ARTICLE

J. Cent. South Univ. (2019) 26: 2129-2135

DOI: https://doi.org/10.1007/s11771-019-4160-1

Effects of TiO2 nanoparticles on thermal conductivity of heat transfer oil

YIN Xiang(尹湘), KOU Guang-xiao(寇广孝), XU Ai-xiang(徐爱祥), FU Tao(符涛), ZHU Jie(朱杰)

College of Civil Engineering, Hunan University of Technology, Zhuzhou 412007, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Abstract: There is a lack of thermophysical data of heat transfer oil and nano-oil in the high temperature range of 50-300 °C for designing and developing heat transfer oil furnace and its heating systems. In the present study, the thermal conductivity values of heat transfer oil and TiO2 nano-oil in the above high temperature range were measured by a newly developed high-temperature thermal conductivity meter. Based on the principle of least square method, the thermal conductivity values obtained from experiments were fitted separately, and the correlation between thermal conductivity and temperature of heat transfer oil and TiO2 nano-oil was obtained. The results show that the thermal conductivity and the increased percentage of thermal conductivity of TiO2 nano-oil are proportional to the increase of particle size and mass fraction of nanoparticles, but thermal conductivity is in reverse proportion to the increase of temperature and the increased percentage of thermal conductivity is less affected by temperature.

Key words: TiO2 nano-oil; thermal conductivity; nanoparticle

Cite this article as: YIN Xiang, KOU Guang-xiao, XU Ai-xiang, FU Tao, ZHU Jie. Effects of TiO2 nanoparticles on thermal conductivity of heat transfer oil [J]. Journal of Central South University, 2019, 26(8): 2129-2135. DOI: https://doi.org/10.1007/s11771-019-4160-1.

1 Introduction

Considered a promising organic heat transfer medium, heat transfer oil is widely used in industrial production of heat transfer material heater due to its high heat transfer efficiency, easy adjustability in temperature control, low corrosive effect on equipment and low investment [1, 2]. Thermal conductivity is an important criterion for the heat transfer capacity of heat transfer oil, and increased thermal conductivity plays a decisive role in improving production efficiency, reducing heat transfer oil consumption and reducing environmental damage [3, 4].

As nanoparticles in Brownian motion do not settle easily, stable nanofluids can be prepared by adding metal and its oxides, non-metal, carbides, nitrides and alloys into fluids, which have good thermal conductivity and good application prospects in industry [5, 6]. Moreover, the thermal conductivity of solids is several orders of magnitude greater than that of liquids [7-9], and it has been shown that adding metal or non-metallic solid particles with diameter less than 100 nm to liquids in certain proportion and manner to make uniform and stable new heat transfer medium [10-12] significantly enhances the thermal conductivity of the fluid and the heat transfer performance [13, 14]. For example, LUO et al [15] added multi-walled carbon nanotubes to high temperature heat transfer oil, and the thermal conductivity increased by 50%. JIANG et al [16] added Cu nanoparticles to high temperature heat transfer oil, and the thermal conductivity increased by 18%.

However, few studies have shown that the thermal conductivity changes with temperature after nanoparticles are added into the heat transfer oil. In the present study, TiO2 nanoparticles are added into LQ and SKX type of heat transfer oil to form TiO2 nano-oil and its thermal conductivity in the temperature range of 50-300 °C is measured with high temperature conductivity meter and the correlation between thermal conductivity and temperature is analyzed.

2 Experimental

2.1 Experimental set-up

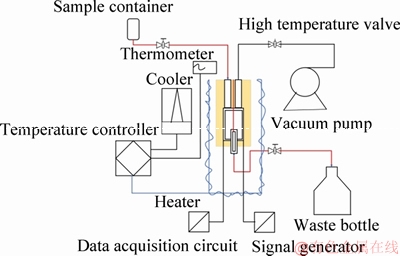

The thermal conductivities of heat transfer oil and TiO2 nano-oil were measured with TC3200L high temperature thermal conductivity meter, a widely used instrument in measuring the thermal conductivity of polar or non-polar liquids. The maximum measuring temperature of the meter can reach 350 °C. The basic measuring method is transient hot-wire method. The thermal conductivity meter consists mainly of temperature controller, data acquisition circuit, signal generator, vacuum pump, thermometer, and high temperature valve, as shown in Figure 1.

Figure 1 Diagram of thermal conductivity meter system

2.2 Preparation of TiO2 nano-oil

As heat transfer oils belong to L-class Q group according to the international classification standard, the heat transfer oils of LQ and SKX with colorless and pale yellowish colors and the nanoparticles with diameters of TiO2 are 15 nm, 20 nm and 30 nm were purchased from a manufacturer in Hangzhou respectively selected as experimental materials.

At present, there are two ways of nanofluid preparation, namely, the one-step method and the two-step method [17-19]. The essential difference between the two methods is that in one method, the creation of solid nanoparticle and nanofluid is simultaneous, and in the other, it is not. TiO2 nano-oil was created by two-step method with oleic acid as catalyst. After 45 min of magnetic heating and stirring and 15 min of ultrasonic vibration, TiO2 nano-oils with mass fraction of 0.2%, 0.5% and 1.0% were created.

2.3 Suspension stability of TiO2 nano-oil

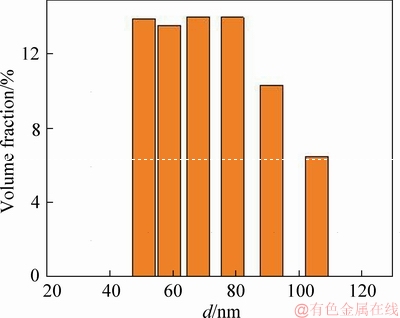

The gravity sedimentation method and the particle size detection method were used to test the suspension stability of the nanofluid. The former was used to observe whether stratification occurred through static test [20, 21]. The latter was adopted to detect whether the particle size of the fluid increased due to agglomeration. Figure 2 shows the precipitation of the TiO2 nano-oil after 7 d. It could be seen that the nanoparticles of TiO2 had not deposited in the heat transfer oil, which means that uniform and stable TiO2 nano-oil could be formed. Figure 3 shows the particle size analysis of the prepared TiO2 nano-oil with a mass fraction of 0.2% and particle size of 30 nm after placed for 7 d through used British Malvern ZEN3600 laser particle size analyser and the results show that the average particle size of the nanoparticles in the TiO2 nano-oil is 93 nm, and the distribution is relatively concentrated, which indicates that nanoparticles of TiO2 were well dispersed in the heat transfer oil. As shown in Figures 2 and 3, the prepared TiO2 nano-oil possesses good dispersion stability and meets the experimental requirements.

Figure 2 TiO2 nano-oil after 7-d-standing (left: 15 nm, 0.2%; middle: 15 nm, 0.5%; right: 15 nm, 1.0%)

3 Results and discussions

3.1 Thermal conductivity of heat transfer oil

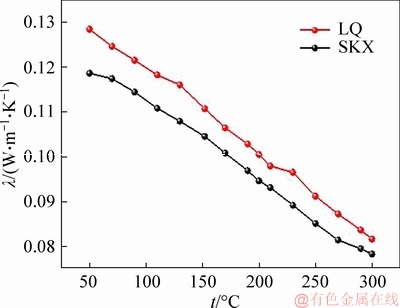

The maximum allowable operating temperature of LQ and SKX type of heat transfer oil is 310 °C. The thermal conductivity of two heat transfer oils at 50-300 °C was measured by TC3200L high temperature thermal conductivity meter. The changing curves corresponding to thermal conductivity and temperature of heat transfer oil were obtained by selecting a measuring point at interval of 20 °C, as shown in Figure 4.

Figure 3 Distribution of TiO2 nano-oil particle size

Figure 4 shows that the thermal conductivities of the two heat transfer oils are in reverse proportion to the increase of temperature. From 50 to 300 °C, the thermal conductivities of LQ and SKX type of heat transfer oil decreased by 41% and 37%, respectively.

Figure 4 Changing curves corresponding to thermal conductivity and temperature for LQ and SKX type of heat transfer oils

Regression analysis is performed on the measured thermal conductivity values of the above- mentioned heat transfer oil, and the correlation Eq. (1) of thermal conductivity and temperature is fitted as follows:

(1)

(1)

where λ is thermal conductivity; t is temperature, °C; C is constant.

3.2 Thermal conductivity of TiO2 nano-oil

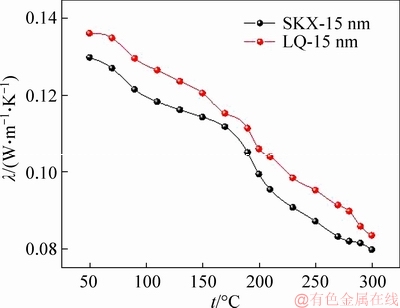

TiO2 nanoparticles with particle size of 15 nm and mass fraction of 0.2% were respectively added to the LQ and SKX type of heat transfer oil to prepare TiO2 nano-oil, whose thermal conductivities between 50 and 300 °C were then measured, and the changing curves corresponding to thermal conductivity and temperature were drawn, as shown in Figure 5.

Figure 5 Changing curves corresponding to thermal conductivity and temperature for TiO2 nano-oil with particle size of 15 nm

The increased percentage, ηj, of the thermal conductivity of TiO2 nano-oil relative to the heat transfer oil after nanoparticles were added was calculated according to Eq. (2), as shown in Figure 6.

(2)

(2)

where ηj is increased percentage of thermal conductivity; λN is thermal conductivity of TiO2 nano-oil; λD is thermal conductivity of heat transfer oil.

Figure 5 shows that the thermal conductivity of the TiO2 nano-oil is in reverse proportion to the increase of temperature. At 50 °C, the thermal conductivities of LQ and SKX type of TiO2 nano-oil are 0.1361 W/(m·K) and 0.1298 W/(m·K), respectively. When the temperature rises to 300 °C, they are 0.0835 W/(m·K) and 0.0818 W/(m·K) respectively. The thermal conductivities decreased by 38.6% and 37% when temperature changes in the range of 50 to 300 °C.

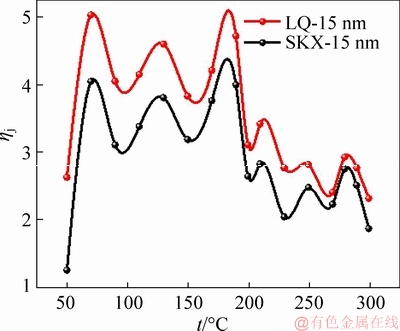

Figure 6 Increased percentage of thermal conductivity for TiO2 nano-oil with particle size of 15 nm

Figure 6 shows that in the range of 50-300 °C, the increase in the thermal conductivity of LQ type of TiO2 nano-oil is greater than that of SKX type. It can be concluded that the thermal conductivity of the nano-oil and its increased percentage, and the thermal conductivity enhancement effect are both in direct proportion to the thermal conductivity of heat transfer oil.

3.3 Effect of particle size on thermal conductivity of TiO2 nano-oil

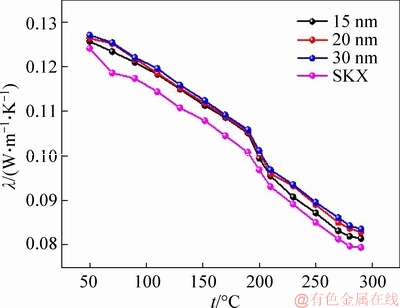

Figure 7 shows the changing curves corresponding to thermal conductivity and temperature of nano-oil with mass fraction of 0.2% and particle size of 15, 20 and 30 nm, respectively, Figure 7 shows that the thermal conductivity of TiO2 nano-oil is higher than that of the heat transfer oil and is in reverse proportion to the increase of temperature. From 50 to 300 °C, the thermal conductivity of TiO2 nano-oil at 15, 20 and 30 nm satisfies the relationship of λ30nm>λ20nm>λ15nm. Meanwhile, the respective average increased percentage of thermal conductivity is 2.9%, 4.0%, 4.63%, and satisfies the relationship of η30nm>η20nm>η15nm. It can be concluded that the larger the particle size is, the greater the thermal conductivity and its increased percentage of the TiO2 nano-oil are, and both are in direct proportion to the increase in the particle size. However, the thermal conductivities of the three kinds of particle sizes TiO2 nano-oils are relatively close, with a difference of 0.001 W/(m·K). The reason is that on one hand, it is speculated that the spherical TiO2 particle size changes little, so the thermal conductivity enhancement effects at different particle sizes are not much different. On the other hand, the existence of the test error of the experimental instrument cannot be ignored, and finally the thermal conductivity of the nano-oil of different particle sizes is relatively close.

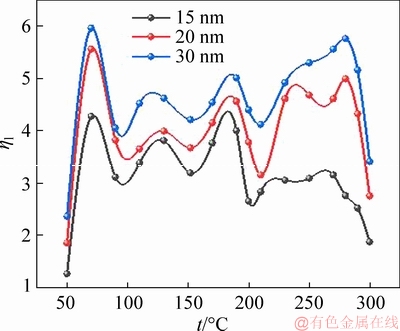

Figure 8 shows the increased percentages ηl of thermal conductivity of TiO2 nano-oil with different particle sizes calculated through Eq. (2). As shown in Figure 8, the increased percentages of thermal conductivity of 15, 20 and 30 nm TiO2 nano-oil reach the maximum at 70 °C, by 4.27%, 5.56% and 5.96%, respectively. At the same time, the increased percentage of thermal conductivity varies with temperature, but its variation range is small. It can be concluded that the increased percentage of thermal conductivity is less affected by temperature.

Figure 7 Changing curves corresponding to thermal conductivity and temperature of TiO2 nano-lil with different sizes of TiO2 particle

Figure 8 Increased percentage of thermal conductivity of TiO2 nano-oil with differeat sizes of TiO2 particles

3.4 Effect of mass fraction on thermal conductivity of TiO2 nano-oil

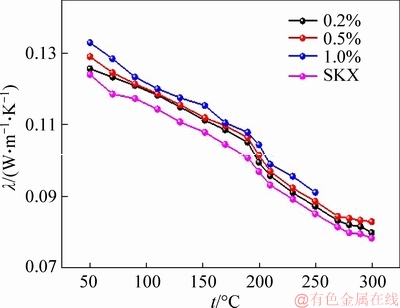

Figure 9 shows the changing curves corresponding to thermal conductivity and temperature of the TiO2nano-oil with particle size of 15 nm and mass fraction of 0.2%, 0.5% and 1.0% respectively. Figure 9 shows that the thermal conductivity of the TiO2 nano-oil is in direct proportion to the increase of the mass fraction of the nanoparticles, and reaches the maximum when the mass fraction is increased to 1%. Compared with the thermal conductivity of the heat transfer oil, the average increased percentage of the thermal conductivity with 0.2%, 0.5% and 1.0% mass fraction of the TiO2 nano-oil is 2.9%, 4.4% and 6.6%, respectively. This is because the larger the volume fraction of nanoparticles, the larger the number of nanoparticles dispersed per unit volume of heat transfer oil, resulting in enhanced micro-convection between particles and particles, particles and heat transfer oil, and the acceleration of energy transfer speed, resulting in the increase of thermal conductivity and increased percentage of thermal conductivity of TiO2 nano-oil with the increase of mass fraction. At the same time, the difference of thermal conductivity between TiO2 nano-oil with different mass fractions is about 0.01 W/(m·K), which is 10 times higher than that of TiO2 nano-oil with different particle sizes. Therefore, the change of mass fraction of nanoparticle has a greater impact on thermal conductivity of TiO2 nano-oil. It can be concluded that the thermal conductivity and the increased percentage of the TiO2 nano-oilare both in direct proportion to the mass fraction.

Figure 9 Changing curves corresponding to thermal conductivity and temperature of TiO2 nano-oil with different mass fractions of TiO2

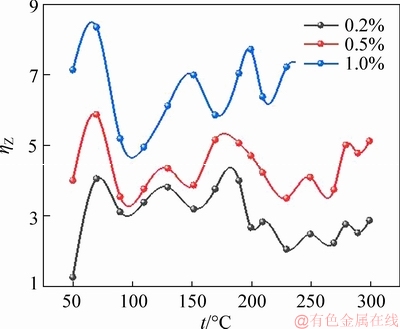

Figure 10 shows the increased percentage ηz of thermal conductivity of TiO2 nano-oil with different particle sizes calculated through Eq.(2). As shown in Figure 10, the increased percentage of thermal conductivity of TiO2 nano-oil with mass fraction of 0.2%, 0.5% and 1.0% also reaches the maximum at 70 °C by 4.05%, 5.87% and 8.05%, respectively, and is less affected by temperature.

Figure 10 Increased percentage of thermal conductivity of TiO2 nano-oil with different mass fractions of TiO2

3.5 Regression analysis of thermal conductivity of TiO2 nano-oil

Regression analysis is carried out on the measured values of the thermal conductivity of TiO2 nano-oils with different heat transfer oils, different particle sizes and mass fractions. The relationship between thermal conductivity and temperature of TiO2 nano-oils accords with Eq. (1).

In Eq. (1), the constant C of the LQ and SKX type TiO2 nano-oil is 0.1392 and 0.1503, respectively. The constant C of the TiO2 nano-oilwith mass fraction of 0.2%, particle size of 15, 20 and 30 nm is 0.1392, 0.1396 and 0.1401, respectively. The constant C of TiO2 nano-oil with particle size of 15 nm, mass fraction of 0.2%, 0.5% and 1.0% is 0.1392, 0.1420 and 0.1432, respectively. It can be concluded that the linear relationship C of TiO2 nano-oil is determined by the thermal conductivity of the heat transfer oil, the particle size and mass fraction of the nanoparticles. The constant C is proportional to the thermal conductivity of the heat transfer oil, the particle size and the mass fraction of the nanoparticles.

4 Conclusions

The thermal conductivities of LQ and SKX heat transfer oil and TiO2 nano-oil were measured by a newly developed high temperature thermal conductivity meter in the high temperature range of 30-300 °C. The experimental data were analyzed by regression method. The conclusions are as follows:

1) The thermal conductivity of both LQ and LKX type of heat transfer oils and TiO2 nano-oils satisfies an equation λ=-0.0002t+C in the range of 50-300 °C. Different constant C of different types of heat transfer oil can be obtained through experiments.

2) The thermal conductivity of TiO2 nano-oil is higher than that of heat transfer oil. Compared with the thermal conductivity of the heat transfer oil, the thermal conductivity of TiO2 nano-oil with size of 15, 20, 30 nm increased by 2.9%, 4.0% and 4.63%, respectively, and the thermal conductivity of TiO2 nano-oil with mass fraction of 0.2%, 0.5%, 1.0% increased by 2.9%, 4.4% and 6.6%, respectively.

3) The thermal conductivity and increased percentage of thermal conductivity of TiO2 nano-oil is proportional to the particle size and mass fraction of nanoparticles, and the change of mass fraction of nanoparticle has a greater impact on thermal conductivity of TiO2 nano-oil. But the thermal conductivity is in reverse proportion to the increase of temperature, and the increased percentage of thermal conductivity, which reaches its maximum at 70 °C, is less affected by temperature. Compared with the thermal conductivity of the heat transfer oil, the maximum increased percentage of thermal conductivity of TiO2 nano-oil with size of 15, 20, 30 nm increased by 4.27%, 5.56% and 5.96%, respectively, and the maximum increased percentage of thermal conductivity of TiO2 nano-oil with mass fraction of 0.2%, 0.5%, 1.0% increased by 4.05%, 5.87% and 8.05%, respectively.

Acknowledgement

The authors are grateful to the Collaborative Innovation Center of Building Energy Conservation & Environmental Control and the anonymous referees who provided detailed and constructive comments.

References

[1] LI Peng, WEI Chao-liang, ZHANG Dong-heng, KONG Ling-jie, SUN Cheng-jie. Overview of the development of high temperature heat conductive oil [J]. Lubricant, 2016, 31(4): 1-5. (in Chinese)

[2] ESFE M H, SAEDODIN S, MAHIAN O, WONGWISES S. Thermophysical properties, heat transfer and pressure drop of drop-functionalized multi-walled carbon nanotubes/water nanofluids [J]. International Communications in Heat & Mass Transfer, 2014, 58: 176-183.

[3] DIAO Y H, LI C Z, ZHAO Y H, LIU Y, WANG S. Experimental investigation on the pool boiling characteristics and critical heat flux of Cu-R141b nanorefrigerant under atmospheric pressure[J]. International Journal of Heat & Mass Transfer, 2015, 89: 110-115.

[4] CHOI S U S. Enhancing thermal conductivity of fluids with Nanopartiles [J]. Developments and Applications of Non-Newtonian Flows, 1995, 231(66): 99-105.

[5] WANG Cai-xia, HUANG Yun, YAO Hua, YE Feng, YANG Jun, DING Yu-long. Progress in Nanofluid research [J]. Energy Storage Science and Technology, 2017, 6(1): 24-34. (in Chinese)

[6] WANG X, XU X, CHOI U S. Thermal conductivity of nanoparticle-fluid mixture [J]. Journal Thermophysics and Heat Transfer, 1999, 13(4): 474-480.

[7] LU Hui, JIANG Bing-yan, WENG Can, ZHOU Ming-yong, LI Xing. Influence of flow field distribution on the quality of nanostructured template electrodeposition molde [J]. Journal of Central South University (Science and Technology), 2017, 48(5): 1211-1217. (in Chinese)

[8] PENG Xiao-fei, YU Xiao-li, XIA Li-feng, YU Feng-qin. Prediction of effective thermal conductivity of nanofluids [J]. Journal of Chemical Industry and Engineering, 2007(2): 299-303. (in Chinese)

[9] LI Chun-hui, WANG Bu-xuan, PENG Xiao-feng. Effect of ferromagnetic microparticles on boiling heat transfer [J]. Journal of Thermal Science and Technology, 2003(1): 30-33. (in Chinese)

[10] GONG Yu-ying. Preparation and physical properties of heat transfer oil-based nanofluids [D]. Ji′nan: University of Jinan, 2016. (in Chinese)

[11] ETTEFAGHI E, RASHIDI A, AHMADI H, MOHTASEBI S S, POURKHALIL M. Thermal and Theological properties of oil-based nanofluids from different carbon nanostructures [J]. International Communications in Heat and Mass Transfer, 2013, 48: 178-182.

[12] ZHANG Q B, ZHANG K L, XU D G, YANG G C, HUANG H, NIE F, LIU C M, YANG S H. CuO nanostructures: Synthesis, characterization, growth mechanisms, fundamental properties, and applications [J]. Progress in Materials Science, 2014, 60: 208-337.

[13] GAO Lin-chao, SHEN Sheng-qiang, HAO Qing-ying, LIU Cun-xiang, YUE Feng. Adding solid particles to improve the photothermal conversion performance of heat transfer oil in solar collector tubes [J]. Journal of Agricultural Engineering, 2013, 29(22): 206-211. (in Chinese)

[14] XIE Hua-qing, WU Qing-ren, WANG Jin-chang, XI Tong-geng, LIU Yan. Study on enhanced thermal conductivity of alumina nano-powder suspension [J]. Journal of the Chinese Ceramic Society, 2002(3): 272-276. (in Chinese)

[15] LUO Zhong-yang, WU Yue-qiong, HU Qian, WANG Tao, NI Ming-jiang. Thermal and rheological properties of carbon nanotubes-oil nanofluid [J]. Journal of Chemical Engineering of Chinese Universities, 2015, 29(1): 35-42. (in Chinese)

[16] JIANG Hai-feng, LI Hui, ZAN Cheng, WANG Fu-qiang, YANG Qian-peng, LIN Shi. Temperature dependence of the stability and thermal conductivity of an oil-based nanofluid [J]. Thermochimica Acta, 2012, 579: 27-30.

[17] ZOUBIDA H, CHERIFA A, HAKAN F O, AMINA M. A review on how the researchers prepare their nanofluids [J]. International Journal of Thermal Sciences, 2014, 76: 168-189.

[18] MUKHERJEE S, PARIA S. Preparation and stability of nanofluids—A review [J]. IOSR Journal of Mechanical and Civil Engineering, 2013, 9(2): 63-69.

[19] LI Yu-qiang, TANG Wei, CHEN Yong, LIU Jiang-wei, LEE Chia-fon F. Potential ofacetone-butanol-ethonal (ABE) as a biofuel [J]. Fuel, 2019, 242: 673-686. DOI: 10.1016/ j.fuel.2019.01.063.

[20] DERAKHSHAN M M, AKHAVAN-BEHABADI M A, MOHSENI S G. Experiments on mixed convection heat transfer and performance evaluation of MWCNT–Oil nanofluid flow in horizontal and vertical microfin tubes [J]. Experimental Thermal and Fluid Science, 2015, 61: 241-248.

[21] ASHTIANI D, AKHAVAN-BEHABADI M A, PAKDAMAN M F. An experimental investigation on heat transfer characteristics of multi-walled CNT-heat transfer oil nanofluid flow inside tubes under uniform wall temperature condition [J]. International Communications in Heat and Mass Transfer, 2012, 39(9): 1404-1409.

(Edited by YANG Hua)

中文导读

纳米TiO2对导热油导热系数的影响

摘要:在设计开发导热油锅炉及其供热系统过程中,缺乏导热油及纳米导热油在高温区间50~300 °C的热物性数据。为此,利用某公司新研发的高温导热系数仪分别测量导热油及TiO2纳米导热油在上述高温区间的导热系数。基于最小二乘法原理对试验所得的导热系数分别进行拟合,得到导热油和TiO2纳米导热油的导热系数-温度的线性关系式。结果表明,TiO2纳米导热油导热系数及导热系数增幅随着纳米颗粒粒径及质量分数的增加而增加,但是,导热系数随着温度的升高而下降,导热系数增幅受温度影响较小。

关键词:TiO2纳米导热油;导热系数;纳米颗粒

Foundation item: Project(51346007) supported by the National Natural Science Foundation of China

Received date: 2019-06-26; Accepted date: 2019-07-24

Corresponding author: KOU Guang-xiao, Professor; Tel: +86-13607330018; E-mail: 443849697@qq.com; ORCID: 0000-0002-3145- 5302