文章编号:1004-0609(2011)04-0714-05

试样尺寸对定向凝固Al-4%Cu合金固/液界面特征的影响

屈 敏1, 2,刘 林2,赵 明1,刘峰斌1,何广平1

(1. 北方工业大学 机电工程学院,北京 100144;

2. 西北工业大学 凝固技术国家重点实验室,西安 710072)

摘 要:采用定向凝固方法研究不同试样尺寸对Al-4%Cu合金凝固固/液界面特征的影响。结果表明:当凝固速率v=1 μm/s时,小尺寸试样的平界面更加平直;当v=5 μm/s时,随着试样尺寸的增大,界面形态分别为浅胞—深胞—初始枝晶,同时,试样边缘的组织比中心的组织更不稳定;在相同凝固速率下,小尺寸试样的温度梯度较大,促使界面稳定性提高;试样尺寸的增大引起径向温差增大,促进溶质流动,使试样边缘产生溶质富集,从而使平界面弯曲;由于试样中心排出的溶质大部分流向界面前沿糊状区的液相中,而枝晶糊状区的液相比胞晶的多,因而形成的枝晶界面弯曲程度比胞晶的小。

关键词:Al-4%Cu合金;固/液界面;径向温差;溶质富集

中图分类号:TG113.1;TG146.2 文献标志码:A

Effect of sample size on solid/liquid interfacial characteristic in directional solidification of Al-4%Cu alloy

QU Min1, 2, LIU Lin2, ZHAO Ming1, LIU Feng-bin1, HE Guang-ping1

(1. School of Electrical and Mechanical Engineering, North China University of Technology, Beijing 100144, China;

2. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: The effect of sample sizes on solid/liquid interfacial characteristic of Al-4%Cu alloy was studied by adjusting sample sizes in directional solidification. The results show that the smaller the sample sizes are, the flatter the planar interface is at solidification rate (v) of 1 μm/s. However, at v=5 μm/s, with increasing sample sizes, the interface morphologies show shallow cells—deep cells—initial dendrites, respectively. For all of the samples, the microstructure at the boundary is not so stable as that in the center. The temperature gradient increases as the sample sizes decrease at the same growth velocity, which makes the interface more stable. The increasing sample sizes can strengthen the radial temperature difference, which can enhance the convection, thus makes the planar interface convex and non-planar interface flatter. In conclusion, the radial temperature difference can weaken the interface stability. The solute rejected from the center of sample flows into the liquid in the mushy zone, and the liquid in dendrite is more than that in the cellular, the curvature at the dendrite interface can be less than that at the cellular.

Key words: Al-4%Cu alloy; solid/liquid interface; radial temperature difference; solute accumulation

凝固过程中的液相流动问题一直备受凝固界研究者的关注。液相流动所引起的动量传输会显著改变传热和传质过程,从而影响界面形态演化,对材料的组织和性能产生显著影响,尤其可显著改变固/液界面形态稳定性。因此,液相流动是影响界面形态演化特征的重要因素[1]。为此,学者们采用计算[2-5]和实验[6-10]的方法研究熔体流动。MOELANS等[4]采用相场模拟方法介绍了扩散界面微观组织演化过程中的热力学驱动力和动力学相场方程,讨论了各种方法中参数和数值方程解的确定。LI等[5]采用CA法研究流动对过冷熔体枝晶形态的影响,模拟得到的枝晶尖端速率与深过冷自由枝晶生长的LMK理论符合得很好,并且得出强迫对流下自由枝晶生长的冲刷行为是由于迎流方向的快速生长。LI等[6-7]通过外加纵向磁场和横向磁场研究了热电磁效应对Al-Cu合金固液界面形状的影响,表明磁场促进界面失稳,使得胞晶和枝晶界面更加复杂。以上研究是采用模拟和外加磁场的方法,未涉及合金自身存在的热对流。

TRIVEDI等[8-9]采用实验方法研究了Al-Cu和Pb-Sn合金系的流动,发现两种合金系的流动情况完全相反:Al-Cu合金系中对流较弱,而Pb-Sn合金系对流非常强烈。BILLIA等[10-11]研究了透明有机物丁二腈-丙酮和Pb-30%Tl(质量分数)合金的双扩散对流模式,得到对流使有机物界面形状发生变化、而对合金的界面稳定性不产生影响的结论,表明这是由合金特性所致,Pb-30%Tl合金的溶质分配系数k>1,而大部分合金的k<1,如丁二腈-丙酮和Al-Cu等。由此可知,不同合金其内在的热对流对组织形态影响并不相同。在垂直向上凝固过程中,对流的模式取决于溶质和溶剂的密度[12-14]。若溶质轻,如丁二腈-丙 酮,Pb-Sn,NH4Cl-H2O和用于涡轮叶片的高温合金等,固/液界面排出的溶质密度比溶剂的小,在垂直方向上产生的大量溶质浓度梯度高于某临界值时,将引起有浮力的对流,通常称为双扩散对流。另一方面,若溶质密度比溶剂的大,如Al-Cu、Sn-Cd、Pb-Au和Sn-Pb等,将不会产生双扩散对流,比较稳定。以上这些研究几乎都是在试样尺寸不变的情况下获得,但是随着试样尺寸的改变,流动强度的变化及其对界面形状的影响尚不明确。鉴于此目的,本文作者对不同试样尺寸的Al-Cu合金进行研究,旨在得到试样尺寸对流动的影响,进而得到试样尺寸对固/液界面特征的影响。

1 实验

实验用Al-4%Cu(质量分数,下同)合金采用Al-Cu中间合金(Cu质量分数为51.87%)和99.99%超纯铝在真空感应炉中配制而成,将铸锭分别切割成直径为1.8、3.5和7 mm,长为150 mm的3种规格试棒。进行实验时,将试棒表面打磨光滑,用丙酮清洗,在定向凝固炉中加热至1 000 ℃并保温30 min,然后按设定的速率进行抽拉,并采用气动装置进行液淬。实验结束后,对试样进行纵切和横切,经过打磨抛光后,用Kroll腐蚀剂(H2O、HNO3、HF混合液)进行表面处理,利用Lecia DM4000光学显微镜观察金相组织。

2 实验结果

2.1 试样的宏观界面形貌

对直径为1.8 mm和3.5 mm的试样在凝固速率为1 μm/s下的界面形态进行研究。结果表明,两种试样的界面形态均为平界面,而且小尺寸试样的平界面比大尺寸的更加平整,如图1(a)所示。大尺寸试样的界面略显弯曲,且向上凸向液相如图1(b)。可以看出,试样尺寸越小,平界面越平齐。

2.2 试样的微观组织形态

本研究还对3种尺寸的试样在凝固速率为5 μm/s下进行实验,得到界面形态如图2所示。对于直径为1.8 mm的试样,界面形态非常杂乱,经历平界面失稳后,界面尚未达到规则的胞晶界面。从图2(a)中可以看出,界面呈弯曲形状,且两端非对称,界面形态演化为不规则的胞晶,称为浅胞晶。在直径为3.5 mm的试样中,界面为规则的深胞晶形态,呈对称弯曲形

图1 在v=1 μm/s下Al-4%Cu合金不同尺寸试样的平界面

Fig.1 Planar interfaces of Al-4%Cu alloy at v=1 μm/s for samples with different sizes: (a) d=1.8 mm; (b) d=3.5 mm

图2 在v=5 μm/s下3种不同尺寸试样的界面形态

Fig.2 Different interfacial morphologies for three samples at v=5 μm/s with different sizes: (a) d=1.8 mm; (b) d=3.5 mm; (c) d= 7 mm (Interfacial morphologies vary from shallow cellular(a) to deep cellular(b) and then to initial dendrite(c))

状,如图2(b)所示。试样尺寸增大到7 mm后,界面比较平齐,已不再是胞晶形态,而呈现出枝晶的初始形态,二次枝晶臂还未明显出现,如图2(c)所示。实验发现,在相同速率下,对不同尺寸的试样,界面形态分别经历了平界面→浅胞晶,平界面→深胞晶和平界面→初始枝晶的演变过程。结果表明,在相同速率下,随着试样尺寸的增大,界面形态发生明显变化,试样尺寸的增大促使界面稳定性降低。

3 分析与讨论

3.1 试样尺寸对温度梯度的影响

在前面的研究中,通过对不同尺寸试样的温度梯度进行测量,得到尺寸为3.5 mm和7 mm试样的温度梯度变化趋势相同[15]。该试验也反映了相同凝固速率 下,小尺寸试样具有更高的温度梯度[15]。这是由于在小尺寸试样中,径向温度比较均匀,熔体中热对流较 弱[9, 12, 14]。而熔体中的热对流使得温度均匀化,液相温度梯度显著降低,因此,小试样的温度梯度更高。温度梯度也是凝固速率的函数,具体表示如下:

(1)

(1)

式中:Kl和Ks分别为液、固相的热导率;ρ为合金密度;h为铸件与冷却介质的复合换热系数;α为导热系数;T0为冷却介质温度;T为铸件温度;d为试样尺寸;Lf为结晶潜热。试样尺寸在温度梯度的分母中,与温度梯度成反比。可以得出,对相同材料,在凝固速率一定的情况下,试样尺寸d 越小,则固相温度梯度Gs越大。而根据成分过冷判据,由于动力学过冷度?Tk很小,予以忽略,则成分过冷?Tc的数学表达式为

(2)

(2)

式中:

(3)

(3)

(4)

(4)

式中:Tx为离界面x处的液相线温度,K;m为液相线斜率,K/%;T0为原始成分c0合金的液相线温度,K;k为溶质分配系数;Dl为液相扩散系数,m2/s;T1为原始成分c0合金的固相线温度,K;故

(5)

(5)

式(5)给出了成分过冷?Tc随距界面距离x变化的关系。从式(5)可以看出,液相温度梯度(Gl)的增加减小了成分过冷度,即温度梯度的增加使得界面稳定性提高。因此,在相同速率下,小尺寸试样的界面更加稳定。如图1所示的平界面,图1(a)的界面明显要比图1(b)的稳定。

3.2 试样尺寸对平界面弯曲的影响

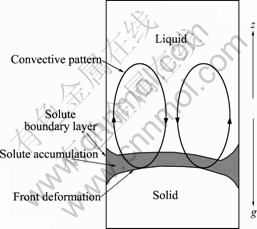

在定向凝固中,一般只考虑一维传热,即热流平行于生长方向由固相导出。而实际中,由于档板附近热区和冷区条件不同,总存在径向散热。从微观方面来说,在垂直向上的凝固中,Al-4%Cu合金溶质的密度比溶剂的大,将不会产生双扩散对流,比较稳定。图3所示为Al-4%Cu合金垂直向上凝固示意图。图中椭圆表示液相合金对流模式:合金液从边缘向上流动,从试样中心下落,在凝固界面前沿的溶质边界层,液相合金又从中心向边缘流动,构成闭合回路。液相合金从中心向边缘流动同时将热量带向边缘,使得边缘温度升高。当溶质在固相中的溶解度比在液相中的小时,界面处将排出溶质。这种被排出的溶质也从中心向边缘流动,如图3所示,在试样边缘处形成了溶质富集,因此,边缘处温度降低。相应地,试样中心溶剂含量增加,在试样中心形成富集。这样,界面处成分发生了变化。而为了满足界面处溶质平衡,固/液界面发生弯曲,并且凸向液相,如图1(b)所示。

图3 对流模式示意图

Fig.3 Schematic representation of convection pattern (Ascending flow corresponds to interface depression and solute accumulation)

从宏观界面图1(a)、(b)中可以发现,两种界面虽然均为平界面,但是大尺寸试样的界面更加弯曲。这主要是由于试样尺寸的改变引起了径向温度差,从而引起对流。对强制对流,对流强度采用Reynold数表示,而对自然对流,对流强度[12]由Rayleigh数决定,表示如下:

(6)

(6)

式中:g 为重力加速度;β为热扩散系数;?t为径向温差;d为试样直径; 为熔体动力学粘度;

为熔体动力学粘度; 是熔体热导率。可以看出,熔体对流强度受以上几个因素影响。对相同合金而言,对流强度主要受径向温差?t和试样尺寸d两个因素影响。定向凝固实验中,径向温差由以下几种因素决定:合金种类,初始条件,外部参数如试样尺寸、坩锅热导率和炉子热参数等。可以看出,试样尺寸越大,径向温差越大,对流强度也越大,这与TRIVEDI等[12]的研究结果一致。而对流引起的动量传输会显著地改变传热和传质过程,严重影响界面稳定性,所以,大尺寸试样的界面更加不稳定。这很好地解释了本实验中的现象。因此,试样尺寸越大,平界面更加弯曲。

是熔体热导率。可以看出,熔体对流强度受以上几个因素影响。对相同合金而言,对流强度主要受径向温差?t和试样尺寸d两个因素影响。定向凝固实验中,径向温差由以下几种因素决定:合金种类,初始条件,外部参数如试样尺寸、坩锅热导率和炉子热参数等。可以看出,试样尺寸越大,径向温差越大,对流强度也越大,这与TRIVEDI等[12]的研究结果一致。而对流引起的动量传输会显著地改变传热和传质过程,严重影响界面稳定性,所以,大尺寸试样的界面更加不稳定。这很好地解释了本实验中的现象。因此,试样尺寸越大,平界面更加弯曲。

3.3 形态转变分析

从微观方面来说,图2(a)的界面形态很杂乱,界面前沿游离状胞晶占主导部分。根据式(6),小尺寸试样中的流动强度低,凝固过程中的动量、质量传输以扩散为主,而以扩散方式进行的界面演化较慢;又由于小试样中的毛细效应对界面具有稳定作用,因此,小尺寸试样的界面稳定性增强。图2(b)所示为典型的胞晶界面。界面前沿略呈弯曲,比图2(a)平整。这是由于试样尺寸增大,径向温度差增大,引起对流增强。而对流引起的熔体流动比扩散引起的熔体流动速率快,界面演化因此加快,由不稳定的浅胞晶转变为稳定的胞晶。因此,径向温差促进界面形态不稳定。图2(c)中,界面已不再是胞晶,取而代之的是初始枝晶界面。这同样表明,径向温差加速界面演化,即径向温差破坏了界面的稳定。

与图2(a)、(b)相比,图2(c)的界面非常平齐。这是由于界面弯曲也取决于其界面形态。对胞/枝晶来说,除了边缘区域,界面弯曲幅度不大,几乎是平整的。胞/枝晶界面和平界面前沿的主要差别在于:平界面的界面前沿不存在糊状区,只能将溶质排斥到液相区;相反,胞/枝晶界面前沿富集的溶质原子排斥到糊状区中的液相中。而对胞晶来说,由于胞晶是整齐的圆柱状或长条状,没有分支,因此,糊状区中的固相占绝大部分,液相仅有很少的一部分。但是在枝晶糊状区中,由于枝晶排列比胞晶的稀疏,又由于枝晶中二次枝晶臂的存在,二次枝晶臂间充满整个液相。在凝固过程中,这些液相被包围在枝晶干中直接凝固,使得糊状区中存在大量液相。而这些液相有足够的空间吸收界面前沿富集的溶质原子,因此,界面非常平整。胞晶糊状区中的液相比枝晶的少得多,因而界面稍微弯曲。因此,可以得出:当界面前沿液相中存在径向温差时,溶质再分配将发生变化,这必将引起界面稳定性发生变化。径向温差促进了溶质的传输过 程,缩短了溶质扩散长度,加快了界面前沿溶质浓度的增大趋势,从而缩短了界面失稳的孕育时间,促进界面不稳定,加快了界面演化,促使枝晶界面前沿更加平齐。

在凝固体系中,对流对微观组织的影响取决于对流的强度和模式:溶质的密度比溶剂的密度大,流动强度小。而熔体流动是影响溶质再分配过程的一个重要而又复杂的因素,不仅受热流、合金物性(粘度、导热性等)条件的影响,而且试样的形状、尺寸、以及坩埚的材料、内壁光洁度等因素也会导致对流、搅拌作用的变化。但是,界面成分的微小变化严重影响界面宏观形状,而且微观组织从中心到边缘发生改变。

从图2中可以清楚地看到,试样边缘的组织相对中心更加不稳定,从图2(b)中看出,试样中心为胞晶,而边缘已经有近似枝晶组织出现,试样边缘比中心演化快。从图2(a)、(c)中也可得到同样的结论。由于径向温差的存在,界面前沿液相从试样中心向边缘流动,造成边缘溶质富集,浓度增大,形成溶质径向偏析。由于试样边缘溶质含量比中间的高,使得边缘稳定性降低[12],因而试样边缘比中心更易失稳。因此,加快试样边缘失稳的主要驱动力是径向温差引起的边缘溶质富集程度的增加。

4 结论

1) 试样尺寸越小,平界面越平直。试样尺寸增加引起径向温差增大,促使试样边缘溶质富集,平界面发生弯曲。

2) 在相同凝固速率下,随试样尺寸增大,界面形态经历了浅胞—深胞—初始枝晶,胞晶界面比枝晶界面弯曲。径向温度差促进界面不稳定,促使非平界面更加平齐。这主要是由于胞晶界面前糊状区的液相远比枝晶界面糊状区的少,排向糊状区液相的胞晶界面排出的溶质原子比枝晶界面的少。

REFERENCES

[1] WU M, LUDWIG A. Modeling equiaxed solidification with melt convection and grain sedimentation—Ⅰ: Model description[J]. Acta Materialia, 2009, 57: 5621-5631.

[2] STELIAN C, DUFFAR T. Modeling of thermosolutal convection during Bridgman solidification of semiconductor alloys in relation with experiments[J]. J Cryst Growth, 2004, 266: 190-199.

[3] LAN C W, TU C Y. Morphological instability due to double diffusive convection in directional solidification: The pit formation[J]. J Cryst Growth, 2000, 220: 619-630.

[4] MOELANS N, BLANPAIN B, WOLLANTS P. An introduction to phase-field modeling of microstructure evolution[J]. Calphad, 2008, 32: 268-294.

[5] LI D M, LI R, ZHANG P W. A cellular automaton technique for modelling of a binary dendritic growth with convection[J]. Appl Mathe Model, 2007, 31: 971-982.

[6] LI X, FAUTRELLE Y, REN Z M. Influence of an axial high magnetic field on the liquid-solid transformation in Al-Cu hypoeutectic alloys and on the microstructure of the solid[J]. Acta Materialia, 2007, 55: 1377-1386.

[7] LI X, GAGNOUD A, REN Z M, FAUTRELLE Y, MOREAU R. Investigation of thermoelectric magnetic convection and its effect on solidification structure during directional solidification under a low axial magnetic field[J]. Acta Materialia, 2009, 57: 2180-2197.

[8] TRIVEDI R, MAZUMDER P, TEWARI S N. The effect of convection on disorder in primary cellular and dendritic arrays[J]. Metall Mater Trans, 2002, 33A: 3763-3775.

[9] TRIVEDI R, MIYAHARA H, MAZUMDER P, SIMSEK E, TEWARI S N. Directional solidification microstructures in diffusive and convective regimes[J]. J Cryst Growth, 2001, 222: 365-379.

[10] JAMGOTCHIAN H, THI H N, BERGEON N, BILLIA B. Double-diffusive convection modes and induced microstructure localization during solidification of binary alloys[J]. Inter J Therm Sci, 2004, 43: 769-777.

[11] THI H N, DABO Y, DREVET B, DUPOUY M D, CAMEL D, BILLIA B, HUNT J D, CHILTON A. Directional solidification of Al-1.5wt%Ni alloys under diffusion transport in spacing and fluid-flow localization on earth[J]. J Cryst Growth, 2005, 281: 654-668.

[12] TRIVEDI R, LIU S, MAZUMDER P, SIMSEK E. Microstructure development in the directionally solidified Al-4.0wt%Cu alloy system[J]. Sci Tech Advan Mater, 2001, 2: 309-320.

[13] LIU S, LI J, TRIVEDI R. Spatio-temporal microstructure evolution in directional solidification processes[J]. Philosophical Magazine, 2006, 86: 3717-3738.

[14] TENG J, LIU S, TRIVEDI R. Onset of sidewise instability and cell-dendrite transition in directional solidification[J]. Acta Materialia, 2009, 57: 3497-3508.

[15] QU M, LIU L, TANG F T, ZHANG J, FU H Z. Effect of sample diameter on primary dendrite spacing of directionally solidified Al-4%Cu alloy[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(1): 1-8.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(50771081,51075004)

收稿日期:2010-04-16;修订日期:2010-07-29

通信作者:屈 敏,讲师,博士;电话:010-88803012;E-mail: qm_021@yahoo.com.cn