文章编号:1004-0609(2013)11-3147-07

真空热处理对NiCrAlY涂层组织与性能的影响

彭小敏1,夏长清2,吴安如1,董丽君1,李东锋1, 2,陶友瑞1

(1 .湖南工程学院 机械工程学院,湘潭 411101;

2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用电弧离子镀(AIP)技术在TC4 (Ti-6Al-4V) 钛合金表面制备NiCrAlY涂层。利用扫描电镜(SEM)、透射电镜(TEM)、能谱(EDS)分析、X射线衍射分析(XRD)及维氏硬度测量试验研究真空热处理对NiCrAlY涂层组织与性能的影响。结果表明:真空热处理后涂层沉积残余应力得到有效释放,涂层平均晶粒尺寸从沉积态的200 nm增加至950 ℃真空热处理后的500 nm;真空热处理过程中发生β→γ′→γ相转变,γ′分布于β晶界或γ晶粒内;γ晶粒内析出的γ′相呈细小弥散分布,与基体γ保持共格起到强化作用;经700~750 ℃真空热处理后,涂层可获得最佳的析出强化效果。

关键词:NiCrAlY涂层;真空热处理;显微组织;性能

中图分类号:TB43 文献标志码:A

Effect of vacuum heat treatment on microstructure and property of NiCrAlY coating

PENG Xiao-min1, XIA Chang-qing2, WU An-ru1, DONG Li-jun1, LI Dong-feng1, 2, TAO You-rui1

(1. School of Mechanical Engineering, Hunan Institute of Engineering, Xiangtan 411101, China;

2.School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: NiCrAlY coating was deposited on TC4 titanium alloy by arc ion plating (AIP). The effect of vacuum heat treatment on the microstructure and properties of NiCrAlY coating were studied by SEM, TEM, EDS, XRD and Vickers hardness test. The results show that, during the vacuum heat treatment, the deposition residual stress of the coating can be released effectually. The average grain size of the coating increases from 200 nm for the as-deposited state to 500 nm for the vacuum heat-treated state at 950 ℃. β→γ′→γ phase transformation happens during the vacuum heat treatment. γ′ phase distributes along the β grain boundaries or in the γ grains. The fine and dispersing γ′ phase in the γ grains is coherent with the substrate, which is able to strengthen the coating substrate. The best precipitation hardening effect for NiCrAlY coating can be obtained after vacuum heat treatment at 700-750 ℃.

Key words: NiCrAlY coating; vacuum heat treatment; microstructure; property

自20世纪70年代来,MCrAlY (M=Ni, Co, NiCo)涂层越来越广泛地被用作抗氧化涂层或热障涂层(TBC)基体与陶瓷涂层间的粘结层,其优点是硬度高、抗氧化性能好,其热膨胀系数与高温合金及陶瓷的接近[1]。另外,MCrAlY本身具有韧性好、强度高以及良好的抗高温氧化与抗热腐蚀性能,也可单独作为高温防护涂层使用[2-4]。制备MCrAlY涂层的方法很多,如真空等离子喷涂(VPS)、电子束物理气相沉淀(EBPVD)及磁控溅射等。电弧离子镀(AIP)是在蒸镀和溅射镀膜的基础上逐步改进和发展起来的新型镀膜技术[5],其在沉积过程中对基体的离子轰击作用能够改善涂层结构、提高涂层结合力,因而在制备MCrAlY涂层中体现了众多优点[6]。

钛合金材料密度小、比强度高、耐蚀性强、中低温性能稳定,是极具应用前景的轻型高温材料之一[7]。但是,钛合金的不耐烧蚀、高温硬度低、易氧化,且在合金表面形成不具保护作用的氧化物,在氧化过程中氧化物层下基体易固溶大量的氧原子,从而形成脆性富氧层等特性严重损害了合金的高温使用性能,影响了合金的使用[8-10]。为此,采取了一系列的措施来提高钛合金的高温性能,包括在合金中加入其他元素,如Nb、W 和Mo[11],对合金进行表面改性如低压氧处理[12],如渗Al[13],在合金表面涂覆抗氧化涂层,如TiAl3、TiAlCr 和MCrAlY [14]等。

目前,MCrAlY涂层虽然主要应用于超合金表面的防护,但由于其良好的综合性能,MCrAlY涂层在钛合金防护方面的应用也逐渐得到了关注[3-4, 15-17]。但上述研究主要集中在MCrAlY涂层对钛合金抗高温氧化性能的改善[3, 15-16],MCrAlY涂层/钛合金基体体系间的元素互扩散和界面反应[4, 17]等问题上。但对MCrAlY涂层在热处理或热暴露(高温氧化、热腐蚀等)对涂层的相变及性能的影响报道较少,如LI等[18-19]主要研究了NiCrAlY/CrON/DSM11体系高温氧化过程中涂层显微组织变化及其对涂层体系弹性模量及力学破坏行为的影响。目前,关于真空热处理过程中NiCrAlY 涂层显微组织变化对涂层硬度影响的报道较少。一般来说,NiCrAlY 涂层服役环境苛刻,如航空航天发动机领域,存在高温、高压、高速气流(含未燃尽固体颗粒、气流一般富含O、S、C、N、H等)的冲刷和烧蚀,涂层往往除承受富O、S、C、N、H气体氧化及化学腐蚀外还要抵抗高速含固体颗粒气流的冲刷。因此,提高NiCrAlY涂层硬度可改善深层抗冲刷性能。另外,对于物理气相沉积涂层来说,涂层沉积后的后续热处理(Post heat treatment) 对于减少沉积缺陷、释放沉积残余应力、均匀化涂层元素分布及增强涂层与基体的冶金结合十分重要[18, 20]。因此,研究电弧离子镀NiCrAlY 涂层真空热处理过程中的相变、稳定性及其对涂层硬度的影响具有理论意义和实践意义。

本文作者利用电弧离子镀在α+β两相钛合金TC4表面制备NiCrAlY 涂层,研究真空热处理对NiCrAlY 涂层的显微组织及涂层硬度的影响。

1 实验

1.1 材料及涂层制备

选择TC4 (Ti-6Al-4V,质量分数,%)钛合金轧制板材作为试验基材,试样被加工成尺寸为15 mm×10 mm×2.5 mm的小片。基体试样先在砂纸上磨光,去除表面氧化物,然后依次在碱液、蒸馏水中清洗,最后在丙酮溶液中超声清洗,干燥后置于沉积设备。

采用电弧离子镀(AIP)技术在TC4基体表面沉积制备NiCrAlY涂层,试验用靶材为Ni30Cr12Al1Y(质量分数,%)。沉积工艺参数如下:先抽真空至5×10-3 Pa,在沉积涂层前进行预溅射,轰击偏压为600~800 V,轰击电流为120~140 A,时间为5~10 min,沉积涂层时,加工作偏压为160~180 V,工作电流为120~140 A,沉积时间为120 min。

1.2 真空热处理

将沉积好NiCrAlY涂层的试样置于真空炉中,抽真空至1.33×10-2 Pa,升温至指定温度,升温速率小于8 ℃/min。真空热处理参数如下:热处理温度为650、750、870和950 ℃,保温3 h后空冷至室温。

1.3 检测分析

采用Rigaku D/Max 2500型X-ray衍射仪对真空热处理前后试样相组成进行分析,试验使用Cu 靶Kα1射线,波长0.154 056 nm,加速电压36 kV,电流30 mA,扫描速率4 (°)/min,步宽0.02°;采用Sirion200场发射扫描电镜(SEM)观察试样表面及截面微观形貌。采用TecnaiG220型透射电镜对真空热处理前后NiCrAlY涂层微观形貌进行观察,利用电子衍射确定涂层相组成,操作电压为200 kV。透射试样由基体侧向涂层侧减薄至30 μm后,冲成d 3 mm圆片,再进行离子减薄。利用SHIMADZU HMV-2维氏硬度测量仪测量真空热处理前后NiCrAlY涂层的显微硬度值,试验载荷为0.245 N,加载时间15 s,其值用HV表示。

2 结果与讨论

2.1 涂层的相组成

为了研究真空热处理对NiCrAlY涂层相组成的影响,对真空热处理后涂层表面进行XRD分析。图1所示为涂层在不同真空热处理温度下保温3 h后的XRD谱。由图1可知,沉积态NiCrAlY涂层主要由γ-Ni相(FCC)、β-NiAl相(B2)以及过饱和的α-Cr(FCC)固溶体组成;试样经650 ℃、3 h真空热处理后,相比沉积态试样,XRD谱中出现γ′相衍射峰,说明NiCrAlY涂层中开始析出γ′-Ni3Al(L12,a0=0.356 nm)相,而且γ相衍射峰明显变窄,说明热处理后γ相含量有所减少,同时β或α相衍射峰增强,表明热处理后β相或α相含量有所增加。当真空热处理温度升高至750 ℃时,涂层的XRD谱与650 ℃热处理后的相似,但γ′-Ni3Al相衍射峰强度稍有增加,说明γ′-Ni3Al相析出量有所增加。NiCrAlY涂层经870及950 ℃真空热处理3 h后,涂层中γ′-Ni3Al相衍射峰强度明显减弱,表明γ′-Ni3Al相含量明显减少。从Ni-Cr-Al三元相图的等温截面可知:当温度由750 ℃升至850 ℃,γ′相区减小,γ相区显著增大,由杠杆定律可知,随温度由750 ℃升至850 ℃,γ′相含量逐渐减少[21]。γ→γ′相转变被认为与涂层中Al元素的扩散相关[22]。在真空热处理过程中,随着Al元素向TC4基体方向扩散参与界面反应或固溶于钛合金基体,NiCrA1Y涂层中Al含量降低。γ-Ni脱溶与β-NiAl发生反应导致γ+β→γ′+α相转变[18],形成Al含量相对较低的γ′相,α-Cr相的析出能促进上述转变过程的进行。因此,试样经650 ℃、3 h真空热处理后γ相含量有所减少,而α相含量增加。随着热处理温度的提高,NiCrA1Y/TC4体系元素互扩散及界面反应更加剧烈[4],涂层中Al元素含量继续降低促使γ′→γ转变以形成不含Al元素的γ相。因此,当真空热处理温度提高至870 ℃及950 ℃时,NiCrAlY涂层中γ′衍射峰强度明显减弱,其含量减少。从Ni-Cr-Al合金中析出的γ′相细小弥散并且与基体保持共格关系,能够强化合金基体[4, 23]。NiCrAlY涂层后续热处理的目的是为了消除在沉积过程中产生的残余应力,提高涂层致密度,促进涂层与基体的冶金结合,同时也是NiCrAlY合金的一个时效硬化过程。在700~750 ℃的温度范围内,即γ′相脱离母相温度区间,可以得到最大的沉淀硬化效果。如果时效温度接近γ′溶解界限时,沉淀过程会中断,沉淀相在原来的地方积聚;如果温度超过溶解线时,会引起沉淀相的重新溶解[24]。

图1 NiCrAlY涂层经不同温度真空热处理3 h前后的XRD谱

Fig. 1 XRD patterns of NiCrAlY coating before vacuum heat treatment and after vacuum heat treatment at different temperatures for 3 h

图2 沉积态NiCrAlY涂层的显微结构

Fig. 2 Microstructures of as-deposited NiCrAlY coating

2.2 涂层的显微组织

在本实验中,从宏观上来看,沉积态电弧离子镀NiCrAlY涂层表面光洁平整,呈灰白色金属光泽,其显微结构如图2所示。由图2(a)可知,涂层表面由直径约为1~3 μm细小颗粒堆积而成,部分颗粒堆积成粗大粒子在涂层表面形成突起。由图2(b)可知,涂层连续致密、不含孔隙、气孔或裂纹等沉积缺陷,与钛合金基体结合紧密,涂层/基体界面平整,涂层厚度约为20 μm;但是在微观结构上,涂层表面凹凸不平,其内部呈现灰、白色层交替出现的层状结构。LI等[19]认为灰色相为防护性能较佳的富铝β-NiAl相,白色基体相为相对贫铝γ-Ni或γ′-Ni3Al相。为进一步研究沉积态NiCrAlY涂层的微观结构和相组成,对沉积态NiCrAlY涂层试样进行透射电镜(TEM)观察。图2(c)为沉积态NiCrAlY涂层TEM明场相及选区衍射(SAD)斑点(插图)。由图2(c)可知,沉积态NiCrAlY涂层为多晶结构,由γ-Ni、β-NiAl及α-Cr相组成(插图),其平均晶粒尺寸为200 nm左右。涂层多晶晶界并不明显,这与沉积态NiCrAlY涂层中存在残余应力有关。涂层中残余应力的存在对涂层的使用寿命是不利的,特别是在热暴露环境中(如高温静态和循环氧化等)残余应力的存在容易导致涂层开裂、剥落而失效。沉积残余应力普遍存在于物理气相沉积涂层中,一般来说,可以通过适当的真空热处理来消除涂层中的残余应力,促进元素的扩散和再分布,获得涂层与基体的冶金结合[2, 20]。

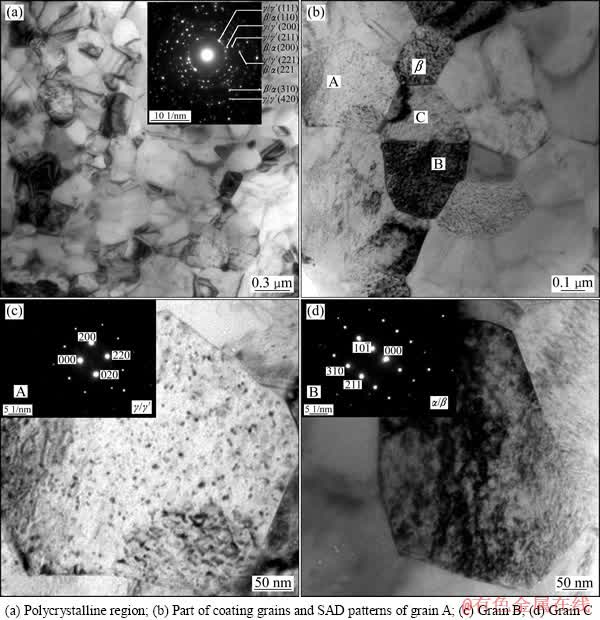

图3 经750 ℃、3 h真空热处理后NiCrAlY涂层的TEM明场像及选区衍射(SAD)斑点

Fig. 3 Bright-field TEM images and respective SAD patterns of NiCrAlY after vacuum heat treatment at 750 ℃ for 3 h

图3所示为NiCrAlY涂层经750 ℃、3 h真空热处理后TEM明场像及选取衍射(SAD)斑点。由图3(a)可知,NiCrAlY涂层经750 ℃、3 h真空热处理后,由于残余应力的消除和元素的再分布,晶界明显,晶粒大小比沉积态更加均匀,其晶粒平均尺寸为300 nm左右。由涂层选区衍射(SAD)斑点(见图3(a)插图)可知:除γ-Ni、β-NiAl、α-Cr相多晶衍射环外,出现了γ′-Ni3Al相(111)、(200)、(211)、(221)及(420)晶面衍射斑点,说明热处理后涂层中形成了γ′相,与XRD谱分析结果相吻合。图3(b)所示为NiCrAlY涂层经750 ℃、3 h真空热处理后TEM局部明场像,其晶粒A和B的明场相及选取衍射斑点(插图)分别如图3(c)和(d)所示。

由图3(c)可知,晶粒A的电子衍射斑点可标定为γ/γ′相,晶带轴为[004]。同时可观察到晶粒A基体上有细小粒状析出相弥散分布。POZE等[20]在真空等离子溅射(VPS)CoNiCrAlY涂层中,也观察到了上述组织。因此,在真空热处理过程中随着Al元素在涂层内部及TC4基体的再分布,γ′相可在NiCrAlY涂层的γ-Ni基体中析出。由图3(d)可知,晶粒B的电子衍射斑点可标定为α/β相,晶带轴为 。由于真空热处理过程中发生γ+β→γ′+α相转变,可观察到γ′-Ni3Al相在β相晶界析出(见图3(b)晶粒C)。

。由于真空热处理过程中发生γ+β→γ′+α相转变,可观察到γ′-Ni3Al相在β相晶界析出(见图3(b)晶粒C)。

图4 经950 ℃、3 h真空热处理后NiCrAlY涂层TEM明场像及选取衍射(SAD)斑点(插图)

Fig. 4 Bright-field TEM images and corresponding SAD patterns (Insert) of NiCrAlY after vacuum heat treatment at 950 ℃ for 3 h

图4(a)所示为沉积态NiCrAlY涂层经950 ℃、3 h真空热处理后TEM明场像及多晶衍射(SAD)斑点。由图4(a)可知,涂层经950 ℃、3 h真空热处理后涂层仍为γ-Ni、β-NiAl、α-Cr、γ′-Ni3Al多晶组织,晶粒大小均匀,其平均晶粒尺寸为500 nm左右。随着真空热处理温度的提高,涂层元素扩散加剧并重新分布,涂层相长大。图4(b)所示为NiCrAlY涂层经950 ℃、3 h真空热处理后TEM局部明场像及晶粒A选取衍射斑点(插图),B和C的明场像及选取衍射斑点(插图)分别如图4(c)和(d)所示。由图4(b)可知,晶粒A的电子衍射斑点可标定为γ-Ni相,晶带轴为 ,尺寸约为500 nm。晶粒B的电子衍射斑点可标定α/β相,晶带轴为

,尺寸约为500 nm。晶粒B的电子衍射斑点可标定α/β相,晶带轴为 ,结合元素能谱分析结果(Cr 92.3%,Ni 7.7%,摩尔分数)可知晶粒B为α-Cr。α-Cr在γ/γ′晶界(晶粒A和晶粒C)析出或在β晶界析出能促进γ+β→γ′+α相转变过程。图4(d)插图所示为典型的γ/γ′双晶沿{111}晶面<112>方向的衍射斑点,晶粒C为γ/γ′,同时在晶粒C明场相中可观察到弥散细小的γ′-Ni3Al相(见图4(d)黑色点状相)在γ-Ni基体中析出。对比图3(c)可知,涂层经950 ℃、3 h真空热处理后在γ-Ni基体中析出的γ′-Ni3Al相分布密度明显比750 ℃时的要小,说明950 ℃时涂层析出的γ′相明显减少,与XRD结果相吻合。

,结合元素能谱分析结果(Cr 92.3%,Ni 7.7%,摩尔分数)可知晶粒B为α-Cr。α-Cr在γ/γ′晶界(晶粒A和晶粒C)析出或在β晶界析出能促进γ+β→γ′+α相转变过程。图4(d)插图所示为典型的γ/γ′双晶沿{111}晶面<112>方向的衍射斑点,晶粒C为γ/γ′,同时在晶粒C明场相中可观察到弥散细小的γ′-Ni3Al相(见图4(d)黑色点状相)在γ-Ni基体中析出。对比图3(c)可知,涂层经950 ℃、3 h真空热处理后在γ-Ni基体中析出的γ′-Ni3Al相分布密度明显比750 ℃时的要小,说明950 ℃时涂层析出的γ′相明显减少,与XRD结果相吻合。

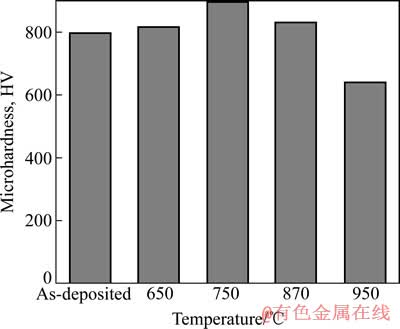

图5 真空热处理对NiCrAlY涂层显微硬度的影响

Fig. 5 Effect of vacuum heat treatment on microhardness of NiCrAlY coating

2.3 涂层的显微硬度

真空热处理对NiCrAlY涂层显微硬度的影响如图5所示。由图5可知,沉积态NiCrAlY涂层的显微硬度为798.5HV,涂层经650 ℃、3 h真空热处后,其表面硬度值的提高不明显为815.8HV;当真空热处理温度提高到750 ℃时,涂层表面硬度值达到最大值896.3HV;当真空热处理温度进一步升高时,涂层表面硬度值开始下降:当真空热处理温度为870 ℃时,涂层表面硬度值为830.4HV;当真空热处理温度为950 ℃时,涂层表面硬度显著下降为640.8HV。由图2(c)可知,由于沉积态涂层中沉积残余应力的存在,涂层显微硬度值保持在较高值。由图1、图3(c)和图4(d)的相关讨论可知:涂层经650 ℃、3 h真空热处理后,开始析出γ′-Ni3Al相;经750 ℃真空热处后,γ′-Ni3Al相析出量增加;进一步提高热处理温度至870及950 ℃时,涂层中γ′-Ni3Al相含量明显降低;从Ni-Cr-Al合金中析出的γ′相细小弥散并且与基体保持共格关系,能够强化合金基体。因此,涂层经650 ℃真空热处理后,虽然涂层的残余应力得到释放,但随着γ′-Ni3Al相的析出其硬度还是得到提高。经750 ℃真空热处理后,涂层中γ′-Ni3Al相析出量增加,涂层达到最大硬度值。但随着真空热处理温度的进一步提高,涂层中γ′-Ni3Al相含量明显降低,同时,由于残余应力的充分释放及涂层元素分布的均匀化,涂层的硬度显著降低。文献[24]表明,在700~750 ℃的温度范内,即γ′相脱离母相的温度区间,可以得到最大的沉淀硬化效果。如果温度接近γ′溶解界限时,沉淀过程会中断,沉淀相在原来的地方积聚;如果温度超过固溶度线时,还会引起沉淀相的重新溶解。因此,电弧离子镀NiCrAlY涂层的后续热处理不但是减少涂层沉积缺陷、释放沉积残余应力、均匀化涂层元素及增强涂层与基体的冶金结合的过程,而且是NiCrAlY涂层的时效硬化过程。NiCrAlY涂层最佳的析出硬化效果温度范围为700~750 ℃,NiCrAlY 涂层硬度的提高可改善涂层抗冲刷性能,延长涂层的使用寿命。

3 结论

1) 采用电弧离子镀技术在TC4钛合金表面沉积了约20 μm厚NiCrAlY涂层,涂层连续、均匀、致密、与基体结合紧密。真空热处理过程中涂层沉积残余应力得到有效释放,由于元素的扩散及均匀化,涂层晶粒平均尺寸从沉积态的200 nm增加至950 ℃的500 nm。

2) 沉积态NiCrAlY涂层由γ-Ni、β-NiAl及α-Cr 相组成,真空热处理过程中涂层发生β→γ′→γ相转变,γ′分布于β晶界或γ晶粒内,经650 ℃真空热处理后,涂层析出γ′-Ni3Al相;当真空热处理温度为750 ℃时,其含量增加;当温度进一步提高至870 ℃或950 ℃时,发生γ′→γ相转变导致γ′相含量明显减少。

3) 由于γ晶粒内析出的γ′相细小弥散与基体γ保持共格,对涂层起到析出强化作用,真空热处理过程中涂层硬度随γ′相含量的增加而提高,随γ'相含量的减少而下降,经700~750 ℃真空热处理后,NiCrAlY涂层可获得最佳析出强化效果。

REFERENCES

[1] BOSE S, DEMASHI-MARCIN J. Thermal barrier coating experience in gas turbine engines at Pratt & Whitney[J]. Journal of Thermal Spray Technology, 1997, 6(1): 99-104.

[2] 彭小敏, 夏长清, 王金惠, 刘莹颖, 刘 娟. TC4钛合金沉积NiCrAlY涂层的氧化行为[J]. 中国有色金属学报, 2008, 18(4): 601-607.

PENG Xiao-min, XIA Chang-qing, WANG Jin-hui, LIU Ying-ying, LIU Juan. Oxidation behavior of TC4 titanium alloy with NiCrAlY coating[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(4): 601-607.

[3] TANG Zhao-lin, WANG Fu-hui, WU Wei-tao. Effect of MCrAlY overlay coatings on oxidation resistance of TiAl intermetallics[J]. Surface and Coatings Technology, 1998, 99(3): 248-252.

[4] PENG Xiao-min, XIA Chang-qing, MA Ke, DAI Xiao-yuan. Interaction of TC4 titanium alloy with NiCrAlY coating after vacuum heat treatment[J]. Materials Chemistry and Physics, 2008, 107(1): 158-163.

[5] 王 冰, 卢春燕, 孙 超, 黄荣芳, 闻立时. NiCrAlY 涂层对Ni基高温合金K17抗氧化性能的影响[J]. 腐蚀科学与防护技术, 2002, 14(1): 7-10.

WANG Bing, LU Chun-yan, SUN Chao, HUANG Rong-fang, WEN Li-shi. Effect of NiCrAlY coatings on oxidation resistance of Ni-base superalloy K17[J]. Corrosion Science and Protection Technology, 2002, 14(1): 7-10.

[6] VETTER J, KNOTEK O, BRAND J, BEELE W. MCrAlY coatings deposited by cathodic vacuum arc evaporation[J]. Surface and Coatings Technology, 1994, 68/69: 27-31.

[7] 彭超群, 黄伯云, 贺跃辉, 王健农. TiAl基合金的抗氧化性及其改善[J]. 稀有金属材料与工程, 1999, 28(2): 93-96.

PENG Chao-qun, HUANG Bai-yun, HE Yue-hui, WANG Jian-nong. Oxidation resistant and its improvement of the Ti-Al alloys[J]. Rare Metal Materials and Engineering, 1999, 28(2): 93-96.

[8] 夏长清, 李 佳, 古 一, 彭小敏, 武文花. NiCrAlY 涂 层/TC4基体界面反应机理[J]. 中南大学学报: 自然科学版, 2005, 36(4): 550-553.

XIA Chang-qing, LI Jia, GU Yi, PENG Xiao-min, WU Wen-hua. Interaction behavior between NiCrAlY coating and TC4 ally substrate[J]. Journal of Central South University: Science and Technology, 2005, 36(4): 550-553.

[9] 崔文芳, 罗国珍, 周 廉. 氧在Ti-1100 高温钛合金氧化中的扩散规律[J]. 东北大学学报: 自然科学版, 1998, 19(1): 19-22.

CUI Weng-fang, LUO Guo-zhen, ZHOU Lian. Diffusion kinetics of oxygen in oxidation of Ti-1100 high temperature titanium alloy[J]. Journal of Northeastern University: Natural Science, 1998, 19(1): 19-22.

[10] 崔文芳, 罗国珍, 周 廉, 洪 权. 高温钛合金溅射NiCrAlY涂层氧化行为的研究[J]. 稀有金属材料与工程, 1998, 27(6): 348-351.

CUI Weng-fang, LUO Guo-zhen, ZHOU Lian, HONG Quan. Oxidation behaviors of a sputtered NiCrAlY coating on the surface of a high temperature titanium alloy[J]. Rare Metal Materials and Engineering, 1998, 27(6): 348-351.

[11] SHIDA Y, ANADA H. The effect of various ternary additives on the oxidation behavior of TiAl in high-temperature air[J]. Oxidation of Metals, 1996, 45(1/2): 197-219.

[12] YOSHIHARA M, TANAKA R, SUZUKI T, SHIMIZU M. Development of surface treatment techniques to improve oxidation resistance of titanium aluminide[C]//JOHNSON L A, POPE D P, STIEGLER J O. High-Temperature Ordered Intermetallic Alloys IV. Cambridge: Cambridge University Press, 1991: 975-980.

[13] 沈嘉年, 江竹梅. Ti3Al金属间合金渗铝涂层及其高温氧化行为[J]. 腐蚀科学与防护技术, 1992, 4(3): 139-143.

SHEN Jia-nian, JIANG Zhu-mei. High temperature behavior of aluminizing coatings on Ti3Al intermetallic alloy[J]. Corrosion Science and Protection Technology, 1992, 4(3): 139-143.

[14] 郑传林, 徐 重, 谢锡善, 贺志勇, 董建新, 张麦仑. NiCrMoNb合金化层对TiAl金属间化合物抗氧化性能的影响[J]. 稀有金属材料与工程, 2003, 32(1): 32-36.

ZHENG Chuang-lin, XU Zhong, XIE Xi-shan, HE Zhi-yong, DONG Jian-xin, ZHANG Mai-lun. Effect of NiCrMoNb alloying coating on the oxidation resistance of TiAl intermetallics[J]. Rare Metal Materials and Engineering, 2003, 32(1): 32-36.

[15] WANG Q M, ZHANG K, GONG J,CUI Y Y, SUN C, WEN L S. NiCoCrAlY coatings with and without an Al2O3/Al interlayer on an orthorhombic Ti2AlNb-based alloy: Oxidation and interdiffusion behaviors[J]. Acta Materialia, 2007, 55(4): 1427-1439.

[16] LI H Q, WANG Q M, JIANG S M, MA J, GONG J, SUN C. Oxidation and interfacial fracture behaviour of NiCrAlY/Al2O3 coatings on an orthorhombic-Ti2AlNb alloy[J]. Corrosion Science, 2011, 53(3): 1097-1106.

[17] LI H Q, WANG Q M, JIANG S M, GONG J, SUN C. Ion-plated Al-Al2O3 films as diffusion barriers between NiCrAlY coating and orthorhombic-Ti2AlNb alloy[J]. Corrosion Science, 2010, 52(5): 1668-1674.

[18] LI W Z, WANG Q M, BAO Z B, YAO Y, GONG J, SUN C, JIANG X. Microstructural evolution of the NiCrAlY/CrON duplex coating system and its influence on mechanical properties[J]. Materials Science and Engineering A, 2008, 498(1/2): 487-494.

[19] LI W Z, YAO Y, LI Y Q, LI J B, GONG J, SUN C, JIANG X. Damage behavior of the NiCrAlY coating systems with or without barrier layer during three-point bending[J]. Materials Science and Engineering A, 2009, 512(1/2): 117-125.

[20] POZE P, GRANT P S. Microstructure evolution of vacuum plasma sprayed CoNiCrAlY coatings after heat treatment and isothermal oxidation[J]. Surface and Coatings Technology, 2006, 201(6): 2887-2896.

[21] DAVIS J R. ASM specialty handbook: Nickel, cobalt and their alloys[M]. OH: ASM International Materials Park, 2000: 100-102.

[22] BAUFELD B, SCHMUCKER M. Microstructural evolution of a NiCoCrAlY coating on an IN100 substrate[J]. Surface and Coatings Technology, 2005, 199(1): 49-56.

[23] 刘桂兰, 邹宇超. 回火温度对Ni-Cr-Al硬弹合金组织和性能的影响[J]. 东北大学学报: 自然科学版, 1994, 15(4): 399-402.

LIU Gui-lan, ZOU Yu-chao. Effect of tempering temperature on structures and properties of Ni-Cr-Al hard elastic alloys[J]. Journal of Northeastern University: Natural Science, 1994, 15(4): 399-402.

[24] KOLOMATSEV P T. 耐热扩散涂层[M]. 马志春, 译. 北京: 国防工业出版社, 1988: 201-205.

KOLOMATSEV P T. Hot-Resistant diffusion coatings[M]. MA Zhi-chun, transl. Beijing: National Defense Industry Press, 1988: 201-205.

(编辑 龙怀中)

基金项目:国家自然科学青年基金资助项目(51101054);新金属材料国家重点实验室开放基金资助项目(2012-Z03);湖南工程学院科研启动资助 项目

收稿日期:2013-07-15;修订日期:2013-10-20

通信作者:彭小敏,讲师,博士;电话:0731-58688521;E-mail:tanfen1028@163.com