文章编号:1004-0609(2016)-07-1451-08

ZChSnSb11-6/20号钢双金属复合材料的扩散连接

邹军涛,赵 艳,王 婵,杨晓红,梁淑华

(西安理工大学 材料学院 陕西省电工材料与熔渗技术重点实验室,西安 710048)

摘 要:为了获得较高的界面结合强度,对20号钢表面采用热浸镀锡处理后,进行液固扩散连接,制备ZChSnSb11-6/20号钢双金属复合材料。采用扫描电子显微镜(SEM),X射线衍射仪(XRD)表征了ZChSnSb11-6/20号钢结合过渡区的形貌及其元素分布,并对其硬度和界面结合强度进行检测。结果表明:通过20号钢热浸镀锡后,再进一步进行液固扩散可以制备结合面均匀稳定的ZChSnSb11-6/20号钢双金属复合材料,20号钢中Fe与Sn形成一层互扩散组织的结合过渡层,实现了20号钢与巴氏合金ZChSnSb11-6的冶金结合;结合过渡区的硬度明显高于两侧基体的,界面结合强度可达60.15MPa。

关键词: ZChSnSb11-6合金;双金属复合材料;过渡区;热浸镀;扩散连接

中图分类号:TG136. 03 文献标志码:A

巴氏合金主要由锡、铜、锑等金属元素构成,在软的基体内形成硬六方体组织[1],从而使巴氏合金具有耐磨的性质。巴氏合金轴瓦以其优良的表面性能广泛应用于矿山机械、轧钢机械及船用推力轴承合金 中[2]。巴氏合金作为轴瓦材料具有浇注温度低,加工工艺简单以及表面性能优良的特性,且与其他轴瓦合金相比较,有良好的顺应性和咬合性,这种优点对运转初期的磨合十分有利。巴氏合金的嵌藏性好,故在轴颈表面不易出现划痕,它与润滑油的亲和力强,亲油性好,所以能很快达到液体润滑,锡和铅在常温下可形成再结晶而软化,因此,在摩擦面上由于重复载荷作用而发生的硬化,可很快软化复原[3-5]。因而,直至今日,巴氏合金轴瓦在汽油机、低速船用柴油机以及内燃机车上仍有一定的应用。在生产实践中,低碳钢与巴氏合金双金属轴瓦存在着因结合强度低而造成产品使用早期疲劳剥落的质量问题。为了提高巴氏合金与钢的结合力,一般采用纯锡为过渡层的措施[6]。常见的钢与巴氏合金的连接方法有挂锡浇铸法、挂锡堆焊法、电镀法及火焰喷涂法[7]。

结合区是双金属复合材料特有且极其重要的组成部分,结合区内物相种类及分布对于复合材料起着极其重要的作用,有时甚至起到控制作用,直接影响材料的使用寿命[8-11]。由于结合区原子键结合和原子结构的化学成分与两侧基体不同,结合区的性质明显区别于两侧合金的,因此,研究双金属复合材料的结合界面具有重大的意义。在钢、纯锡、巴氏合金3种金属之中,以纯锡的强度最弱,纯锡的作用在于与钢基体互相扩散反应形成过渡层,巴氏合金与钢的结合力完全依靠锡与钢之间的结合强度来保证[12]。因此,提高巴氏合金/钢复合材料结合力的关键在于增强纯锡与钢的结合强度。

本文作者通过液固扩散连接法制备ZChSnSb11-6/20号钢双金属复合材料,研究不同镀锡温度下锡与20号钢基体的界面扩散行为,以及制备的双金属复合材料结合区组织与性能影响。

1 实验

实验原料采用巴氏合金ZChSnSb11-6、纯锡以及20号钢棒材。ZChSnSb11-6的化学成分如表1所列。

将20号钢置于氮气保护管式炉中进行熔浸镀锡,熔浸温度分别为600、700、800及900 ℃,熔浸保温时间为5~8 h,20号钢保持固态,二者以液固扩散结合,形成钢与锡反应层。再将表面镀锡后的20号钢与巴氏合金进行扩散连接,连接温度400 ℃、保温30 min,获得巴氏合金ZChSnSb11-6/20钢双金属复合材料。

表1 ZChSnSb11-6合金的化学成分

Table 1 Composition of ZChSnSb11-6 alloy (mass fraction, %)

采用SM-6700F场发射扫描电子显微镜、Oxford INCA型高性能小射线能谱仪(EDS)及7000S型X射线衍射仪(XRD)表征材料的过渡区显微组织、元素分布及物相种类,TUKON2100B型显微硬度计测定材料硬度,WE-60型液压万能材料试验机测定界面结合强度。

2 结果与分析

2.1 巴氏合金ZChSnSb11-6与20号钢的扩散反应 机理

扩散是相互接触的物质因为原子迁移而发生的互相渗透,使原子在所占有的空间内均匀分布,可以是自身原子的扩散,也可是外来原子形成的异质扩散[13-15]。为了提高钢基体与巴氏合金的结合力,采用以纯锡为中间过渡层的方法,仅靠钢基体与纯锡的结合力,改善其与巴氏合金的结合情况。在熔浸镀锡保温过程中,钢基体与熔融锡形成扩散组织,双方所含元素原子通过界面向对方扩散。Fe、Sn原子半径相近(rα-Fe=0.1241 nm,rγ-Fe=0.1288 nm;rSn=0.1620 nm),要以间隙方式扩散比较困难,所以扩散主要是以空位机制进行。根据研究人员提出的单分子反应的碰撞理论[16],液态锡原子依靠布朗运动互相碰撞获得能量扩散进入表面基体,一些能量较高的外部锡原子继续与其碰撞使之向内部扩散,从而占据此原子留下的空位,实现原子的自扩散[17]。Sn原子以这种方式由外向内逐层向基体内部扩散,同时,熔融态Sn原子间平均距离增加并形成许多空隙和空穴,有利于钢中Fe及其他元素向液态Sn中扩散。

2.2 镀锡温度对ZChSnSb11-6/20号钢双金属复合材料过渡区组织与性能的影响

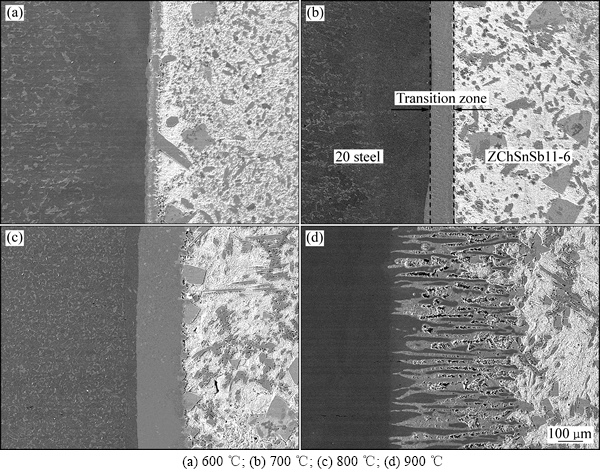

图1所示分别为在不同熔浸温度下对20号钢表面镀锡后所制备ZChSnSb11-6/20号钢双金属复合材料的结合过渡区形貌。

图1中左侧均为20号钢,右侧为ZChSnSb11-6合金,中间为结合过渡层。从图1中可看出,20号钢与中间层金属锡扩散反应形成清晰可见的界面反应层,且温度对结合过渡层的组织形貌和厚度影响显著。在ZChSnSb11-6合金一侧并无合金与中间层金属锡的界面反应层,这是由于ZChSnSb11-6合金的主要成分为锡,在与基体的熔接过程中,20号钢表面的镀锡层完全溶解于ZChSnSb11-6中。

图1 不同镀锡温度下ZChSnSb11-6/20号钢双金属复合材料结合过渡区形貌

Fig. 1 Microstructures of bonding transition zone for ZChSnSb11-6/20 steel bimetal composites under different tin plating temperatures:

因此,ZChSnSb11-6/20号钢双金属复合材料的结合过渡区是由20号钢与中间层金属锡的界面反应层形成。由图1(a)可知,镀锡温度在600 ℃时,由于温度较低,元素扩散不充分,结合过渡层不平整且厚度较窄。随着温度的升高,在700 ℃时,如图1(b)所示,结合过渡层清晰可见,厚度有所增宽且结合界面平直。过渡区组织致密,主要由黑色及灰色两种物质组成,分析认为,这是基体中的合金元素与锡扩散反应生成的不同种金属间化合物均匀分布在过渡区域内所致。当温度升高至800 ℃时,如图1(c)所示,结合过渡层厚度显著增加,过渡区的组织形态及分布与700 ℃时的过渡区相比有明显变化,主要是因为20号钢由铁素体α转变为奥氏体γ,促进了Sn向铁基体内部扩散。当熔铸温度升高至900 ℃时,从图1(d)可以看出,界面反应层厚度继续增宽,过渡区组织形态及分布发生明显改变,主要由类似于基体颜色的黑色物质以及灰色物质交替分布在锡基底上,组织沿界面法线方向生长并延伸至ZChSnSb11-6侧,并未形成连续且致密的过渡区。

综上所述,熔浸镀锡温度越高,体积膨胀系数越高,原子热运动强度及原子热运动引起的结构起伏越大,原子间的扩散越充分,因此,ZChSnSb11-6/20号钢双金属复合材料的结合过渡区的厚度随镀锡温度的升高而显著增加。

为了确定ZChSnSb11-6/20号钢双金属复合材料过渡区中合金元素的分布状况,对具有清晰平整的结合过渡区进行能谱分析,以镀锡温度为700 ℃时为例,其结果如图2所示。图2中左侧均为20号钢,右侧为ZChSnSb11-6合金,中间为结合过渡层。

从图2(b)可明显看出,结合过渡层内以Fe、Sn和Sb元素为主,且在一定的区域内元素分布均匀,出现一个元素成分含量相对稳定的平台。在靠近巴氏合金侧的过渡区内,Fe元素和Sn元素含量出现较大幅度的波动。巴氏合金ZChSnSb11-6/20号钢双金属复合材料的制备分为两部分进行,即20号钢与中间层金属锡的扩散连接,以及20号钢表面镀锡后与巴氏合金的连接,因此,合金中元素的扩散也分两步完成。首先钢与中间层金属锡的熔合主要为20号钢中的Fe元素与Sn的扩散反应,双方元素原子通过界面向对方自然对流和扩散,生成的金属间化合物均匀分布在界面反应层内。在过渡层的边界处,Fe、Sn元素含量出现大幅度波动的情况,这是由于为了得到镀锡温度下相应的铁-锡化合物,扩散结束后的冷却过程采用水冷方式,达不到非常缓慢的平衡冷却条件,凝固速度较快,对组织的生长形态产生影响并发生偏析。其次,在与巴氏合金连接时,20号钢表面的锡层在保温过程中完全溶解于ZChSnSb11-6合金中,且合金中的Sb元素扩散至过渡区并均匀分布于整个过渡区内。

通过研究ZChSnSb11-6/20号钢双金属复合材料结合过渡区的元素扩散情况,确定了液固连接过程中参与扩散的元素主要为Fe元素、Sn元素以及少量的Sb元素,其中Fe元素和Sn元素的扩散反应是在镀锡过程中进行的。根据Fe-Sn二元相图可知,在不同的温度范围内,Fe、Sn元素可反应生成不同的金属间化合物。为确定600、700、800及900 ℃ 4个镀锡温度下结合过渡区中的物相种类,分别使用X射线衍射技术对4个结合过渡区进行了XRD物相判定,其结果如图3(a)~(d)所示。按照X射线衍射法物相鉴别的三强线原则,对比相应物相的标准X射线衍射图谱,分析结果为:600 ℃镀锡温度下,过渡区内形成的金属间化合物主要由FeSn及FeSn2构成;而700 ℃时,结合过渡区主要由FeSn和SnSb金属间化合物构成; 800 ℃和900 ℃时,结合过渡区的金属间化合物主要由Fe-Sn化合物FeSn2以及Fe3Sn2构成;900 ℃时,过渡区除了FeSn2和Fe3Sn2外还分布有SnSb。其中SnSb是在连接巴氏合金时合金中的Sb元素扩散至铁和锡的界面反应层并与Sn结合形成的金属间化合物。此外,在过渡区域内还发现了极少量Fe和Sb的化合物。

图2 在700 ℃镀锡处理后的ZChSnSb11-6/20号钢结合过渡区的线扫描分析

Fig. 2 Line scanning spectrum of bonding transition zone for ZChSnS11-6/20 steel bimetal composites at 700 ℃ tin plating temperatures:

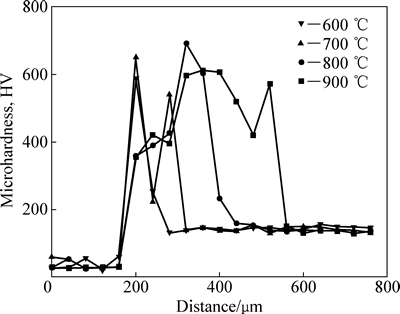

图4所示为不同镀锡温度下ZChSnSb11-6/20号钢双金属复合材料结合过渡层的显微硬度。

从图4中可看出,结合过渡层的显微硬度变化范围为224~692HV,ZChSnSb11-6侧显微硬度变化范围为27~62HV,20号钢一侧显微硬度变化范围为130~ 157HV。从图4中还可看出,结合过渡层的硬度明显高于两侧基体的,20号钢侧合金的显微硬度高于ZChSnSb11-6的。各镀锡温度下过渡层的显微硬度都出现较大幅度的波动,这是由于过渡层中形成不同的金属间化合物所致,如FeSn2硬质点的硬度可达300HV左右,而FeSn的硬度在600HV左右,最高时将近700HV,过渡层中化合物分布不均匀,因此,结合过渡区硬度曲线出现一定的起伏。

图5所示为不同镀锡温度下复合材料的界面结合强度。由图5可知,镀锡温度对复合材料的界面结合强度影响显著。镀锡温度600 ℃时,结合过渡区较窄,界面结合强度仅有8.94 MPa;镀锡温度为700 ℃时,结合强度为37.77 MPa,比600 ℃时有了显著提高;镀锡温度升高至800 ℃时,结合强度达到60.15 MPa,界面结合强度随着镀锡温度的升高而提高;而在900℃时镀锡时,结合强度降低至49.27 MPa,这是由于900 ℃时,复合材料的结合过渡区厚度虽有所增加,但组织不连续且不致密,因此,结合强度有所降低。

图3 不同镀锡温度下ZChSnSb11-6/20号钢双金属复合材料结合区组织的XRD谱

Fig. 3 XRD patterns of bonding transition zone for ZChSnS11-6/20 steel bimetal composites under different tin plating temperatures:

图4 不同镀锡温度下ZChSnSb11-6/20号钢复合材料结合过渡区的显微硬度

Fig. 4 Microhardness of transition zone for ZChSnSb11- 6/20 steel under different tin plating temperatures

2.3 熔浸镀锡时间对ZChSnSb11-6/20号钢双金属复合材料过渡区组织及性能的影响

图6(a)~(d)所示为800 ℃镀锡处理时分别熔浸保温5、6、7及8 h后制备ZChSnSb11-6/20号钢双金属复合材料的结合过渡区的显微组织形貌。组织中左侧为20号钢,右侧为ZChSnSb11-6合金,中间为结合过渡层。

从图6可看出,保温时间对结合过渡层的形貌和厚度影响很大,其中最为显著的变化是,随着保温时间延长,金属间化合物层的厚度即过渡区的厚度增加。各图中的结合过渡区均由两部分组成,即靠近20号钢基体侧的颜色较深但区别于基体材料的反应层以及巴氏合金侧的颜色较浅但组织致密的反应层。深色区域的反应层是由Sn原子扩散至20号钢基体所形成,液态Sn原子在加热熔化后,经过自身原子间碰撞达到活化状态,具有足够的能量扩散进入基体与Fe原子接触并反应生成固溶体,之后一些活化能更高的液态Sn原子扩散并通过外围的FeSn层进入基体内部继续进行化学反应,此过程进行缓慢,需要足够的保温时间。浅色区域由基体中的Fe元素扩散至熔融Sn中并与之反应生成相应金属间化合物所形成。由图6可直观地反映ZChSnSb11-6/20号钢双金属复合材料结合过渡区的形成主要依靠Fe元素向中间层金属Sn的扩散,且随保温时间的增加,过渡区厚度显著增加,但组织形态并未改变。这是由于延长保温时间并不会改变基体中扩散原子的扩散系数和元素在基体中的扩散速率。扩散时间的延长主要会对各原子在基体中的扩散距离产生影响。结合过渡层的形成是一个量的积累和均匀化的过程,因此,保证足够的保温时间是获得适宜的结合过渡层厚度的必要条件之一。

图5 不同镀锡温度下ZChSnSb11-6/20钢双金属复合材料的界面结合强度

Fig. 5 Interface bonding strength of ZChSnSb11-6/20 steel bimetal composites under different tin plating temperatures

图6 经800 ℃镀锡保温不同时间ZChSnSb11-6/20号钢复合材料结合过渡区的形貌

Fig. 6 Morphologies of bonding transition zone of ZChSnSb11-6/20 steel composites at 800 ℃ tin plating for different holding time:

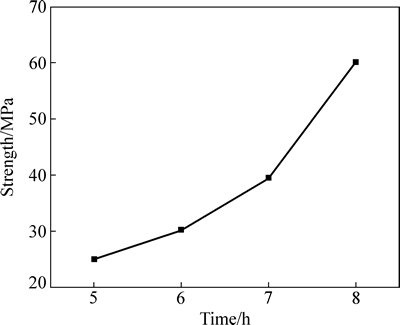

图7所示为800 ℃熔浸镀锡时,分别保温5、6、7和8 h后制备ZChSnSb11-6/20号钢双金属复合材料的界面结合强度。

由图7可知,镀锡保温5 h时,结合强度为25.06 MPa;保温至8 h时,结合强度为60.15 MPa;随着镀锡保温时间增加,ZChSnSb11-6/20号钢复合材料的界面结合强度呈现上升趋势,进一步验证了保温时间是影响双金属复合材料性能的一个重要参数。对于ZChSnSb11-6/20号钢来说,合金与基体的紧密结合主要依赖于基体与锡的扩散结合,但是在一定的熔铸温度内,Fe和Sn的互扩散只能极为缓慢的进行,需要足够的保温时间以使其充分扩散。因此,保温时间直接影响ZChSnSb11-6/20号钢元素间的扩散程度,进而影响到复合材料界面结合强度。

图7 经800 ℃熔浸镀锡不同时间后制备ZChSnSb11-6/20号钢双金属复合材料的界面结合强度

Fig. 7 Interface bonding strength of ZChSnSb11-6/20 steel bimetal composites at 800 ℃ tin plating for different time

3 结论

1) ZChSnSb11-6/20号钢双金属复合材料在扩散连接过程中主要有Fe、Sn、Sb元素参于扩散反应。在不同熔浸温度下,基体中的Fe向液体Sn侧扩散反应生成FeSnx化合物。将镀锡后的20号钢与ZChSnSb11-6连接时,合金中的Sb元素扩散至过渡区并与过渡区的Fe、Sn元素反应生成Sn-Sb以及少许Fe-Sb化合物,均匀分布在过渡区内。

2) ZChSnSb11-6/20号钢双金属复合材料结合过渡层的厚度随熔浸温度的升高而增加,结合过渡区的显微硬度明显高于基体两侧的。

3) 随着熔浸镀锡时间延长,ZChSnSb11-6/20号钢结合过渡区厚度明显增加,但组织形态并未改变,结合过渡层的显微硬度波动趋于平缓,界面结合强度显著提高。

REFERENCES

[1] KAMAL M, EL-BEDIWI A, LASHIN A R, EL-ZARKA A H. Copper effects in mechanical properties of rapidly solidified Sn-Pb-Sb Babbitt bearing alloys[J]. Materials Science and Engineering A, 2011, 530: 327-328.

[2] 罗继伟, 李济顺, 杨咸启. 滚动轴承分析[M]. 北京: 机械工业出版社, 2010: 5-6.

LUO Ji-wei, LI Ji-shun, YANG Xian-qi. Rolling bearing analysis[M]. Beijing: China Machine Press, 2010: 5-6.

[3] 郭亚希, 谢敬佩, 王文焱, 王爱琴. 铸造方法对巴氏合金组织及性能的影响[J]. 河南科技大学学报, 2009, 30(4): 8-9.

GUO Ya-xi, XIE Jing-pei, WANG Wen-yan, WANG Ai-qin. The effects of casting processes on the microstructure and properties of Babbitt[J]. Journal of Henan University of Science and Technology, 2009, 30(4): 8-9.

[4] 张忠礼, 段思华, 张洪兵, 李德元, 孙文哲, 杨春麒. 电弧喷涂锡基巴氏合金涂层的组织与性能[J]. 焊接学报, 2010, 31(4): 17-24.

ZHANG Zhong-li, DUAN Si-hua, ZHANG Hong-bing, LI De-yuan, SUN Wen-zhe, YANG Chun-lin. Study on microstructure and properties of arc sprayed tin-base Babbitt coating[J]. Journal of Welding, 2010, 31(4): 17-24.

[5] 陈丽娟, 刘 剑, 张连芝. 影响轴瓦巴氏合金浇注质量的因素及改进措施[J]. 沈阳工业大学学报, 2002, 24(3): 193-194.

CHEN Li-juan, LIU Jian, ZHANG Lian-zhi. The influencing factors on the pouring quality of babbitt bearing and the improvement measures[J]. Journal of Shenyang University of Technology, 2002, 24(3): 193-194.

[6] 叶小芳. 离心铸造巴氏合金轴瓦粘结不牢的因素分析[J]. 铸造技术, 2012, 6: 750-752.

YE Xiao-fang. Analysis on effect factors of low bond strength in centrifugal casting babbitt alloy[J]. Casting Technology, 2012, 6: 750-752.

[7] 张文毓. 轴瓦材料工业化生产技术综合分析[J]. 新材料产业, 2008, 4: 47-50.

ZHANG Wen-yu. Comprehensive analysis of bearing material industrialization production technology[J]. The New Material Industry, 2008, 4: 47-50.

[8] 朱纯傲, 耿永亮, 张 博. 金属熔体扩散的研究进展[J]. 中国科学, 2012, 42(6): 624-627.

ZHU Chun-ao, GENG Yong-liang, ZHANG Bo. The research progress of metal melt diffusion[J]. China Science, 2012, 42(6): 624-627.

[9] ZHAO Jia-lei, JIE Jin-chuan, CHEN Fei, CHEN Hang, LI Ting-ju, CAO Zhi-qiang. Effect of immersion Ni plating on interface microstructure and mechanical properties of Al/Cu bimetal[J]. Transactions of Nonferrous Metals Society of china, 2014, 24(6): 1659-1665.

[10] 徐光晨, 陈翌庆, 刘丽华, Alan LUO, 马立坤. La对镁/铝液固扩散连接界面组织及性能的影响[J]. 中国有色金属学报, 2014, 24(11): 2743-2748.

XU Guang-chen, CHEN Yi-qing, LIU Li-hua, Alan LUO, MA Li-kun. Effect of La on structures and properties of the liquid-solid diffusion bonding interface of magnesium/ aluminum[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2743-2748.

[11] 徐光晨, 陈翌庆, LUO A, SACHDEV A K. 铝合金表面处理对AM60/A390液固扩散连接界面组织及性能的影响[J]. 中国有色金属学报, 2014, 24(4): 855-862.

XU Guang-chen, CHEN Yi-qing, LUO A, SACHDEV A K. Effect of aluminum surface treatment on structures and properties of liquid-solid diffusion bonding interface of AM60/A390[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4):855-862.

[12] 孙艳明. 巴氏合金性能与分析[J]. 广东化工, 2012, 39(1): 181-184.

SUN Yan-ming. Performance and analysis of Babbitt metal[J]. Guangdong Chemical, 2012, 39(1): 181-184.

[13] 李海斌, 黄庆学, 帅美荣, 王建梅, 马 勤. 锡原子在25钢表面的扩散行为[J], 材料热处理学报, 2014, 35(3): 204-208.

LI Hai-bin, HUANG Qing-xue, SHUAI Mei-rong, WANG Jian-mei, MA Le. Thermal diffusion behavior of tin atom on 25 carbon steel surface[J]. Transactions of Materials and Heat Treatment, 2014, 35(3): 204-208.

[14] 李海斌, 王建梅, 黄庆学, 翟启杰. 铁和液体锡反应的动力学研究[J]. 太原科技大学学报, 2008, 29(5): 369-372.

LI Hai-bin, WANG Jian-mei, HUANG Qing-xue, ZHAI Qi-jie. Kinetics study on reaction of iron and molten tin[J]. Journal of Taiyuan University of Science and Technology, 2008, 29(5): 369-372.

[15] 李海斌, 冀俊杰, 程东升, 王建梅, 黄庆学. 液态锡与铁反应的扩散厚度研究[J]. 太原科技大学学报, 2007, 28(4): 331-334.

LI Hai-bin, JI Jun-jie, CHENG Dong-sheng, WANG Jian-mei, HUANG Qing-xue. Study on the diffusing thickness of molten tin and iron[J]. Taiyuan University of Science and Technology, 2007, 28(4): 331-334.

[16] 马秉先, 朱维东. 钢铁镀Sn扩散处理中镀层组织的形成[J]. 理化检验, 1995, 31(4): 18-20.

MA Bing-xian, ZHU Wei-dong. The formation of coating structure of the steel specimen coated with tin in its diffusion treatment[J]. The Physical and Chemical Inspection, 1995, 31(4): 18-20.

[17] 傅献彩, 沈文霞, 姚天扬. 物理化学手册[M]. 北京: 高等教育出版社, 2005: 246-249.

FU Xian-cai, SHEN Wen-xia, YAO Tian-yang. Handbook of physical and chemistry[M]. Beijing: Higher Education Press, 2005: 246-249.

Diffusion bonding of ZChSnSb11-6/20 steel bimetal composite material

ZOU Jun-tao, ZHAO Yan, WANG Chan,YANG Xiao-hong, LIANG Shu-hua

(Shanxi Province Key Laboratory for Electrical Materials and Infiltration Technology,

School of Materials Science and Engineering, Xi’an University of Technology, Xi’an 710048, China)

Abstract: In order to higher bonding strength, ZChSnSb11-6/20 steel bimetal composite material was prepared by means of diffusion bonding after hot dipping tin plating in the 20 steel surface. The transition zone morphology and element distribution of ZChSnSb11-6/20 steel bimetallic material were characterized by scanning electron microscopy (SEM) and X-ray diffractometer (XRD). Also, the hardness and interface bonding strength were tested. The results show the functionality and availability of the method using the hot dipping tin to attach the ZChSnSb11-6 with 20 steel. There is a bonding transition zone generated by the diffusion between the steel substrate and tin, which achieves close combination of the steel and Babbitt. Besides, the hardness of transition zone is significantly higher than that of both sides of the substrate, and the bonding strength reaches up to 60.15 MPa.

Key words: ZChSnSb11-6 alloy; bimetallic material; transition zone; hot dipping; diffusion bonding

Foundation item: Projects(51401162, 51201132) supported by the National Natural Science Foundation of China; Project(TS12493) supported by the Specialty Construction Project of the Ministry of Education, China; Projects(2012KTCQ01-14, 2014SZS08-Z01, 2015XT-16) supported by the Program of Shaanxi Natural Science Foundation, China; Project supported by the Shaanxi Provincial Special Foundation of Key Disciplines, China

Received date: 2015-08-25; Accepted date: 2016-01-18

Corresponding author: ZOU Jun-tao; Tel: +86-29-82312185; E-mail: zoujuntao@xaut.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51401162,51201132);教育部高等学校特色专业建设点项目(TS12493);陕西省科技计划项目(2012KTCQ01-14,2014SZS08-Z01,2015XT-16);陕西省重点学科建设资助项目

收稿日期:2015-08-25;修订日期:2016-01-18

通信作者:邹军涛,副教授,博士;电话:029-82312185;E-mail:zoujuntao@xaut.edu.cn