文章编号: 1004-0609(2006)09-1570-07

AZ31镁合金圆锭连铸过程温度场的数值模拟

郭鹏, 张兴国, 郝海, 金俊泽

(大连理工大学 材料科学与工程学院, 三束材料改性国家重点实验室, 大连 116024)

摘要: 通过有限差分法, 利用Visual C++ 6.0建立直接水冷法(DC)AZ31镁合金连铸过程的数学模型, 该模型可预测铸锭以及底模的温度分布。 通过对铸造过程物理现象的理论研究, 确定一冷区、 二冷区以及铸锭与底模之间的边界条件。 通过与文献实测温度的比较, 证明该模型可以用来模拟实际铸造过程。 考察不同铸造条件对铸锭温度场分布的影响, 为优化镁合金直冷连铸的工艺参数提供了依据。

关键词: 镁合金; 连铸; 温度场; 数值模拟 中图分类号: TG146.2

文献标识码: A

Temperature simulation of direct chill casting of AZ31 magnesium alloy billets

GUO Peng, ZHANG Xing-guo, HAO Hai, JIN Jun-ze

(State Key Laboratory of Materials Modification by Laser, Ion and Electron Beams,School of Materials Science and Engineering, Dalian University of Technology,Dalian 116024, China)

Abstract: A mathematical model of DC casting process for magnesium billets was developed to predict the temperature in the billet and dummy block using Microsoft Visual C++ 6.0 and finite difference method (FDM). The boundary conditions used for primary and secondary cooling and interfacial cooling between the billet and dummy block were defined based on the basic physical phenomena during the casting process. By comparing the predicted results with the measured data in the literature, it is proved that the programmed model can be used to investigate the casting process. The effects of the casting parameters on the billet temperature distribution were studied, which is helpful to optimize the casting recipe.

Key words: magnesium alloy; direct chill casting; temperature field; numerical simulation

与铝合金的直冷连铸(direct chill casting, DC casting)过程类似, 在镁合金连铸过程中仍然存在缩松、 缩孔、 裂纹、 偏析等缺陷, 这些缺陷对镁合金产品的安全使用构成了严重威胁[1]。 它们的形成主要是由铸造及凝固过程中的温度场及冷却率的变化所引起的[2], 通过对镁合金凝固过程的分析可以找到行之有效的方法消除或减少这些缺陷。 为了提高DC法铸造镁合金的效率、 效益以及铸锭质量, 其工艺参数仍需进一步优化。 变换铸造参数, 例如铸造速度、 冷却水量和浇注温度等所带来的铸造过程的变化是十分复杂的, 而采用实验的方法来研究这些变化会带来时间与经济上的浪费。 借助计算机建立合理精确的数学模型可以帮助分析铸造缺陷的产生、 优化工艺参数、 减少浪费、 缩短生产周期及降低生产成本[3, 4], 而国内这方面的报道较少。 数学模型是否精确合理, 取决于模型是否能够准确地反映铸造过程。 本文作者通过确定初始及边界条件, 建立模型, 编写程序, 模拟并分析了几个主要铸造参数对连铸过程的影响。

1 数学模型的建立

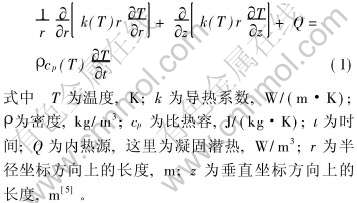

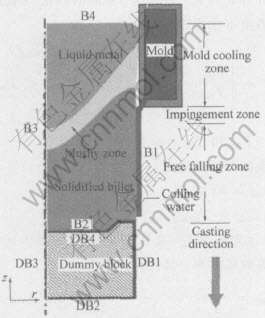

图1所示为DC法铸造镁合金的示意图。 采用圆柱坐标系模型模拟直径为455mm的圆锭, 圆柱坐标下传热的控制方程为

图1 DC法铸造镁合金的示意图

Fig.1 Schematic drawing of DC casting for magnesium alloy billet

模拟从浇注开始阶段到稳定阶段底模及铸锭温度场的变化, 其程序包括前处理、 数值计算和后处理3个模块[6]。 前处理模块主要是进行初始化工作, 包括网格剖分、 赋单元属性、 铸锭尺寸、 热物性值和时间步长等参数的获取; 数值计算模块是程序的核心部分, 包括传热方程计算和网格下移、 计算区域扩展后的温度场重新分布计算; 后处理模块也即对计算完毕后的数据处理工作, 包括等温线绘制及监测点冷却曲线显示等。 计算过程中, 模型内的网格是静止不动的, 而一冷区与二冷区的边界条件以浇注速度相对于网格向上移动, 这样易于程序的编写。

1.1 计算区域与网格剖分

由对称性, 可只对铸锭与底模结构的一半进行计算, 如图1所示。 铸锭与底模的剖分网格数分别为11400和3420。 连铸过程温度场不同于静态温度场的特点之一是热传导计算区域的不断扩展[7]。 为方便计算, 网格剖分时将所需计算高度的铸锭整体全部剖分, 计算时未填充到的空单元不进行计算。 这种方法并不增加计算量和时间, 但加大了内存的占有量。 随着底模的向下运动, 铸锭的网格被一层层加入到计算区域。 采用二维传热控制方程(1)计算下一时刻(t+Δt)的温度场, 然后判断是否满足网格推进条件, 如果满足, 网格下移, 温度场及潜热重新分配计算, 计算区域增加, 然后继续计算下一时刻的温度场, 如此循环下去, 直至计算区域高度大于最大计算区域, 即拉坏结束[8]。 该程序采用了显式有限差分法, 显式差分格式对时间步长的选取受到严格的限制, 当网格剖分较细时, 时间步长大大减小, 程序的计算时间也会明显地延长。 应先选定空间步长, 再根据收敛条件计算得到时间步长, 以便空间离散化处理易于进行[9]。

1.2 初始条件

开始时, 底模温度与冷却水温度一致, 加入到计算区域的第一层铸锭网格与浇注温度一致, 结晶器在整个计算过程中保持恒定的温度, 即冷却水的温度[10]。

1.3 边界条件

根据图1所示, 用来描述铸造过程中不同时刻、 不同位置边界条件的公式和参数如下。

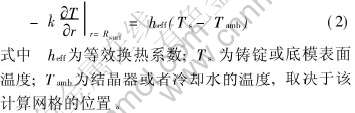

1) 铸锭及底模的侧表面(B1&DB1)

此界面为对流换热边界:

铸锭和底模在铸造过程中要经过一冷区与二冷区两个冷却区域。 一冷区是指在结晶器内的部分。 在一冷区过程内, 铸锭与冷却水的换热系数有明显的减小, 这是由于随着铸锭的凝固和收缩变形, 铸锭表面与结晶器之间出现空隙。 为了体现这种变化, 等效换热系数将作为温度的函数[11], 如图2所示。 铸造过程刚刚开始的时候, 底模的一部分伸入到结晶器内, 这时在一冷区内底模的换热系数假设恒定为75W/(m2·K)。

图2 铸锭与结晶器换热系数随温度的变化

Fig.2 Billet/mold heat-transfer coefficients as function of billet surface temperature

二冷区包括冲击区和流水区。 冲击区是指结晶器出口以下冷却水直接喷射的范围, 这里取为25mm; 流水区是指冲击区以下的范围, 冷却水沿着铸锭表面流淌下来, 与铸锭产生热交换。 为了区别冲击区与流水区, 换热系数在2个冷却区域内有所不同。 在铸锭或底模表面相同温度的条件下, 流水区换热系数为冲击区的75%。 图3所示为冷却水量Qstd为4.5L/s时的换热系数曲线[12]。 为了反映冷却水量的变化, 换热系数将会与冷却水量按照同比例增减。

图3 冲击区与流水区的换热系数随温度的变化

Fig.3 Heat-transfer coefficients as function of temperature in impingement and free falling zones

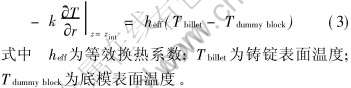

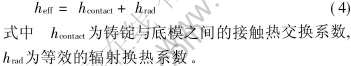

2) 铸锭(B2)与底模(DB4)的接触面[11]

此边界为考虑辐射的等效对流换热边界:

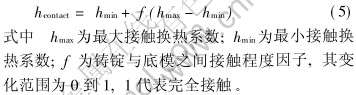

hcontact采用如下公式计算:

这样, 接触换热系数从hmin到hmax的变化就体现了铸锭由于凝固和变形所带来的对热传导效果的影响。 hmin取值为800W/(m2·K), hmax取值为1200W/(m2·K), 而f的取值由下式决定:

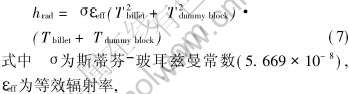

辐射换热系数由下式决定:

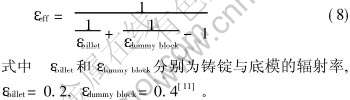

其计算式如下:

3) 铸锭及底模的对称轴(B3&DB3)

4) 铸锭顶层(B4)

铸锭顶层是刚刚加入到计算区域的网格, 新网格加入的速率由拉坏速度决定。 计算式如下:

5) 底模底部[11](DB2)

此界面为考虑辐射的等效对流换热边界:

hrad的值由下式计算得出:

底模的辐射率为0.4。

1.4 热物性参数

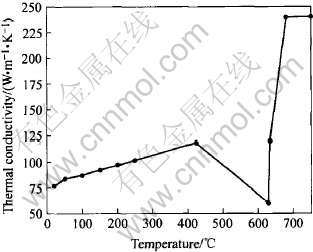

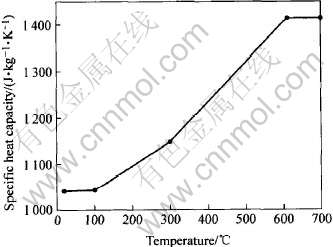

铸造合金为AZ31(Mg-3%Al-1%Zn), 其固相线温度为542℃, 液相线温度为635℃, 导热系数如图4所示, 为考虑液体的流动性, 高温时的导热系数人为加大。 比热容随温度的变化如图5所示。 密度为1780kg/m3, 潜热为339kJ/kg, 采用温度补偿法处理凝固潜热[13]。 底模是AA6061铝合金, 导热系数为180W/(m·K), 比热容为896J/(kg·K)。

图4 AZ31镁合金导热系数随温度的变化

Fig.4 Thermal conductivity as function of temperature for AZ31 magnesium alloy

图5 AZ31镁合金比热容随温度的变化

Fig.5 Specific heat capacity as function of temperature for AZ31 magnesium alloy

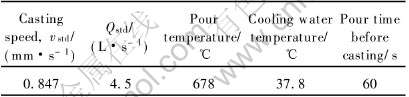

1.5 铸造参数

表1列出了基本铸造参数, 计算中分别改变几个主要参数来考察它们对连铸过程的影响。

表1 基本铸造参数

Table 1 Basic casting parameters

2 结果与讨论

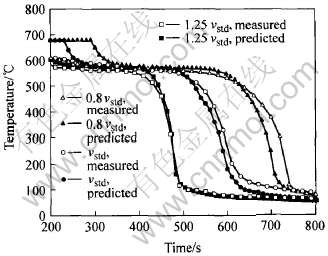

通过修改数学模型来模拟不同铸造条件下铸锭与底模中的温度分布情况。 图6所示为3种不同铸速下(相同的冷却水量和浇注温度), 位于距铸锭侧表面5mm、 高于底模200mm的监测点的模拟值与文献中实测数据[11]的对比图。

图6 不同铸速下相同冷却水量和浇注温度的模拟值与实测值的比较

Fig.6 Comparison of predicted and measured temperatures for different casting speeds under same flow rate of cooling water and pour temperature

对比图中的实测数据与模拟数据, 可以看出该模型比较准确地反映了凝固实际过程, 特别是当监测点处于一冷区或者铸速较快时, 模拟结果非常精确。 所以, 将模拟结果作为实际铸造过程的分析依据是可靠的。

从图6中还可以看到, 铸造速度的增加只是使铸锭通过结晶器(一冷区)所花费的时间缩短, 但改变铸造速度, 并没有使铸锭进入二冷区时的温度有明显变化, 图中所示监测点在3种不同铸速下的温度均为560℃左右。

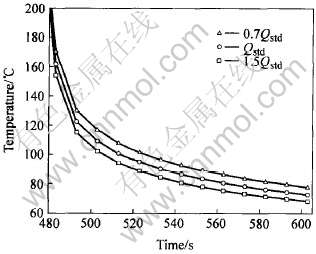

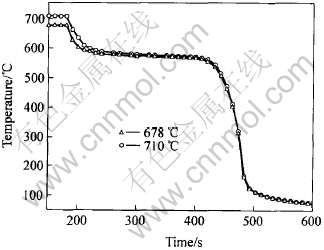

图7和图8所示分别为模拟不同冷却水量(相同的铸造速度1.25mm/s、 相同的浇注温度678℃)和不同浇注温度(相同的铸造速度1.25mm/s、 相同的冷却水量Qwater), 位于距铸锭侧表面5mm、 高于底模200mm监测点的凝固过程。 由于冷却水量的变化不会影响一冷区的冷却效果, 所以图7只给出了监测点在二冷区以后的温度变化。

图7 相同的铸造速度与浇注温度时监测点在不同冷却水量下的温度变化

Fig.7 Change of temperature of monitor location at different flow rates of cooling water under same casting speed and pour temperature

图8 相同的铸造速度与冷却水量时监测点在不同浇注温度下的温度变化

Fig.8 Change of temperature of monitor location at different pour temperatures under same casting speed and flow rate of cooling water

从图7和图8可以看出, 相同铸速时, 冷却水量和浇注温度的改变并没有给凝固过程以及温度分布带来十分明显的变化。

冷却水量只对最外层铸锭表面有所影响, 而铸锭内部的温度受冷却水量的影响很弱。 因此, 冷却水量的增加将增大铸锭表面与内部的温差, 使铸锭横截面的温度梯度增大; 当浇注温度低时, 虽然铸锭上部液体和固体的温度较低, 但是喷水点下方铸锭的表面温度与浇注温度较高时基本相同, 而在浇注温度较高时, 铸锭中心的凝固前沿也会有所下移, 所以提高浇注温度也会使铸锭横截面的温度梯度加大。 高的浇注温度虽然可以加强液态金属的流动性, 但不利于晶粒细化, 影响铸锭组织均匀性。

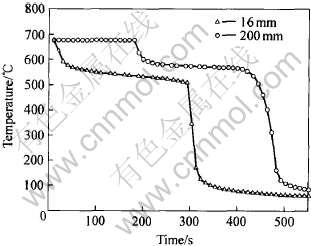

在相同铸造参数下, 与底模距离不同高度(分别为16mm和200mm, 与铸锭侧面距离同为5mm)的监测点的凝固过程的比较如图9所示。

图9 与底模距离不同高度的监测点在相同铸造参数条件下凝固过程的比较

Fig.9 Temperature of monitor location at different heights with same casting parameters

由此可见, 距离底模较近的点除开始冷却的时刻较快外, 在到达二冷区以前的温度也要略低一些, 这是因为底模对离它较近的点会产生冷却作用, 但这个冷却的作用不是很大。 该监测点和铸锭侧表面与底模的距离分别为5mm和16mm, 所以铸锭侧面的冷却占主要作用。 事实上, 在整个铸造凝固过程中, 约80%的热量在二冷区内被带走[14], 约20%的热量归功于一冷区和底模的传热, 而底模的冷却作用只占了20%中很小的一部分。

连铸过程中另外一个很重要的因素就是液穴形状及深度, 根据液穴形状及深度曲线可以分析铸造速度的改变对铸锭外层凝固壳厚度的影响和是否会导致铸锭拉漏。 图10所示为3种不同铸速下(其余铸造参数相同)的液穴形状及深度的比较。 图中液穴深度定义为对称轴上铸锭顶部到固相分数为0.8的等温线的距离[15]。

图10 3种不同铸速的液穴形状

Fig.10 Sump profiles with three different casting speeds

可以看出, 液穴深度随着铸速的提高而加大, 且液穴深度随着铸速的增加大致呈线性增加[16], 凝固壳的厚度随着铸造速度的增加而变薄, 即铸造速度的提高是以凝固壳变薄为基础的。 因此, 铸速的最大值可以根据模型模拟的结果分析得出, 这样就避免了采用实验实际测试方法所带来的经济与时间上的浪费。

3 结论

1) 通过确定边界条件和热物性参数, 建立了AZ31镁合金圆锭直冷连铸过程的数学模型。 模型模拟结果与文献中实测数据对比表明, 模拟结果与实际过程基本吻合, 可以作为实际铸造过程的分析依据。

2) 冷却水量和浇注温度的改变不会给凝固过程以及温度分布带来十分明显的变化; 而铸造速度的改变影响较大, 铸速越快, 凝固壳厚度越薄, 液穴越深, 并且液穴深度在一定范围内随着铸速变化大致同比例增减。

3) 铸锭在二冷区内传热最多, 一冷区次之, 底模最少。

REFERENCES

[1]张红松, 张希俊, 张方. 铸造过程计算机数值模拟的国内外研究概况[J]. 昆明理工大学学报, 2003, 28(4): 56-58.

ZHANG Hong-song, ZHANG Xi-jun, ZHANG Fang. Present foreign and domestic research on the computer digital simulation of casting progress[J]. Journal of Kunming University of Science and Technology, 2003, 28(4): 56-58.

[2]Hao H, Maijer D M, Wells M A, et al. Prediction and measurement of residual stresses/strains in a direct chill casting magnesium alloy billet[A]. Neelameggham N, et al. Magnesium Technology 2005[C]. Warrendale, PA: TMS, 2005: 223-228.

[3]熊守美, 苏仕方. 镁合金成形技术研究发展[J]. 铸造, 2005, 54(1): 20-23.

XIONG Shou-mei, SU Shi-fang. Research progress on processing technology of magnesium alloys[J]. Foundry, 2005, 54(1): 20-23.

[4]刘金城. 铸件计算机凝固模拟的现状、 发展与前景[J]. 现代铸铁, 2003(6): 17-22.

LIU Jin-cheng. Present situation, development and prospects of computer solidification simulation of castings[J]. Modern Cast Iron, 2003(6): 17-22.

[5]卫超, 庞维诚. 圆环连铸温度场模拟[J]. 铸造, 2002, 51(2): 106-108.

WEI Chao, PANG Wei-cheng. Temperature field simulation of round billet continuous casting[J]. Foundry, 2002, 51(2): 106-108.

[6]郝海. 电磁铸造工艺及其温度场数值模拟[D]. 大连: 大连理工大学, 1999.

HAO Hai. Technology of Electromagnetic Casting and Its Numerical Simulation of Temperature Field[D]. Dalian : Dalian University of Technology, 1999.

[7]Li Z X, Zheng X S, Cao Z Q, et al. Temperature simulation of EMC aluminum ingot with induced heat[J]. Trans Nonferrous Met Soc China, 2001, 11(3): 369-373.

[8]郑贤淑, 王一成, 金俊泽. 电磁铸造大板环半连铸过程温度场的数值模拟[J]. 金属学报, 1999, 35(8): 861-864.

ZHENG Xian-shu, WANG Yi-cheng, JIN Jun-ze. Numerical simulation of temperature field of semi-continuous casting of slab in EMC[J]. Act Metallurgica Sinica, 1999, 35(8): 861-864.

[9]陈海清, 李华基, 曹阳. 铸件凝固过程数值模拟[M]. 重庆大学出版社, 1991. 41.

CHEN Hai-qing, LI Hua-ji, CAO Yang. Numerical Simulation of Solidification Process of Castings[M]. Chongqing: Chongqing University Press, 1991. 41.

[10]李玉梅. 铝合金电磁连铸工艺及温度场数值模拟研究[D]. 大连: 大连理工大学, 2002.

LI Yu-mei. Technology of Electromagnetic Casting and Temperature Simulation of Magnesium Alloy[D]. Dalian: Dalian University of Technology, 2002.

[11]Hao H, Maijer D M, Wells M A, et al. Development and validation of a thermal model of the direct chill casting of AZ31 magnesium billets[J]. Metall Mater Trans A, 2004, 35(12): 3843-3854.

[12]Grandfield J F, Hoadley A, Instone S. Water cooling in direct chill casting (Part 1): boiling theory and control[A]. Light Metals 1997[C]. Warrendale, PA: TMS, 1997: 691-699.

[13]程军. 计算机在铸造中的应用[M]. 北京: 机械工业出版社, 1993: 127-130.

CHENG Jun. Application of Computer in the Casting Process[M]. Beijing: China Machine Press, 1993: 127-130.

[14]Sengupta J, Maijer D M, Wells M A, et al. Mathematical modelling of the thermomechanical behavior of a 5182 aluminum ingot during the start-up phase of the DC casting process: The role of bottom block[A]. Light Metals 2001[C]. Warrendale, PA: TMS, 2001: 879-885.

[15]Lu E H, Maijer D M, Sediako D. A mathematical model of heat transfer and fluid flow in the direct chill casting of AZ31 magnesium billets[J]. JOM, 2004, 56(11): 137.

[16]李朝霞, 熊守美, 郑贤淑. 工艺参数对电磁铸造铝板坯温度场的影响[J]. 铸造, 2003, 52(1): 13-16.

LI Zhao-xia, XIONG Shou-mei, ZHENG Xian-shu. Influence of casting parameters on the temperature distribution of EMC aluminum slabs[J]. Foundry, 2003, 52(1): 13-16.

基金项目: 国家自然科学基金资助项目(50475157, 50234020); 教育部重点资助项目(105052)

收稿日期: 2006-02-18; 修订日期: 2006-07-17

通讯作者: 张兴国, 教授; 电话: 0411-84706183; E-mail: zxgwj@dlut.edu.cn

(编辑李向群)