Trans. Nonferrous Met. Soc. China 27(2017) 741-746

Effect of 0.3% Sc on microstructure, phase composition and hardening of Al-Ca-Si eutectic alloys

Nikolay BELOV1, Evgenia NAUMOVA1, Torgom AKOPYAN1,2

1. National University of Science and Technology, MISIS, 4, Leninskiy pr. 4, Moscow 119049, Russia;

2. Institute of Russian Academy of Sciences A. A., Baikov Institute of Metallurgy and Material Science RAS, Leninskiy pr. 49, Moscow 119991, Russia

Received 28 April 2016; accepted 21 November 2016

Abstract: The phase composition, microstructure and hardening of aluminum-based experimental alloys containing 0.3% Sc, 0-14% Si and 0-10% Ca (mass fraction) were studied. The experimental study (electron microscopy, thermal analysis and hardness measurements) was combined with Thermo-Calc software simulation for the optimization of the alloy composition. It was determined that the maximum hardening corresponded to the annealing at 300-350 °C, which was due to the precipitation of Al3Sc nanoparticles with their further coarsening. The alloys falling into the phase region (Al)+Al4Ca+Al2Si2Ca have demonstrated a significant hardening effect. The ternary eutectic (Al)+Al4Ca+Al2Si2Ca had a much finer microstructure as compared to the Al-Si eutectic, which suggests a possibility of reaching higher mechanical properties as compared to commercial alloys of the A356 type. Unlike commercial alloys of the A356 type, the model alloy does not require quenching, as hardening particles are formed in the course of annealing of castings.

Key words: Al-Ca-Si-Sc system alloy; eutectic; Al3Sc nanoparticles; phase composition; microstructure; heat treatment; hardening

1 Introduction

Aluminum alloys of 3xx series hardened by heat treatment casting based on the silicon-containing eutectics are widely used for shaped castings [1,2]. A significant disadvantage of these alloys (in particular, the 356/357 type alloys) is the necessity for heat treatment as per T6 mode (including quenching) in order to achieve maximum hardening. On the other hand, it is known that using just annealing without quenching of wrought aluminum alloys, the comparable hardening can be obtained by the addition of scandium in the amount of about 0.3% (mass fraction) due to the formation of coherent Al3Sc (L12) phase precipitates with a size less than 10 nm [3-7]. However, for Al-Si-based alloys, the addition of scandium does not allow to achieve a significant strengthening effect. The reason for this is that silicon leads to forming the ternary AlSc2Si2 phase during solidification [3,8], which further reduces the amount of Sc in (Al). The reduction of the scandium content in (Al) makes it impossible to form a sufficient amount of hardening nanoparticles of the Al3Sc phase during annealing. To obtain a significant hardening effect in casting aluminum alloys by adding scandium, it seems reasonable to search for other aluminum-based eutectic systems.

According to Ref. [9], for the alloys based on the (Al)+Al4Ca eutectic, the addition of 0.3% Sc allows to obtain almost the same effect of strengthening as in the binary alloys based on the Al-Sc system. Thus, the (Al)+Al4Ca eutectic microstructure is substantially finer than that of the (Al)+Si eutectic. According to Refs. [10,11], in the ternary system Al-Ca-Si, there is a compound Al2Si2Ca, which is involved in three eutectic reactions. Among these eutectics, the ternary eutectic (Al)+Al4Ca+Al2Si2Ca (612 °C, 7%-8% Ca and 0.8%- 1.1% Si) has a finer microstructure than the binary eutectic (Al)+Al4Ca. We believe that the alloys based on this ternary eutectic may have a good combination of various processing and mechanical properties. It should also be taken into account that in the alloys based on the Al-Si system, calcium is considered as a harmful impurity due to the microstructure of the ternary Al-Ca-Si system near the binary system Al-Si [1,2,12]. On the other hand, many publications considering calcium-containing magnesium alloys have appeared in recent years [13,14].

Given the above, we believe that the study of the microstructure, phase composition and hardening of the alloys based on the Al-Ca-Si-Sc system should be conducted. Taking into consideration the scarcity of information regarding the aluminium alloys with the addition of calcium, the main objectives of this work are as follows: 1) to study the phase composition of alloys based on the Al-Ca-Si-Sc system in an aluminum-rich corner at a constant content of 0.3% Sc (mass fraction) using experimental and computational methods; 2) to investigate the dependence of the Ca and Si contents and annealing mode on the effect of precipitation hardening by the formation of Al3Sc nanoparticles; 3) to evaluate the mechanical and technological properties of the alloy based on the ternary eutectic (Al)+Al4Ca+Al2Si2Ca.

2 Experimental

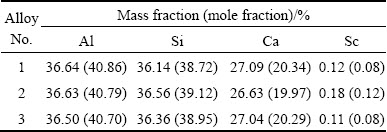

The main objects of the experimental study were the four alloys based on the Al-Ca-Si-Sc system with the addition of 0.3% Sc (Table 1). The melting was conducted in an electric resistance furnace in clay- graphite crucibles. All the alloys (1 kg in mass) were prepared based on high purity aluminum (99.99%). Calcium and scandium were added in the form of master alloys (Al-18%Ca and Al-2%Sc correspondingly) and silicon was added as a pure element. The melt was poured into a graphite mould at 800 °C to produce flat castings with 15 mm × 30 mm × 180 mm in size (the cooling rate during solidification was about 10 K/s). The actual chemical composition of the alloys obtained by a spectral analysis is given in Table 1. The heat treatment of the castings was carried out in a muffle electric furnace using step cycles in the range from 200 to 550 °C (Table 2). The Brunell hardness was determined in a DuraVision-20/200/250 hardness testing machine. The hardness values are given as arithmetic mean values from at least 5 single hardness measurements for at least 3 samples. The hot rolling was carried out by the 260 laboratory camp.

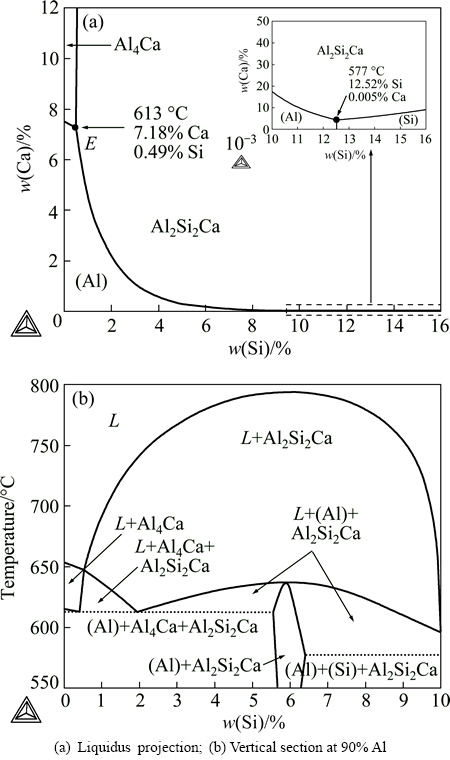

Table 1 Actual chemical composition of experimental alloys

The microstructure was examined by means of transmission electron microscope (TEM, JEM-2100) and scanning electron microscope (SEM, TESCAN VEGA 3) and by electron microprobe analysis (EMPA, OXFORD AZtec). The samples were cut from the castings, ground and polished using standard procedures. Mechanical polishing (Struers Labopol-5) with further etching using Keller’s reagent was applied. Thin foils for transmission electron microscopy (TEM) were prepared by ion thinning with a PIPS (precision ion polishing system, Gatan) machine and studied at 160 kV. To calculate the phase composition, the Thermo-Calc software (TTAL5 database [15]) was used.

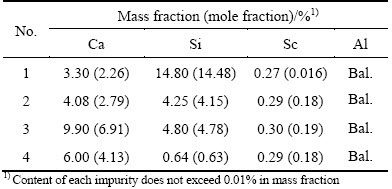

Fig. 1 Phase diagram of Al-Ca-Si

3 Results and discussion

The contents of Ca and Si in the experimental alloys (Table 1) were chosen based on the results of the Al-Ca-Si phase diagram calculations. The feature of this ternary system is a vast area of primary crystallization of the Al2Si2Ca compound (Fig. 1(a)). As shown in the vertical section which was calculated at 90% Al (Fig. 1(b)), a small addition of Ca (a few hundredths of a percent) in binary Al-Si alloys dramatically increases the liquidus temperature (TL). From Fig. 1(b), it also follows that the addition of Si up to 0.8% in the Al-Ca alloys should not increase TL. At the content of Si up to 0.5%, the Al2Si2Ca compound must be formed only via the eutectic reaction: L→(Al)+Al4Ca+Al2Si2Ca. Alloys 1-3 with compositions listed in Table 1 are located in the areas where the primary crystals of the Al2Si2Ca phase must be present. Alloy 4 (its composition was assumed as the optimal) is located near the ternary eutectic (point E in Fig. 1(a)) which corresponds to the reaction L→(Al)+Al4Ca+Al2Si2Ca. Alloys 3 and 4 fall exactly into this three-phase region. Alloys 1 and 2 are in the other three-phase region: (Al)+(Si)+Al2Si2Ca.

Table 2 Annealing regimes of experimental alloys

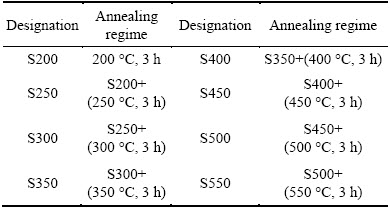

Vertical sections of quaternary system calculated at 0.3% Sc are shown in Fig. 2. In accordance with Fig. 2(a), the equilibrium solidification of the Al-6%Ca- 0.6%Si-0.3%Sc alloy proceeded via the following reactions: initially the appearance of the Al3Sc phase primary crystals at 650 °C, then the successive formation of the binary L→(Al)+Al3Sc, ternary (L→(Al)+ Al2Si2Ca+Al3Sc) and quaternary (L→(Al)+Al4Ca+ Al2Si2Ca+Al3Sc) eutectics. The calculation shows that the temperature of the final eutectic reaction is 613 °C at the contents of 7.12% Ca, 0.48% Si and 0.16% Sc. However, in accordance with the results presented in Ref. [9], it can be expected that in real conditions, all scandium may enter in (Al) during solidification. The results of EPMA have confirmed this assumption. The vertical section calculated at 0.3% Sc and 10% Si (Fig. 2(b)) also shows the presence of quaternary eutectic, with the temperature (577 °C) and composition being very close to the binary eutectic in the Al-Si system (in particular, the Ca content is less than 0.05%).

It was found that the microstructure of the hypereutectic alloys 1-3, as predicted by thermodynamic calculations (Fig. 1), contains significant amounts of primary crystals, which have the form of polyhedrons. According to the EMPA analysis (Table 3), compositions of these crystals in all three alloys are close to the Al2Si2Ca compound formula. Scandium in these crystals has not been identified. On the other hand, in alloys 1 and 2, the primary crystals of the Sc-containing phase in the form of polyhedrons were also detected.

Fig. 2 Vertical sections of Al-Ca-Si-Sc system at 0.3%Sc

Table 3 Average compositions of Al2Si2Ca primary crystals in annealed (S500) alloys 1-3

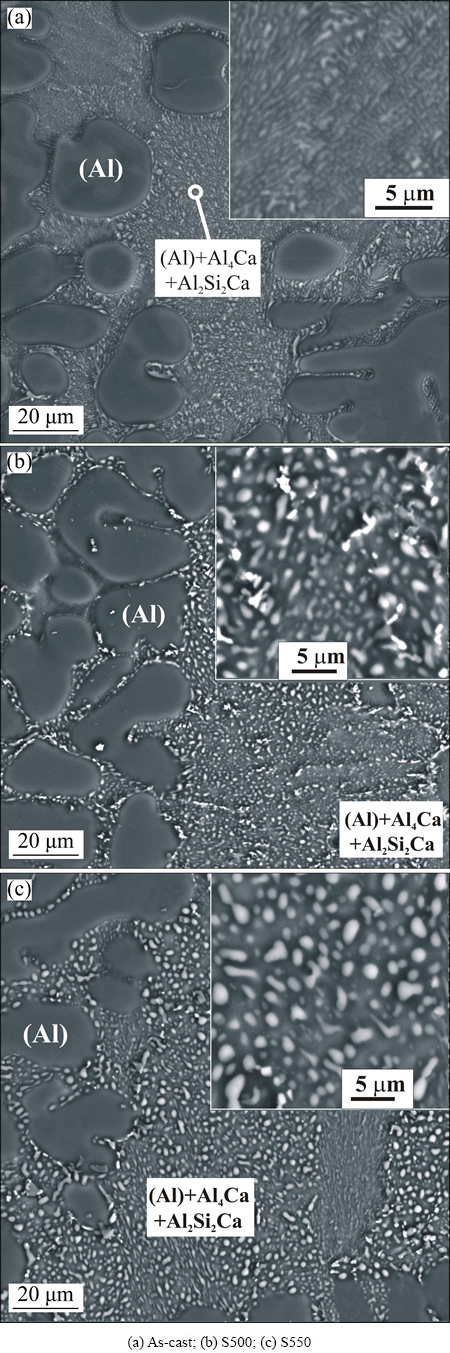

According to Fig. 3(a), the ternary eutectic in alloy 4 has a highly fine microstructure (the size of the dendritic branches less than 0.2 μm). It is known that the fineness of the eutectic microstructure in the as-cast state determines, to a great extent, its capability to change its form during heat treatment [2,16]. The study on the influence of an annealing temperature (with 3 h holding) on the morphology of the eutectic constituents detects the first symptoms of fragmentation at 450 °C. With an increase in the temperature, the changes become detectible at the resolution of optical microscope. At 500 °C, almost all Al4Ca and Al2Si2Ca particles take a globular form, but their sizes remain submicron (Fig. 3(b)). At the maximum tested temperature of annealing (550 °C), the microstructure becomes much coarser, the size of some particles reaches 5 μm (Fig. 3(C)).

Fig. 3 SEM images of eutectic (Al)+Al4Ca+Al2Si2Ca in alloy 4

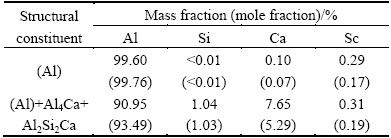

The experimentally determined contents of Ca and Si in the eutectic (Table 4) are close to the calculated results. It should be noted that the Sc content in the (Al) primary crystals and eutectic (Al)+Al4Ca+Al2Si2Ca is approximately the same and is close to its content in the alloy.

Table 4 Average composition of aluminum solid solution and eutectic in as-cast alloy 4

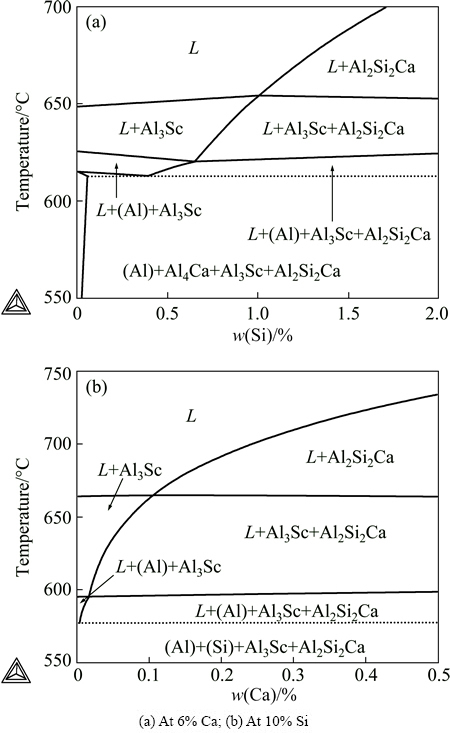

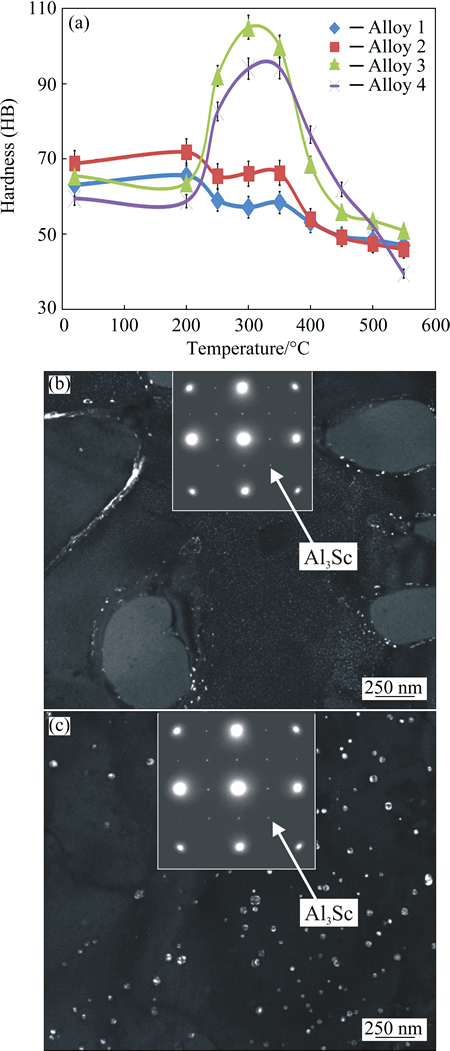

Figure 4(a) shows the hardness change of the experimental alloys during annealing. In alloys 3 and 4 whose compositions fall into the phase region (Al)+ Al4Ca+Al2Si2Ca, the level of hardening (about HB 40) is comparable to the hardening of the binary alloy Al-0.3%Sc [3,8]. The maximum hardness is achieved in S300 and S350 modes (Table 2). Hardening in these alloys is due to the formation of the Al3Sc nanoparticles, as shown in Fig. 4(b). These nanoparticles form in the process of annealing from supersaturated aluminium solid solution (Al). On the other hand, at higher temperatures the hardness decreases due to coarsening of precipitates Al3Sc (Fig. 4(c)), as well as due to fragmentation and spheroidization of the eutectic intermetallics (Figs. 4(b) and (c)). In the alloys 1 and 2 whose compositions fall into the phase region (Al)+(Si)+ Al2Si2Ca, the hardening is virtually absent. This is connected with a low content of scandium in (Al) (less than 0.1%).

The alloys based on the ternary eutectic (Al)+Al4Ca+Al2Si2Ca show the combination of the high castability (due to the narrow temperature range of solidification) and ability to plastically deform with a significant degree of compression. Moreover, the high deformability can be available even for alloys with a high volume fraction of the eutectic intermetallics (more than 20%, volume fraction), because after annealing at high temperatures, these intermetallic compounds acquire a globular shape. It was exemplified by the (Al)+Al8Cu4Ce eutectic [17]. Determination of the casting properties of alloy 4 shows that its fluidity and hot cracking resistance are close to those of the standard alloy 356 [1,2,16]. This suggests that the experimental model alloy can be used to obtain castings with a complex shape.

To evaluate the deformability by hot rolling, alloy 4 was also used. The initial state of the alloy before rolling was S500, which provided the microstructure with globular eutectic particles intermetallics (Fig. 3(b)). The hot rolling was conducted at 450 °C. The total degree of reduction is 50% which is a proof of sufficient reserve of plasticity. After rolling, the hardness increases from HB 58 to HB 72, which is an indicator of the recrystallization processes incompletion. There are no significant changes in the microstructure of the deformed specimens, only slight elongation in the deformation direction of the aluminum solid solution branches and eutectic colonies.

Thus, using the studied results of alloy 4 based on the (Al)+Al4Ca+Al2Si2Ca eutectic, the principal possibility to create technologically universal eutectic composites type alloys, which allow to obtain both shaped castings and deformed intermediates, was demonstrated.

Fig. 4 Effect of annealing temperature on hardness (a) and TEM (dark field) microstructures of experimental alloys in S300 (b) and S450 (c) modes

4 Conclusions

The phase compositions of aluminum alloys of the Al-Ca-Si-Sc system, containing 0.3% Sc, were studied using computational and experimental methods. It is shown that only phases of the binary systems (Al4Ca, Al3Sc and (Si)) and the ternary compound Al2Si2Ca may be in equilibrium with the aluminium solid solution. It was determined that the maximum hardening corresponded to the annealing at 300-350 °C, which was due to the precipitation of Al3Sc nanoparticles with their further coarsening. It is shown that the (Al)+Al4Ca+ Al2Si2Ca eutectic has a fine structure, and after annealing above 450 °C, the eutectic compounds may acquire a globular shape. The structure with uniformly distributed compounds (reinforcing phases) in the aluminum solid solution (matrix) is the basis for the creation of the so-called natural composites produced by conventional casting.

Acknowledgement

The work has been supported by Russian Science Foundation (Grant No. 14-19-00632).

References

[1] Kaufman G J, Rooy E L. Aluminum alloy castings: Properties, processes, and applications [M]. Kinsman: ASM International, 2004.

[2] ZOLOTOREVSKIY V S, BELOV N A, GLAZOFF M V. Casting aluminum alloys [M]. Amsterdam: Elsevier, 2007.

[3] TOROPOVA L S, ESKIN D G, KHARAKTEROVA M L, DOBATKINA T V. Advanced aluminum alloys containing scandium: Structure and properties [M]. Amsterdam: Gordon and Breach Science Publishers, 1998.

[4]  R, RYUM N. Scandium in aluminium alloys [J]. International Materials Reviews, 2005, 50: 19-44.

R, RYUM N. Scandium in aluminium alloys [J]. International Materials Reviews, 2005, 50: 19-44.

[5] COSTA S, PUGA H, BARBOSA J, PINTO A M P. The effect of Sc additions on the microstructure and age hardening behaviour of as cast Al-Sc alloys [J]. Materials and Design, 2012, 42: 347-352.

[6] KNIPLING K E, KARNESKY R A, LEE C P, DUNAND D C, SEIDMAN D N. Precipitation evolution in Al-0.1Sc, Al-0.1Zr and Al-0.1Sc-0.1Zr (at.%) alloys during isochronal ageing [J]. Acta Materialia, 2010, 58: 5184-5195.

[7] PENG Yong-yi, LI Shu, DENG Ying, ZHOU Hua, XU Guo-fu, YIN Zhi-min. Synergetic effects of Sc and Zr microalloying and heat treatment on mechanical properties and exfoliation corrosion behavior of Al-Mg-Mn alloys [J]. Materials Science and Engineering A, 2016, 666: 61-71.

[8] NADIMPALLI R, RAVI K. The role of the bimodal distribution of ultra-fine silicon phase and nano-scale V-phase (AlSi2Sc2) on spark plasma sintered hypereutectic Al-Si-Sc alloys [J]. Materials Science and Engineering A, 2016, 657: 123-135.

[9] BELOV N A, NAUMOVA E A, ALABIN A N, MATVEEVA I A. Effect of scandium on structure and hardening of Al-Ca eutectic alloys [J]. Journal of Alloys and Compounds, 2015, 646: 741-747.

[10] MONDOLFO L F. Aluminum alloys: Structure and properties [M]. London: Butterworths, 1976.

[11] Petzow G, Effenberg G. Ternary alloys: A comprehensive compendium of evaluated constitutional data and phase diagrams [M]. Weinheim: Wiley-VCH, 1990.

[12] LUDWIG T H, SCHONHOVD DASHLEN E, SCHAFFER P L, ARNBERG L. The effect of Ca and P interaction on the Al-Si eutectic in a hypoeutectic Al-Si alloy [J]. Journal of Alloys and Compounds, 2014, 586: 180-190.

[13] Kim W J, Lee Y G. High-strength Mg-Al–Ca alloy with ultrafine grain size sensitive to strain rate [J]. Materials Science and Engineering A, 2011, 528: 2062-2066.

[14] LIU Yi-chi, LIU De-bao, ZHAO Yue, CHEN Min-fang. Corrosion degradation behavior of Mg-Ca alloy with high Ca content in SBF [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3339-3347.

[15] Backerud L, Krol E, Tamminen J. Solidification characteristics of aluminium alloys [M]. Oslo: Tangen Trykk A/S, 1986.

[16] YANG Chang-lin, LI Yuan-bing, DANG Bo,  He-bin, LIU Feng. Effects of cooling rate on solution heat treatment of as-cast A356 alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3189-3196.

He-bin, LIU Feng. Effects of cooling rate on solution heat treatment of as-cast A356 alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3189-3196.

[17] BELOV N A, KHVAN A V. The ternary Al-Ce-Cu phase diagram in the aluminum-rich corner [J]. Acta Materialia, 2007, 55: 5473-5782.

添加0.3%Sc对Al-Ca-Si共晶合金显微组织、相组成及硬化性能的影响

Nikolay BELOV1, Evgenia NAUMOVA1, Torgom AKOPYAN1,2

1. National University of Science and Technology, MISIS, 4, Leninskiy pr. 4, Moscow 119049, Russia;

2. Institute of Russian Academy of Sciences A. A., Baikov Institute of Metallurgy and Material Science RAS, eninskiy pr. 49, Moscow 119991, Russia

摘 要:研究含0.3% Sc、0-14% Si和0-10% Ca铝基合金的相组成、显微组织和硬化性能。采用实验研究包括扫描电镜、热分析和硬度测试与Thermo-Calc软件模拟相结合的方法对合金的组成进行优化。结果表明,经300~500 °C退火处理后合金的硬化效果最好,这是由于Al3Sc纳米颗粒的析出及其进一步粗化。成分在(Al)+Al4Ca+Al2Si2Ca相区的合金呈现明显的硬化效应。三元共晶合金(Al)+Al4Ca+Al2Si2Ca比Al-Si共晶合金的显微组织细得多,这表明实验合金相对于A356系列工业合金具有更高的力学性能。与A356系列合金不同,实验合金不需要淬火处理,因为在其铸件的退火过程中形成了硬化粒子。

关键词:Al-Ca-Si-Sc系列合金;共晶;Al3Sc纳米颗粒;相组成;显微组织;热处理;硬化

(Edited by Wei-ping CHEN)

Corresponding author: Nikolay BELOV; E-mail: nikolay-belov@yandex.ru

DOI: 10.1016/S1003-6326(17)60084-0