DOI: 10.11817/j.ysxb.1004.0609.2020-39648

柱塞泵用C67300锰黄铜油的润滑摩擦磨损性能

苟佩佩1,王 娜2,徐 瑞2,董志刚3,王 清1,康仁科3,董 闯1

(1. 大连理工大学 材料科学与工程学院,大连 116024;

2. 中航工业西安飞行自动控制研究所,西安 710065;

3. 大连理工大学 机械工程学院,大连 116024)

摘 要:研究退火态和冷轧态C67300锰黄铜合金在油润滑状态以及不同加载载荷和转速条件下,与对磨副GCr15钢的摩擦磨损性能,并借助一系列表征测试技术研究C67300锰黄铜的微观组织、力学性能(尤其硬弹比H/E)与摩擦性能的关联。结果表明:C67300锰黄铜主要由α-Cu(FCC结构)固溶体基体、β′-CuZn(B2结构)、和硬质颗粒ω-Mn5Si3 (D88结构)构成。冷轧态C67300锰黄铜的硬度(184 HV)和屈服强度(410 MPa)略高于其退火态的(137 HV,345 MPa),从而导致合金的硬弹比(H/E)从0.014增大至0.020。在恒定载荷300 N、不同转速400~700 r/min条件下,冷轧态和退火态C67300锰黄铜的摩擦因数都随转速增加而降低,即摩擦因数f从0.06~0.07减小至0.02;而在恒定转速400 r/min、不同施加载荷200~500 N条件下,冷轧态和退火态合金摩擦因数都随施加载荷增加而增加,如冷轧态时摩擦因数从0.03增大至0.07。在不同试验条件下,冷轧态C67300锰黄铜的摩擦因数均低于退火态的,且变化幅度较小,表现出更佳的耐磨性,这主要是由于冷轧态C67300锰黄铜的H/E更接近于对磨副GCr15钢的H/E=0.035,从而有望通过提高合金的硬弹比,以实现与对磨副合金匹配来改善材料的耐磨性。

关键词:锰黄铜合金;预变形;摩擦;磨损

文章编号:1004-0609(2020)-12-2920-10 中图分类号:TG146.1 文献标志码:A

轴向柱塞泵是现代液压传动动力源的核心组件,斜盘柱塞式液压泵由于具有转换效率高、结构紧密、易于变量控制等优势,主要用作飞行控制和燃油泵及部分工业装备、机械制造液压系统[1-5]。其中,滑靴部件在较大转动惯量的作用下受到重载偏心载荷的影响,最容易发生磨损和擦伤,并显著影响柱塞泵的寿命[6-10]。滑靴的备选材料主要有铝青铜、球墨铸铁、铝黄铜和锰黄铜,其中锰黄铜由于其良好的耐磨性、优良的塑性加工能力和自润滑作用应用最为广泛。锰黄铜的主要牌号有SM2158、LTH60、C67300、LMtsKNS、E133等[11-15],其合金成分范围为Cu 56.0~ 66.4、Mn 2.0~4.0、Si 0.5~2.0、Pb 0.2~1.8、Fe≤0.5、Al≤0.5、Ni≤0.5、Zn余量(质量分数,%)。高强耐磨锰黄铜的理想组织是在α-Cu(FCC结构)的软基体上分布高硬度的第二相颗粒[14, 16],如β′-CuZn(B2结构)和ω-Mn5Si3(D88结构)等。其耐磨机理主要是FCC基体优异的塑性有助于提高收口合格率,而且可以抑制裂纹扩展、存贮润滑油等[17];微量Si、Fe和Mn等元素的添加可形成细小且弥散分布的(Mn,Fe)5Si3硬质相,提高合金的耐磨性[18];少量游离的Pb单质在摩擦表面铺展,起到固体润滑的作用[19-21]。例如,WAHEED等[11]研究了三种商业黄铜(326、SIB、E133)与低碳钢对磨时的干滑动摩擦磨损行为,在滑动速度0.16~0.41 m/s和施加载荷10~70 MPa下,黄铜的摩擦因数f约为0.36,其磨损机理主要是黏着磨损和磨粒磨损。

然而,微量元素的添加量会影响硬质相粒子的析出状态,其尺寸、形貌和分布、以及基体晶粒尺寸都会影响合金的耐磨性能,目前,从工艺角度来说已经很难提升材料的耐磨性能。近年来,研究学者们从成分设计角度考虑对现有锰黄铜合金进行了成分微调,以期获得具有最佳耐磨性的微观组织。王子文等[22]通过在HMn64-8-5-1.5黄铜中添加Ce元素,使得Mn5Si3硬质相粒子更加细小且分布均匀,可显著提高合金的耐磨性。MINDIVAN等[12]发现在Cu-8Mn-4Al-1Si-20Zn(质量分数,%)合金与M2工具钢干磨时,当α-Cu的体积分数从8%增大到23%,合金的硬度从281 HV降低到250 HV,但耐磨性提高15%以上,这主要是由于磨损表面产生的裂纹向下扩展时遇到塑性良好 的α-Cu会产生钝化,减少裂纹的形核与扩展。MOSHKOVICH等[23]研究了Cu-38Zn-3Pb(质量分数,%)合金与Cu对磨时的油润滑摩擦磨损行为,发现在施加载荷为3~64 MPa、滑动速度为0.35 m/s条件下,合金的摩擦因数f仅为0.01~0.02,这是由于在亚表面上,α-Cu晶内发生滑移,产生超塑性变形,且磨损表面上Pb单质颗粒均匀分布,均提高了材料的耐磨性。

柱塞泵苛刻的服役环境为高压28~35 MPa、高转速15000~20000 r/min、高振动30 G以上及宽温域-55~135 ℃,且滑靴的对磨副材料为高硬度的GCr15(HRC65)轴承钢,这些条件对滑靴的耐磨性能要求极高。目前,在该条件下对C67300锰黄铜与GCr15轴承钢油润滑摩擦磨损行为的相关研究鲜有报道。因此,本文主要研究了退火态和冷轧态的C67300锰黄铜在不同加载载荷和不同转速下与GCr15对摩副的摩擦磨损行为。为模拟滑靴苛刻的服役环境,选择的摩擦试验条件为:载荷200~500 N,对应的接触应力为11~28 MPa;转速为400~700 r/min,对应的滑动速度为0.48~0.84 m/s,并对试验后的摩擦副表面形貌进行了表征,探讨了油润滑磨擦时的磨损机理;此外,还对退火态和冷轧态C67300锰黄铜的微观组织和力学性能进行了对比,其中退火态为300 ℃保温1 h,冷轧态为预变形处理后的状态,即退火态经30%冷变形处理。

1 实验

实验采用的C67300锰黄铜和GCr15轴承钢的合金成分见表1。采用Bruker D8 Focus型X射线衍射仪(Cu Ka辐射,l=0.15406 nm)对合金进行物相结构分析;采用OLYMPUS金相显微镜和Zeiss Supra场发射扫描电镜观察C67300锰黄铜的微观组织及磨损后的形貌,其中腐蚀液为3 g FeCl3+30 mL盐酸+100 mL无水乙醇;采用UTM5504-G型电子万能试验机测试C67300锰黄铜的力学性能,拉伸样品采用圆棒状,标距为6 mm×20 mm,拉伸速率为0.5 mm/min,并在弹性拉伸区采用引伸计;采用HVS-1000型维氏硬度计测定合金的显微硬度,其中施加载荷为300 N、加载时间15 s,每个样品至少测试10次,取其平均值;采用MVF-1A型立式摩擦磨损试验机对试样进行滑动摩擦磨损实验,摩擦副类型为销盘式,退火态(其热处理工艺为300 ℃保温1 h)和冷轧态(退火态预变形30%)的C67300锰黄铜作为摩擦销,对磨副为GCr15钢(其热处理工艺为860 ℃淬火+200 ℃回火),润滑油为聚甲基苯基硅油。实验前将摩擦副均进行抛光处理,试验温度为25 ℃,施加载荷范围为200~500 N,对应的接触应力为11~28 MPa;试验转速为400~700 r/min,对应的滑动速度为0.48~0.84 m/s;接触面积为18 mm2,摩擦时间为20 min;对于每一个参数至少进行三次实验,然后取其平均值;使用Image-J软件统计析出相的体积分数。

2 结果和讨论

2.1 合金的微观组织与力学性能

表1 C67300锰黄铜和GCr15轴承钢合金的化学成分

Table 1 Chemical compositions of C67300 manganese brass and GCr15 steel alloy (mass fraction, %)

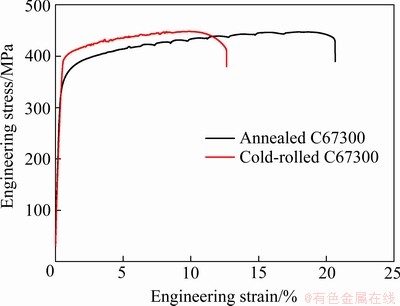

C67300锰黄铜的XRD谱如图1所示。由图1可知,C67300锰黄铜主要由三相构成,分别为面心立方FCC结构的α-Cu固溶体、简单立方B2-CsCl结构β′-CuZn相和六方结构D88 ω-Mn5Si3相。图2所示分别为退火态和冷轧态C67300锰黄铜的OM显微组织图,其中图2(a)和(c)所示为横截面形貌组织,图2(b)和(d)所示为纵截面形貌组织。可以看出,无论退火态还是冷轧态,α-Cu基体晶粒为多边形,且存在退火孪晶(见图2(a)和(c)),晶粒尺寸在两个状态下分别为15 μm和13 μm;β′呈不规则条状,较α更容易腐蚀;Mn5Si3相在横截面上表现为六角状,在纵截面上表现为粗大的长条状。统计各相的体积分数分别为:α 83%、β′ 8%、Mn5Si3 9%。结合XRD谱和金相组织形貌可知,C67300锰黄铜主要是α和β′作为基体,少量均匀分布的Mn5Si3作为强化颗粒。图3所示为C67300锰黄铜拉伸工程应力-应变曲线,从中测得退火态C67300锰黄铜的弹性模量E=94 GPa,屈服强度σ0.2=345 MPa;而冷轧态C67300锰黄铜的弹性模量E=92 GPa,屈服强度σ0.2=410 MPa。冷轧后C67300锰黄铜的弹性模量无显著变化,屈服强度得到了明显提升,此外在屈服之后拉伸曲线出现明显的锯齿波动现象,这可能与拉伸过程中Mn5Si3强化相的被拉断有关。摩擦副的力学性能数据均列于表2中。通过显微硬度测试得GCr15硬度为7.419 GPa (757 HV)、退火态C67300锰黄铜硬度为1.343 GPa(137 HV),冷轧态C67300锰黄铜的硬度相比退火态的有所提升,为1.803 GPa(184 HV)。查阅文献可知GCr15合金的各项力学性能,如表2所列[24],其中弹性模量E=212 GPa。由此,可计算得到GCr15钢的硬弹比为H/E=0.035,退火态和冷轧态C67300锰黄铜的硬弹比分别为0.014和0.020,其中冷轧态C67300锰黄铜的硬弹比相比退火态的提高43%,且更为接近GCr15钢的硬弹比(H/E=0.035)。

图1 退火态C67300锰黄铜的XRD谱

Fig. 1 XRD pattern of annealed C67300 manganese brass

图2 C67300锰黄铜退火态和冷轧态的OM光学微观组织形貌

Fig. 2 OM microstructural images of annealed((a), (b)) and cold-rolled ((c), (d)) C67300 manganese brass samples

表2 摩擦副的力学性能

Table 2 Mechanical properties of friction pair

图3 退火和冷轧C67300锰黄铜的工程拉伸应力-应变曲线

Fig. 3 Engineering tensile stress-strain curves of annealed and cold-rolled C67300 manganese brass samples

2.2 C67300锰黄铜的摩擦性能

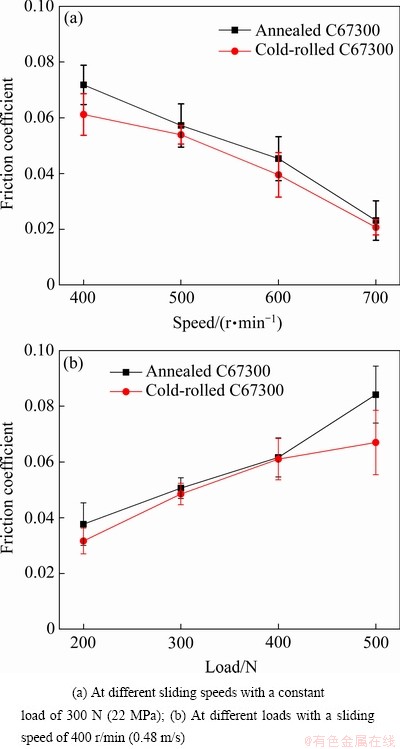

图4(a)所示为施加载荷为300 N(22 MPa)、退火态C67300锰黄铜在不同滑动速度下的摩擦因数曲线,可以看出,在400 r/min(0.482 m/s)下,摩擦因数刚开始维持在f=0.07,随后呈现先下降后上升的趋势最后稳定在f=0.06;当转速增大到500 r/min(0.60 m/s)时,摩擦因数从最初的f=0.04开始增大,最后稳定在f=0.05附近;而600 r/min(0.72 m/s)的摩擦因数和400 r/min(0.48 m/s)的变化趋势相似,先下降再上升,约为f=0.04;当转速继续增大到700 r/min(0.84 m/s)时,摩擦因数f进一步下降到0.02。冷轧态C67300锰黄铜在400 r/min(0.48 m/s)的滑动速度下不同载荷时摩擦因数随时间的变化曲线基本一致(见图4(b));在500 N(28 MPa)载荷作用下,摩擦因数f从0.07逐渐降至0.05,图中400 N(22 MPa)的曲线明显波动较大,f均值为0.04。300 N(16.6 MPa)和200N(11 MPa)时的摩擦因数分别稳定在f=0.03和f=0.02左右。从不同速度和不同载荷下的摩擦曲线均可看出,随速度增大摩擦初期的摩擦因数下降,载荷增加摩擦因数增加,且随时间的延长摩擦因数呈现一定的波动,进入磨合期后最终稳定在某一数值附近。摩擦初期呈现不同程度的波动,可能是摩擦面微凸体分布不均匀促使接触面面积发生变化而引起的。此外,摩擦表面可能存在的微小杂质和颗粒,也会引起摩擦因数发生变化。进入磨合期,C67300锰黄铜在径向载荷作用下,表面与润滑油形成一层稳定的耐磨层,故而摩擦因数逐步稳定。

图4 不同加载条件下的C67300锰黄铜的摩擦因数随时间的变化曲线

Fig. 4 Variations of frictional coefficient of C67300 manganese brass with time

图5 不同加载条件下C67300锰黄铜的摩擦因数变化情况

Fig. 5 Variations of frictional coefficient of C67300 manganese brass

图5(a)所示为退火态C67300锰黄铜和冷轧态C67300锰黄铜在不同滑动速度下载荷为300 N(22 MPa)的平均摩擦因数对比。可以看出,退火态C67300锰黄铜的摩擦因数从f=0.07减小到f=0.03,而冷轧态C67300锰黄铜的摩擦因数均低于退火态。随着摩擦副之间的相对滑动速度增大,对接触面的润滑油产生了流体动压的效应,表面膜厚增大,摩擦副之间的微凸起接触面积减少,金属之间的干摩擦比例减少,边界与液体摩擦成分增大,因此摩擦因数减小[25]。但C67300锰黄铜在不同载荷下滑动速度为400 r/min (0.48 m/s)的平均摩擦因数的变化规律反而均呈上升趋势(见图5(b)),且冷轧态C67300锰黄铜的摩擦因数均低于退火态C67300锰黄铜的,其增大幅度较退火态的更为平缓,表现出良好的耐磨性。其中施加载荷为200 N (11 MPa)和500 N(28 MPa)时,不同状态的C67300锰黄铜摩擦因数相差较大,同时退火态C67300锰黄铜的摩擦因数波动程度也较大。这是由于摩擦副表面的接触面压力增大,摩擦销和对磨副之间的间隙减小,实际金属接触的微凸体表面积增大,间隙中所能容纳的油膜厚度减小,甚至发生润滑状态转变;其次在载荷增大时,摩擦副接触面之间的分子作用力增大;C67300锰黄铜在GCr15对磨副表面高速滑动,产生大量热量,导致润滑油的黏度减小,造成润滑效果降低,均造成了摩擦因数的增加。当摩擦速度从400 r/min增大到700 r/min,C67300锰黄铜的摩擦因数f从0.06~0.07减小到0.02;而施加载荷从200 N增大到500 N时,不同状态的C67300锰黄铜的摩擦因数f从0.03~0.04增大到0.07~0.08,冷轧态C67300锰黄铜相较于退火态整体呈现出更佳的耐磨性。此外在不同摩擦条件下、两种状态C67300锰黄铜的耐磨性良好,摩擦因数均较低,约为0.05±0.03。这主要是由于C67300锰黄铜中83%的α固溶体不仅易于加工成滑靴即降低收口难度,而且可以提高材料的塑性,在摩擦过程中阻止裂纹扩展,易于储油;其次,作为硬质颗粒的载体易于变形而不至于擦伤摩擦的表面;C67300锰黄铜中8%的β′具有较高的硬度和热加工能力,提高材料的表面耐磨性;C67300锰黄铜中9% Mn5Si3主要承受纵向交变载荷,提高抗冲击能力,进而提高寿命。因此,C67300锰黄铜能够在航空柱塞泵服役过程中提供良好的耐磨性。

2.3 C67300锰黄铜的磨损表面形貌表征及微观机理研究

对实验后的C67300锰黄铜和GCr15钢试样磨损表面进行了SEM分析。图6所示为300 N(17 MPa)载荷下,退火态C67300锰黄铜和对磨副GCr15钢在不同滑动速度下摩擦表面的SEM像。可以看出,退火态C67300锰黄铜试样表面在400 r/min(0.48 m/s)速度下,有很明显的磨痕,部分磨痕沿着宽度方向扩展,并在表面存在剥离层;另外,对磨副GCr15钢试样表面出现不同程度的磨痕,在磨痕的沟槽位置附着形状不规则的5 μm大小的磨粒A(见图6(a))。EDS能谱分析结果表明磨粒A的成分主要是Cu、Zn、Fe等元素(见表3),说明是磨粒A从退火态C67300锰黄铜表面脱落下来的C67300锰黄铜。磨粒A的脱落主要是摩擦副的擦伤,以及变形应力的积累所引起的,从而导致了C67300锰黄铜亚表面裂纹形核,并沿滑动方向逐步扩展到试样表面,在亚表面裂纹和滑动表层之间分层,并以片状形式脱离,形成磨粒。随着滑动速度增加,掉落在C67300锰黄铜试样表面的大块磨粒逐渐被磨除棱角,变成数目较多且尺寸更小的磨粒。如图6(b)所示,退火态C67300锰黄铜在500 r/min的速度下,光滑C67300锰黄铜试样表面上分布着大小不一的圆饼状磨粒,且C67300锰黄铜表面的磨痕较低速下的宽度均有所增加,同时在磨痕的周围出现剥离迹象。其次,C67300锰黄铜试样表面脱落的不规则磨粒在摩擦表面上不断的滑动,磨粒的周围逐渐变得光滑,继而在对磨副GCr15钢试样表面观察到球形的磨粒B(见图6(b)),说明磨粒从C67300锰黄铜表面脱落下来并黏着在对磨副GCr15钢表面。转速为500 r/min时的摩擦因数相比于400 r/min时的有所下降,主要是由于在摩擦过程中,大的磨粒被润滑油排除和碾碎,形成类似于滚动摩擦的效果;此外在摩擦过程中C67300锰黄铜试样合金表面产生热量,摩擦表面逐渐被氧化。EDS结果表明,磨粒B和C主要含有Cu、Zn和部分O元素(见表3)。C67300锰黄铜试样在600 r/min的速度下,其磨损表面试样表面存在极少量的磨粒,和大片的氧化产物(见图6(c)),EDS能谱分析结果表明片状颗粒D主要含有Cu、Zn、O、Fe等元素(见表3)。这可能是由于滑动速度增大,润滑油的动压效果增强,大的颗粒被碾碎或排出,但摩擦产生的热量增多,氧化磨损增加。当转速为700 r/min时,C67300锰黄铜试样摩擦表面较为平整,部分面积发生黏着(见图6(d)),这是由于C67300锰黄铜试样表面形成强度较低的氧化层,并在交变载荷作用下发生黏着,继而在剪切力的作用下脱落。综上分析,在300 N(17 MPa)载荷下,转速从400 r/min增大到700 r/min时,退火态C67300锰黄铜和对磨副GCr15钢主要的磨损形式为磨粒和剥离磨损逐渐转变为黏着和氧化磨损,且摩擦因数呈下降趋势。

图6 载荷300 N(17 MPa)和不同滑动速度下退火态C67300锰黄铜摩擦副试样表面的SEM像

Fig. 6 SEM surface images of annealed C67300 manganese brass under load of 300 N(17 MPa) at different sliding speeds

表3 图6中摩擦副磨损表面磨粒的EDS分析结果

Table 3 EDS analysis results of abrasive particles on worn surfaces of friction pairs show in Fig. 6

图7所示为冷轧态C67300锰黄铜试样在不同载荷下磨损表面的SEM像。由图7可知,随着磨擦表面接触应力的增加,冷轧态C67300锰黄铜试样表面的磨损程度逐渐增加。在200 N(11 MPa)作用下,材料表面沿滑动方向出现少量轻微的划痕,且表面发生轻微的擦伤(见图7(a))。当载荷增大到300 N(17 MPa)时(见图7(b)),C67300锰黄铜试样的表面划痕增多,并逐渐沿着沟槽的两边向外扩展,发生剥离。这可能是由于摩擦副表面接触应力增大,导致摩擦副的金属表面直接接触,C67300锰黄铜表面脱落的硬质磨粒对滑动产生较大的阻力,促使摩擦副表面塑性变形加剧,沟槽加深。当施加载荷增大到400 N(22 MPa)时,摩擦副实际接触表面积继续增加,C67300锰黄铜表面沿滑动方向存在部分氧化层掉落后形成的点蚀坑和鳞剥,磨损的形式转变为疲劳磨损,其对磨副GCr15钢出现粘着的痕迹(见图7(c))。当载荷为500 N(28 MPa)时(见图7(d)),C67300锰黄铜试样表面全部转变为凹凸不平的小坑,观察不到明显的摩擦方向,从放大的点蚀坑明显观察到C67300锰黄铜发生破碎形成纳米颗粒。综上分析,C67300/GCr15钢摩擦副的接触载荷在200~ 500 N(11~28 MPa)变化的范围内,其磨损主要形式是磨粒磨损逐步过渡为剥离和氧化磨损进而转化为疲劳和黏着磨损;且在摩擦过程中,其磨损程度轻,则摩擦因数较小,如冷轧态C67300锰黄铜试样表面的磨损程度(见图7)与摩擦因数变化(见图4)对应较好。

在相同加载载荷和滑动速度下,300 N和400 r/min下的退火态C67300锰黄铜和冷轧态C67300锰黄铜摩擦表面的SEM像分别如图6(a)和图7(b)所示。对比发现,冷轧态C67300试样磨损程度明显较轻,磨痕深度较浅。LEYLAND等[26]和MUSIC等[27]通过研究硬弹比与耐磨性的关系,发现大弹性存储能能够容忍载荷变化,高硬度的材料表面能够起到减磨耐磨的作用,因此硬弹比越高的材料其耐磨性越好。冷轧态C67300锰黄铜的晶粒相对小,硬度高;而弹性模量变化较小,其硬弹比较高,与GCr15钢的更为接近,从而体现出更好的耐磨性。为了进一步分析硬质相在软基体中的作用,观察了退火态C67300锰黄铜试样在300 N、400 r/min下的纵截面,结果如图8所示。可以看出试样存在15 μm厚度的塑性流动,硬质相Mn5Si3颗粒发生了断裂,较短的颗粒直接脱离基体,形成裂纹,较长的颗粒从中间断裂,沿摩擦方向发生旋转。这是由于基体中的硬质相过于粗大,不能很好地嵌合在基体中,容易造成材料发生塑性变形,产生裂纹,而冷轧态C67300锰黄铜并无明显变化。此外,硬质相的分布较分散,没有形成良好的耐磨支撑面,而硬质相的尺寸、分布以及软基体的分布往往对耐磨性产生最重要的影响。WAHEED等[11]的研究中也发现材料在滑动时容易脱落出Mn5Si3颗粒。这些研究均表明,摩擦副材料本身在摩擦过程中十分重要,不仅要求具有合适的软基体和硬质点的比例、分布和形貌,而且还要求摩擦副材料需要具有较小的弹性模量、较高的硬度、良好的塑性。

图7 滑动速度400 r/min(0.48 m/s)和不同加载载荷条件下冷轧态C67300锰黄铜的表面SEM像

Fig. 7 SEM surface images of cold-rolled C67300 manganese brass under different loads at constant sliding speed of 400 r/min(0.48 m/s)

图8 300 N和400 r/min条件下退火态C67300锰黄铜摩擦亚表面的SEM像和示意图

Fig. 8 SEM images(a) and schematic diagram(b) of friction subsurface of annealed C67300 manganese brass under load of 300 N with sliding speed of 400 r/min

3 结论

1) 退火态和冷轧态C67300锰黄铜主要由α-Cu (FCC结构)固溶体基体、β′-CuZn(B2结构)、和硬质颗粒ω-Mn5Si3(D88结构)构成,后两者的体积分数分别约为8%和9%,其中退火态的晶粒更为细小。

2) 冷轧态C67300锰黄铜的力学性能优于退火态。冷轧态C67300锰黄铜室温下的屈服强度σ0.2=410 MPa,硬度1.803 GPa (184 HV),伸长率d=12.6%,退火态C67300锰黄铜屈服强度σ0.2=345 MPa,硬度1.343 GPa (137 HV),伸长率d=20.6%,并计算得到两种状态合金的硬弹比(退火态时H/E=0.014,冷轧态时H/E=0.020),且冷轧态C67300锰黄铜的H/E相较于退火态的提高43%。

3) 随着C67300锰黄铜摩擦销的转动速度在400~700 r/min(0.48~0.84 m/s)之间增加,摩擦因数均减小。冷轧态的f从0.06减小至0.02;退火态C67300锰黄铜摩擦因数f从0.07减小至0.02,其主要的磨损形式为磨粒和剥离磨损逐渐转变为黏着和氧化磨损。C67300/GCr15钢摩擦副的接触载荷在200~500 N(11~28 MPa)变化的范围内,摩擦因数均增大,退火态C67300锰黄铜摩擦因数f从0.04增大到0.08;而冷轧态C67300锰黄铜摩擦因数f从0.03增大至0.07,其磨损主要形式是磨粒磨损逐步过渡为剥离和氧化磨损进而转化为疲劳和黏着磨损。

4) 在不同摩擦条件下,冷轧态C67300锰黄铜的摩擦因数均低于退火态的,且变化幅度较小,体现出较好的耐磨性。这主要由于冷轧态C67300锰黄铜的硬弹比H/E=0.020更接近于GCr15的H/E=0.035,两者可以更好地匹配着,而退火态合金由于硬弹比H/E=0.014远小于GCr15的。此外退火态C67300锰黄铜的亚表面形成了15 μm厚度的塑性流动层,硬质相Mn5Si3发生断裂并脱落,基体形成裂纹,影响了其耐磨性。

REFERENCES

[1] CHEN Y, ZHANG J, XU B, CHAO Q, LIU G. Multi-objective optimization of micron-scale surface textures for the cylinder/valve plate interface in axial piston pumps[J]. Tribology International, 2019, 138: 316-329.

[2] XU B, ZHANG J, YANG H. Investigation on structural optimization of anti-overturning slipper of axial piston pump[J]. Science China Technological Sciences, 2012, 55(11): 3010-3018.

[3] HAIDAK G, WANG D, E S, LI F. The impact of the deformation phenomenon on the process of lubricating and improving the efficiency between the slipper and swashplate in axial piston machines[J]. IEEE Access, 2019, 7: 69393-69409.

[4] WANG Z Q, HU S, JI H, WANG Z, LIU X T. Analysis of lubricating characteristics of valve plate pair of a piston pump[J]. Tribology International, 2018, 126: 49-64.

[5] SHIN J, KIM K. Effect of surface non-flatness on the lubrication characteristics in the valve part of a swash-plate type axial piston pump[J]. Meccanica, 2014, 49(5): 1275-1295.

[6] 雷 勇. 航空高压高速液压柱塞泵的设计研究[D]. 贵州: 贵州大学, 2006: 7-23.

TEI Yong. Design and research of aviation high pressure and high speed hydraulic piston pump[D]. Guizhou: Guizhou University, 2006: 7-23.

[7] 毕 岗. 柱塞泵关键摩擦副材料抗擦伤性能评价研究[D]. 合肥: 合肥工业大学, 2017: 1-11.

BI Gang. Evaluation of anti-scratch performance of key friction pair materials of piston pump[D]. Hefei: Hefei University of Technology, 2007: 1-11.

[8] MA J, M, CHEN J, LI J, LI Q L, REN C Y. Wear analysis of swash plate/slipper pair of axis piston hydraulic pump[J]. Tribology International, 2015, 90: 467-472.

[9] SCHUHLER G, JOURANI A, BOUVIER S, PERROCHAT J M. Wear mechanisms in contacts involving slippers in axial piston pumps: A multi-technical analysis[J]. Journal of Materials Engineering and Performance, 2018, 27(10): 5395-5405.

[10] 张雪超. 航空柱塞泵滑靴副和柱塞副油膜特性研究[D]. 浙江: 浙江大学, 2016: 1-11.

ZHANG Xue-chao. Study on oil film characteristics of slide shoe pair and plunger pair of aviation plunger pump[D]. Zhejiang: Zhejiang University, 2016: 1-11.

[11] WAHEED A, RIDLEY N. Microstructure and wear of some high-tensile brasses[J]. Journal of Materials Science, 1994, 29(6): 1692-1699.

[12] MINDIVAN H, CIMENOGLU H, KAYALI E S. Microstructures and wear properties of brass synchroniser rings[J]. Wear, 2003, 254(5/6): 532-537.

[13] 董福伟, 张 铎, 黄国兴. 高强耐磨锰黄铜的研究[J]. 理化检验(物理分册), 2006(8): 389-391.

DONG Fu-wei, ZHANG Duo, HUANG Guo-xing. Research on high-strength wear-resistant manganese brass[J]. Physical and Chemical Testing (Physics), 2006(8): 389-391.

[14] SUN Y S, LORIMER G W, RIDLEY N. Microstructure of high-tensile strength brasses containing silicon and manganese[J]. Metallurgical Transactions A, 1989, 20(7): 1199-1206.

[15] PUGACHEVA N B, PANKRATOV A A, FROLOVA N Y, KOTLYAROV I V. Structural and phase transformations in α+β brasses[J]. Russian Metallurgy, 2006, 2006(3): 239-248.

[16] 陈一胜, 傅 政, 朱志云. 高强耐磨黄铜的研究现状[J]. 有色金属科学与工程, 2012(5): 27-33.

CHEN Yisheng, FU Zheng, ZHU Zhi-yun. Research status of high-strength wear-resistant brass[J]. Nonferrous Metal Science and Engineering, 2012(5): 27-33.

[17] LI H, JIE J, LIU S. Crystal growth and morphology evolution of D88 (Mn, Fe)5Si3phase and its influence on the mechanical and wear properties of brasses[J]. Materials Science and Engineering A, 2017, 704: 45-56.

[18] LI H, LIU S C, JIE J C, LIU S C, ZHANG Y B, LI T J. Influence of precipitation hardening on the sliding wear behavior of a Cu-Zn-Al-Mn-Si based brass alloy[J]. Materials Science Forum, 2017, 898: 355-360.

[19] LI H, JIE J, ZHANG P C, JIE C X, WANG T M, LI T J. Study on the formation and precipitation mechanism of Mn5Si3 phase in the MBA-2 brass alloy[J]. Metallurgical and Materials Transactions A, 2016, 47(6): 2616-2624.

[20] PANAGOPOULOS C N, GEORGIOUS E P, SIMEONIDI K. Lubricated wear behavior of leaded α+β brass[J]. Tribology International, 2012, 50: 1-5.

[21] PUGACHEVA N B. Structure of commercial α+β brasses[J]. Metal Science & Heat Treatment, 2007, 49(1/2): 67-74.

[22] 王子文, 陈少华, 李艳锋, 黄国杰, 解浩峰, 彭丽君, 米绪军. 稀土Ce对HMn64-8-5-1.5黄铜组织和磨损性能的影响[J]. 摩擦学学报, 2016, 36(5): 606-613.

WANG Zi-wen, CHEN Shao-hua, LI Yan-feng, HUANG Guo-jie, XIE Hao-feng, PENG Li-Jun, MI Xu-jun. Effect of rare earth Ce on microstructure and wear properties of HMn64-8-5-1.5 brass[J]. Chinese Journal of Tribology, 2016, 36(5): 606-613.

[23] MOSHKOVICH A, PERFILYEV V, LAPSKER I, RAPOPORT L. Friction, wear and plastic deformation of Cu and α/β brass under lubrication conditions[J]. Wear, 2014, 320: 34-40.

[24] 《中国航空材料手册》委员会. 中国航空材料手册. 第1卷. 结构钢 不锈钢[M]. 北京: 中国标准出版社, 2002: 502-514.

Committee of “China Aviation Material Handbook”. China Aviation Material Handbook. Volume 1. Structural steel and stainless steel[M]. Beijing: China Standard Press, 2002: 502-514.

[25] 李贻琤. 黄铜在润滑状态下的摩擦因数[J]. 华侨大学学报(自然科学版), 1989, 3(12): 87-91.

LI Yi-zheng. Friction coefficient of brass under lubrication[J]. Journal of Huaqiao University (Natural Science), 1989, 3(12): 87-91.

[26] LEYLAND A, MATTHEWS A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour[J]. Wear, 2000, 246(1): 1-11.

[27] MUSIL J, KUNC F, ZEMAN H, POLAKOVA H. Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings[J]. Surface & Coatings Technology, 2002, 154(2): 304-313.

Friction and wear properties of C67300 manganese brass under oil lubrication for application in piston pumps

GOU Pei-pei1, WANG Na2, XU Rui2, DONG Zhi-gang3, WANG Qing1, KANG Ren-ke3, DONG Chuang1

(1. School of Material Science and Engineering, Dalian University of Technology, Dalian 116024, China;

2. The Aviation Industry Corporation of China, Xi’an Flight Automatic Control Institute, Xi’an 710065, China;

3. School of Mechanical Engineering, Dalian University of Technology, Dalian 116024,China)

Abstract: The present work investigated primarily the friction and wear properties of annealed and cold-rolled C67300 manganese brass against the GCr15 steel (friction pair) under the conditions of different loads and speeds, as well as the oil lubrication. The microstructures, mechanical properties, and friction properties of annealed and cold-rolled C67300 manganese brass were characterized by a series of testing techniques. Experimental results show that the C67300 manganese brass is constituted of α-Cu solid solution matrix with a face-centered-cubic (FCC) structure, plus β′-CuZn with a B2 structure and ω-Mn5Si3 with a D88 structure. The microhardness (184 HV) and yield strength (410 MPa) of cold-rolled C67300 manganese brass are slightly higher than those of annealed alloy (137 HV and 345 MPa), which results in a ratio of microhardness to Young’s modulus of the cold-rolled alloy (H/E=0.02) much higher than that of the annealed (H/E=0.014). The friction coefficients of both annealed and cold-rolled C67300 manganese brass decrease, with the increase of speed from 400 r/min to 700 r/min when fixing the applied load of 300 N, from f=0.06-0.07 to f=0.02. By contrast, the friction coefficients of both annealed and cold-rolled C67300 manganese brass increase with the applied load from 200 N to 500 N when fixing the speed of 400 r/min, as exampled by the fact that the friction coefficient of cold-rolled alloy increases f=0.03 to f=0.07. It is found that a relatively lower friction coefficient always appears in the cold-rolled alloy under any applied conditions, indicating that the cold-rolled C67300 manganese brass possesses a better wear resistance than the annealed. It is mainly ascribed to the fact that the H/E value (H/E=0.02) of cold-rolled C67300 manganese brass is much close to that of the friction pair of GCr15 steel (H/E=0.035), which is expected to improve the wear resistance of alloys by matching the H/E values of friction pairs well.

Key words: C67300 manganese brass; pre-deformation; friction; wear

Foundation item: Project(41423020209) supported by the National Defense Basic Research Funding Project of China

Received date: 2020-01-15; Accepted date: 2020-08-28

Corresponding author: WANG Qing; Tel: +86-411-84708615; E-mail: wangq@dlut.edu.cn

(编辑 龙怀中)

基金项目:国防基础科研计划资助项目(41423020209)

收稿日期:2020-01-15;修订日期:2020-08-28

通信作者:王 清,教授,博士;电话:0411-84708615;E-mail:wangq@dlut.edu.cn