文章编号:1004-0609(2007)11-1814-07

SiC颗粒表面修饰对铜基复合材料性能的影响

王德宝1,吴玉程1,王文芳1,宗 跃2

(1. 合肥工业大学 材料科学与工程学院,合肥 230009;

2. 合肥工业大学 复合材料公司,合肥 230009)

摘 要:采用粉末冶金结合化学沉积工艺制备SiC颗粒增强铜基复合材料。研究在SiC颗粒表面修饰不同金属(铜、镍)对复合材料界面结合状况的作用,并比较两种金属涂层各自对材料性能的影响。结果表明:SiC颗粒经表面修饰铜、镍后,复合材料界面结合紧密,界面结合强度提高,在基体和增强颗粒之间可以有效传递载荷,使得复合材料的相对密度、宏观硬度和力学性能获得提高。由于基体铜和镍镀层之间可以相互扩散,形成连续固溶层,从而使复合材料力学性能提升更为显著,但是由于在修饰镍过程中引入少量镍磷化合物夹杂,所以材料的导电、导热性能没有获得明显改善。

关键词:铜基复合材料;表面修饰;界面优化;力学性能

中图分类号:TB 331; TG 146.11 文献标识码:A

Effect of SiC particle surface modification on properties of Cu-matrix composites

WANG De-bao1, WU Yu-cheng1, WANG Wen-fang1, ZONG Yue2

(1. School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China;

2. Composites Company, Hefei University of Technology, Hefei 230009, China)

Abstract: Copper-matrix composites reinforced with SiC particles were fabricated by powder metallurgy plus electroless deposition. The effects of modification with different metals (Cu, Ni) on SiC particle surface on the interfacial bonding and properties of composites were investigated. The results indicate that the interface of composites is compact, the interfacial bonding strength is improved, and the loads can be transferred effectively between matrix and SiC by the surface modification with Cu and Ni. Therefore, the densification, macrohardness and mechanical properties of composites are improved. The atoms in matrix and Ni coating can diffuse to each other to form a continual film of solid solution, which is in favor of improving mechanical properties of composites. The electrical conductivity and thermal conductivity of composites, however, are not obviously improved because of introducing nickel phosphide during the process of electroless nickel plating.

Key words: copper-based composites; surface modification; interfacial optimization; mechanical properties

颗粒增强金属基复合材料(PMMC)以其制备工艺简单、成本低廉、以及力学、物理性能优异等优点而成为目前开发复合材料的方向之一[1?2]。颗粒增强铜基复合材料是将高强度、高硬度、高模量、高温稳定性好的陶瓷颗粒加入到塑性良好的铜基体中,可以在不过多牺牲导电性的前提下,大幅度提高材料力学性能,可望作为导电、导热功能材料广泛地应用于电接触、电机、汽车等应用领域[3?4]。然而外加陶瓷颗粒增强铜基复合材料由于加入的颗粒不可避免的有表面污染和附着物,与基体浸润性差,影响界面结合,导致材料的性能提升有限。良好的界面结合是关系到基体和增强材料性能是否得到充分发挥,以及是否能够形成最佳综合性能,对于决定该种复合材料的性能具有极为重要的作用。研究发现[5?7],用化学气相沉积、化学镀、电镀、溶胶?凝胶法在纤维、颗粒等增强体表面涂覆铜、镍等金属涂层以及BN、TiB2、B4C复合涂层,有明显改善润湿性和阻止界面反应的作用,可望获得高性能金属基复合材料。然而,对增强体表面用不同金属涂层修饰时,其改善界面结合和提高材料性能的作用机制是不尽相同的[8]。根据有关文献研究[9?10],铜和SiC的润湿性较差,在900 ℃以下的温度不发生界面反应。本文作者通过化学沉积方法在SiC颗粒表面分别镀覆铜和镍涂层以优化界面,比较两种金属涂层对复合材料力学和物理性能的影响,并研究其对改善Cu-SiC界面结合的作用机制,为开发新型高强度高导电、导热功能复合材料提供实验依据。

1 实验

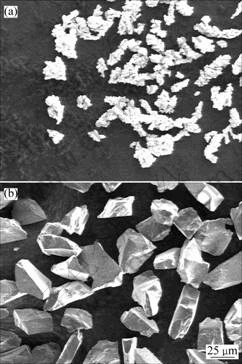

实验基体材料为纯度≥99.9%的树枝状电解铜粉,平均粒度44 μm;增强物为具有六方晶系结构的普通磨料级α-SiC颗粒,纯度≥98.5%,平均粒度38 μm;两者原始形貌如图1所示。

图1 电解铜粉和SiC粉末形貌

Fig.1 Micrographs of original electrolysis copper and SiC powders: (a) Cu powders; (b) SiC powders

SiC颗粒镀铜镀液配方为:以硫酸铜为主盐,甲醛为还原剂,酒石酸钾钠为络合剂,联吡啶为稳定剂,pH值12~13,温度60~65 ℃。SiC颗粒镀镍镀液配方为:以硫酸镍为主盐,次磷酸钠为还原剂,络合剂为乙醇酸,硫脲为稳定剂,pH值4.8~5.4,温度85~95 ℃。加入一定量的SiC粉末于镀液中,连续搅拌并控制温度和pH值,镀后经清洗、过滤、干燥。

将经化学沉积工艺制备有表面金属涂层的SiC颗粒按体积分数(下同)2%、5%、10%、15%、20%与铜粉混合均匀(计算时必须考虑镀层金属的质量),在650 MPa压制成坯,然后采用氢气保护烧结,烧结工艺为:850 ℃、2 h,最后在750 MPa复压,820 ℃、2 h复烧。采用相同工艺路线制备没有经过化学沉积处理的SiC颗粒增强铜基复合材料作为比较。使用岛津实验机进行拉伸实验,HV-1型维氏硬度计测试硬度,排水法测密度,采用四探针测试仪测电阻,在TCT416型热导率测试仪上测定复合材料热导率,采用Sirion200场发射扫描电镜观察颗粒形貌和材料断口,采用H800透射电镜观察复合材料界面。

2 实验结果

2.1 SiC颗粒表面修饰后形貌及XRD分析

表面修饰后的SiC颗粒表面形貌如图2所示。可看出在颗粒表面有效地包覆一层均匀的涂层,表面较为粗糙,没有包覆不周的现象,但在局部有少量的修饰物质堆积(图2(b)),而末经表面修饰的SiC颗粒表面较为光滑,呈不规则尖角状(图1(b))。图3所示是SiC颗粒表面修饰铜和镍并经氢气还原后的XRD谱,由图可看出,SiC颗粒修饰镍后引入了少量镍磷化合物夹杂。

图2 SiC颗粒经表面修饰后的SEM形貌

Fig.2 SEM images of modified SiC particles: (a) Surface modification with Cu; (b) With higher magnitude in Fig.2(a); (c) Surface modification with Ni

图3 表面修饰后SiC颗粒的XRD图谱

Fig.3 XRD patterns of SiC with surface modification

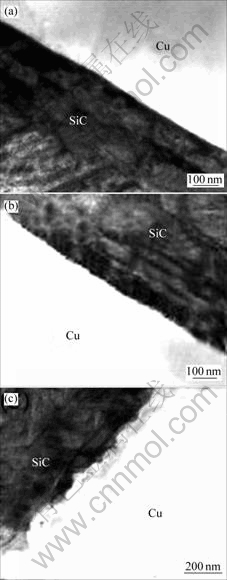

2. 2 Cu/SiCP复合材料界面形貌

图4所示为SiC颗粒经过表面修饰前后复合材料的界面。由图可见,复合材料经过表面修饰后,界面结合紧密,没有发现明显的杂质存在,而SiC颗粒未经表面修饰的复合材料界面上可以观察到少量的杂质存在。这可能是在生产和存放SiC颗粒过程中引入的。在表面修饰过程中,由于活化、敏化作用可以将这些杂质去除,因此可以大大净化界面[11?12]。

图4 Cu/SiC复合材料界面TEM形貌

Fig.4 TEM micrographs of interface of Cu/SiC composites: (a) Cu/ SiCp(Cu); (b) Cu/SiCp(Ni); (c) Cu/SiCp

2.3 Cu/SiCP复合材料性能

Cu/SiCP复合材料相关性能如图5所示。由图可看出,随着SiC含量的增加,复合材料的相对密度、导电性和导热性能均有所降低,而硬度则明显提高。同时发现在增强颗粒体积分数相同的情况下,SiC颗粒表面修饰铜不仅提高了复合材料的硬度和相对密度,而且导电和导热能力也有一定程度的提升;SiC颗粒表面修饰镍虽然可以更大幅度提升硬度和相对密度(超过Cu/SiCp(Cu)),但导电和导热能力与Cu/SiCp相比却变化不大。这是由于SiC颗粒在修饰镍的过程中引入了镍和镍磷化合物,会影响复合材料中的电子运动与界面优化,抵消复合材料致密化对材料导电、导热性能的改善作用,从而使得材料的物理性能没有发生明显改善。

图5 复合材料相对密度、硬度、导电率、导热率与SiC含量的关系

Fig.5 Relationships of relative densification, hardness, electrical conductivity and thermal conductivity with SiC content: (a) Relative density; (b) Hardness; (c) Electrical conductivity; (d) Thermal conductivity

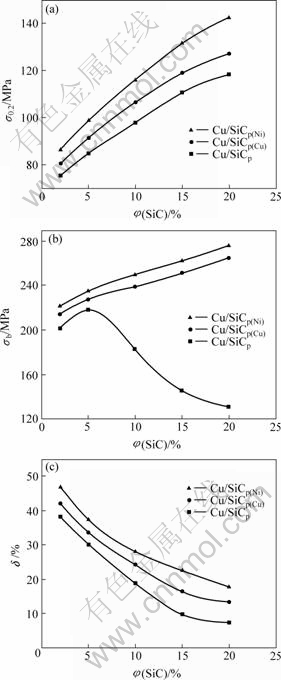

2. 4 Cu/SiCP复合材料的拉伸性能

图6所示为3种复合材料(在SiC颗粒表面修饰铜、镍和未经修饰处理)的力学拉伸性能。由图可看出,随着SiC含量的提高,复合材料的屈服强度有大幅度提高(图6(a)),其中SiC修饰镍提高最为显著,修饰铜次之。而对于抗拉强度则表现出不同的变化趋势(图6(b)),未经过表面修饰处理的复合材料抗拉强度先随着SiC含量的提高而上升,当SiC含量为5%时,达到最大值(218.2 MPa),随后当SiC含量进一步增加,强度则下降。而对于SiC经过表面修饰后,复合材料抗拉强度随着增强颗粒含量的增加而提高,其中修饰镍后,材料的强度提高最为显著,在SiC含量(体积分数)为20%时,Cu/SiCp(Cu)和Cu/SiCp(Ni)抗拉强度达到最大值,分别为264.5和275.9 MPa,说明SiC颗粒经表面修饰后充分发挥了增强作用,复合材料抵抗变形断裂能力得到提高。从图6(c)可以看出,材料强度的提高是以损失塑性为代价的,SiC的加入均降低了3种复合材料的塑性,然而经过颗粒修饰处理的复合材料具有更高伸长率,即Cu/SiCp(Ni)>Cu/SiCp(Cu)>Cu/SiCp。

图6 Cu/SiC复合材料的拉伸性能

Fig.6 Tensile properties of Cu/SiC composites: (a) Yield strength; (b) Ultimate tensile strength; (c) Elongation percentage

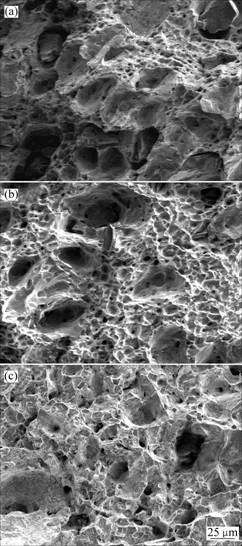

图7所示为SiC颗粒含量为10%时3种复合材料拉伸断口形貌。对于Cu/SiCp,可以观察到增强体与铜基体发生脱粘而留下的大坑,有部分颗粒在拉伸过程中与基体发生了脱粘(图7(a)),说明复合材料的界面结合较弱,SiC颗粒和基体界面脱粘是复合材料主要失效机制。而对于Cu/SiCp(Ni)和Cu/SiCp(Cu),则在其断面上很少看到增强颗粒的脱落,而是可以看到大量深浅不一的韧窝,表明复合材料的断裂是由于塑性变形过大而导致基体断裂而引起的(图7(b)和(c))。

图7 Cu/SiC复合材料断口形貌

Fig.7 Fractographs of Cu/SiC composites: (a) Cu/SiCp; (b) Cu/SiCp(Cu); (c)Cu/SiCp(Ni)

3 分析与讨论

在颗粒增强金属基复合材料中,第二相颗粒的体积分数、界面对复合材料的性能有着极为重要的影响。SiC颗粒为硬质点,与铜基体润湿性较差,可压缩性小。当SiC颗粒和铜粉混合后,在压制过程中会阻碍铜粉的压缩变形,在随后的烧结过程中,仅基体颗粒的软化和部分熔化,形成烧结颈并扩散长大,而SiC颗粒的存在会阻碍烧结颈的形成,影响材料烧结后的收缩,使复合材料的相对密度随着SiC含量的增加而降 低[13]。由于SiC属于陶瓷颗粒,导电、导热性能明显低于铜基体,所以SiC颗粒含量的增加,必然导致复合材料的导电、导热性能下降。同时复合材料中存在的大量Cu-SiC界面,自由电子、声子的定向传输也会受到界面电阻、热阻的影响[14?16],从而使得复合材料的导电率、导热率进一步恶化。当SiC颗粒没有经过表面修饰时,Cu-SiC界面属于弱界面结合,在含量较低的情况下(2%~5%),当材料受到拉伸应力时,SiC颗粒对穿晶位错运动和晶界滑移具有阻碍作用,因此复合材料的抗拉强度随SiC颗粒含量的增加而升高。但当SiC颗粒含量过高时(>5%),由于Cu-SiC界面增多,界面结合不牢,致使裂纹的萌生与发展加速,塑性变形的形变强化阶段被大大缩短,而使抗拉强度下降(图6(b))。但是硬质相SiC加入所形成的基体与增强物的界面成为位错运动的障碍,在发生局部塑性变形时产生位错塞积,提高了变形抗力,从而导致复合材料的硬度随着SiC颗粒含量的增加而提高。而SiC经过表面修饰铜后,由于活化和敏化过程不但清除了颗粒表面的杂质,而且SiC颗粒表面在粗化过程变的粗糙,可以使铜镀层嵌入SiC颗粒表面的凹陷处,增加了铜与SiC颗粒的机械互锁作用。烧结时,镀铜层易于与基体发生充分互扩散,使得镀层与基体几乎溶为一体,形成了一种双层界面结合模式,使得材料的力学性能得到提升。同时由于界面结合紧密,界面杂质在镀覆预处理过程中被去除,导致复合材料在提升力学性能的同时,物理性能(导电、导热)也得到了改善。而SiC颗粒表面修饰镍后,在烧结过程中,镀镍层可与基体铜相互扩散,无限互溶,形成了一个从浓度上由增强体向基体逐渐过渡的连续固溶体层,使得复合材料界面结合从简单的机械互锁结合变为成分呈梯度变化的连续固溶体结合[17?18],这一固溶体层的强度较高,可在基体和增强体之间有效传递载荷,从而可以进一步提升复合材料的力学性能(硬度、抗拉强度)。但是在修饰镍的过程中会引入新的介质,如镍和镍磷化合物,所以材料的导电、导热性能没有得到明显改善。

4 结论

1) 采用化学沉积工艺在SiC颗粒表面修饰铜和镍涂层,可以使复合材料中的Cu-SiC界面结合紧密,强度增加。

2) 通过对SiC颗粒表面修饰不同金属(铜、镍)均可以提高复合材料相对密度,硬度,但在修饰镍过程中由于引入了第三相,导致Cu/SiCp(Ni)的导电、导热性能未获得明显改善。

3) 复合材料拉伸性能因Cu-SiC界面的优化而得到改善,使复合材料获得了更高的抗拉强度、屈服强度,且随着SiC颗粒含量的增加而提高,在本实验中,SiC体积分数为20%时,经界面优化后复合材料的抗拉强度达到最大值,分别达到264.5 MPa和275.9 MPa,而未经界面优化的复合材料抗拉强度则在SiC体积分数5%时达到峰值(218.2 MPa)。

4) 虽然SiC颗粒经过表面修饰镍或铜都可以增强复合材料的强度,但是在Cu/SiCp(Ni)复合材料界面形成的强度较高的连续固溶体层可在基体和增强物之间有效传递载荷,减少了拉伸变形时的界面脱粘,所以在相同SiC体积分数下,Cu/SiCp(Ni)比Cu/SiCp(Cu)具有更高的力学性能。

REFERENCES

[1] Kaczmar J W, Pietrzak K, Wlosinski W. The production and application of metal matrix composite materials[J]. Journal of Materials Processing Technology, 2000, 106: 58?67.

[2] 朱建华, 刘 磊, 胡国华, 等. 复合电铸制备Cu/SiCp复合材料[J]. 中国有色金属学报, 2004, 14(1): 84?87.

ZHU Jian-hua, LIU Lei, HU Guo-hua, et al. Composite electroforming of Cu/SiCp composites[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 84?87.

[3] Kuen M S, Tu G C. The microstructure and the thermal expansion characteristics of Cu/SiCp composites[J]. Mater Sci Eng A, 2003, A349: 236?247.

[4] Tjong S C, Lau K C. Tribological behaviour of SiC particle-reinforced copper matrix composites[J]. Materials Letters, 2000, 43: 274?280.

[5] 张国定. 金属基复合材料界面问题[J]. 材料研究学报, 1997, 11(6): 649?657.

ZHANG Guo-ding. Interface in metal matrix composites[J]. Chinese Journal of Material Research, 1997, 11(6): 649?657.

[6] Zhan Y Z, Zhang G D. The effect of interfacial modifying on the mechanical and wear properties of SiCp/Cu composites[J]. Materials Letters, 2003, 57: 4583?4591.

[7] Chung D D L. Interface engineering for cement-matrix composites[J]. Composite Interface, 2001, 8(1): 67?81.

[8] 李四年, 沈金龙, 余天庆, 等. 不同涂层碳纳米管对增强镁基复合材料力学性能的影响[J]. 铸造技术, 2004, 25(8): 592?595.

LI Si-nian, SHEN Jin-long, YU Tian-qing, et al. Effect of different plating carbon nanotubes on mechanical properties of magnesium matrix composite[J]. Foundry Technology, 2004, 25(8): 592?595.

[9] Rado C, Drevet B, Eustathopoulos N. The role of compound formation in reactive wetting the Cu/SiC system[J]. Acta Materialia, 2000, 48: 4483?4491.

[10] Nikolopoulos P. Study of the admixture method of powder metallurgy for metal-matrix composites[J]. Journal of Materials Science, 1994, 32: 23?28.

[11] 刘君武, 吕 珺, 王建民, 等. SiC粉体化学镀铜工艺研究[J]. 电镀与涂饰, 2005, 24(12): 15?18.

LIU Jun-wu, L? Jun, WANG Jian-min, et al. Study on technics of SiC composite powder electroless copper plating[J]. Electroplating & Finishing, 2005, 24(12): 15?18.

[12] Moustafa S F, Abdelhamid Z, Abdelhay A M. Copper matrix SiC and Al2O3 particulate composites by powder metallurgy technique[J]. Materials Letters, 2002, 53: 244?249.

[13] 黄云培. 粉末冶金原理[M]. 北京: 冶金工业出版社, 1982: 289?290.

HUANG Yun-pei. Powder metallurgy technology[M]. Beijing: Metallurgical Industry Press, 1982: 289?290.

[14] 陈国钦, 朱德志, 占 荣, 等. 挤压铸造法制备高致密Mo/Cu及其导热性能[J]. 中国有色金属学报, 2005, 15(11): 1864?1868.

CHEN Guo-qin, ZHU De-zhi, ZHAN Rong, et al. Highly dense Mo/Cu composites fabricated by squeeze casting and their thermal conduction properties[J]. The Chinese Journal of Nonferrous Metal, 2005, 15(11): 1864?1868.

[15] 吉 元, 钟涛兴, 高晓霞, 等. 高导热电封装复合材料界面热传导的扫描热显微镜分析[J]. 电子显微学报, 2001, 20(3): 238?243.

JI Yuan, ZHONG Tao-xing, GAO Xiao-xia, et al. Scanning thermal microscopic analysis of interface thermal conductivity of high thermal conductivity composites for electronic packaging[J]. Journal of Chinese Electron Microscopy Society, 2001, 20(3): 238?243.

[16] 范志康, 梁淑华, 王 强, 等. CuW/CrCu整体材料的复合电导研究[J]. 稀有金属材料与工程, 2002, 31(3): 179?182.

FAN Zhi-kang, LIANG Shu-hua, WANG Qiang, et al. Electrical conductivity of CuW/CrCu composite[J]. Rare Metal Materials and Engineering, 2002, 31(3): 179?182.

[17] Wynblatt P. The effects of Interfacial segregation on wetting in solid metal-on-metal and metal-on-ceramic systems[J]. Acta Materialia, 2000, 48: 4439?4447.

[18] Villars P, Prince A, Okamoto H. Hand of ternary alloy phase diagrams[M]. Ohio: ASM, 1997: 8734?8735.

基金项目:安徽省“十五”科技攻关计划资助项目(040020392);合肥市重点科技攻关计划资助项目(20051004);安徽省自然科学基金资助项目(070414180)

收稿日期:2007-03-04;修订日期:2007-06-20

通讯作者:吴玉程,教授,博士;电话:0551-2905085;E-mail: ycwu@hfut.edu.cn

(编辑 何学锋)