DOI: 10.11817/j.issn.1672-7207.2018.04.007

超高强度硼钢38MnB5的热冲压工艺研究

郝亮1,朱国明1,闻玉辉1,袁静玺1,康永林1, 2

(1. 北京科技大学 材料科学与工程学院,北京,100083;

2. 北京科技大学 新金属材料国家重点实验室,北京,100083)

摘要:利用扫描电镜(SEM)、光学显微镜、万能拉伸试验机对2.2 mm厚的38MnB5钢在不同加热温度和不同保温时间工艺参数下,对微观组织、原始奥氏体晶粒粒径和力学性能进行研究,制定出最佳的热冲压工艺参数。研究结果表明:当保温时间一定时,随着加热温度的升高试样抗拉强度逐渐增强,在950 ℃时达到峰值,随着温度继续升高,抗拉强度降低;当加热温度一定时,随着保温时间的加长,原始奥氏体晶粒不断长大,试样抗拉强度随时间增加而增加,在10 min时达到峰值,保温时间继续加长,抗拉强度降低;38MnB5钢在加热温度为950 ℃和保温时间为10 min的工艺参数下,得到最佳力学性能。抗拉强度达到2 061 MPa,屈服强度达到1 421 MPa,断后伸长率为7%。

关键词:热冲压;38MnB5钢;组织;力学性能

中图分类号:TG115 文献标志码:A 文章编号:1672-7207(2018)04-0817-07

Study on hot stamping process of 38MnB5 ultra high strength boron steel

HAO Liang1, ZHU Guoming1, WEN Yuhui1, YUAN Jingxi1, KANG Yonglin1, 2

(1. School of Materials Science and Engineering,

University of Science and Technology Beijing, Beijing 100083, China;

2. State Key Laboratory for Advanced Metals and Materials,

University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Microstructure and prior austenite grain size of 38MnB5 hot stamping steel were observed and investigated via scanning electron microscopy (SEM) and optical microscope. Mechanical properties were obtained via universal tensile testing machine. Hot stamping steels with different heating temperature and soaking time were performed and the optimal process was confirmed. The results show that the tensile strength increases at first and then decreases with the increase of temperature, peaking at 950 ℃. The prior austenite grain grows with the increase of soaking time while tensile strength increases at first and then decreases, peaking at 10 min. The 38MnB5 hot stamping steel with the most optimal mechanical properties is obtained at the heating temperature of 950 ℃ and the soaking time of 10 min. The tensile strength is 2 061 MPa, the yield strength is 1 421 MPa and the elongation is 7%.

Key words: hot stamping; 38MnB5 steel; microstructure; mechanical property

随着经济的快速发展,人类面临的能源、环境等方面的危机越来越大,根据统计,以现在的开采速度,全球的石油储量仅能满足40年的需求[1]。而汽车燃油是能源消耗的大户之一,而且排放也为环境治理带来了巨大的负担。研究表明,约75%的油耗与汽车质量有关[2],因此,在保证汽车安全的前提下,实现汽车的轻量化是降低油耗及排放的有效途径。热冲压成形部件的应用,既强化了车身,提高了安全性,又可以减轻车身质量,是同时实现车身轻量化和提高碰撞安全性的最好途径。热冲压钢已经广泛应用于汽车的各个部件上,屈服强度达到1 200 MPa,抗拉强度达到1 500 MPa。目前,国内外普遍采用的硼钢为22MnB5;国内则仅有宝钢可批量生产冷轧B1500HS和热轧BR1500HS 2种热冲压用硼钢[3-4]。文献[5-7]主要围绕22MnB5进行合金元素、模拟仿真分析和氢致裂纹等进行研究。然而,随着对钢强度的要求越来越高,更高强度等级的钢的需求很快被提上日程。现阶段研究的38MnB5钢就是一种在冲压后屈服强度达到了1 400 MPa,抗拉强度更是达到了2 000 MPa的热冲压成形钢[8]。热冲压工艺有3个环节:1) 加热温度和保温时间确保均匀奥氏体化;2) 快速冲压保证相变前完成形变;3) 快速冷却获得完全马氏体转变[9]。整个过程为T-σ-t三围热处理(形变热处理)[10]。本文作者针对38MnB5在不同加热温度和不同保温时间下,形成的组织及组织对力学性能的影响进行试验研究。

1 实验材料与方法

1.1 实验材料

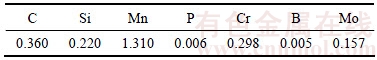

实验材料为试验室50 kg真空冶炼炉冶炼的38MnB5坯料,在两辊可逆轧机经过7道次热轧轧制至2.2 mm厚度,终轧表面温度为840 ℃,放入650 ℃加热炉中随炉冷却至室温。其主要化学成分如表1所示。

表1 38MnB5的化学成分(质量分数)

Table 1 Chemical composition of 38MnB5 %

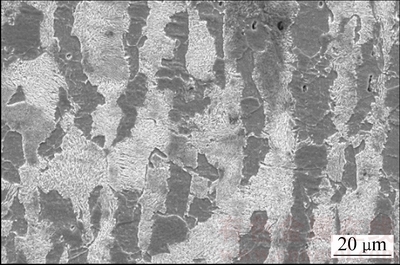

图1所示为热轧后随炉冷却状态下38MnB5钢原始组织金相显微照片,其主要由铁素体和珠光体构成,测得热轧态下的38MnB5钢的抗拉强度为604 MPa,屈服强度为405 MPa,断后伸长率为24%。

1.2 实验方法

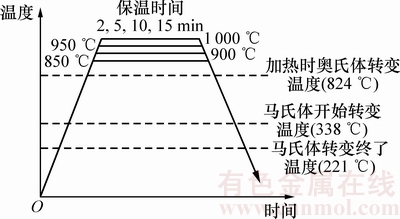

实验设计为在不同加热温度、不同保温时间下进行水淬来探讨38MnB5热成形钢最佳成形工艺参数,具体的热处理工艺流程如图2所示,加热温度分别为850,900,950和1 000 ℃,每组试验的保温时间分别为2,5,10和15 min,取出淬火。

图1 38MnB5钢的原始组织金相显微照片

Fig. 1 Microstructure of as-received 38MnB5 steel

图2 38MnB5钢的热处理工艺示意图

Fig. 2 Schematic diagram of heat treatment process of 38MnB5 steel

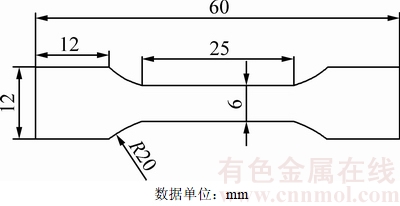

从水淬后的试样上切取金相和拉伸试样,金相试样在其水淬试样1/4处切取长×宽为10 mm×10 mm的试样,拉伸试样切取在水淬试样1/4处垂直于轧制方向进行取样,其拉伸试样尺寸如图3所示。切好的金相试样经过机械研磨、抛光后,采用体积分数为4%的硝酸酒精溶液进行腐蚀,利用扫描电镜(SEM)观察其组织形貌;在MTS810电子万能试验机上按照标准GB/T 228.1—2010进行拉伸,拉伸速率为2 mm/s;将经过机械研磨、抛光后的金相试样在70 ℃的饱和苦味酸中保温90 s后,在光学显微镜下观察原始奥氏体晶粒。用Image-tool软件测量晶粒并进行统计。最后根据试验结果得出38MnB5最佳热冲压工艺参数。

图3 拉伸试样尺寸

Fig. 3 Shape and size of tensile test

2 结果与分析

2.1 38MnB5淬火后微观组织

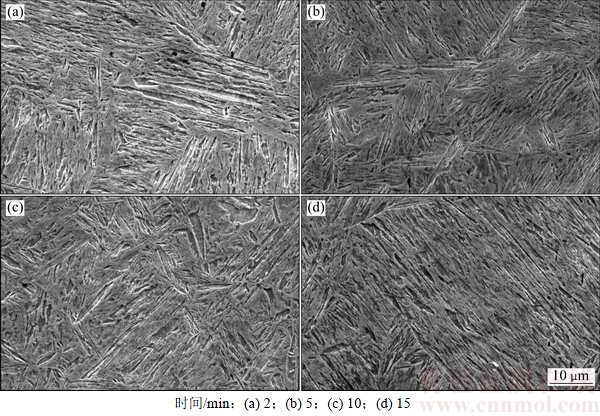

热冲压过程的主要工艺参数包括:加热温度、保温时间、淬火速度及保压时间等,都对热冲压零件的最终质量有很大的影响[11]。在该文中,只对加热温度和保温时间进行研究。加热温度应确保温度在钢板再结晶温度以上从而实现板料的奥氏体化,温度不宜过高或过低,加热温度如果过低,奥氏体化会不完全,会有部分的铁素体和珠光体没有转变成奥氏体组织,导致组织不均匀,并使淬火后的马氏体减少,影响力学性能;若加热温度过高,则会导致板料表面过烧和晶粒粗大进而影响淬火后钢板的力学性能。通过NADERI等[12]的实验证实细致光滑的晶粒也会促使马氏体转变升高,而粗糙的晶粒使马氏体的转变温度降低,进而影响最终材料性能。将38MnB5钢在不同奥氏体化加热温度下保温5 min,淬火后的微观组织如图4所示。可以看出试样在加热温度为850 ℃时,虽然组织为马氏体,但马氏体板条块分界并不清晰,钢板基体中应仍存在小部分残余奥氏体组织;当温度达到900 ℃,板料基体中的马氏体板条开始清晰。当温度上升到950 ℃以上时,开始出现明显的马氏体板条,且分界清晰。特别是在奥氏体化温度为1 000 ℃时,马氏体板条束呈现出明显的长大趋势,出现了明显的宽化和锐化。马氏体的板条束越宽,越容易对晶体造成割裂,从而降低材料的力学性能[13]。

此外,奥氏体化的保温时间也是影响38MnB5钢淬火后组织的重要因素之一。板料经过奥氏体化后,需经过一定时间的恒温处理以保证组织的均匀性,从而获得稳定的质量和性能。保温时间过短,达不到恒温均热的效果;保温时间过长,会导致原始奥氏体晶粒长大,从而因为遗传作用影响淬火后的马氏体组织,进而影响力学性能。图5所示为38MnB5钢在加热温度为950 ℃时,不同保温时间下淬火后的微观组织。由图5可以看出:当保温时间为2 min时,淬火后组织基体已成为马氏体组织,但随着保温时间延长,马氏体组织更加均匀化,而当保温时间达到15 min时,马氏体出现了非常明显的长大和宽化,从而导致材料的力学性能降低。

2.2 38MnB5原始奥氏体晶粒粒径

多晶金属材料的强度和韧性与其晶粒粒径有着密切的关系,并遵循Hall-Petch关系:σs=σ0+Kyd-1/2[14]。式中:σs为屈服应力,σ0和Ky皆为常数,前者表示晶内对形变的抗力,后者表征晶界对形变的影响,随结构而定;d为晶粒平均直径。原始奥氏体的晶粒粒径和均匀程度决定着热冲压板的组织和力学性能,因此,通过实验研究加热温度和保温的时间对原始奥氏体晶粒粒径和均匀程度的影响,再通过组织和力学性能得出最佳工艺参数。

图4 不同奥氏体化加热温度下38MnB5钢淬火后的微观组织形貌

Fig. 4 Microstructures of quenched 38MnB5 specimens at different austenitizing temperatures

图5 不同保温时间下奥氏体化温度950 ℃时38MnB5钢淬火后的微观组织形貌

Fig. 5 Microstructures of quenched 38MnB5 specimens at 950 ℃ and different soaking time

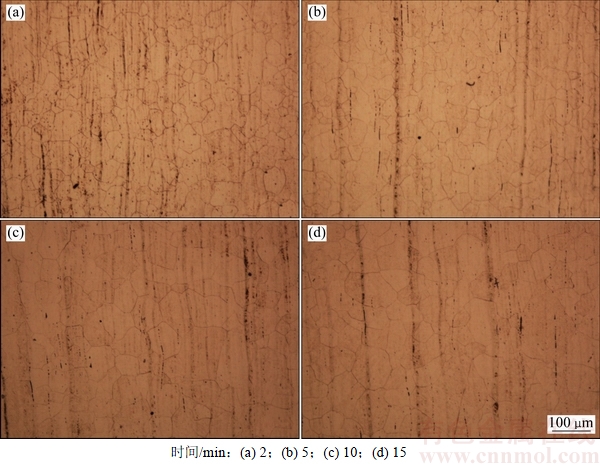

图6所示为不同加热温度下保温时间为5 min时,采用晶粒边界腐蚀法所得原始奥氏体晶界的金相显微照片。从图6可以看出:随着奥氏体化温度升高晶粒粒径增大,奥氏体化温度为950 ℃时相比于900 ℃时晶粒要更加均匀;当奥氏体化温度高于950 ℃时,晶粒均匀度增加,但晶粒增大显著。从晶粒粒径和晶粒均匀度2个方面综合考虑,最佳奥氏体化加热温度为950 ℃。

图7所示为38MnB5钢在奥氏体化加热温度为950 ℃,保温时间分别为2,5,10和15 min时原始奥氏体的金相图。从图7可以看出:当保温时间为2 min和5 min时,虽然晶粒较小,但晶粒不均匀,其原因可能是保温时间不足,晶粒分布不够均匀。当保温时间为10 min时,晶粒粒径虽然相较于2 min和5 min时略有增大,但是晶粒粒径趋于稳定。当保温时间为15 min时,由于保温时间过长,部分晶粒再次开始长大,使原始奥氏体晶粒过于粗大且出现不均匀性。因此,可以得出:板料在保温时间为10 min左右时,可以获得较为理想的原始奥氏体晶粒。

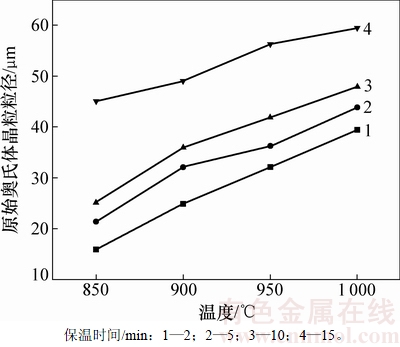

图8所示为在不同温度不同时间下原始奥氏体晶粒粒径。从图8可以看出:当保温时间一定时,原始奥氏体晶粒粒径随着加热温度的升高而增加。而且增长趋势大体相同;当加热温度一定时,原始奥氏体晶粒粒径随着保温时间的增加而增加;当温度高于950 ℃时,原始奥氏体晶粒粒径的增长速率明显加快;特别是当保温时间为15 min时,晶粒变得明显粗大,曲线的最低值也与其他3条曲线最高值相当。温度过高导致的晶粒粗大的微观机理主要在于原子的扩散机制,加热温度越高,原子运动越剧烈,原子扩散就会越剧烈,奥氏体晶粒的长大速度就会越快。

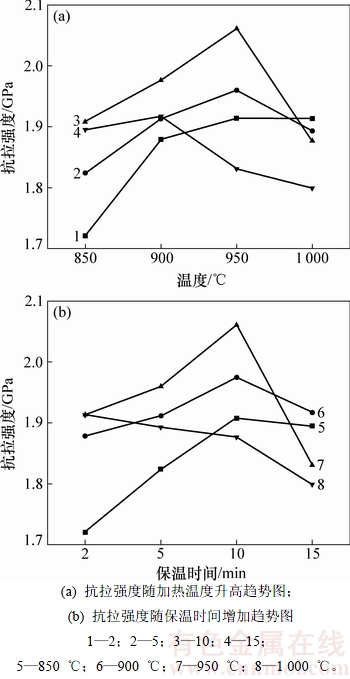

2.3 38MnB5钢淬火后力学性能

图9所示为保温时间和加热温度对淬火后的38MnB5钢抗拉强度和屈服强度的影响。由图9(a)可以看出:当保温时间一定时,随着奥氏体化加热温度的升高,淬火后材料的抗拉强度迅速升高,到达1个峰值后,随着温度的继续升高,抗拉强度开始下降。这是由于随着奥氏体化温度的升高,材料的奥氏体化程度趋于完全,淬火后的马氏体含量增加,导致其抗拉强度不断升高,其最高值达到2 061 MPa,此时的奥氏体化温度为950 ℃;当温度为1 000 ℃时,原始奥氏体晶粒的粒径开始迅速长大,马氏体板条也开始粗大影响了材料的力学性能,抗拉强度开始降低。

由图9(b)可知:当奥氏体化温度为850,900和950 ℃时,随着保温时间增加,抗拉强度增大,并达到1个峰值后,抗拉强度开始降低;而当奥氏体化加热温度为1 000 ℃时,随着保温时间的增加,抗拉强度持续降低。从图9(b)可以看出:在2 min和5 min时,由于奥氏体化的时间比较短,组织内的渗碳体还未来得及完全溶解和扩散,奥氏体两侧的碳的浓度不均匀,还需要一定的保温时间促使碳的扩散实现奥氏体均匀化;当保温时间达到10 min时,碳元素在奥氏体中也达到均匀化,组织完全奥氏体化,淬火后此时板料的抗拉强度达到了峰值;当保温时间达到15 min时,由于奥氏体晶粒逐渐增大,淬火后形成的马氏体板条粗大,因此,抗拉强度降低;当奥氏体化加热温度为1 000 ℃时,由于温度过高,使晶粒迅速长大,在奥氏体均匀化还未完全时,晶粒已经迅速粗大,因此,抗拉强度呈下降趋势。

图6 保温5 min时不同加热温度下38MnB5钢的原始奥氏体晶界的金相显微照片

Fig. 6 Prior austenite grain boundary of 38MnB5 specimens at different austenitizing temperatures for 5 min

图7 奥氏体化温度950 ℃时不同保温时间下38MnB5钢原始奥氏体晶界的显微照片

Fig. 7 Prior austenite grain boundary of 38MnB5 specimens at 950 ℃ and different soaking time

图8 奥氏体化温度和保温时间对原始奥氏体晶粒粒径的影响

Fig. 8 Effect of austenitizing temperature on prior austenite grain size at different soaking time

图9 38MnB5钢的抗拉强度与奥氏体化加热温度和保温时间的关系

Fig. 9 Relationship between tensile strength of 38MnB5 and austenitizing temperature and soaking times

3 结论

1) 当保温时间一定时,随奥氏体化加热温度的升高,马氏体组织转化完全,试样抗拉强度在950 ℃达到峰值,之后随加热温度的继续升高,抗拉强度降低。

2) 当奥氏体化加热温度一定时,随着保温时间增长,碳的扩散更加充分,使奥氏体均匀化,淬火后得到的马氏体组织较为均匀,但当保温时间超过10 min时,马氏体板块宽化和锐化,抗拉强度降低。

3) 随着加热温度的升高和保温时间的延长都会使晶粒长大,当加热温度为950 ℃,保温时间为10 min时,得到的原始奥氏体晶粒较均匀,其平均晶粒粒径为40.9 μm。

4) 38MnB5热成形钢在950 ℃保温10 min时,其伸长率和抗拉强度获得最佳化,抗拉强度为2 061 MPa,伸长率为7%。

参考文献:

[1] 王智文. 汽车轻量化技术发展现状初探[J]. 汽车工艺与材料, 2009(2): 1-5.

WANG Zhiwen. Study of development of reduce the weight of automotive[J]. Automobile Technology & Material, 2009(2): 1-5.

[2] 唐见茂. 新能源汽车轻量化材料[J]. 新型工业化, 2016, 6(1): 1-14.

TANG Jianmao. New energy automobile lightweight materials[J]. The Journal of New Industrialization, 2016, 6(1): 1-14.

[3] TURETTA A, BRUSCHI S, GHIOTTI A. Investigation of 22MnB5 formability in hot stamping operations[J]. Journal of Materials Processing Technology, 2006, 177(1): 396-400.

[4] 颜震, 韩先洪, 郝新, 等. 热冲压用硼钢B1500HS的高温热力学性能实验[J]. 塑性工程学报, 2013, 20(3): 97-101.

YAN Zhen, HAN Xianhong, HAO Xin, et al. Experimental study on thermodynamic performance of boron steel B1500HS used for hot stamping process[J]. Journal of Plasticity Engineering, 2013, 20(3): 97-101.

[5] 靳海亮, 赵爱民, 陈银莉, 等. 钛对含硼热冲压成形用钢组织和性能的影响[J]. 机械工程材料, 2012(8): 6-9.

JIN Hailiang, ZHAO Aimin, CHEN Yinli, et al. Effect of titanum on microstructure and properties of hot stamp-formed steels containing boron[J]. Materials for Mechanical Engineering, 2012(8): 6-9.

[6] 黄鸣东, 王宝雨, 李学涛, 等. 硼钢热冲压微观组织仿真及力学性能预测[J]. 工程科学学报, 2015(7): 913-918.

HUANG Mingdong, WANG Baoyu, LI Xuetao, et al. Microstructure simulation and mechanical property prediction of boron steel during hot stamping[J]. Chinese Journal of Engineering, 2015(7): 913-918.

[7] ZHANG Shiqi, HUANG Yunhua, SUN Bintang, et al. Effect of Nb on hydrogen-induced delayed fracture in high strength hot stamping steels[J]. Materials Science and Engineering A, 2015, 626: 136-143.

[8] TAYLOR T, FOURLARIS G, EVANS P, et al. New generation ultrahigh strength boron steel for automotive hot stamping technologies[J]. Materials Science and Technology, 2014, 30(7): 818-826.

[9] 姜超, 单忠德, 庄百亮, 等. 热冲压成形22MnB5钢板的组织和性能[J]. 材料热处理学报, 2012, 33(3): 78-81.

JIANG Chao, SHAN Zhongde, ZHUANG Bailing, et al. Microstructure and properties of hot stamping 22MnB5 steel[J]. Transactions of Materials and Heat Treatment, 2012, 33(3): 78-81.

[10] 戴启勋. 金属组织控制原理[M]. 北京: 化学工业出版社, 2009: 3-5.

DAI Qixun. The principle of metal microstructure control[M]. Beijing: Chemical Industry Press, 2009: 3-5.

[11] 王立影, 王芝斌. 热冲压成形零件质量控制因素分析[J]. 锻压技术, 2010(2): 117-119.

WANG Liying, WANG Zhibin. Hot stamping parts quality control factors analysis[J]. Forging & Stamping Technology, 2010(2): 117-119.

[12] NADERI M, SAEED-AKBARI A, BLECK W. The effects of non-isothermal deformation on martensitic transformation in 22MnB5 steel[J]. Materials Science and Engineering A, 2008, 487(1/2): 445-455.

[13] 王春芳, 王毛球, 时捷, 等. 利用EBSD技术研究板条马氏体钢的微观组织及力学性能的关系[C]//第二届全国电子背散射衍射技术及其应用会议论文集. 北京: 中国体视学学会, 2007: 171-176.

WANG Chunfang, WANG Maoqiu, SHI Jie, et al. Microstructural characterization and its effect on the strength of low carbon martensitic steel[C]//The 2nd National Conference on the Electron Back Scattering Diffraction Technique and its Application. Beijing: Chinese Society for Stereology, 2007: 171-176.

[14] 宋维锡. 金属学[M]. 北京: 冶金工业出版社, 2007: 156-157.

SONG Weixi. Metallization[M]. Beijing: Metallurgical Industry Press, 2007: 156-157.

(编辑 杨幼平)

收稿日期:2017-04-15;修回日期:2017-07-13

基金项目(Foundation item):国家自然科学基金资助项目(U1460101);高等学校博士学科点专项科研基金资助项目(20120006120002) (Project(U1460101) supported by the National Natural Science Foundation of China; Project(20120006120002) supported by the Specialized Research Fund for Doctoral Program)

通信作者:朱国明,博士,副教授,从事塑性加工,数值模拟仿真研究;E-mail:zhuguoming@ustb.edu.cn