文章编号:1004-0609(2016)-02-0383-09

Al含量对TiC-Fe钢结硬质合金组织与性能的影响

龙坚战1, 2, 3,夏艳萍2, 3,陈 冲1,陆必志2, 3,易茂中1,武文花2, 3

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 硬质合金国家重点实验室,株洲 412000;

3. 株洲硬质合金集团有限公司,株洲 412000)

摘 要:为开发新型TiC基钢结硬质合金,采用Fe2Al5预合金粉末添加方式和普通液相烧结法制备不同Al含量(占粘结相含量的0、0.77%、1.54%、2.3%,质量分数)的TiC-65%(Fe-Cr-Mo-Al-C)钢结硬质合金。探讨Al含量对TiC-65%(Fe-Cr-Mo-Al-C)钢结硬质合金的组织与性能的影响规律;并考察Al含量对合金的烧结性、相种类及硬度的影响规律。结果表明:随Al含量的增加,Fe-C合金的包晶反应温度点降低,包晶反应区间、BCC铁素体区和低温区的κ-碳化物沉淀区扩大;合金的硬质相TiC形貌及分布相近,且Al主要是溶解在粘结相中;合金的铁磁性与粘结相中奥氏体数量有关,随Al含量的增加,淬火+回火态合金的硬度增加;其断裂韧性、抗弯强度在Al含量为1.54%时达到峰值。

关键词:TiC;钢结硬质合金;Fe-Al-C;组织;性能

中图分类号:TF125.3 文献标志码:A

钢结硬质合金是在硬质合金基础上发展起来的新型工模具材料[1-3]。相比硬质合金中的钴粘结相来说,它是一种以钢作粘结相的耐磨合金。因其具有硬质合金的高硬度、高耐磨性和高强度,同时具有钢的可加工性、可热处理性、可锻性和可焊接性[4],被认为是可加工、可热处理的硬质合金[1],可广泛地应用于耐磨零件、矿山工具等材料中。钢结硬质合金中最典型材料是以TiC作为硬质相的TiC基钢结硬质合金[5],因TiC具有高硬度、抗氧化、耐腐蚀、密度小、热稳定性好以及优异的物理化学性能,一直是钢结硬质合金中性价比较高的一种钢结硬质合金。

TiC基钢结硬质合金是采用粉末冶金的方法制备的一种复合材料。硬质相TiC主要赋予材料高硬度和高耐磨性;而钢粘结相的含量一般大于50%(质量分数),对材料的性能影响更大,同时,钢粘结相可以赋予合金一系列独特性能,其成分可根据具体使用工况和使用性能要求进行灵活的调整,有利于满足合金使用要求。根据钢粘结相的成分的不同,可以延伸出大量的合金牌号,如碳钢、工具钢、不锈钢、耐热钢基粘结相。高铝钢[6]是一种专用氮化钢,如38CrMoAl,由于在Fe-C钢基体中添加Al后能形成纳米级的Fe3AlCx沉淀强化相[7]可使钢基体得到强化,合金经过热处理和精加工后,具有很高的表面硬度、耐磨性及疲劳强度,并具有良好的耐热性及腐蚀性,被广泛应用于军工、航空工业和机械制造等行业。目前,TiC-(Fe-Cr-Mo)钢结硬质合金是一种以中合金工具钢为粘结相的钢结硬质合金,如GT35牌号,其具有较高的耐磨性,被广泛地应用于耐磨零件上。随着特殊行业对零部件性能的要求的多样化,如应用于注塑机套筒和螺杆(注塑机的关键部件)上,不仅需要好的耐磨性,还需要合金具有较好的抗腐蚀性能、韧性等性能。而普通的钢结硬质合金牌号很难很好地满足使用要求。因此,有必要根据使用工况对钢粘结相进行改性。而以高铝钢作为钢结硬质合金粘结相有望制备出高强韧钢结硬质合金。即添加Al可以提高合金的抗氧化性及抗腐蚀性能,如形成金属间化合物FeAl[8-9],可以更有效地改善合金的这些性能。

本文作者结合热力学相图计算,在钢结硬质合金GT35牌号基础上,开展了添加不同Al含量对合金性能与组织的影响规律。研究结果对拓宽钢结硬质合金粘结相的品种和应用具有重要的指导意义。

1 实验

以TiC-(Fe-Cr-Mo-C)钢结硬质合金为研究对象,其中硬质相TiC为35%(质量分数,下同);粘结相为Fe-Cr-Mo-C,成分为3%Cr、3%Mo、0.5%C,余量Fe;本实验中Al的添加量为粘结相的0、0.77%、1.54%、2.3%。试样成分如表1所列。

表1 实验合金的化学成分

Table 1 Chemical composition of experiment alloys

本实验中采用还原Fe粉,费氏粒度为30 μm,粉末形貌如图1(a)所示;Cr以Cr-Fe的形式添加,费氏粒度为10 μm;Mo采用Mo粉形式添加,费氏粒度为2 μm;为避免Al与Fe发生剧烈化合放热反应及柯肯达尔效应[10]引起的膨胀,本实验中Al是采用Fe-Al的中间化合物Fe2Al5[11]预合金粉末的形式添加,费氏粒度为10 μm,粉末形貌如图1(b)所示。

采用粉末冶金制备工艺,经配料、混合、干燥、过筛、压制、真空烧结后获得合金。烧结温度为1425 ℃,保温时间60 min后随炉冷却到室温。烧结后,分别对合金进行退火(860 ℃)、油淬(1000 ℃)、回火(200 ℃)等热处理。

图1 原料粉末的显微形貌

Fig. 1 Morphologies of powders

将相应的合金制备成金相样品,在光学显微镜下对TiC硬质相的形貌及分布进行检测分析;经硝酸腐蚀后,检测分析粘结相组织结构;利用差热分析仪对不同Al加量的混合粉末进行热效应分析;采用X衍射分别对烧结态、退火态、淬火+回火态合金进行物相检测分析,检测条件如下:Cu 靶 Kα、40 kV、40 mA 、2.3 (°)/min;采用阿基米德排水法测试了合金的密度;采用钴磁仪测定合金粘结相的磁饱和强度即“铁磁”;采用JSM-6701F型扫描电镜(Jeol,日本)和能谱仪分析检测粘结相的成分含量;用三点弯曲法测定试样(尺寸为5.25 mm×6.5 mm×20 mm)的抗弯强度;用维氏硬度计(30 kg)测定合金的硬度及压痕法测定合金的断裂韧性。

由于TiC性能稳定,同时 Mo、Cr加量较少而对Fe基粘结相的影响较小。为了简化,本文作者重点研究C、Al对Fe基粘结相即Fe-Al-C粘结相的影响。基于CALPHAD方法,利用文献报道的热力学参数[12],采用ThermoCalc软件对Fe-Al-C三元系粘结相系统进行热力学计算。

2 结果与讨论

2.1 热力学计算及相图

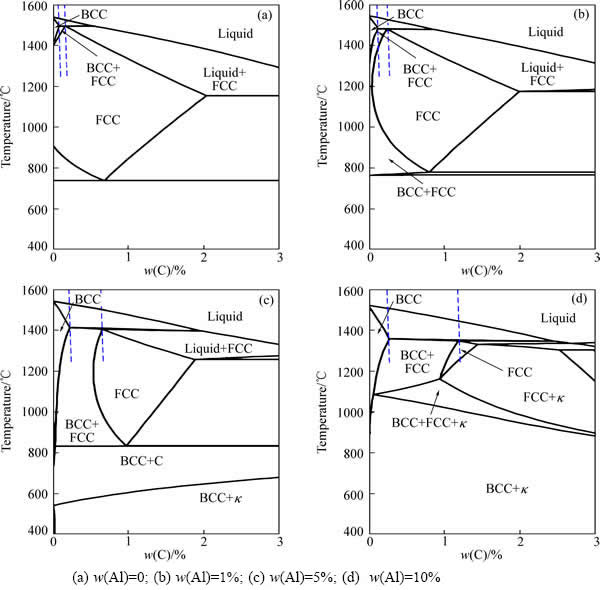

根据文献[13],不同Al含量的Fe-Al-C粘结相的平衡相图如图2所示。相图上的包晶反应区间对应两个重要的碳平衡点(如图中两条蓝色线标识位置),在这两个碳含量成分区间合金发生包晶反应,即液相+BCC→FCC。在高铝钢的连铸过程中,在该成分区间的钢容易出现热裂纹等缺陷[14]。为避免包晶反应易产生缺陷的影响,本实验中粘结相中的C含量设定为0.5%,在包晶反应区右方。根据平衡相图,有以下规律,随Al含量的增加,包晶反应温度点降低;包晶反应区间扩大;FCC奥氏体区缩小,BCC铁素体区扩大;且在低温区开始出现κ-碳化物沉淀。

为了精确预测实验结果,根据Al含量重新计算的Fe-Al-C三元系垂直截面图如图3所示。本实验中成分如图中虚线标识(C含量0.5%)。Al为铁素体稳定化元素,同样地,从图3可以看出,随Al含量的增加,BCC铁素体区扩大,相图整体右移。同时包晶温度点降低。

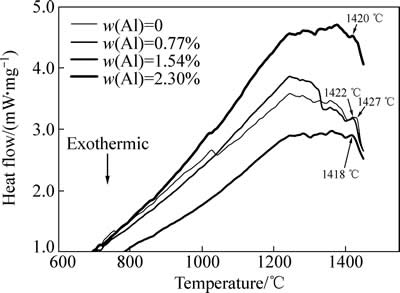

2.2 烧结过程中的热效应

对添加不同Al含量的混合料进行了差热分析检测,在600~1450 ℃温度区间的结果如图4所示。随着Al含量的增加,出现液相的温度略有降低,如w(Al)=0、w(Al)=0.77%、w(Al)=1.54%、w(Al)=2.3%合金的液相温度分别为1427、1422、1418和1420 ℃。从图3可知,随Al含量的增加,合金的包晶反应温度点下降,使合金出现液相的温度点降低;同时,实验点所在位置的奥氏体相区右移,又使得开始出现液相温度点增高。这两种影响因素同时作用于开始出现液相温度点,相互抵消,导致出现液相的温度相差不大。

尽管随着Al含量的增加,出现液相温度点受两种相反的作用而相互抵消,使得出现液相温度点相差不大。但是,合金烧结时出现的液相量存在差异。如w(Al)=1.54%和 w(Al)=2.3%合金在烧结1425 ℃可能超过包晶温度点。由相图杠杆定律可知,其液相量比例会出现大幅度提高。如合金w(Al)=0和w(Al)=1.54%经1425 ℃真空烧结后的实物照片如图5所示。烧结后,合金w(Al)=1.54%出现了明显的变形,且其底部有明显的液相流动痕迹。而合金w(Al)=0烧结后的表面状况属于正常范围。总之,随Al含量的增加,合金出现液相的温度点接近,但烧结过程中出现的液相量增加。

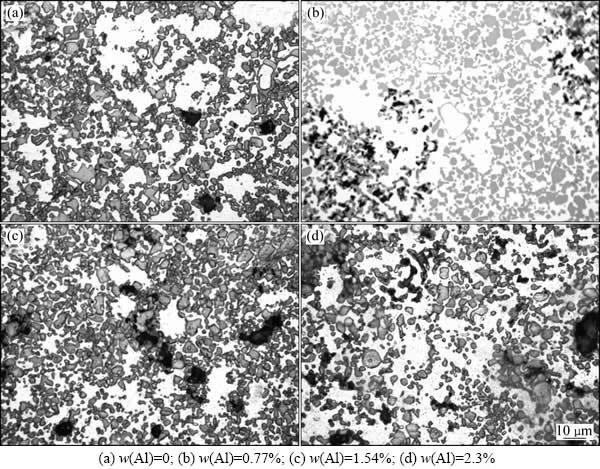

2.3 显微结构特征

经1425 ℃烧结后的合金的显微组织如图6所示。由图6可以看出,随着Al含量的增加,合金的硬质相TiC形貌及分布相近。一方面是由于TiC在烧结过程中性能稳定,TiC晶粒不易发生较大的转变;另一方面,粘结相的基本成分和结构接近。Al的变化幅度相对较小,如图3所示,烧结后,其粘结相成分点仍然位于奥氏体区。因此,粘结相对硬质相TiC的形貌影响不大。

图2 不同Al含量Fe-Al-C合金的计算相图[13]

Fig. 2 Calculated phase diagrams[13] of Fe-Al-C alloys with different Al contents

图3 不同Al含量Fe-Al-C计算相图

Fig. 3 Calculated phase diagrams of Fe-Al-C alloys with different Al contents

图4 不同Al含量合金混合料的差热分析曲线

Fig. 4 DSC curves of alloy mixtures with different Al contents

2.4 粘结相相种类及成分

2.4.1 相种类

Al是扩大铁素体区元素,随着Al含量的增加,相图整体向右偏移,相当于碳含量减小。也就是说随Al含量的增加相当于降低合金中C含量。而一般来说,冷却转变曲线即C曲线随C含量多少而发生变化。即碳含量越低,一般来说Ms和Mf越高,碳浓度低的区域先转化成为马氏体后(马氏体相变属于无扩散型切变,相变后发生体积膨胀),碳浓度高区域的奥氏体由于体积膨胀而受空间的限制不能相变,导致该部分只能以残余奥氏体存在。

图5 1425 ℃液相烧结后的实物照片

Fig. 5 Photos of alloys after 1425 ℃ liquid phase sintering

图6 不同铝含量合金的显微组织

Fig. 6 Microstructures of alloy with different Al contents

不同Al含量烧结态合金的XRD谱如图7(a)所示。由图7(a)可以看出,合金中都存在一定含量的奥氏体(43°处)。但由于铁素体与马氏体(45°)的X衍射峰重叠,很难区分。但马氏体与铁素体的硬度相差大。结合合金的硬度(见图10(a))来分析,可以看出烧结态合金的硬度随Al含量的增加略有降低。说明合金粘结相中存在马氏体相,且其数量是逐渐减少的。这与Al提高Ms和Mf的作用效果是一致的。总之,烧结态合金的粘结相的相种类与随炉冷却的速度有关,其冷却速度在3~10 ℃/min,冷却速度较慢,除了大部分的铁素体外,还会形成少量的奥氏体和马氏体。

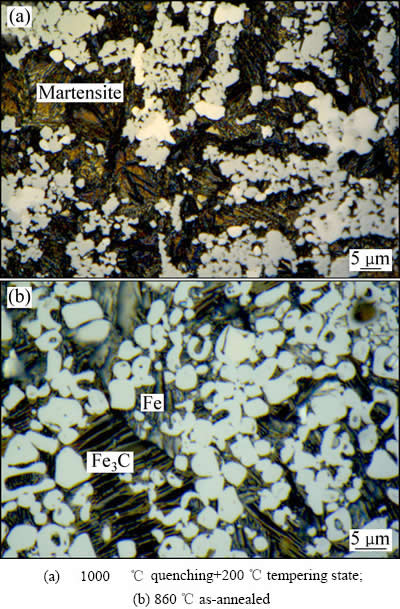

对于1000 ℃淬火+200 ℃回火态合金来说,其冷却快,合金粘结相主要发生马氏体相变。如图7(c)所示,随Al含量的增加,合金粘结相除了大部分的马氏体组织外,奥氏体组织逐渐增加。其中w(Al)=0合金只有马氏体组织;w(Al)=1.54%合金的粘结相由马氏体和奥氏体组成,其金相组织如图8(a)所示。w(Al)=2.3%合金粘结相中的残余奥氏体(43°)最多。同样地,结合图10(b)中的硬度变化可以看出,其整体硬度值大大高于烧结态合金的,进一步证明了合金粘结相中大部分是马氏体组织。另外,尽管Al含量的增加使得合金粘结相中的残余奥氏体数量增加,但淬火+回火态合金的硬度并没有随Al含量的增加而降低。这可能是由于合金的硬度除了受粘结相马氏体数量影响外,还可能与低温区(高Al含量)析出的纳米κ-碳化物沉淀有关[15-16],如图2(c)和(d)所示。

对于860 ℃退火态合金来说,粘结相相成分主要由铁素体和Fe3C构成,如图7(b)所示。退火态的w(Al)=1.54%合金的粘结相金相组织如图8(b)所示,可以发现粘结相组织除了大部分的铁素体外,还存在少量的Fe3C相。如表3所列的退火态合金硬度在450HV左右,远低于烧结态(600HV左右)和淬火+回火态合金(900HV左右)的硬度。这与合金粘结相中的相种类和数量是一致。

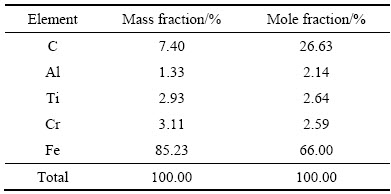

2.4.2 粘结相成分

烧结后,对w(Al)=1.54%合金的粘结相的成分进行了能谱分析,如图9所示。能谱成分结果如表2所列。可以看出,粘结相中的Al含量为1.33%,与理论含量1.54%接近。说明Al主要是溶解于粘结相中。从而也进一步说明Al主要是通过影响粘结相而影响合金的组织与性能。

2.5 物理力学性能

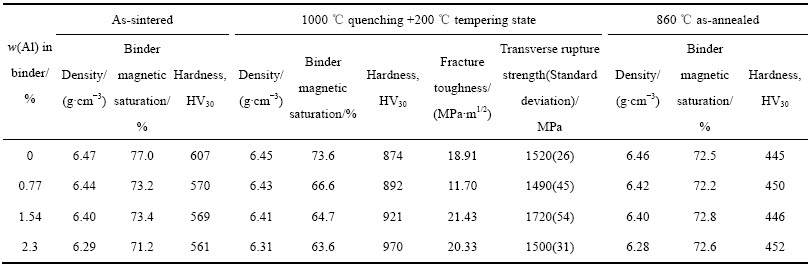

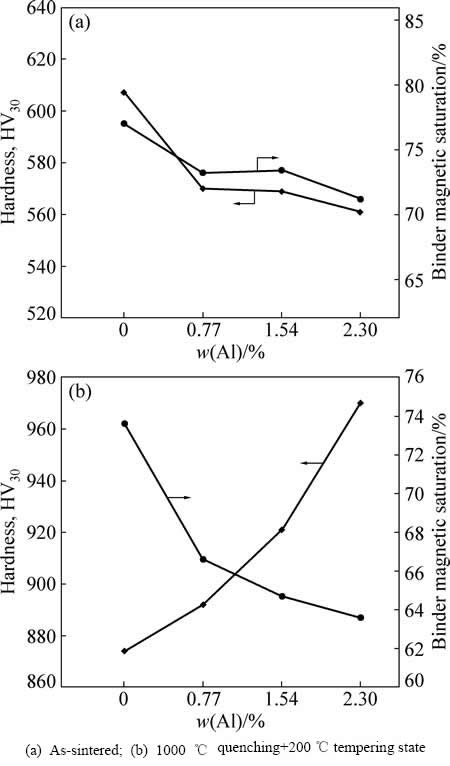

不同Al含量合金的物理力学性能如表3所列,可以看出不同状态合金的密度相差不大。但由于Al的密度小(2.7 g/cm3),烧结后合金的密度随Al含量增加而降低。

表2 Al含量1.54%合金粘结相的能谱分析结果

Table 2 Energy spectrum analysis results of binder phase in alloy with Al content of 1.54%

图7 不同状态合金的XRD谱

Fig. 7 XRD patterns of alloys at different states

图8 腐蚀后Al含量1.54%合金的粘结相组织

Fig. 8 Microstructures of binder phase in alloy with Al content of 1.54% after corrosion

图9 Al含量1.54%合金粘结相的显微形貌及相应区域的EDS谱

Fig. 9 Microstructure(a) and corresponding EDS spectrum of zone 1(b) of binder phase in alloy with Al content of 1.54%

表3 合金的物理力学性能

Table 3 Physical and mechanical properties of alloys

2.5.1 铁磁及硬度

不同热处理状态合金的磁性能及硬度如图10所示。由于奥氏体不显磁性或弱磁性,因此铁磁值在一定程度上可以代表铁素体或马氏体的含量。通过测量合金中磁性物质的含量即“铁磁”(粘结相的磁饱和强度)对奥氏体含量可以做定性的分析。如对烧结态(随炉冷却3~10 ℃/min)合金来说,如图7(a)所示,43°处的奥氏体峰较低,奥氏体含量几乎没有变化。但从“铁磁”值来说,如图10(a)所示,随Al含量的增加,“铁磁”值略有减小,说明奥氏体数量略有增加;同样,对于1000 ℃淬火态+200 ℃回火态的合金来说,如图7(c)所示,随Al的增加,奥氏体峰出现明显的增加,相应的对应于“铁磁”值来说,其随Al的增加,“铁磁”值也出现了明显地减小,如图10(b)所示。而对于860℃退火态合金来说,如表3所列,“铁磁”值几乎相等,且合金都具有较低的硬度值,说明退火态合金组织大部分转变成铁素体组织。

图10  不同热处理状态合金的硬度和粘结相磁饱和强度

不同热处理状态合金的硬度和粘结相磁饱和强度

Fig. 10 Hardness and binder magnetic saturation of alloys with different heat treatments

对于硬度来说(见图10(a)),烧结态合金在随炉冷却过程中,合金粘结相存在多种组织,以铁素体为主,含有少量的马氏体和奥氏体。随Al含量的增加,粘结相中马氏体数量减小,合金的硬度值也是略有下降。同样,对于1000 ℃淬火态+200 ℃回火态的合金来说,粘结相组织主要是马氏体,且随合金中的Al含量的增加,奥氏体组织逐渐增加。同时纳米级的κ-碳化物(Fe3AlCx)沉淀析出强化的作用,使得合金的硬度随Al含量的增加而提高。

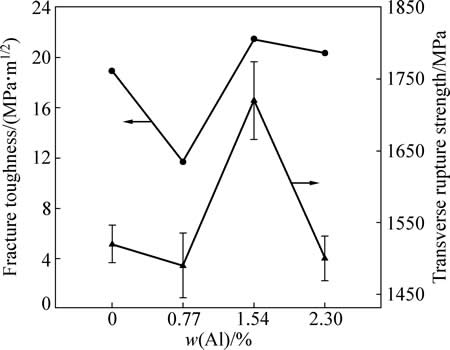

2.5.2 抗弯强度及断裂韧性

1000 ℃淬火态+200 ℃回火态合金的抗弯强度和断裂韧性如图11所示。可以看出,随着Al含量的增加,合金的断裂韧性和抗弯强度在w(Al)=1.54%成分处都存在一个峰值。断裂韧性和抗弯强度都不同程度地受粘结相的相种类和显微组织结构的影响。一方面,随Al含量的增加,合金淬火态+回火态合金粘结相中的奥氏体数量增加,合金的韧性提高,但强度降低;另一方面,纳米级的κ-碳化物(Fe3AlCx)[7]强化相的含量随Al含量的增加而增加,对粘结相起增强作用,但提高合金强度的同时,也降低了合金的塑韧性。因此,两个因素的影响,使得w(Al)=1.54%合金在断裂韧性和抗弯强度上达到了峰值。

图11 不同Al含量合金的断裂韧性和抗弯强度

Fig. 11 Fracture toughness and transverse rupture strength of alloys with different Al contents

3 结论

1) 根据Fe-Al-C三元计算相图,随Al含量的增加,包晶反应温度点降低;包晶反应区间、BCC铁素体区和低温区的κ-碳化物沉淀区扩大。

2) 随Al含量的增加,合金烧结时出现液相温度点略有降低,但液相量增大。

3) 随着Al含量的增加,合金硬质相TiC基本保持不变。Al主要是溶解在粘结相中。

4) 合金不同热处理状态的铁磁与粘结相中奥氏体数量有关。

5) 随Al含量的增加,合金淬火+回火态的硬度增加;其断裂韧性、抗弯强度在Al含量为1.54%时达到峰值。

REFERENCES

[1] 张 煜, 赵一生, 高志国. 钢结硬质合金的研究和发展现状[J]. 湖南有色金属, 2010, 26(5): 39-41.

ZHANG Yu, ZHAO Yi-sheng, GAO Zhi-guo. Review of study and development of steel-bonded cemented carbide[J]. Hunan Nonferrous Metals, 2010, 26(5): 39-41.

[2] 熊拥军, 李溪滨, 刘如铁, 赵福安. 新型TiC钢结硬质合金致密化技术[J]. 中南大学学报(自然科学版), 2009, 40(6): 1563-1567.

XIONG Yong-jun, LI Xi-bin, LIU Ru-tie, ZHAO Fu-an. Densification processing of a new steel bonded titanium carbide[J]. Journal of Central South University (Science and Technology), 2009, 40(6): 1563-1567.

[3] 尤显卿, 郑玉春, 程 娟文, 任 昊. 热应力作用下碳化钨基钢结硬质合金梯形裂纹的形成机理[J]. 中国有色金属学报, 2003, 13(5): 1098-1102.

YOU Xian-qing, ZHANG Yu-chun, CHEN JUAN-wen, REN Hao. Formation mechanism of trapezoid crack in WC steel bonded carbide under action of thermal stress[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(5): 1098-1102.

[4] 宾建林, 刘东华, 汤 波, 汤富山. 添加稀土的TiC基钢结硬质合金性能研究[J]. 金属材料与冶金工程, 2013, 41(3): 3-5.

BIN Jian-lin, LIU Dong-hua, TANG Bo, TANG Fu-shan. Effect of rare earth addition on microstructure and properties of tic-based steel bonded carbide[J]. Metal Materials and Metallurgy Engineering, 2013, 41(3): 3-5.

[5] 范安平, 肖平安, 李晨坤, 轩翠华, 曲选辉. TiC基钢结硬质合金的研究现状[J]. 粉末冶金技术, 2013, 31(4): 298-303.

FAN An-ping, XIAO Ping-an, LI Chen-kun, XUAN Cui-hua, QU Xuan-hui. Research situation of TiC-based steel bonded carbide[J]. Powder Metallurgy Technology, 2013, 31(4): 298-303.

[6] 刘 侠. 国内38CrMoAl高铝钢现况及开发建议[J]. 冶金管理, 2008, 9: 22-24.

LIU Xia. The current state and development suggestions of the domestic 38CrMoAl high aluminum steel[J]. Metallurgical Industry Management, 2008, 9: 22-24.

[7] KIM H, SUH D W, KIM N J. Fe-Al-Mn-C lightweight structural alloys: A review on the microstructures and mechanical properties[J]. Science and Technology of Advanced Materials, 2013, 14(1): 014205-014215.

[8] HABIBI R M, AHMADIAN M, GOLOZAR M A. Investigation of the corrosion behavior of WC-FeAl-B composites in aqueous media[J]. International Journal of Refractory Metals and Hard Materials, 2012, 35: 62-69.

[9] SCHNEIBEL J, CARMICHAEL C, GERMAN R, MESSING G, CORNWALL R. Liquid-phase sintering of iron aluminide- bonded ceramics[M]. New York: CRC Press, 1996: 253-260.

[10] GEDEVANISHVILI S, DEEVI S. Processing of iron aluminides by pressureless sintering through Fe+Al elemental route[J]. Materials Science and Engineering A, 2002, 325(1): 163-176.

[11] 龙坚战, 魏修宇, 陆必志, 方 晴, 余怀民, 李 勇, 卢少武, 管玉明, 蒋洪亮. 铁-铝金属间化合物Fe2Al5的预合金粉末的制备方法: 中国, CN101984110A[P]. 2011-03-09.

LONG Jian-zhan, WEI Xiu-yu, LU Bi-zhi, FANG Qing, YU Huai-min, LI Yong, LU Shao-wu, GUAN Yu-min, JIANG Hong-liang. The preparation method of iron-aluminium intermetallic compound Fe2Al5 prealloyed powder: China, CN101984110A[P]. 2011-03-09.

[12] CONNETABLE D, LACAZE J, MAUGIS P, SUNDMAN B. A Calphad assessment of Al-C-Fe system with the carbide modelled as an ordered form of the FCC phase[J]. Calphad, 2008, 32(2): 361-370.

[13] PHAN A T, PAEK M K, KANG Y B. Phase equilibria and thermodynamics of the Fe-Al-C system: Critical evaluation, experiment and thermodynamic optimization[J]. Acta Materialia, 2014, 79: 1-15.

[14] PRESOLY P, PIERER R, BERNHARD C. Identification of defect prone peritectic steel grades by analyzing high- temperature phase transformations[J]. Metallurgical and Materials Transactions A, 2013, 44(12): 5377-5388.

[15] CHIN K G, LEE H J, KWAK J H, KANG J Y, LEE B J. Thermodynamic calculation on the stability of (Fe,Mn)3AlC carbide in high aluminum steels[J]. Journal of Alloys and Compounds, 2010, 505(1): 217-223.

[16] KIM H, SUH D W, KIM N J. Fe-Al-Mn-C lightweight structural alloys: A review on the microstructures and mechanical properties[J]. Science and Technology of Advanced Materials, 2013, 14(1): 014205-014216.

Effects of Al content on microstructure andmechanical properties of TiC-Fe alloys

LONG Jian-zhan1, 2, 3, XIA Yan-ping2, 3, CHEN Chong1, LU Bi-zhi2, 3, YI Mao-zhong1, WU Wen-hua2, 3

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. State Key Laboratory of Cemented Carbide, Zhuzhou 412000, China;

3. Zhuzhou Cemented Carbide Group Co., Ltd., Zhuzhou 412000, China)

Abstract: In order to develop new TiC based steel bonded carbide,TiC-65%(Fe-Cr-Mo-Al-C) (mass fraction) hard alloys with different Al contents (with respect to binder phase contents of 0, 0.77%, 1.54%, 2.3%, mass fraction) were prepared by common liquid phase sintering method with addition of Fe2Al5 prealloyed powder. The effects of Al contents on the microstructure and mechanical properties of TiC-65%(Fe-Cr-Mo-Al-C) alloys were explored. The effects of Al contents on the sinterability, phase species and hardness of alloys were investigated. The results show that, according to the calculated phase diagrams of the Fe-Al-C alloys, with the increase of Al content, the peritectic reaction temperature decreases and the intervals of peritectic reaction, BCC ferrite and low temperature region κ-carbide precipitation zone expand. With the increase of Al contents, the morphology and distribution of hard phase TiC are similar. Al dissolves into the binder phase. The ferromagnetic is connected with the amount of austenite of binder phase. With the increase of Al content, the hardness of quenched and tempered alloys increases with the increase of Al content. And their fracture toughness and bending strength reach the peak values.

Key words: TiC; steel bonded carbide; Fe-Al-C; microstructure; property

Fund Project: Project (2012CB723906) supported by the National Key Basic Research Program of China

Received date: 2015-06-29; Accepted date: 2015-10-29

Corresponding author: YI Mao-zhong; Tel: +86-731-88877700; E-mail: yimaozhong@126.com

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划资助项目(2012CB723906)

收稿日期:2015-06-29;修订日期:2015-10-29

通信作者:易茂中,教授,博士;电话:0731-88877700;E-mail:yimaozhong@126.com