文章编号:1004-0609(2014)02-0424-08

Cr3C2-Ni-Ti3SiC2新型减摩复合材料的高温摩擦学行为

李立鑫,柳学全,丁存光,李 一,李 楠,李金普,李发长

(钢铁研究总院 粉末冶金研究室,北京 100081)

摘 要:采用粉末冶金工艺制备一种新型Cr3C2-Ni-Ti3SiC2减摩材料,并研究Ti3SiC2添加量对其与GCr15摩擦副在400 ℃大气环境下摩擦学行为的影响。结果表明:在高温摩擦场的作用下,复合材料中的Ti3SiC2能够 诱发形成具有良好减摩作用的摩擦氧化膜,不仅可以降低摩擦副的摩擦因数,避免摩擦因数的较大波动,而且能够显著降低摩擦系统的总磨损率,对摩擦偶件起到极好的保护作用。当Ti3SiC2含量(质量分数)分别为2.5%、5.0%、7.5%和10%时,复合材料的摩擦因数比未添加Ti3SiC2的Cr3C2-Ni金属陶瓷的摩擦因数分别下降5.3%、15.8%、26.3%和13.2%,摩擦副的总磨损率也下降了一个数量级;同时,摩擦偶件的磨损率也由3.5×10-5 mm3/(N·m)逐步下降到9.8×10-7 mm3/(N·m)。

关键词:Cr3C2-Ni;Ti3SiC2;摩擦学行为;高温减摩;摩擦氧化膜

中图分类号:TB333;TB34 文献标志码:A

High temperature tribology behavior of new anti-friction/composites Cr3C2-Ni-Ti3SiC2

LI Li-xin, LIU Xue-quan, DING Cun-guang, LI Yi, LI Nan, LI Jin-pu, LI Fa-chang

(Powder Metallurgical Research Department, Central Iron and Steel Research Institute, Beijing 100081, China)

Abstract: The new anti-friction Cr3C2-Ni-Ti3SiC2 composites were fabricated by powder metallurgy process, and the influence of Ti3SiC2 content on tribology behaviors of Cr3C2-Ni matrix composites against GCr15 was studied at 400 ℃ in air. The results show that the new as-prepared composites with Ti3SiC2 are of favorable anti-friction properties because of the tribo-oxidation film formation induced by Ti3SiC2 during the friction. After adding Ti3SiC2, not only the coefficient of friction (COF) is obviously decreased and its fluctuation is flattened, but also the wear rate of the tribo-system is sharply decreased and the friction pair is effectively protected. When the Ti3SiC2 contents (mass fraction) of the composites are 2.5%, 5%, 7.5% and 10%, the COFs are respectively decreased by 5.3%, 15.8%, 26.3% and 13.2% compared with that of the Cr3C2-Ni cermet without Ti3SiC2. Meanwhile, the wear rate of the friction pair is downgraded by an order of magnitude and the wear rate of the friction partner is gradually decreased from 3.5×10-5 mm3/(N·m) to 9.8×10-7 mm3/(N·m).

Key words: Cr3C2-Ni; Ti3SiC2; tribology behavior; high temperature anti-friction; tribo-oxidation film

随着现代科学技术的发展, 高性能热动力机械及高温传动设备等部件对候选材料的要求越来越高,不仅要求材料具有较优的耐磨性、抗氧化性和耐腐蚀性,而且要求其具有较好的减摩性能。Cr3C2-Ni金属陶瓷是一种较理想的耐磨、耐腐蚀材料,具有优异的红硬性和耐蚀性,由于其密度低、强度高和抗氧化,因此可作为摩擦部件[1-5],广泛应用在航空、航天、电力、冶金等动力机械及高温传动设备上,并受到越来越普遍的关注。然而,Cr3C2-Ni金属陶瓷虽耐磨、耐腐蚀性能优异,但不具备减摩能力,摩擦阻力较大,尤其在高温、重载等极端服役条件下,极易造成摩擦偶件的快速磨损,甚至导致机械设备损坏,严重影响机械设备的使用寿命。

近年来,三元层状陶瓷Ti3SiC2因其独特的结构而受到广泛关注。Ti3SiC2是一种层状六方结构化合物,晶体结构为Ti3C2层与Si原子所构成的平面层间隔堆垛,属P63/mmc对称的空间群[6]。Ti3SiC2兼具陶瓷和金属特性,既具有优异的抗氧化性、耐腐蚀性,又具有良好的导电、导热和高温塑性[7-10],尤其是其类似石墨的层状结构,可能具备较好的减摩性能[11-12]。为此,一些学者进行了初步研究,SHI等[13]制备了NiAl基Ti3SiC2复合材料,高宇等[14]制备了Ti3SiC2增强Al基复合材料,FAN等[15]制备了含有Ti3SiC2的C/C-SiC复合材料,均获得了较好的减摩效果。然而,上述研究均是在室温条件下进行的,而Ti3SiC2具有优异的高温性能,在高温材料领域的应用潜力极大,但目前对于Ti3SiC2在高温条件下是否具有减摩性能的研究尚鲜有报道。

为此,本文作者拟采用粉末冶金工艺将Ti3SiC2引入Cr3C2-Ni金属陶瓷中[16],制备含有Ti3SiC2的Cr3C2-Ni基新型复合材料,通过研究其在高温氧化性环境中的摩擦磨损性能及Ti3SiC2添加量对复合材料摩擦磨损行为的影响,以期研制出新型高性能Cr3C2-Ni基高温减摩、耐磨材料,并验证Ti3SiC2作为高温减摩剂的可行性。

1 实验

1.1 试样制备

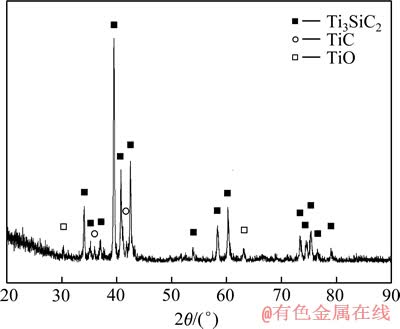

原料粉选用金川集团生产的羰基Ni粉(粒径3 μm,纯度大于99%)、株洲广源硬质材料有限公司生产的冶金级Cr3C2粉(粒径3 μm,纯度大于99%)以及实验室自制Ti3SiC2粉(粒径小于5 μm,纯度大于 98%,主要杂质为TiC和TiO,见图1)。将Ti3SiC2粉分别按0、2.5%、5%、7.5%和10% (质量分数)的添加量加入已混好的CN20金属陶瓷粉(含80% Cr3C2粉和20% Ni粉,质量分数)中,以无水乙醇为介质进行高能球磨,固液比20:1,球料比10:1,旋转频率20 Hz,球磨时间24 h。在预混粉中加入成形剂后,压制成密度为4 g/cm3的压坯,再经脱脂、1 320 ℃真空烧结100 min后制得试验用试样,并按Ti3SiC2含量从低到高分别标记为CN20、CN20T1、CN20T2、CN20T3和CN20T4。

图1 Ti3SiC2粉的XRD谱

Fig. 1 XRD pattern of Ti3SiC2 powders

1.2 摩擦磨损试验

将上述5种试样加工成d 4 mm×12 mm的销,以淬火GCr15盘(HRC58)为摩擦偶件,在MMU-10G型高温端面磨损试验机上进行销-盘接触式摩擦磨损试验。试验条件如下:温度400 ℃,法向载荷200 N,主轴转速200 r/min,磨痕半径11.5 mm,时间3 h。试验所得摩擦因数曲线由试验机自动测量并记录,磨损率由试验前后的质量差与氧化质量增益求和后换算出的磨损体积除以正压力和行程而得。测量前,所有试样均在无水乙醇中超声清洗15 min。

1.3 测试与表征

烧结后试样的密度和硬度分别采用排水法(GB 03850)和HVS-50Z型维氏硬度计测量,并采用X’pert Pro MPD衍射仪分析试样的物相组成。试样的金相组织、摩擦磨损试验后的摩擦表面及磨屑形貌均采用FEI公司生产的Quanta 650环境扫描电子显微镜分析,以研究其减摩机理。

2 结果与讨论

2.1 材料的组织成分、密度及硬度

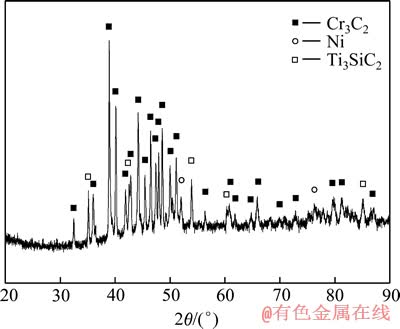

对所制备的CN20T1、CN20T2、CN20T3和CN20T4复合材料进行XRD物相分析,结果表明,这些复合材料均由Cr3C2、Ni及Ti3SiC2 3种物相组成,所添加的Ti3SiC2在烧结过程中均未发生物相变化。其中,CN20T3试样的XRD谱如图2所示,成分标定显示,其组织成分中仅含有Cr3C2、Ni及Ti3SiC2 3种物相,表明已成功制得了含有Ti3SiC2的Cr3C2-Ni金属陶瓷基复合材料。

图2 CN20T3试样XRD谱

Fig. 2 XRD pattern of CN20T3 composite

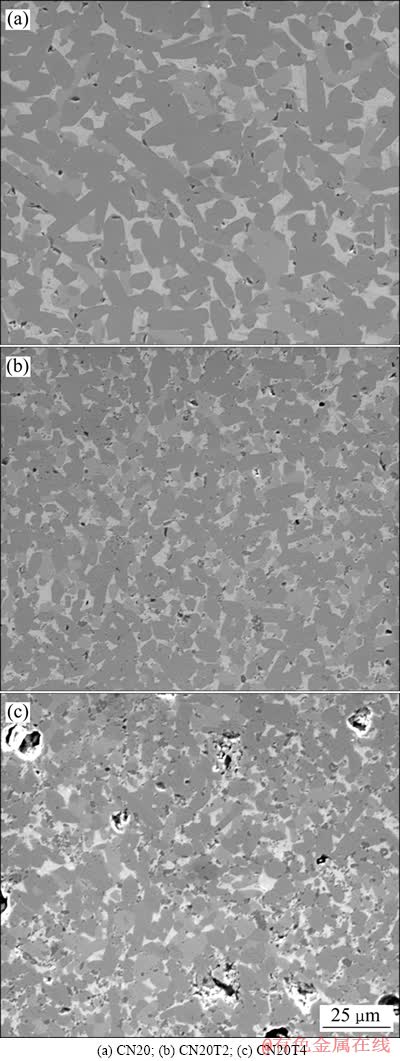

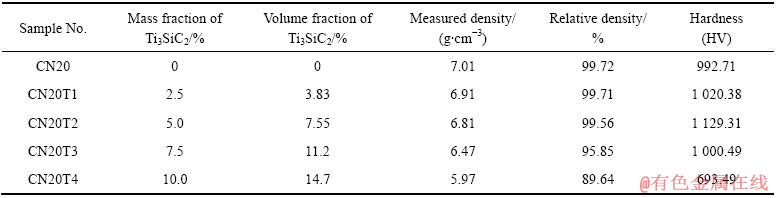

图3和表1所示分别为不同Ti3SiC2含量复合材料的金相照片及密度和硬度。图3显示,Ti3SiC2的加入对CN20金属陶瓷基体材料的晶粒长大有一定的抑制作用,晶粒明显变得细小,但当其含量高于5%后,晶粒度基本不再发生变化;同时,由表1可以看出,由于Ti3SiC2与Ni浸润性较差[17],Ti3SiC2的加入会降低材料的烧结性能,导致材料的相对密度不断降低,表现在材料的孔隙度随Ti3SiC2含量的增加而增大。因此,当Ti3SiC2的添加量较少时,其细晶强化作用使得材料的硬度有所增加,当Ti3SiC2的添加量为5%时,材料的硬度达到最大值(1 129.31HV)。但是,随着Ti3SiC2含量的继续增加,孔隙度的增大逐渐削弱了细晶强化的效果,导致了材料硬度的逐渐下降,当Ti3SiC2的添加量达到10%时,CN20T4的硬度下降显著,较CN20的硬度降低了30%。

2.2 摩擦学性能

图3 不同Ti3SiC2含量复合材料的金相组织

Fig. 3 Metallographs of composites with different Ti3SiC2 contents

表1 不同Ti3SiC2含量复合材料的密度及硬度

Table 1 Density and hardness of composites with different Ti3SiC2 contents

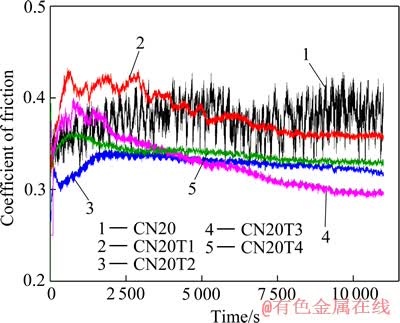

图4 不同Ti3SiC2含量复合材料的动态摩擦因数曲线

Fig. 4 Dynamic COF curves of composites with different Ti3SiC2 contents

图4所示为不同Ti3SiC2含量复合材料在400 ℃下的动态摩擦因数曲线。由图4可以看出,添加Ti3SiC2可使材料获得减摩能力,缩短磨合期。400 ℃时,CN20与摩擦偶件GCr15盘之间的摩擦扰动较大,摩擦因数较大,约为0.38;添加Ti3SiC2后,4种复合材料的摩擦因数较CN20的均有所降低,扰动明显减小,且稳态摩擦前的磨合期随Ti3SiC2含量的增加而逐渐缩短,虽然CN20T1和CN20T3材料在试验开始阶段的摩擦因数高于CN20的,但随着摩擦磨损试验的进行,其摩擦因数曲线均降至CN20曲线以下,最后CN20T1、CN20T2、CN20T3和CN20T4的摩擦因数分别稳定在约0.36、0.32、0.29和0.33,较CN20的摩擦因数分别下降了5.3%、15.8%、26.3%和13.2%。

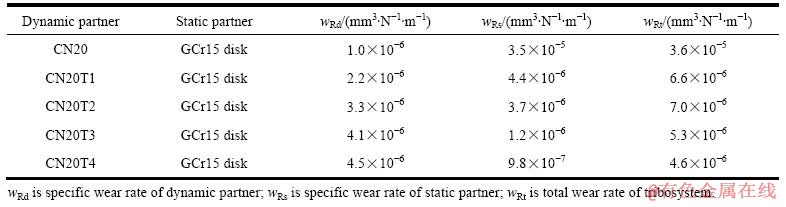

表2所列为Ti3SiC2含量对复合材料磨损率的影响。由表2可以看出,添加Ti3SiC2后,摩擦副的总磨损率下降了一个数量级,尽管复合材料自身的表观磨损率有所增加,但仍处于较低的水平,而GCr15盘的磨损率却降低了一个数量级,且随着Ti3SiC2含量的继续增加,GCr15盘的磨损率又有一个数量级的下降。但是,Ti3SiC2的添加量不宜过高,否则会导致复合材料自身磨损率较大,甚至减摩性能也会有所下降,如图4所示。当Ti3SiC2含量为10%时,复合材料自身的磨损率增加到4.5×10-6 mm3/(N·m),其动态摩擦因数曲线5也较曲线3和4有所回升。

2.3 减摩机理分析

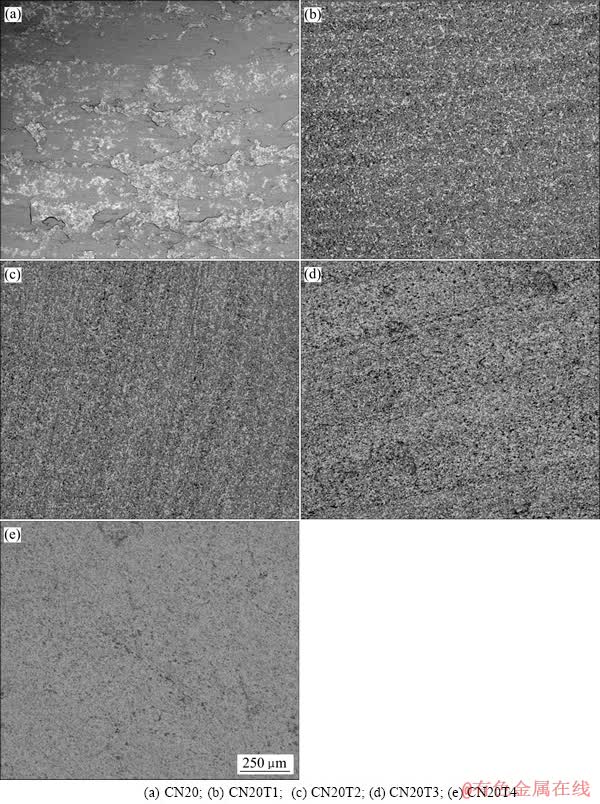

图5所示为不同Ti3SiC2添加量复合材料的摩擦表面宏观形貌。由图5可以看出,在进行了3 h的摩擦磨损试验后,CN20摩擦表面出现面积较大的粘附层,而添加Ti3SiC2后,摩擦表面粘附层消失,CN20T1、CN20T2、CN20T3及CN20T4的摩擦表面上仅沿着滑动方向出现犁沟,且随着Ti3SiC2含量的增加,摩擦表面的犁沟逐渐变细变浅,犁沟效应随之减弱,当Ti3SiC2含量达到10%时,摩擦表面已较为光滑,犁沟基本消失不见,如图5(e)所示。

表2 不同Ti3SiC2含量的复合材料及其对摩偶件的磨损率

Table 2 Wear rates of tribosystems with different Ti3SiC2 contents

图5 不同Ti3SiC2含量复合材料的摩擦表面宏观形貌

Fig. 5 Macro-morphologies of friction surfaces of composites with different Ti3SiC2 contents

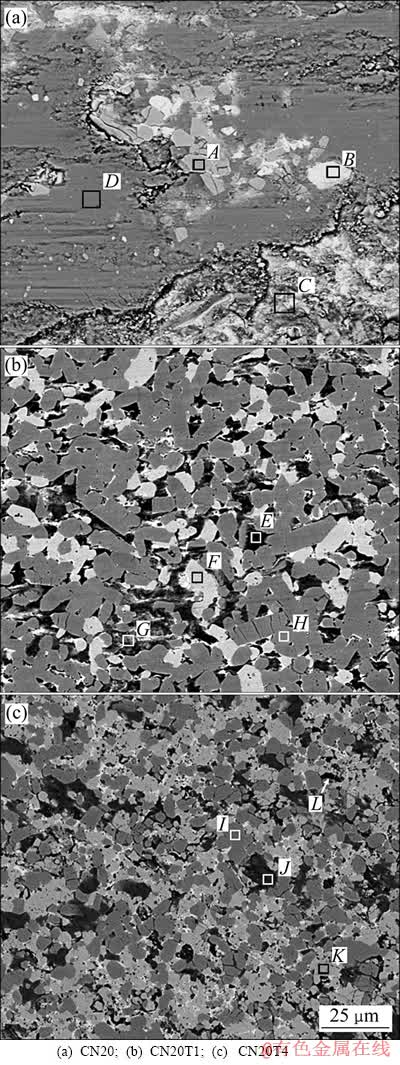

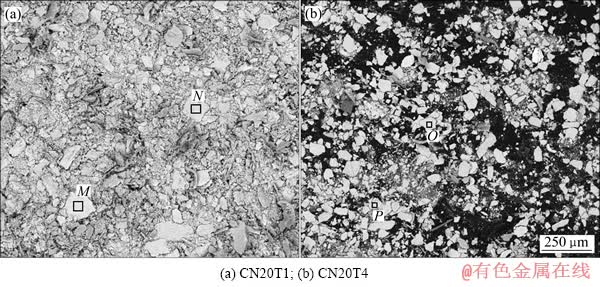

对摩擦表面形貌进行微观观察和元素分析发现,未添加Ti3SiC2的CN20摩擦表面存在明显的犁沟及塑性变形(见图6(a)),除含有基体Ni、Cr、C和氧化引入的O外,其表面粘附区域还含有大量的Fe元素,表明在400 ℃高温氧化性环境和法向载荷的共同作用下,摩擦偶件GCr15被剪切并转移到CN20表面,发生焊合粘附,出现严重的粘着磨损,形成大面积的富铁粘附层,如图6(a)区域D所示。这些较软的富铁粘附层由于在高温摩擦磨损过程中不断发生焊合、氧化和剥落,且极易被磨屑中的硬质相切削、划伤,在发生粘着磨损的同时伴随着磨粒磨损和磨蚀磨损,因此导致材料的摩擦因数增大,摩擦因数波动也较大(见图4),呈现出如图6(a)所示摩擦表面的密集犁沟和严重塑性变形。而在磨损方面,尽管CN20摩擦表面上大面积富铁粘附层的存在使CN20的表观磨损率变得较小,但由于焊合粘附引起的粘着磨损极大地加剧了摩擦系统的磨损,导致摩擦副的总磨损率最大,摩擦偶件的磨损也最快。加入Ti3SiC2后,摩擦表面除含有Ni、Cr、Ti、Si、C和O外,仅还含有少量的Fe(见图6(b)和(c)),图6(a)中大面积的富铁粘附层消失,摩擦表面形貌变得较为光滑。由此表明,具有层状结构的Ti3SiC2在高温摩擦场的作用下,直接参与了摩擦表面复杂的理化反应,诱发形成摩擦氧化膜,从而改变了复合材料的磨损形式[18-22],也抑制了复合材料与GCr15的焊合粘附,因此,Ti3SiC2的加入不仅降低了材料的摩擦因数,避免了摩擦因数的较大波动(见图4),而且显著降低了摩擦副的总磨损率(见表2)。随Ti3SiC2添加量的不断增加,复合材料形成摩擦氧化膜的能力不断增强,如图6(b)、(c)、表2和表3所示复合材料摩擦表面总氧含量逐渐增加,使得复合材料的减摩能力不断提高,摩擦因数随之降低,也使摩擦偶件GCr15的磨损率由4.4×10-6 mm3/(N·m)逐渐下降到9.8×10-7 mm3/(N·m)。但是,由于Ti3SiC2与Ni的浸润性不佳,添加Ti3SiC2会引起复合材料烧结性能的下降,导致Ti3SiC2与金属陶瓷基体的结合较差,使摩擦过程中Ti3SiC2易于从摩擦表面脱落[23],故随着Ti3SiC2含量的增加,复合材料的孔隙度及Ti3SiC2从摩擦表面脱落所形成的孔洞也随之增加,导致摩擦表面的微凹体不断增多。由于微凹体边缘应力状态复杂,且较为集中,极易作为裂纹源在亚表面形成微裂纹,并在法向载荷作用下沿平行于摩擦表面的方向拓展连接,引起脆性断裂,以片状形式从摩擦表面剥落(见图7和表4),加之微凹体的出现使得摩擦表面实际接触面积减小,在同等法向载荷下的摩擦表面实际接触压强增加,共同加剧了摩擦表面的微切削作用。因此,复合材料中Ti3SiC2含量的增加会使摩擦表面微凹体增多,提供了更多的裂纹源,裂纹扩展的距离减小,使基体摩擦表面的剥落加速,复合材料的磨损率随之增加(见表2),其片状磨屑也随之逐渐变得细小,如图7所示。此外,摩擦表面微凹体的存在还破坏了摩擦表面的平整性,使得复合材料的摩擦因数在开始阶段增大,甚至出现图4所示曲线2和4在开始阶段高于曲线1的现象。不过,随着摩擦过程的进行,摩擦氧化膜逐渐生成,同时部分微凹体区域被磨屑填充(如图6所示G和O等与基体成分差异较大的区域),摩擦表面又变得平整,摩擦因数随之降低,并趋于平稳。但是,如果Ti3SiC2含量过高,复合材料烧结性能明显降低,硬度显著降低(见表1),此时Ti3SiC2含量增强所起到减摩作用的增加已不足以补偿基体支撑作用下降而引起减摩作用的下降,复合材料的摩擦因数会有所增大,如图4所示CN20T4的摩擦因数比CN20T3的略大。

总之,Ti3SiC2在高温摩擦场的作用下能够诱发形成摩擦氧化膜,从而改变了Cr3C2-Ni金属陶瓷与GCr15钢摩擦副的摩擦学行为,赋予Cr3C2-Ni-Ti3SiC2复合材料良好的高温减摩性能。Ti3SiC2 的添加不仅降低了复合材料的摩擦因数,避免了摩擦因数的较大波动,而且显著降低了摩擦副总的磨损,对摩擦偶件也有极好的保护作用。然而,随Ti3SiC2含量的增加,Ti3SiC2与Ni浸润性较差,使摩擦表面微凹体逐渐增多,微切削作用加剧,导致复合材料自身磨损率增大。因此,实际应用中应在Cr3C2-Ni金属陶瓷基体中添加适量的Ti3SiC2,在不影响基体耐磨性能的同时获得一定的减摩性能,以减小摩擦偶件的磨损率。

图6 不同Ti3SiC2含量复合材料摩擦表面的微观形貌

Fig. 6 Micro-morphologies of friction surfaces of composites with different Ti3SiC2 contents

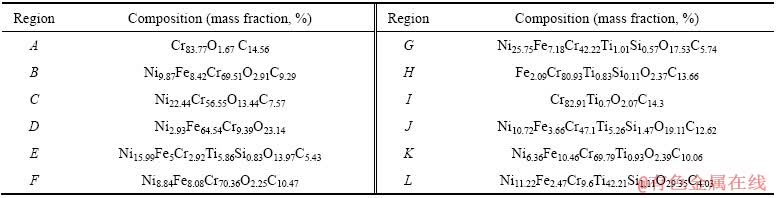

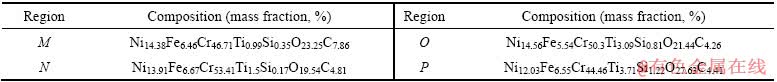

表3 不同Ti3SiC2含量复合材料的摩擦表面的成分

Table 3 Compositions of friction surfaces of composites with different Ti3SiC2 contents

图7 不同Ti3SiC2含量复合材料磨屑的微观形貌

Fig. 7 Micro-morphologies of debris of composites with different Ti3SiC2 contents

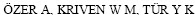

表4 不同Ti3SiC2含量复合材料的成分

Table 4 Compositions of debris of composites with different Ti3SiC2 contents

3 结论

1) 采用粉末冶金工艺将Ti3SiC2引入Cr3C2-Ni金属陶瓷中,制备出含有Ti3SiC2的新型Cr3C2-Ni-Ti3SiC2减摩材料,当Ti3SiC2含量为7.5%(质量分数)时,复合材料的减摩性能最佳,摩擦因数仅为0.29。

2) 当添加量不高于7.5%时,Ti3SiC2可以作为高温减摩剂使用,能在高温摩擦场的作用下诱发形成具有良好减摩作用的摩擦氧化膜,使复合材料的摩擦因数降低,对摩擦偶件起到了极好的保护作用,显著降低了摩擦副的总磨损率。

3) Ti3SiC2含量的增加会加剧摩擦表面的微切削作用,导致复合材料自身的磨损率随之逐渐增大。当Ti3SiC2含量增至10%时,剧烈的微切削作用使复合材料减摩性能的下降,故其含量不宜过高。

REFERENCES

[1] 吴月天. 碳化铬硬质合金密封环的研制[J]. 流体工程, 1987, 11: 32-35.

WU Yue-tian. The development of Cr3C2 cemented carbide sealing ring[J]. Fluid Machinery, 1987, 11: 32-35.

[2] 赵志伟, 彭泳丙, 袁海英, 郝春艳, 马建强, 刘亚培, 张静文. 碳热还原法制备纳米碳化铬粉末及其特性表征[J]. 中国有色金属学报, 2012, 22(7): 2005-2009.

ZHAO Zhi-wei, PENG Yong-bing, YUAN Hai-ying, HAO Chun-yan, MA Jian-qiang, LIU Ya-pei, ZHANG Jing-wen. Preparation and characterization of chromium carbide nanopowders produced by carbon thermal reduction[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 2005-2009.

[3] JUHANI K, PIRSO J,  S, VILJUS M. Phase evolution, microstructure characteristics and properties of Cr3C2-Ni cermets prepared by reactive sintering[J]. International Journal of Materials and Product Technology, 2011, 40(1/2): 75-91

S, VILJUS M. Phase evolution, microstructure characteristics and properties of Cr3C2-Ni cermets prepared by reactive sintering[J]. International Journal of Materials and Product Technology, 2011, 40(1/2): 75-91

[4] HUSSAINOVA I, PIRSO J, ANTONOV M, JUHANI K,  S. Erosion and abrasion of chromium carbide based cermets produced by different methods[J]. Wear, 2007, 263(7): 905-911.

S. Erosion and abrasion of chromium carbide based cermets produced by different methods[J]. Wear, 2007, 263(7): 905-911.

[5]  . The effect of 3mol% Y2O3 stabilized ZrO2 produced by a steric entrapment method on the mechanical and sintering properties of Cr3C2 based cermets[J]. Materials Science and Engineering A, 2012, 556: 878-884.

. The effect of 3mol% Y2O3 stabilized ZrO2 produced by a steric entrapment method on the mechanical and sintering properties of Cr3C2 based cermets[J]. Materials Science and Engineering A, 2012, 556: 878-884.

[6] GAMARNIK M Y, BARSOUM M W. Bond lengths in the ternary compound Ti3SiC2, Ti3GeC2 and Ti2GeC[J]. Journal of Materials Science, 1999, 34: 169-174.

[7] 卢琳琳, 尹洪峰, 袁蝴蝶. Ti3SiC2层状陶瓷的研究进展[J]. 陶瓷学报, 2012, 33(2): 226-229.

LU Lin-lin, YIN Hong-feng, YUAN Hu-die. Research progress of the layered Ti3SiC2 ceramics[J]. Journal of Ceramics, 2012, 33(2): 226-229.

[8] BARSOUM M W. The MN+1AXN phases: A new class of solids thermodynamically stable nanolaminates[J]. Progress in Solid State Chemistry, 2000, 28(3/4): 201-281.

[9] PANIGRAHI B B, REDDY N S, BALAKRISHNAN A, CHO M C, GRACIO J J. Nickel assisted sintering of Ti3SiC2 powder under pressureless conditions[J]. Journal of Alloys and Compounds, 2010, 505(1): 337-342.

[10] ZHANG H B, BAO Y W, ZHOU Y C. Current status in layered ternary carbide Ti3SiC2—A review[J]. Journal of Materials Science and Technology, 2009, 25(1): 1-38.

[11] BARSOUM M W, EL-RAGHY T. Synthesis and characterization of a remarkable ceramic: Ti3SiC2[J]. Journal of the American Ceramic Society, 1996, 79(7): 1953-1956.

[12] MYHRA S, SUMMERS J W B, KISI E H. Ti3SiC2—A layered ceramic exhibiting ultra-low friction[J]. Materials Letters, 1999, 39(1): 6-11.

[13] SHI X L, WANG M, ZHAI W Z, XU Z S, ZHANG Q X, CHEN Y. Influence of Ti3SiC2 content on tribological properties of NiAl matrix self-lubricating composites[J]. Materials and Design, 2013, 45: 179-189.

[14] 高 宇, 刘可心, 霍 俊, 李 响, 赵 明. Ti3SiC2增强铝基复合材料的摩擦磨损特性研究[J]. 长春工业大学学报: 自然科学版, 2010, 31(4): 394-398.

GAO Yu, LIU Ke-xin, HUO Jun, LI Xiang, ZHAO Ming. Friction and wear characteristics of Ti3SiC2 reinforced aluminum matrix composite materials[J]. Journal of Changchun University of Technology: Natural Science Edition, 2010, 31(4): 394-398.

[15] FAN X M, YIN X W, HE S S, ZHANG L T, CHENG L F. Friction and wear behaviors of C/C-SiC composites containing Ti3SiC2[J]. Wear, 2012, 274: 188-195.

[16] 王常川, 王日初, 彭超群, 冯 艳, 韦小凤. 金属基固体自润滑复合材料的研究进展[J]. 中国有色金属学报, 2012, 22(7): 1945-1955.

WANG Chang-chuan, WANG Ri-chu, PENG Chao-qun, FENG Yan, WEI Xiao-feng. Research progress of metallic solid self-lubricating composites[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 1945-1955.

[17] LI H, PENG L M, GONG M, HE L H, ZHAO J H, ZHANG Y F. Processing and microstructure of Ti3SiC2/ M (M=Ni or Co) composites [J]. Materials Letters, 2005, 59(21): 2647-2649.

[18] 管明林, 翟洪祥, 黄振莺, 周 炜, 艾明星. Ti3SiC2的高速摩擦特性及摩擦氧化行为[J]. 北京交通大学学报, 2007, 31(1): 14-17.

GUAN Ming-lin, ZHAI Hong-xiang, HUANG Zhen-ying, ZHOU Wei, AI Ming-xing. High-speed friction characteristics and frictional oxidation behavior of Ti3SiC2[J]. Journal of Beijing Jiaotong University, 2007, 31(1): 14-17.

[19] ZHANG Y, DING G P, ZHOU Y C, CAI B C. Ti3SiC2—A self-lubricating ceramic[J]. Materials Letters, 2002, 55(5): 285-289.

[20] SARKAR D, MANOJ K B V, BASU B. Understanding the fretting wear of Ti3SiC2[J]. Journal of European Ceramic Society, 2006, 26: 2441-2452.

[21] GUPTA S, BARSOUM M W. On the tribology of the MAX phases and their composites during dry sliding: A review [J]. Wear, 2011, 271(9/10): 1878-1894.

[22] REN S F, MENG J H, LU J J, YANG S R. Tribological behavior of Ti3SiC2 sliding against Ni-based alloys at elevated temperatures[J]. Tribological Letters, 2008, 31(2): 129-131.

[23] GUPTA S, FILIMONOV D, ZAITSEV V, PALANISAMY T, BARSOUM M W. Ambient and 550 ℃ tribological behavior of select MAX phases against Ni-based superalloys[J]. Wear, 2008, 264(3/4): 270-278.

(编辑 陈卫萍)

基金项目:国家国际科技合作资助项目(2010DFB53840);中国钢研科技集团公司科技创新基金资助项目(12040860A)

收稿日期:2013-02-11;修订日期:2013-10-25

通信作者:柳学全,教授,博士;电话:010-62182924;E-mail: xqnliu@sina.com