式Hopkinson压杆试验,测定其在高应变速率和高温条件的动态力学性能。

图3所示为高应变率条件下置氢Ti-6Al-4V的流动应力—应变曲线。由图3可见,300 ℃和500 ℃变形条件下,开始阶段流动应力随应变量的增加而增加,达峰值应力之后,应力明显下降后又上升,然后波动趋于下降;温度上升到700 ℃时,流动应力在开始阶段随应变量增加,随后呈现波动趋于稳定的状态,并未出现应力剧烈变化的现象。这是由于在高应变率下,温升引起的强度下降大于应变硬化引起的强度增加,材料发生热塑失稳,流动应力迅速下降,随后应力—应变曲线的变化实际上是应变硬化效应和绝热温升引起的热软化效应共同作用的结果。在700 ℃变形条件下,不同氢含量TC4均没有出现热塑失稳现象,特别是氢含量为0.2%~0.4%对应的流动应力曲线在未置氢合金发生热塑失稳对应的应变区域过渡非常均匀,分析其原因是由于温度较高,合金变形抗力明显降低,新增的变形热较少,因而不易导致局部热塑失稳,这与文献[7-8]中绝热剪切随环境温度的降低而更易发生的结论一致;随着变形增大,硬化与软化效应相当,流动应力相对稳定。

图4所示为流动应力与氢含量的关系。由图4可见:置氢前后TC4钛合金有很强的温度敏感性,随着

图1 置氢Ti-6Al-4V合金光学金相组织

Fig.1 Optical microstructures of hydrogenated Ti-6Al-4V alloys: (a) Without H; (b) 0.08%H; (c) 0.12%H; (d) 0.30%H; (e) 0.39%H; (f) 0.51%H

图2 置氢Ti-6Al-4V合金的XRD谱

Fig.2 XRD patterns of hydrogenated Ti-6Al-4V alloys: (a) Without H; (b) 0.08% H; (c) 0.20%H; (d) 0.30%H; (e) 0.39%H; (f) 0.51%H

变形温度的升高应变强化作用越来越弱,流动应力迅速下降;每条高温应力—应变曲线都呈先降后升的规律,即随着氢含量的增加,流动应力先下降后升高。流动应力升高的原因可能是一方面随着氢含量增加,晶格畸变增大而产生强化[9],另一方面氢含量较高时,组织中出现了氢化物,其数量随氢含量增加而增多,作为脆性相对材料起到强化作用。在不同温度条件下,钛合金所对应的最小应力值基本都位于氢含量0.4%左右,其应力值较未置氢TC4的下降约8%~30%,温度越高,下降幅度越大。分析图3和4可知,材料都具有一定的应变强化效果,但其效果相对于温度的热软化效应要弱。除室温条件下,置氢钛合金的流动应力几乎均小于未置氢材料的,说明氢作为β稳定元素可以提高钛合金的高温塑性。氢的加入降低了Ti-6Al-4V合金的β相转变温度并提高其含量,而β相

图3 应变速率为5 000 s-1时置氢TC4合金流动应力—应变曲线

Fig.3 σ―ε curves of hydrogenated Ti-6Al-4V alloy at strain rate of 5 000 s-1: (a) 300 ℃; (b) 500 ℃; (c) 700 ℃

具有较多的滑移系, 在高温下易于变形, 具有增加塑性和降低流变应力的作用;氢不仅能诱发新的滑移系, 而且促进位错增殖和增加位错的可动性, 使更多的位错开动并参与滑移, 甚至攀移, 有利于塑性变形过程的进行。

2.3 切屑形态

2.3.1 置氢对切屑宏观形貌的影响

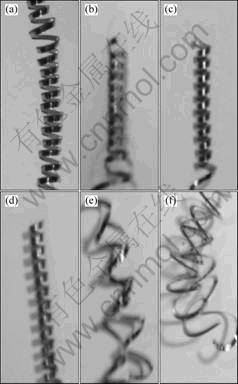

切屑卷曲是金属切削过程的一种基本现象,当切屑沿前刀面流动时,切屑底层的流动速度较切屑的其他部分缓慢得多,产生了滞留现象,并发生了二次塑性变形,于是切屑以曲面形状弯曲。图5为置氢TC4合金切屑的宏观形貌。结果表明,随氢含量的增加,钛合金切屑由较紧密的螺旋状,逐渐转变为松散的卷曲状切屑。

图4 置氢TC4合金流动应力与氢含量的关系

Fig.4 Relationship between flow stress and hydrogen content of hydrogenated Ti-6Al-4V alloy (ε=0.1;  =5 000 s-1)

=5 000 s-1)

图5 置氢TC4合金切屑宏观形貌

Fig.5 Macrographs of chips of hydrogenated Ti-6Al-4V alloy: (a) Without H; (b) 0.1%H; (c) 0.2%H; (d) 0.3%H; (e) 0.4%H; (f) 0.5%H

切屑的卷曲程度可由切屑收缩系数进行评价。影响切屑收缩系数的因素较多[10],但在本次实验中,主要是由于置氢导致材料组织性能变化而致。置氢使钛合金高温流变应力下降,减轻了切屑底部晶粒受挤压程度,有利于减小底层膨胀量,同时,前期研究[11]表明,钛合金的比热容和热传导率随氢含量增加而普遍提高,置氢钛合金热物理性能的变化明显减轻材料的热膨胀。因此,置氢钛合金的切屑收缩系数增加,切屑卷曲程度得到改善,同时,切屑与刀具的接触面积狭窄得到一定程度的改善,对减轻切削时刀具的磨损是非常有利的。

2.3.2 置氢对切屑微观形貌的影响

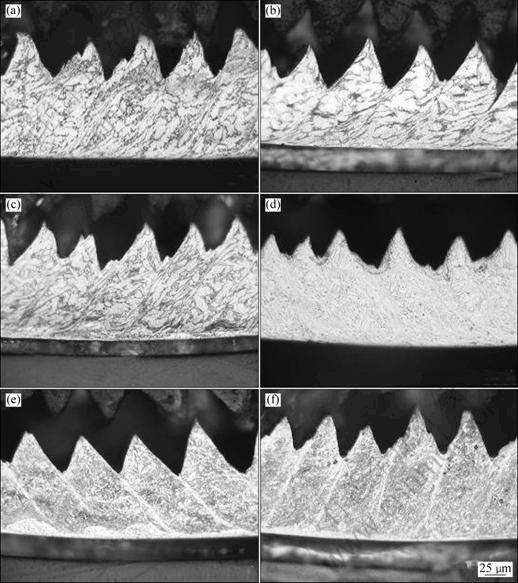

图6所示为置氢TC4钛合金切屑横截面金相组织。由图6可知,随着氢含量的增加,切屑组织明显细化。钛合金置氢前后,形成锯齿形切屑的特点不 变[12-14],但氢含量为0.3%时锯齿呈现不规则分布。图6中可观察到贯穿整个切屑厚度方向的周期性条纹,且垂直于切削方向;随氢含量由0%增加到0.3%时,条纹逐渐弱化,特别是氢含量0.3%的切屑组织中条纹已经不易分辨,氢含量继续增加时,条纹的形貌转变为较窄的白亮带。

图6 置氢TC4合金切屑横截面金相组织

Fig.6 Micrographs of cross-section of chip formed from hydrogenated Ti-6Al-4V alloy: (a) Without H; (b) 0.1%H; (c) 0.2%H; (d) 0.3%H; (e) 0.4%H; (f) 0.5%H

目前,大多数研究者支持由于热塑失稳导致局部剪切而产生钛合金锯齿形切屑的观点[12, 14-15],在高速切削过程中,钛合金工件和切屑发生了巨大的塑性变形,并产生大量的热,大部分的切削热集中在切屑根部的狭小区域,使局部温度升高,材料软化失稳形成了绝热剪切带。判断图6(a)~(d)中的绝热剪切带存在于垂直切削方向的条纹内,这些条纹说明绝热剪切带内组织在切削时曾发生过强烈的剪切滑移及挤压。条纹内的晶粒被明显拉长,有的晶粒镶嵌在绝热剪切带的边缘,有的晶粒参与到绝热剪切带内部,而在距离绝热剪切带较远的区域,晶粒的形状变化不大。但图6(d)中切屑的集中剪切带不明显,说明置氢减轻了钛合金切屑的绝热剪切现象,表现在切屑形态上即为锯齿化程度减轻。

图6(e)和(f)所示的切屑中的条纹与6(a)~(c)中的有明显区别,前者条纹处是致密的组织结构,似乎晶粒严重碎化并紧密地挤压在一起,造成了难以侵蚀的白亮带,经分析此处白亮带并非绝热剪切带,这是因为以下几个原因:1) 由上述图3和4可知,高氢含量时钛合金流动应力有上升趋势,说明此时硬化逐渐大于热软化效应;2) 置氢后钛合金热导率增加[10],切屑与刀具的接触面积增大,利于散热,变形热集中现象得到一定改善;以上两方面对绝热剪切带的形成都起到阻碍作用。当氢含量超过0.3%后,切削塑性变形时,极易在TiH、TiH1.971、TiH2等不同的氢化物脆性相处产生微裂纹,可能在绝热剪切带形成前材料就已经达到其极限剪切力,刀尖前被挤压的楔形材料沿第一剪切变形区的下部挤裂出工件,挤裂部位的晶粒经历了挤压变形、破碎、转动与焊合等,形成了类似绝热剪切带的白亮带;同时其切削变形热也满足不了形成绝热剪切带的热量。因此,推测图6(e)、(f)中切屑局部剪切的形成是因为微裂纹的存在引起的。

图7所示为不同氢含量Ti-6Al-4V切屑SEM像。图7中大量的层片结构清晰可见,垂直于切削方向。层片结构的尺寸随着氢含量的增加有减小的变化趋势,氢含量0.652%时,切屑层片结构尺寸明显减小,层片的间距缩减到未置氢时的八分之一,仅有2~4 μm。据文献[15]报道,连续带状切屑的层片结构尺寸一般不超过几个微米,较大结构尺寸常对应锯齿状切屑,说明随着氢含量的增加,置氢能降低切屑的锯齿化程度,明显改善切削变形时的局部剪切现象,减轻塑性变形不稳定性。

图7 置氢TC4合金切屑表面SEM像

Fig.7 SEM images of chips formed from hydrogenated Ti-6Al-4V alloy: (a) Without H; (b) 0.224%H; (c) 0.372%H; (d) 0.652%H

3 结论

1) 较低氢含量时,Ti-6Al-4V合金β相增多,流动应力随氢含量增加而下降,高温(300~700 ℃)塑性提高。由于局部材料的热塑失稳而形成锯齿状切屑,但绝热剪切现象随氢含量增加而减弱。

2) 较高氢含量时,随氢含量增加,置氢Ti-6Al-4V合金组织中氢化物增多,流动应力有上升趋势,切削变形时易产生微裂纹,导致锯齿状切屑的形成。

REFERENCES

[1] 侯红亮, 李志强, 王亚军, 关 桥. 钛合金热氢处理技术及其应用前景[J]. 中国有色金属学报, 2003, 13(3): 533-549.

[2] HOU Hong-liang, LI Zhi-qiang, WANG Ya-jun, GUAN Qiao. Technology of hydrogen treatment for titanium alloy and its application prospect[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 533-549.

[3] KOLACHEV B A, ILYIN A A, NOSOV K. Hydrogen technology as new perspective type of titanium alloy processing[J]. Advances in the Science and Technology of Titanium Alloy Processing, 1997, 2: 331-338.

[4] KOLACHEV B A, EGOROVA Y B, TALALAEV V D. Hydrogen influence on machining of titanium alloys[J]. Advances in the Science and Technology of Titanium Alloy Processing, 1997, 2: 339-346.

[5] DOMENICO UMBRELLO. Finite element simulation of conventional and high speed machining of Ti-6Al-4V alloy[J]. Journal of Materials Processing Technology, 2008, 196: 79-87.

[6] DENG Jian-xin, LI You-sheng, SONG Wen-long. Diffusion wear in dry cutting of Ti-6Al-4V with WC/Co carbide tools[J]. Wear, 2008, 265: 1776-1783.

[7] MOLINARI A, MUSQUAR C, SUTTER G. Adiabatic shear banding in high speed machining of Ti-6Al-4V[J]. Experiments and Modeling, 2002, 18: 443-459.

[8] 常德功, 于宁宁, 吕明利. TC4钛合金在不同温度下的剪压缩失效[J]. 青岛科技大学学报: 自然科学版, 2009, 30(4): 349-352.

[9] CHANG De-gong, YU Ning-ning, L? Ming-li. The shear compression failure of TC4 yitanium alloy at different temperatures[J]. Journal of Qingdao University of Science and Technology: Natural Science Edition, 2009, 30(4): 349-352.

[10] LIU Xin-qin, TAN Cheng-wen, ZHANG Jing. Correlation of adiabatic shearing behavior with fracture in Ti-6Al-4V alloys with different microstructures[J]. International Journal of Impact Engineering, 2009, 36(9): 1143-1149.

[11] 李晓华, 牛 勇, 侯红亮, 李志强. 置氢 Ti-6Al-4V 合金显微组织演变与高温变形行为[J]. 中国有色金属学报, 2008, 18(8): 1414-1420.

[12] LI Xiao-hua, NIU Yong, HOU Hong-liang, LI Zhi-qiang. Microstructure evolution and high temperature deforming behavior of hydrogenated Ti-6Al-4V alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(8): 1414-1420.

[13] 谭美田. 金属切削微观研究[M]. 上海: 科学技术出版社, 1988: 51.

[14] TAN Mei-tian. Microscopic study of metal cutting[M]. Shanghai: Science and Technology Press, 1988: 51.

[15] 李 红, 孙中刚, 侯红亮. 氢对TC4合金物理力学性能的影响及其与切削性能的相关性[J]. 航空制造技术, 2008, 20: 80-83.

[16] LI Hong, SUN Zhong-gang, HOU Hong-liang. Relationship between the effect of hydrogen on physical and mechanical properties and its machinability for TC4 titanium alloy[J]. Aeronautical Manufacturing Technology, 2008, 20: 80-83.

[17] ARRAZOLA P J, GARAY A, IRIARTE L M, ARMENDIA M, MARYA S, MAITRE F L. Machinability of titanium alloys[J]. Journal of Materials Processing Technology, 2009, 209(5): 2223-2230.

[18] VYAS A, SHAW M C. Mechanics of sawtooth chip formation in metal cutting[J]. Materials Science and Engineering A, 1999, 121: 163-172.

[19] TAMIN M N, SUDIN I, MON T T. Thermal-mechanical responses of Ti-6AI-4V during orthogonal cutting process[J]. Diffusion and Defect Data A, 2008, 273: 673-678.

[20] BARRY J, BYRNE G, LENNON D. Observations on chip formation and acoustic emission machining Ti-6Al-4V[J]. Machine Tools and Manufacture, 2001, 41: 1055-1070.

(编辑 龙怀中)

收稿日期:2009-12-01;修订日期:2010-03-01

通信作者:侯红亮,研究员;电话:010-85701497;E-mail: hou_hl@163.com