文章编号:1004-0609(2010)10-1932-09

3104铝合金热粗轧板的织构梯度及其对热压缩变形后退火织构演变的影响

唐建国1, 2,张新明1, 2,徐 敏1, 2,欧 军1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:采用X-ray衍射和光学显微镜对AA3104铝合金热粗轧板沿厚向的织构和组织进行研究。结果表明:热粗轧板中存在明显的组织和织构梯度现象;在表层及次表层,剪切织构占主导地位,表现为较强的旋转立方织构R-cube {001}á110?和{112}á110?织构,显微组织以再结晶组织为主;在中心层及过渡层,则以典型的形变织构(即Cu{112}á111?、S{123}á634?和Bs{011}á211?)及热变形流线组织为主;这种沿厚度方向的组织和织构梯度对热变形后再结晶织构也有很大影响,热粗轧板中原始的剪切织构有助于退火后立方织构的形成,而原始中心层的形变织构会促使热变形退火后产生{111}á110?剪切织构和P织构。

关键词:铝合金;热粗轧板;织构;显微组织

中图分类号:TG335.5 文献标志码:A

Texture gradient in rough-rolled plate of aluminum alloy 3104 and its effect on annealing textures evolution after hot compression

TANG Jian-guo1, 2, ZHANG Xin-ming1, 2, XU Min1, 2, OU Jun1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering,

Ministry of Education, Central South University, Changsha 410083, China)

Abstract: The textures and microstructures along rough-rolled plate aluminum alloy 3104 were investigated by X-ray diffractometry and optical microscopy, respectively. The results show that a pronounced through-thickness texture and microstructure gradient is found in the rough-rolled plate. At the surface and sub-surface layers, the dominant texture and microstructure are shear textures (strong R-cube{001}á110? and {112}á110?) and recrystallization microstructure, respectively. While at the center and intermediate layers, the typical β-fiber texture of Cu{112}á111?, S{123}á634? and Bs{011}á211?, and a fibrous microstructure characterized by banded-like structure is observed. This kind of through-thickness texture and microstructure gradient have strong influence on the recrystallization texture after hot compression, i.e., the rolling shear textures are changed to cube texture, while the other deformation textures are rotated to the {111}á110? and P orientation during the annealing after hot compression.

Key words: aluminum alloy; rough-rolled plate; texture; microstructure

易拉罐生产中的制耳大小是制约产品生产效率和成品率的一个关键因素,其主要是由材料的塑性各向异性所造成。通过获得较强的立方织构以平衡形变织构[1-2]是控制材料的织构组成以降低材料的塑性各向异性和减小制耳率的主要思路与途径。目前,国内外很多生产厂家采用“1+4”热连轧机生产铝易拉罐料板,即一机架的热粗轧加四机架的热精轧。在热粗轧过程中,变形和再结晶的交替发生会改变板材显微组织及织构;在4机架热精轧过程中,通过高温、高速和大变形的方式获得较高的卷曲温度和充足的储能,保证热连轧卷曲后发生自退火,生成较强的立方织构以平衡随后冷轧过程中形成的形变织构[3]。轧制过程中织构梯度的研究一直受到广泛的关注。TRUSZKOWSKI 等[4-5]认为冷轧厚板中宏观织构的不均匀性主要与轧辊和板材间的摩擦、材料本身的性质及轧制变形区的几何参数有关。DALLAND和NES[6]以及VATNE 等[7]研究Al-Mn-Mg铝合金热轧中立方织构的起源,结果表明热轧开始时形成的“立方过渡带”可成为随后热轧时板中立方织构的形核位置,促进立方织构的形成。ENGLER等[8]用VPSC多晶体变形模型模拟了轧板厚向各层的织构演变。但是,对于AA3104铝合金热粗轧板中的织构类型对随后热变形及退火过程中的织构演变,尤其是对立方织构的影响鲜见报道。因此,研究热粗轧板中的织构可为罐料板生产中建立织构与工艺间的关系并控制织构演变提供依据。

本文作者采用X-ray 衍射和光学显微镜研究罐料板用AA3104铝合金热粗轧板沿厚度方向的织构分布及组织不均匀性。测定和计算出厚板各层所含织构组分的取向密度与体积分数,分析热粗轧板各层的织构及组织特征;并用全约束(Full constraint,FC)多晶体变形模型模拟验证热粗轧板内的织构特征,研究热粗轧板中沿厚向不同部位薄层热压缩变形及退火后织构的变化情况。

1 实验

实验采用某公司提供的30 mm厚的“1+4”工艺中的3104铝合金热粗轧板。

为分析热粗轧板从表层到中心层的织构分布,将热粗轧板沿厚度方向取样进行研究。具体取样部位用相对位置L=?h/H(?h是取样层与表层间的距离,H为原始板厚)来表示。L=0,0.125,0.250和0.500分别代表热粗轧板表层、次表层、过渡层和中心层(见图1(a)所示)。

采用热模拟平面应变压缩实验模拟了一机架热精轧中材料的织构。考虑热模拟实验对样品厚度的限制,实验样品的厚度取为10mm。为研究热粗轧板原始织构对热压缩变形后织构的影响,将实验样品分为两类:取表面10 mm的试样记为S10,中心10 mm的试样记为C10(取样示意图见图1(b))。在Gleeble-1500 热模拟机上对S10和C10试样进行热压缩实验。变形参数的选择考虑了实际生产情况,其中变形温度选为380 ℃,真应变和应变速率分别为2和12 s-1。变形后的试样立即水冷以保持变形组织。为进一步模拟变形后退火过程中的织构演变,将水冷后的试样放入380 ℃的盐浴炉中分别保温30 min和60 min。

对试样的RD-TD面(轧面)进行织构检测。待检测试样经机械抛光后,用5%(质量分数)的NaOH水溶液浸泡2~3 min以去除表面应力层。织构测定在Bruker D8 Discovery型X射线衍射仪上完成,加载电压和电流分别为40 kV和40 mA。采用Cu Kα 辐射,用Schulz衍射法测定{111}、{200}、{220}和{311}4张不完整极图,并进行散焦修正。采用Burge提出的球函数展开法(lmax=18)计算出取向分布函数(ODF),结果用恒φ2(Δφ2=5)截面图表示。采用TANG等[9]提出的方法进行织构的定量计算(体积分数),角度偏差在15.5?以内视为同一种织构。

采用电解抛光和阳极覆膜观察热粗轧板各层处RD-ND面(纵截面)的金相显微组织。电解抛光溶液为10%(体积分数)的高氯酸和90%的无水乙醇,阳极覆膜溶液为2%(质量分数)的氟硼酸和98%的蒸馏水;操作电压和时间分别为20~22 V、约10 s以及16~18 V、3~5 min。

图1 3104铝合金热粗轧板织构检测分层部位及热模拟取样部位示意图

Fig.1 Schematic diagrams of samples for texture measurement of rough-rolled aluminum alloy 3104 plate (a) and plain-strain hot-compression (b)

2 结果与讨论

2.1 热粗轧板的显微组织

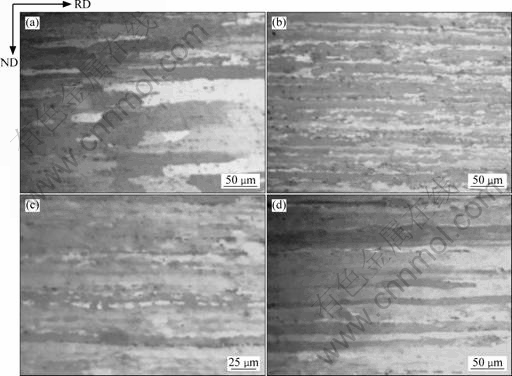

图2所示为3104铝合金热粗轧板的光学金相显微组织。由图2可知,板材沿厚度方向存在明显的显微组织不均匀性。板表层由粗大的再结晶晶粒组成,且

图2 3104铝合金热粗轧板沿板厚向的分层光学显微组织

Fig.2 Optical microstructures in layers along thickness of rough-rolled plate of aluminum alloy 3104: (a) Surface layer (L=0); (b) Subsurface layer (L=0.125); (c) Intermediate layer (L=0.25); (d) Center layer (L=0.5)

晶粒沿轧制变形方向拉长;次表层组织主要是沿着轧制方向分布的细小再结晶晶粒;中心层是典型的热变形流线组织;过渡层则表现为流线组织之间夹着沿轧制变形方向分布的细小再结晶晶粒的混合组织。且通过观测可知,具有表层、次表层、过渡层和中心层的组织分别约为2.5 mm、2 mm、4 mm和6 mm(取热轧板厚向的一半进行的组织观察)。

AA3104铝合金厚板的热粗轧是高温大变形过程:压下量在90%以上,轧制温度为500 ℃左右;轧板与轧辊接触表面的摩擦作用会导致板材内剪切变形的产生,且热粗轧开始时,变形区形状参数1/ha<1。式中:ha为轧件平均宽度;变形区长度为1。板材中心层变形小。板材表层与轧辊摩擦大,剪切变形小,再结晶晶核少,晶粒粗大(见图2(a));次表层金属的剪切变形最大,再结晶晶核多,晶粒细小(见图2(b));剪切变形随离表层距离的增加而逐渐减小,导致过渡层和中心层中存在较粗大的晶粒组织(见图2(c)~(d))。

2.2 热粗轧板的宏观织构

图3所示为3104铝合金热粗轧板中织构沿板厚度方向的分布,取φ2= 90?,65?和45? 3个具有代表性的截面进行分析。从图3中可以看出,热轧板中主要含有3种织构类型:剪切织构(旋转立方织构R-cube{001}á110?和{112}á110?织构)、再结晶织构(立方织构Cube {001}á100?)和形变织构(Cu{112}á111?,S({123}á634?和Bs{011}á211?)。

3104铝合金热粗轧板沿厚度方向存在着明显的织构梯度。在其表面层,主要是强的旋转立方织构、{112}á110?织构以及立方织构; 次表层中仅存在旋转立方织构和{112}á110?织构,且两者的取向密度最大;而在热粗轧板的中心层,织构以沿着β取向线分布的形变织构为主,即由黄铜织构Bs{011}á211?,铜织构Cu{112}á111?和S织构{123}á634?组成;板材的过渡层处为混合织构,既存在典型的形变织构,也含有再结晶织构和剪切织构。图4所示为3104铝合金热轧板沿厚向各层沿β取向线的取向密度分布。从图4中可明显看出,热轧板表层和次表层的形变织构是以Bs为主;而过渡层和中心层的形变织构则以S为主。图5所示为各织构组分的体积分数随着板厚度方向的变化关系。其中,剪切织构的含量随着L值的增加先增大后减小,并在次表层达到最大值,R-cube织构和{112}á110?织构的含量分别为31.1%和27.1%;立方织构的含量随着L值的增加先减少后增大,并在次表层中减小为零;板材中心层处,形变织构的含量达到峰

图3 3104铝合金热粗轧板沿板厚向的织构梯度

Fig.3 Texture gradient in rough-rolled plate along thickness of aluminum alloy 3104: (a) Surface layer (L=0); (b) Subsurface layer (L=0.125); (c) Intermediate layer (L=0.25); (d) Center layer (L=0.5)

图4 AA3104铝合金热粗轧板的板厚向各层沿β取向线的取向密度分布

Fig.4 Orientation density along β-fiber in different layers along thickness of aluminum alloy 3104 rough-rolled plate

图5 AA3104铝合金热粗轧板沿板厚向各层织构组分的体积分数

Fig.5 Volume fraction of textures in each layer of rough-rolled plate of aluminum alloy 3104

值,其中S织构的含量最高(28.3%);过渡层中,剪切织构的含量较次表层的明显减少,形变织构的含量较中心层的有所减少。

在热粗轧过程中,板材的表面由于受到与轧辊之间的摩擦作用而发生剪切变形,其在厚板材各层分布的不同是导致板材宏观织构不均匀的重要因素[4, 10]。通常认为,在厚板的轧制过程中,板材的中心层处于平面应变状态,其应变张量可表示为[11-12]

(1)

(1)

轧辊与轧板表层摩擦作用不会影响到该层的变形模式[10]。如图3(d)所示,厚板中心层中所有的晶粒取向都稳定在β取向线附近。但由图5可知,热轧板中心层沿轧向剪切变形小,旋转立方织构为零 ,而过渡层中含有4.1%的旋转立方织构,说明后者受到部分剪切变形的作用。此时随着L值的减小,单纯的平面应变状态逐渐向剪切状态过渡,其应变张量为[8]

(2)

(2)

从过渡层到表层,随着摩擦作用的增强,其产生的剪切应变ε13逐渐增大,剪切织构随之增强并在次表层达到最大。剪切变形会产生3种典型的剪切织构,即R-cube、{111}á110?和{111}á112?织构[4, 11]。ENGLER等[8]的研究表明,在一些铝合金中,{112}á110?是除了旋转立方织构之外最强的剪切织构[8]。如图3(a)和(b)所示,AA3104铝合金热粗轧板的表层和次表层中含有很强的R-cube织构和{112}á110?织构,没有观察到{111}á110?和{111}á112?织构。对比图4可知,次表层中的R-cube织构和{112}á110?织构含量明显高于表层的。同时,对于厚板次表层,虽然在其组织中观察到细小的再结晶晶粒(见图2(b)),其ODF中却未发现有明显的立方织构组分(见图3(b))。由此可知,在厚板的高温大变形中,板材近表层处的织构类型主要受剪切作用的影响,并以剪切织构(R-cube和{112}á110?)为主。综合分析图3和5可知,剪切变形主要作用在板表层和次表层,且其影响的深度占厚板的1/3。

2.3 宏观织构演变的模拟

采用完全约束(Full constraint,FC)模型模拟热粗轧板中各层的织构。如前所述,对于理想的平面应变状态,应变张量如式(1)所示,可改写为

(3)

(3)

在考虑剪切应变后,应变张量如下:

(4)

(4)

分别取x为0、0.2、1.0和2.0,所模拟的织构结果如图6所示。从图6可知,当x=0时即式(2)中的ε13=0时,在平面应变状态下,织构完全是形变织构。其中,S织构为主要的形变织构,Bs织构含量最低。随着 值增大,ε13的增加,形变织构减弱,剪切织构R-cube逐渐增强。模拟结果与实际织构梯度的规律吻合,说明由摩擦作用引起的剪切应变ε13大小的差异是造成热粗轧板中织构梯度的主要原因。

值增大,ε13的增加,形变织构减弱,剪切织构R-cube逐渐增强。模拟结果与实际织构梯度的规律吻合,说明由摩擦作用引起的剪切应变ε13大小的差异是造成热粗轧板中织构梯度的主要原因。

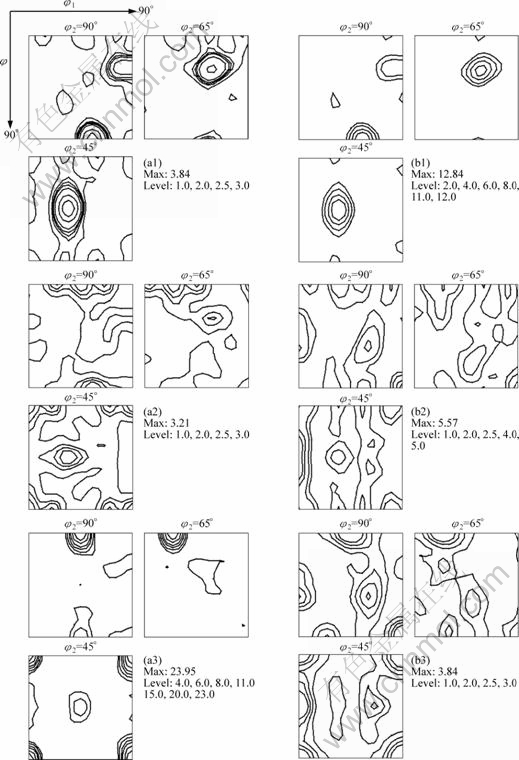

2.4 热压缩退火后的织构演变

图7所示为AA3104铝合金热粗轧板S10和C10试样经热模拟后的变形试样及在380 ℃下退火30 min和60 min后试样的织构。从图7可以看出,在相同的热变形条件下,S10试样中除了明显的变形织构外,仍含有较弱的旋转立方织构;C10试样中则为完全的变形织构。经30 min退火后,S10和C10试样中的变形织构均逐渐变弱,其中S10中变形织构逐渐转为立方织构,并有部分立方织构沿ND方向发生旋转;而C10试样中的变形织构则向Goss织构、P织构及{111}á110?织构转变。当退火60 min后,S10试样再结晶基本完成,表现为强的立方织构;C10试样中Goss织构转向立方织构,且P织构及{111}á110?织构都有所增强。

图8所示为S10和C10试样在变形及经不同时间退火后所含织构的体积分数。由图8可知,S10试样退火后的主要织构为立方织构,且退火60 min后立方织构的体积分数达到30%;C10试样的退火织构则呈现多样化,除了立方织构外,还含有{111}á110?剪切织构,Goss织构和P织构。在60 min退火后,C10所含的立方织构的体积分数较S10试样的少,仅14%。但{111}á110?剪切织构的体积分数达到19%,Goss织构及P织构也分别占13%和6%。

2.5 AA3104铝合金热粗轧板原始织构对热压缩变形退火后织构演变的影响

由于热模拟过程中摩擦作用的影响,变形集中在

图6 FC模型模拟的热粗轧板中的织构

Fig.6 Simulation of texture development in rough-rolled plate of aluminum alloy 3104 by FC model: (a) x=0; (b) x=0.2; (c) x=1.0; (d) x=2.0

试样的中间部位,退火时也只有中间部位发生再结晶。因此,对于S10试样,其发生变形和再结晶的部位表现为热粗轧板的次表层和过渡层的组织特征,而C10试样发生变形和再结晶的部位则全是热粗轧板中心层的变形组织。

在热变形后,C10试样中所含的变形织构的取向密度明显较S10试样的大,这是由于此时所测的变形织构既包括热变形过程中产生的变形织构,又包含了原始热轧板中心层的变形织构。从退火后的织构演变结果分析来看,具有热粗轧板次表层和过渡层混合织构(即原始织构中含有旋转立方织构、{112}á110?织构、立方织构和变形织构)的S10试样的再结晶速率较高,经相同时间退火后,所含的立方织构含量更多。众所周知,立方织构是罐料铝材中理想的退火织构,因其可产生0?或90?的制耳以抵消形变织构所产生的45?的制耳[13-15],从而达到减小材料各向异性,降低制耳率的目的。具有热轧板中心层织构(即原始织构含有变形织构和少量立方织构)的C10试样的退火织构除了含有较少量的立方织构之外,还包含{111}á110?剪切织构和P织构。其中,P织构与形变织构的制耳行为十分类似,它会产生30?或60?的制耳,从而提高材料的各向异性,不利于深冲制耳的消除[1]。

图7 热压缩变形及退火后AA3104铝合金板的织构演变

Fig.7 Texture evolution of aluminum alloy AA3104 plate after hot-compression and subsequent annealing: (a1) S10, compressed state; (a2) S10, annealed for 30 min; (a3) S10, annealed for 60 min; (b1) C10, compressed state; (b2) C10, annealed for 30 min; (b3) C10, annealed for 60 min

研究表明[16],原变形组织中存在的具有立方取向的晶粒与退火后形成高含量的立方织构具有紧密的联系。其中,具有旋转立方织构取向的晶粒的稳定性高于立方织构取向的晶粒,其对退火中生成立方织构的贡献大。对比S10试样和C10试样可知,两者所含的原始织构中均包含少量的立方织构,但前者的旋转立方织构含量远远高于后者。故在随后的退火中,S10试样中立方织构的形核位置多,立方织构体积分数大;C10试样相比之下立方织构的含量较少。

由此可知,热粗轧板中原始的剪切织构可以促进热变形退火后立方织构的形成,而原始再结晶程度很低的中心层组织中,其变形织构会促使热变形退火后产生增加制耳率的退火织构,如P织构。因此,在“1+4”热连轧生产罐料板的过程中,若能在热粗轧过程中实现轧制变形的深入,保证轧板的整个厚向都发生再结晶,减少单纯的变形组织及形变织构,则可有利于最终立方织构的形成,并消除对降低制耳率不利的退火织构。

图8 3104铝合金热变形及其退火后S10和C10样品所含织构组分的体积分数

Fig.8 Volume fraction of texture in aluminum alloy 3104 after hot compressed and annealed: (a) S10; (b) C10

3 结论

1) 由于大的外摩擦作用和l/ha由小于1到大于1,热粗轧板中具有强的织构梯度:中心层是典型的变形织构,即包括沿着β取向线分布的Cu、S和Bs织构,并以S织构的体积分数和取向密度最大;而过渡层兼有再结晶织构、剪切织构和变形织构。厚板的近表层以剪切织构(R-cube和{112}á110?织构)为主,其中剪切织构的含量和密度在次表层达到最高值,表层还含有一定的立方织构且组织也呈现明显的不均匀性(由中心层典型的热变形流线组织经过渡层到次表层的细小再结晶晶粒组织,最后到表层粗大的再结晶晶粒组织)。

2) 热粗轧过程中变形的不均匀及剪切变形在厚轧板各层分布的不同是导致AA3104铝合金热粗轧板宏观织构不均匀和组织分层的主要原因。剪切变形主要作用在板的表层和次表层,且其影响的深度占了厚板的1/3。

3) 热变形退火后,热粗轧板中原始的剪切织构转变成立方织构,而中心层的变形织构转变成{111}á110?和P织构。

REFERENCES

[1] LIU J, DICK R E, FRIDY J M, ROUNS T N. Crystallographic texture evolution of continuous cast Al-Mn-Mg alloy sheet during cold rolling and annealing[J]. Mater Sci Eng A, 2007, 458(1/2): 73-87.

[2] QUADIR M Z, AL-BUHAMAD O, BASSMAN L, FERRY M. Development of a recovered/recrystallized multilayered microstructure in Al alloys by accumulative roll bonding[J]. Acta Mater, 2007, 55(16): 5438-5448.

[3] ENGLER O, LOCHTE L, HIRSCH J. Through-process simulation of texture and properties during the thermomechanical processing of aluminium sheets[J]. Acta Mater, 2007, 55(16): 5449-5463.

[4] TRUSZKOWSKI W, KROL J, MAJOR B. Inhomogeneity of rolling texture in FCC metals[J]. Metall Trans A, 1980, 11(5): 749-758.

[5] TRUSZKOWSKI W, KROL J, MAJOR B. On penetration of shear texture into the rolled aluminium and copper[J]. Metall Trans A, 1982, 13(4): 665-669.

[6] DALLAND O, NES E. Origin of cube texture during hot rolling of commercial Al-Mn-Mg alloys[J]. Acta Mater, 1996, 44(4): 1389-1411.

[7] VATNE H E, SHAHANI R, NES E. Deformation of cube-oriented grains and formation of recrystallized cube grains in a hot deformed commercial A-Mg-Mn aluminum alloy[J]. Acta Materialia, 1996, 44(11): 4447-4462.

[8] ENGLER O, HUH M, TOME C N. A study of through-thickness texture gradients in rolled sheets[J]. Metall Trans A, 2000, 31(9): 2299-2315.

[9] TANG J G, ZHANG X M, DENG Y L, DU X Y, CHEN Z Y. Texture decomposition with particle swarm optimization method[J]. Comp Mater Sci, 2006, 38(2): 395-399.

[10] LIU W C, RADHAKRISHNAN B, LI Z, MORRIS J G. Through-thickness texture gradient in continuous cast AA 5052 aluminum alloy sheet[J]. Mater Sci Eng A, 2008, 472: 170-178.

[11] MAO W M. Texture in inhomogeneously rolled aluminium sheet[J]. Trans Nonferrous Met Soc, 1992, 2(1): 98-103.

[12] 毛卫民, 张新明. 晶体材料织构定量分析[M]. 北京: 冶金工业出版社, 1995: 127-131.

MAO Wei-min, ZHANG Xin-ming. Quantitative texture analysis of crystalline materials[M]. Beijing: Metallurgical Industry Press, 1995: 127-131.

[13] 林 林, 温庆红, 高晓玲. 3104制罐板中间退火冷却方式改变对性能的影响[J]. 铝加工, 2002, 24(1): 44-46.

LIN Lin, WEN Qing-hong, GAO Xiao-ling. The effect of changing cooling model of intermediate annealing on properties of 3104 can stock[J]. Aluminium Treatment, 2002, 24(1): 44-46.

[14] ENGLER O, HIRSCH J. Texture control by thermomechanical processing of AA6××× Al-Mg-Si sheet alloys for automotive applications—A review[J]. Mater Sci Eng A, 2002, 336: 249-262.

[15] 张德芬, 黄 涛, 胡卓超, 左 良, 王 福. 3104铝合金再结晶织构的研究[J]. 材料工程, 2004, 36(11): 28-31.

ZHANG De-fen, HUANG Tao, HU Zhuo-chao, ZUO Liang, WANG Fu. Study of recrystallization texture of aluminium alloy 3104[J]. J Mater Eng, 2004, 36(11): 28-31.

[16] BOLINGBROKE R K, MARSHALL G J, RICKS R A. The influence of initial microstructure on the recrystallization textures of aluminium alloys after hot deformation by laboratory simulation[J]. Materials Science Forum, 1993, 157/162: 1145-1152.

(编辑 龙怀中)

基金项目:国家科技支撑计划资助项目(2007BAE38B01);国家自然科学基金资助项目(50905188)

收稿日期:2009-10-09;修订日期:2010-01-13

通信作者:张新明,教授;电话:0731-88830265;E-mail:xmzhang_cn@yahoo.cn