文章编号:1004-0609(2013)S1-s0193-05

Ti35合金与Nb的异材质焊接

吴金平1, 2,杨英丽1,奚正平1,孙 军2,苏航标1,罗媛媛1,宋飞飞1

(1. 西北有色金属研究院,西安 710016;

2. 西安交通大学 材料科学与工程学院,西安 710049)

摘 要:对Ti35合金和Nb用钨极氩弧焊及爆炸复合两种工艺方法进行连接试验,通过光学显微镜、扫描电镜和能谱仪研究了两种工艺方法对Nb/Ti35连接界面附近组织形貌和成分的影响。结果表明:爆炸复合方法连接Ti35合金与Nb,在界面附近会产生爆炸旋涡,爆炸旋涡卷入大量Ti-Ta-Nb混合物,结合界面存在熔化缝隙,这些形貌特征和成分不利于接头在腐蚀性环境中使用。Nb/Ti35氩弧焊接的焊接接头界面处未发现孔洞等不结合缺陷,Nb在焊缝界面处呈梯度过渡,焊接接头具有较好的力学性能,氩弧焊工艺方法连接Ti35合金与Nb较为可行。

关键词: Ti35合金;铌;氩弧焊;爆炸复合;界面

中图分类号:TG 146.4 文献标志码:A

Dissimilar metal jointing of Ti35 alloy to Nb

WU Jin-ping1, 2, YANG Ying-li1, XI Zheng-ping1, SUN Jun2, SU Hang-biao1, LUO Yuan-yuan1, SONG Fei-fei1

(1. Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China;

2. School of Materials Science and Engineering, Xi’an Jiaotong University, Xi’an 710049, China)

Abstract: The dissimilar metal joints of Ti35 titanium alloy to Nb were carried out with explosive cladding and argon tungsten-arc welding (TIG) processes. The effects of processes on metallographic microstructure and composition besides the bonding interfaces were investigated by means of optical microscope, scan electron microscope and energy spectrum. The results show that molten region in swirl and molten fracture layers comprised of Ti-Ta-Nb mixtures occur along the interface of Nb/Ti35 exploding joint. This is disadvantageous for joint to using in corrosive conditions. However, molten fracture layers are not observed in the TIG joint. Nb content is changed slowly along the interface of Nb and welding seam. Adequate mechanical properties are also obtained in the welding joint. These results indicate that TIG process is feasible to bonding Ti35 alloy and Nb.

Key words: Ti35 alloy; niobium; argon tungsten-arc welding; explosive cladding; interface

Ti35钛合金作为一种Ti-Ta二元合金,在氧化性酸性介质中具有强烈的钝化倾向,在硝酸腐蚀性环境中均具有较优的耐蚀性,在核工业中有着广泛的应用[1-5]。在工业应用中,Ti35钛合金常要求与其他金属材料连接在一起。但对于物理和化学性能存在较大差异的两种金属材料的连接,通常的连接工艺方法会由于元素扩散,界面处形成脆性相,而导致连接接头失效[6]。

爆炸复合技术是通过瞬时的爆炸冲击力将2种材料压接在一起,在界面上形成冶金结合,由于瞬时结合,2种材料几乎不存在元素间的相互扩散,抑制了脆性相的产生,因此,该方法在异种材料的连接中得到广泛的应用[7-9]。Nb/Ti35复合材料应用在腐蚀性环境中,爆炸复合界面结合的好坏、复合界面形貌及成分分布对材料的力学性能及耐腐蚀性能有较大的影响。

目前,还没有相关资料报道Ti和Nb直接进行钨极氩弧焊,但根据Ti-Nb二元合金相图[10-11],钛与铌在室温下以α相、α+β或β相存在,不产生金属间化合物,因而,采用钨极氩弧焊的方法进行Nb与Ti35的焊接连接是可行的方法之一。

本文作者通过爆炸复合与钨极氩弧焊2种方法进行Nb与Ti35的连接试验,研究连接界面组织形貌与成分分布,并进行连接接头的力学性能比较。为工业化应用中Ti35与Nb的异材质连接方法选择提供实验依据及技术支持。

1 实验

爆炸焊接的复材采用1.5 mm厚退火态纯Nb板。基材选用6 mm厚的退火态Ti35钛合金。

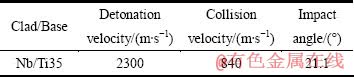

实验采用的炸药为低爆速硝铵混合炸药,爆炸复合预置角为零,采用平行安装法进行爆炸复合。参数选用爆炸复合窗口上限,实验动态参数如表1所示。

表1 爆炸复合工艺动态参数

Table 1 Dynamic parameters for exploding processing

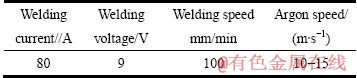

焊接试板采用厚度为1.5 mm冷轧退火Nb板和Ti35合金板,充填焊丝为直径1.0 mm的Ti35合金专用Ti35HS焊丝,钨极氩弧焊焊接前,焊接试板及焊丝用丙酮擦拭干净。焊接参数如表2所示。

表2 主要焊接参数

Table 2 Main welding parameters of TIG

爆炸平板样和氩弧焊接接头样经切割取样,通过打磨、抛光后,采用体积比为3:1的HNO3与HF进行腐蚀。运用金相显微镜(OM),JSM-5800扫描电镜 (SEM)及能谱仪(EDS)对复合界面的组织及成分进行分析,采用维氏硬度计测量界面附近的显微硬度。在剪切试验设备上对爆炸界面进行剪切试验,氩弧焊接头在万能拉伸试验机上进行抗拉强度测试。

2 结果与讨论

2.1 界面组织形貌

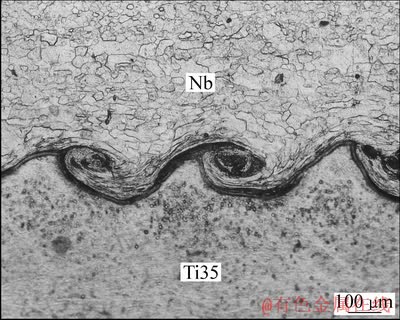

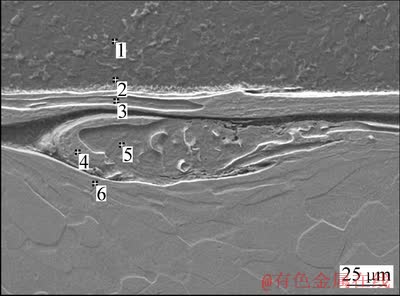

Nb/Ti35爆炸焊接结合界面呈大波状,其形貌如图1如示,每个波峰产生一漩涡,漩涡内有空洞物,靠近结合界面的铌板一侧晶粒发生严重塑性流变,晶粒沿爆炸冲击波的传播方向被拉长,并随着波形弯曲,将铌与Ti35的混合熔化物包裹起来,形成1个旋涡区。同时,沿着界面有1条明显的“缝隙”,这可能由于实验的炸药量为可焊性窗口的上限,药量过大,使界面呈大波状,并在界面产生过熔。

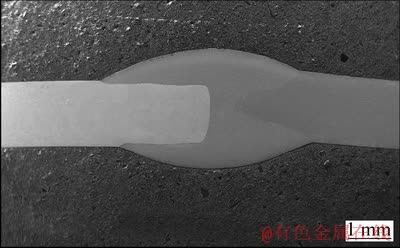

图2所示为Nb/Ti35焊接接头的母材和焊缝的组织形貌。焊接过程中Nb和Ti35母材都发生熔化。由于焊接采用的是Ti35合金专用焊丝,在Ti35合金一侧,焊缝和Ti35合金母材基本熔合在一起。在Nb一侧,焊接时,母材Nb发生的熔化,但焊缝和Nb母材分界较为清晰,由于充填焊丝成分接近于Ti35合金母材,焊丝和Ti35合金的熔点与Nb的熔点有较大的差距,因此,研制新的焊丝及改进氩弧焊焊接工艺,将有助于改善Nb/Ti35氩弧焊接头的性能。

图1 Nb/Ti35爆炸复合界面形貌

Fig. 1 Nb/Ti35 explosion cladding interface morphology

图2 Nb/Ti35氩弧焊焊接接头组织形貌

Fig. 2 Nb/Ti35 welding interface morphology

2.2 界面化学成分

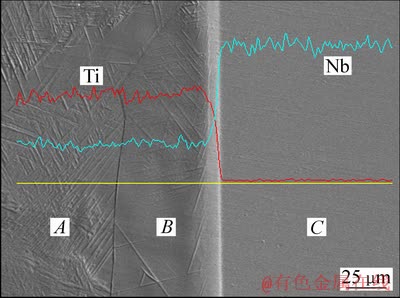

对Nb/Ti35爆炸焊接结合界面各区域进行成分分析(图3),结果如表3所列。在Ti35合金一侧的1区和2区,只有钛、钽成分,其成分与Ti35母材成分相同,在离界面10~12 μm距离外,没有铌的扩散,这是由于爆炸复合过程是在瞬间完成的,约1×10-5 s,在熔化及凝固过程中,元素来不及扩散。

图3 Nb/Ti35爆炸复合界面成分

Fig. 3 Composition at interface of explosion cladding

表3 Nb/Ti35爆炸复合界面成分

Table 3 Composition at interface of explosion cladding (mass fraction, %)

3区和5区主要由Ti-Ta-Nb合金构成,它是铌与Ti35合金在较高的冲击能量下熔化后形成的机械混合物。4区和6区为纯铌。在爆炸过程中,铌板在较高的应变率下,界面处的晶粒产生严重塑性变形而破碎。并被卷入旋涡区。

爆炸复合过程中,复板的碰撞速度过快而形成了较大的漩涡。波形漩涡中的物质大部分是捕捉的射流物质。这些夹杂物质对材料的耐蚀性有较大的损伤,在以后的使用过程中,会成为材料失效的根源。

已有实验证明[8],采用Ti35合金专用焊丝Ti35HS焊接Ti35合金时,主合金化元素Ta在焊缝与Ti35合金的界面呈平缓的梯度变化,使焊缝与母材获得良好的强韧性匹配。

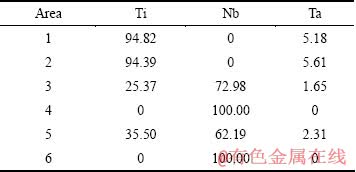

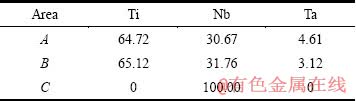

在焊缝与母材Nb之间,有一条明亮的宽约10~15 μm的熔合区,如图4所示。在熔合区中可看到Ti和Nb相互扩散,Ti含量在溶合区内急剧下降,但在焊接中由于母材的熔化,使得在焊缝组织中固溶有一定含量的Nb。

表4列出A、B和C 3个区域的Ti、Nb、Ta的质量分数,Nb在界面附近的焊缝区中,固溶有31%左右的Nb,随着远离界面,Nb质量分数在焊缝中逐渐下降。

图4 氩弧焊焊缝与Nb界面的成分变化

Fig. 4 Element distribution lines along interface of Nb and welding seam

表4 氩弧焊接头焊缝与Nb界面附近的成分

Table 4 Composition at interface of Nb and welding seam (mass fraction, %)

2.3 接头力学性能

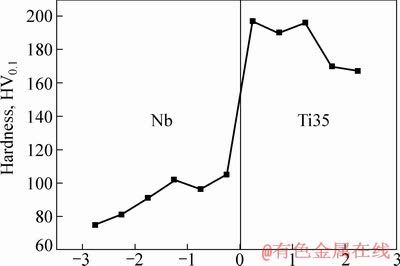

Nb/Ti35爆炸复合界面附近的硬度分布如图5所示。

从爆炸界面到Ti35合金,硬度呈由高到低分布,在爆炸界面附近,Ti35合金硬度升高,随后逐渐降低。从爆炸界面到铌,硬度也由高到低分布。这与界面处Ti35合金及Nb的爆炸变形所引起的加工硬化有关。

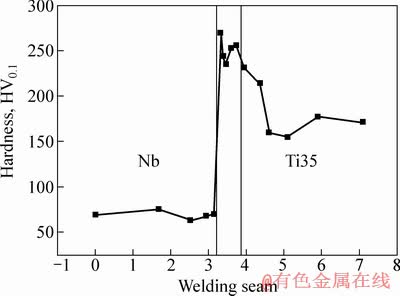

Nb/Ti35氩弧焊接头附近的硬度分布如图6所示,焊缝处硬度最高,达到250 MPa左右,这可能一方面由于Nb熔化扩散到焊缝中,造成一定的固溶强化,同时焊接时带入的杂质元素对焊缝也有一定的强化作用。在靠近焊缝的Ti35和Nb两侧,硬度值出现微小的低凹区,这可能与热影响区材料的强度降低有关。

图5 Nb/Ti35爆炸复合界面的硬度

Fig. 5 Distribution of microhardness along interface of explosion cladding

图6 Nb/Ti35氩弧焊界面的硬度

Fig. 6 Distribution of microhardness along joint of welding

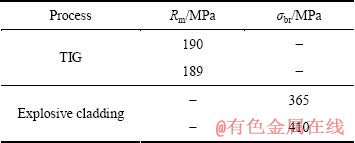

Nb与Ti35合金爆炸复合界面的抗剪试验和氩弧焊焊接接头的拉伸实验结果显示(表4):Nb/Ti35爆炸复合界面的抗剪强度达到350 MPa以上,抗剪强度满足使用力学性能要求。Nb/Ti35氩弧焊接头抗拉强度大于180 MPa,拉伸断裂位置在Nb端,同时Nb/Ti35氩弧焊接头弯曲角可达140°以上,弯曲工艺性能良好, 这表明氩弧焊接Nb和Ti35的焊缝处强度大于母材Nb的强度,同时焊缝处也具有较优的塑性和韧性。

表5 氩弧焊与爆炸复合接头的力学性能

Table 5 Mechnical properties of joints of welding and explosion cladding

3 结论

1) 采用爆炸复合方法连接Ti35合金与Nb,界面剪切强度能够满足使用力学性能要求,但爆炸界面处存在爆炸旋涡和熔化缝隙,爆炸旋涡和熔化缝隙由Ti-Ta-Nb混合物组成,该结构不利于复合接头在腐蚀环境中的应用。

2) 采用钨极氩弧焊接连接Ti35合金与Nb是可行的,氩弧焊焊接接头界面处未发现孔洞等不结合缺陷,Nb在焊缝界面处呈梯度过渡,焊接接头有较好的强度和弯曲工艺性能,焊接接头的表面形貌较适合应用于腐蚀性环境中。

REFERENCES

[1] BALDEV R, KAMACHI M U. Materials development and corrosion problems in nuclear fuel reprocessing plants[J]. Progress in Nuclear Energy, 2006, 48(4): 283-313.

[2] SANO Y, TAKEUCHI M, NAKAJIMA Y, HIRANO H, UCHIYAMA G, NOJIMA Y, FUJINE S, MATSTMOTO S. Effect of metal ions in a heated nitric acid solution on the corrosion behavior of a titanium-5% tantalum alloy in the hot nirtric acid comdensate[J]. Journal of Nuclear Materials, 2013, 432(1/3): 475-481.

[3] KAREN S, ALAIN R. Preparation and characterization of Ti-Ta alloys for application in corrosive media[J]. Materials Letters, 2003, 57: 3010-3016.

[4] TAKAO Y, SHIGEKI T, SHINICHI O, et al. Gamma-ray irradiation effect on corrosion rates of stainless steel, Ti and Ti-5Ta in boiling 9N nitric acid[J]. Journal of Nuclear Materials, 1996, 228: 162-167.

[5] MYTHILI R, SAROJA S, VIJAYALAKSHMI M. Characterization of passive oxide film on a Ti-5%Ta-1.8%Nb alloy on exposure to severe oxidizing conditions[J]. Materials Characterization, 2010, 61(12): 1326-1334.

[6] WANG H T, WANG G Z, XUAN F Z, TU S T. Fracture mechanism of a dissimilar metal welded joint in nuclear power plant[J]. Engineering Failure Analysis, 2013, 18: 134-148.

[7] SONG J, KOSTKA A, VEEHMAYER M, RAABE D. Hierarchical microstructure of explosive joint: Example of titanium to steel cladding[J]. Materials Science and Engineering A, 2011, 528(6): 2641-2647.

[8] WANG Bing-feng, CHEN Wei, LI Juan, LIU Zhao-lin, ZHU Xie-bin. Microstructure and formation of melting zone in the interface of Ti/Ni/Cr explosive cladding bar[J]. Materials & Design, 2013, 47: 74-79.

[9] SUDHA C, PRASANTHI T N, MURUGESAN S, SAROJA S, KUPPUSAMI P, VIJAYALAKSHMI M. Study of interface and base metal microstructures in explosive clad joint of Ti-5Ta-1.8Nb and 304l stainless steel[J]. Science and Technology of Welding & Joining. 2011, 16(2): 133-139.

[10] 刘安生. 二元合金状态图集[M]. 北京: 冶金工业出版社, 2004: 280.

LIU An-sheng. Binary alloy phase-diagrams[M]. Beijing: Metallurgical Industry Press, 2004: 280.

[11] 吴金平, 杨英丽, 赵恒章, 赵永庆, 赵 彬, 郭荻子, 林 桥. Ti35钛合金的焊接组织与性能[J]. 稀有金属材料与工程, 2008, 37(Suppl.3): 205-208.

WU Jin-ping, YANG Ying-li, ZHAO Heng-zhang, ZHAO Yong-qing, ZHAO Bin, GUO Di-zi, LIN Qiao. The welding microstructure and weldability of Ti35 alloy[J]. Rare Metal Materials and Engineering, 2008, 37(Suppl.3): 205-208.

(编辑 邓履翔)

基金项目:陕西省重点科技创新团队计划“钛合金研发创新团队”(2012KCT-23)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:吴金平,高级工程师,博士研究生;电话:13991884771;E-mail:jinpingwu7@126.com